Professional Documents

Culture Documents

Symposium Series No. 54 © 2008 Icheme

Uploaded by

potatoteddyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Symposium Series No. 54 © 2008 Icheme

Uploaded by

potatoteddyCopyright:

Available Formats

Symposium Series NO.

154 2008 IChemE

Simulation

of Real World

Improved

Strategies

Real World Refinery Asset TARO Plant Simulation Model

Current Performance Future Performance

Improved Mean

Good Consistency

Poor Mean

Probability

Probability

Poor Consistency

Improved Performance

Safely & Responsibly

Production (%) Production (%)

Refineries across the world are addressing these issues and benefiting accordingly.

Here is a typical result:

Proposed Optimised

Scenario

Design Design

Gasoline Production

88.30% 89.20%

Efficiency

Gasoline Inefficiencies Comparison

6.0% 5.9%

Current Configuration

5.1%

5.0%

Proposed Configuration

4.1%

4.0%

3.5%

3.0%

2.0%

0.9% 1.0%

1.0% 0.7% 0.5% 0.5%

0.2%

0.0%

Losses caused Losses caused Losses caused Losses caused Losses caused

by scheduled by process unit by impact of by Utilities by Hydrogen

events failures Sulphur units Failures shortfalls

You might also like

- TCI Operations Training Program - GET: A Production & Equipment Management ToolDocument59 pagesTCI Operations Training Program - GET: A Production & Equipment Management Toolminingnova2No ratings yet

- DCF ConeDocument37 pagesDCF Conejustinbui85No ratings yet

- Theme - To Eliminate User Plant Defect of Anti Lock Braking System (ABS) Lamp Continuous ON in Scorpio Refresh VehicleDocument12 pagesTheme - To Eliminate User Plant Defect of Anti Lock Braking System (ABS) Lamp Continuous ON in Scorpio Refresh VehiclePriyaprasad PandaNo ratings yet

- Reliability Maintenance Statergy Focus Improvement StandardsDocument13 pagesReliability Maintenance Statergy Focus Improvement StandardsYen NguyenNo ratings yet

- Improve tire extruder OEE using SMED methodDocument25 pagesImprove tire extruder OEE using SMED methodBudy AriyantoNo ratings yet

- RTN Connect Dfa Dfa PDFDocument24 pagesRTN Connect Dfa Dfa PDFKishanNo ratings yet

- Design For Manufacturing: DFM With SuppliersDocument16 pagesDesign For Manufacturing: DFM With SuppliersNuria VarelaNo ratings yet

- AFM Mini Exam - SolutionDocument6 pagesAFM Mini Exam - SolutionHamid KhanNo ratings yet

- OEE-Sheet01 2Document2 pagesOEE-Sheet01 2Ayman SalahNo ratings yet

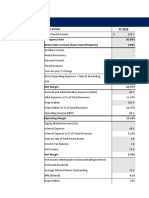

- Appendix 1 Conservative Approach: (In FFR Million)Document6 pagesAppendix 1 Conservative Approach: (In FFR Million)Sarvagya JhaNo ratings yet

- OEE, Machine Downtime & Manufacturing Information Systems: Overall Equipment Effectiveness SpreadsheetDocument4 pagesOEE, Machine Downtime & Manufacturing Information Systems: Overall Equipment Effectiveness SpreadsheetdanielonnarNo ratings yet

- JETIR1907R63Document6 pagesJETIR1907R63Cristiano Jr.No ratings yet

- Question 3 FrojassDocument6 pagesQuestion 3 FrojassPaco RojasNo ratings yet

- Increase Profit through TCD & PIZDocument11 pagesIncrease Profit through TCD & PIZhadiNo ratings yet

- Empowering Reliability Through Lubrication Program Development (LPD) Udey DhirDocument28 pagesEmpowering Reliability Through Lubrication Program Development (LPD) Udey DhirEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- Seider Profitability Analysis-1.1Document21 pagesSeider Profitability Analysis-1.1LFNo ratings yet

- Score Card by BrandDocument8 pagesScore Card by Branddiah Puspita sariNo ratings yet

- Anirudh Acharya FA Exp 1Document5 pagesAnirudh Acharya FA Exp 1Anirudh AcharyaNo ratings yet

- Mistake Proofing and Poka-YokeDocument75 pagesMistake Proofing and Poka-YokeadamNo ratings yet

- Systems Analysis & Design Problem Solving TechniquesDocument13 pagesSystems Analysis & Design Problem Solving TechniquesMark Pius CantaNo ratings yet

- Relative Accuracy: - Relative Accuracy Compares The Total Predicted Quantity For ADocument9 pagesRelative Accuracy: - Relative Accuracy Compares The Total Predicted Quantity For ACésar Zapata RNo ratings yet

- IPMSDocument4 pagesIPMSSDE NorthNo ratings yet

- How To Do Focuses ImprovementDocument39 pagesHow To Do Focuses Improvementashutoshpal21No ratings yet

- Ind-Swift LabsDocument44 pagesInd-Swift Labssingh66222No ratings yet

- Analysis IDocument4 pagesAnalysis IBeugh RiveraNo ratings yet

- All+Rating+Guidelines ManufacturingDocument4 pagesAll+Rating+Guidelines ManufacturingSegu PratheekNo ratings yet

- Dr. Labib PresentationDocument3 pagesDr. Labib Presentationapi-19975041No ratings yet

- FMEA Minus The Pain FiguresDocument3 pagesFMEA Minus The Pain FiguresMUNISNo ratings yet

- OEE, Machine Downtime & Manufacturing Information Systems: Overall Equipment Effectiveness Calculator SpreadsheetDocument2 pagesOEE, Machine Downtime & Manufacturing Information Systems: Overall Equipment Effectiveness Calculator SpreadsheetMelvin Samarita RodasNo ratings yet

- The Demand Planning Process: - Measuring PerformanceDocument19 pagesThe Demand Planning Process: - Measuring PerformanceCésar Zapata RNo ratings yet

- Barringer FMEA 11 17 09Document9 pagesBarringer FMEA 11 17 09peach5100% (1)

- Bobot KPIDocument15 pagesBobot KPIulfa97575No ratings yet

- Progress Sto Pulo Brayan: TelkomnproperlyDocument1 pageProgress Sto Pulo Brayan: TelkomnproperlyMuliadi PutraNo ratings yet

- Integrative Case Track Software LTDDocument19 pagesIntegrative Case Track Software LTDDang DangNo ratings yet

- Schedue IFS Metal 1Document1 pageSchedue IFS Metal 1IsaalexNo ratings yet

- YONWOO Introduction 2019Document16 pagesYONWOO Introduction 2019Azizah Izzatur RahimNo ratings yet

- TPM by ManagementDocument41 pagesTPM by ManagementRahul Kumar100% (1)

- Manufacturing Process ImprovementDocument3 pagesManufacturing Process ImprovementgeniusMAHINo ratings yet

- RatioDocument11 pagesRatioAnant BothraNo ratings yet

- How To Embed Your KPIsDocument13 pagesHow To Embed Your KPIsdtvt40No ratings yet

- Retail Industry Retail Industry Retail IndustryDocument8 pagesRetail Industry Retail Industry Retail IndustryTanmay PokaleNo ratings yet

- First Solar Inc. Ratio ComparisonsDocument7 pagesFirst Solar Inc. Ratio ComparisonsSameer ChoudharyNo ratings yet

- Exceedence ProbabilityDocument2 pagesExceedence ProbabilityFrancis XavierNo ratings yet

- Performance Evaluation Form: Employee Name Designation Head Quarter Reporting Manager/Appraise RDocument12 pagesPerformance Evaluation Form: Employee Name Designation Head Quarter Reporting Manager/Appraise RIndia DiscoverNo ratings yet

- Kotak Infrastructure and Economic Reform FundDocument14 pagesKotak Infrastructure and Economic Reform FundArmstrong CapitalNo ratings yet

- Fmea (Failure Modes and Effects Analysis)Document11 pagesFmea (Failure Modes and Effects Analysis)Oswaldo VallesNo ratings yet

- Fast Response Process: Standardized Rapid Reaction To Quality IssuesDocument162 pagesFast Response Process: Standardized Rapid Reaction To Quality IssuesSudhagarNo ratings yet

- Failure Mode Effect Analysis: Dr. Ir. Muhammad SabriDocument42 pagesFailure Mode Effect Analysis: Dr. Ir. Muhammad Sabricalvin100% (1)

- Quality FMEA Ford Supplier 8 4-FinalDocument22 pagesQuality FMEA Ford Supplier 8 4-FinalErwin RojasNo ratings yet

- AAP Burca Valentin 2016Document9 pagesAAP Burca Valentin 2016studentul86No ratings yet

- KenyaMarket October2008Document25 pagesKenyaMarket October2008opulitheNo ratings yet

- A9R5836 Robust QOS - TMPDocument10 pagesA9R5836 Robust QOS - TMPkoalaboiNo ratings yet

- FMEA & Cost of Quality (COQ) Analysis Tool: EXAMPLE: Current StateDocument51 pagesFMEA & Cost of Quality (COQ) Analysis Tool: EXAMPLE: Current StateDerecichei SergiuNo ratings yet

- Tugas 3 - AM - Calvin Ade Prasetia - 30737Document5 pagesTugas 3 - AM - Calvin Ade Prasetia - 30737Calvin Ade PrasetiaNo ratings yet

- Tracking KPI HO Ytd Mar 2021 - Infra Workshop Rev 2Document475 pagesTracking KPI HO Ytd Mar 2021 - Infra Workshop Rev 2daniel siahaanNo ratings yet

- MistakesDocument78 pagesMistakesSrinath SelvakumaranNo ratings yet

- AFM Sample Model - 2 (Horizontal)Document18 pagesAFM Sample Model - 2 (Horizontal)munaftNo ratings yet

- Prataap Snacks DCF Valuation Upside CaseDocument41 pagesPrataap Snacks DCF Valuation Upside CaseCharanjitNo ratings yet

- GP PetroleumsDocument44 pagesGP Petroleumssingh66222No ratings yet

- Mortgage of Residential Commercial Property TNCDocument20 pagesMortgage of Residential Commercial Property TNCpotatoteddyNo ratings yet

- A Case of Choice of Passive Fire Protection (PFP) in An Oil & Gas EPC Project - Part1Document1 pageA Case of Choice of Passive Fire Protection (PFP) in An Oil & Gas EPC Project - Part1potatoteddyNo ratings yet

- Bu32s01b10 01eDocument9 pagesBu32s01b10 01epotatoteddyNo ratings yet

- Tncs Governing Mortgage LoansDocument15 pagesTncs Governing Mortgage LoanspotatoteddyNo ratings yet

- A Case of Choice of Passive Fire Protection (PFP) in An Oil & Gas EPC Project - Part5Document1 pageA Case of Choice of Passive Fire Protection (PFP) in An Oil & Gas EPC Project - Part5potatoteddyNo ratings yet

- Franklin US OppDocument3 pagesFranklin US OpppotatoteddyNo ratings yet

- A Case of Choice of Passive Fire ProtectionDocument6 pagesA Case of Choice of Passive Fire Protectionعزت عبد المنعمNo ratings yet

- A Case of Choice of Passive Fire Protection (PFP) in An Oil & Gas EPC Project - Part4Document1 pageA Case of Choice of Passive Fire Protection (PFP) in An Oil & Gas EPC Project - Part4potatoteddyNo ratings yet

- 2 SDocument2 pages2 SpotatoteddyNo ratings yet

- Pages From IGU World LNG Report 2016Document1 pagePages From IGU World LNG Report 2016potatoteddyNo ratings yet

- A Case of Choice of Passive Fire Protection (PFP) in An Oil & Gas EPC Project - Part3Document1 pageA Case of Choice of Passive Fire Protection (PFP) in An Oil & Gas EPC Project - Part3potatoteddyNo ratings yet

- A Case of Choice of Passive Fire Protection (PFP) in An Oil & Gas EPC Project - Part2Document1 pageA Case of Choice of Passive Fire Protection (PFP) in An Oil & Gas EPC Project - Part2potatoteddyNo ratings yet

- SsDocument1 pageSspotatoteddyNo ratings yet

- Axa Wealth Accelerate Brochure (English)Document9 pagesAxa Wealth Accelerate Brochure (English)potatoteddyNo ratings yet

- Pages From XV Paper 36Document1 pagePages From XV Paper 36potatoteddyNo ratings yet

- SsDocument1 pageSspotatoteddyNo ratings yet

- AB Global HIgh Yield BondDocument2 pagesAB Global HIgh Yield BondpotatoteddyNo ratings yet

- Symposium Series No. 54 © 2008 Icheme: Design Capacity 100% 150,000 Bbls/DayDocument1 pageSymposium Series No. 54 © 2008 Icheme: Design Capacity 100% 150,000 Bbls/DaypotatoteddyNo ratings yet

- Symposium Series No. 54 © 2008 Icheme: Raw Data 5-Year Average Linear (5-Year Average)Document1 pageSymposium Series No. 54 © 2008 Icheme: Raw Data 5-Year Average Linear (5-Year Average)potatoteddyNo ratings yet

- Symposium Series No. 54 © 2008 Icheme: Total Recordable Injuries and Illnesses 6 ApiDocument1 pageSymposium Series No. 54 © 2008 Icheme: Total Recordable Injuries and Illnesses 6 ApipotatoteddyNo ratings yet

- Pages From A World Class Approach To PSMDocument1 pagePages From A World Class Approach To PSMpotatoteddyNo ratings yet

- Pipe Stress Analysis Using CAESAR IIDocument1 pagePipe Stress Analysis Using CAESAR IIpotatoteddyNo ratings yet

- Pages From 54778259 Must Print 3Document1 pagePages From 54778259 Must Print 3potatoteddyNo ratings yet

- Pages From 54778259 Must Print 4Document1 pagePages From 54778259 Must Print 4potatoteddyNo ratings yet

- Pages From 54778259 Must Print 5Document1 pagePages From 54778259 Must Print 5potatoteddyNo ratings yet

- Pipe Stress Analysis Using CAESAR IIDocument1 pagePipe Stress Analysis Using CAESAR IIpotatoteddyNo ratings yet

- Pipe Stress Analysis Using CAESAR IIDocument42 pagesPipe Stress Analysis Using CAESAR IIpca97100% (1)

- Pages From 54778259 Must Print 2Document1 pagePages From 54778259 Must Print 2potatoteddyNo ratings yet

- Pages From FlowDocument1 pagePages From FlowpotatoteddyNo ratings yet

- CH 403 05 - Capital Cost EstimationDocument91 pagesCH 403 05 - Capital Cost EstimationAyushKumar100% (3)

- Corporate Presentation Feedback VenturesDocument50 pagesCorporate Presentation Feedback VenturesAtanu MukherjeeNo ratings yet

- 521-110 HF CouplingsDocument32 pages521-110 HF CouplingsCancio Florez100% (1)

- UT3 2010 DecemberDocument175 pagesUT3 2010 DecemberMona MohammedNo ratings yet

- Frequency Converters: For Wind TurbinesDocument9 pagesFrequency Converters: For Wind TurbinesAbdallah AbdelrehimNo ratings yet

- Siemens Transformers Manufacturing and Quality PlanDocument14 pagesSiemens Transformers Manufacturing and Quality PlanLuis BrandaoNo ratings yet

- IRB6650S 220818 DatasheetDocument2 pagesIRB6650S 220818 DatasheetJuanjoNo ratings yet

- Necessity of Agricultural Machinery Testing Centers To Promote Farm Mechanization in PakistanDocument4 pagesNecessity of Agricultural Machinery Testing Centers To Promote Farm Mechanization in PakistanEngr Ali Raza100% (1)

- Transmission Rehabilitation and Expansion Program (TREP)Document21 pagesTransmission Rehabilitation and Expansion Program (TREP)BayeNo ratings yet

- Chapter 01 - Refrigeration PrinciplesDocument19 pagesChapter 01 - Refrigeration PrinciplesLaminTunNo ratings yet

- Introduction to Amec Foster WheelerDocument17 pagesIntroduction to Amec Foster WheelerRagerishcire KanaalaqNo ratings yet

- PETplanet PDFDocument52 pagesPETplanet PDFFernando FerreiraNo ratings yet

- Transformer Short Circuit Current Calculation and SolutionsDocument37 pagesTransformer Short Circuit Current Calculation and Solutionsmano_bacsi100% (1)

- M Umair Siddique S/O Wahid Hussain Barki: Web Generated BillDocument1 pageM Umair Siddique S/O Wahid Hussain Barki: Web Generated BillMuhammad Umair SiddiquieNo ratings yet

- Lin AssistDocument4 pagesLin AssistSynyster Patar SulivanNo ratings yet

- Basic Substation TrainingDocument56 pagesBasic Substation Trainingfaizalsaad100% (2)

- Biddle - VRVDocument31 pagesBiddle - VRVutzu_yooNo ratings yet

- Sinovoltaics Inverter Manufacturer Ranking Report Edition 1 2022Document16 pagesSinovoltaics Inverter Manufacturer Ranking Report Edition 1 2022Wepa BizNo ratings yet

- Polyurethane BumpersDocument8 pagesPolyurethane BumpersJuarez LeiteNo ratings yet

- Building Better Green Communities with GBI Township ToolDocument8 pagesBuilding Better Green Communities with GBI Township ToolSrikanthTirlukaNo ratings yet

- AIMCC - Moot Problem 2018Document32 pagesAIMCC - Moot Problem 2018Achmad Rheza MaulanaNo ratings yet

- Invertec V275-S: For Stick and DC TIG WeldingDocument4 pagesInvertec V275-S: For Stick and DC TIG WeldingPedro Ernesto Rodriguez RojasNo ratings yet

- ch001 PDFDocument28 pagesch001 PDFAnbarasan Anandhan0% (1)

- Search For A Product/Service: Package SubstationDocument4 pagesSearch For A Product/Service: Package SubstationSoumya ChaudhuryNo ratings yet

- Dayliff Control PanelsDocument2 pagesDayliff Control Panelscyruskulei100% (1)

- 2012 USBSEC Brochure 2Document54 pages2012 USBSEC Brochure 2Jorge GómezNo ratings yet

- Company CMDocument23 pagesCompany CMArvind AgrawalNo ratings yet

- Vijay Resume QECDocument6 pagesVijay Resume QECeimanoNo ratings yet

- Idoc - Pub Electricity-Bill PDFDocument1 pageIdoc - Pub Electricity-Bill PDFUsman JaffarNo ratings yet

- Battery Rating:: Technical SpecificationDocument6 pagesBattery Rating:: Technical SpecificationAnonymous 0BYsFuVNo ratings yet