Professional Documents

Culture Documents

2n7002k Sot-23 Vishay

Uploaded by

KST5Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2n7002k Sot-23 Vishay

Uploaded by

KST5Copyright:

Available Formats

2N7002K

Vishay Siliconix

N-Channel 60-V (D-S) MOSFET

PRODUCT SUMMARY FEATURES

VDS (V) RDS(on) () ID (mA)

Halogen-free According to IEC 61249-2-21

Definition

60 2 at VGS = 10 V 300 Low On-Resistance: 2

Low Threshold: 2 V (typ.)

Low Input Capacitance: 25 pF

Fast Switching Speed: 25 ns

Low Input and Output Leakage

TrenchFET Power MOSFET

2000 V ESD Protection

Compliant to RoHS Directive 2002/95/EC

TO-236

SOT-23

BENEFITS

Low Offset Voltage

G 1

Low-Voltage Operation

Easily Driven Without Buffer

3 D

High-Speed Circuits

Low Error Voltage

S 2

APPLICATIONS

Top View

Direct Logic-Level Interface: TTL/CMOS

2N7002K (7K)* Drivers: Relays, Solenoids, Lamps, Hammers, Display,

* Marking Code Memories, Transistors, etc.

Ordering Information: 2N7002K-T1 Battery Operated Systems

2N7002K-T1-E3 (Lead (Pb)-free) Solid-State Relays

2N7002K-T1-GE3 (Lead (Pb)-free and Halogen-free)

ABSOLUTE MAXIMUM RATINGS TA = 25 C, unless otherwise noted

Parameter Symbol Limit Unit

Drain-Source Voltage VDS 60

V

Gate-Source Voltage VGS 20

TA = 25 C 300

Continuous Drain Current (TJ = 150 C)b ID

TA = 100 C 190 mA

Pulsed Drain Currenta IDM 800

TA = 25 C 0.35

Power Dissipationb PD W

TA = 100 C 0.14

Maximum Junction-to-Ambientb RthJA 350 C/W

Operating Junction and Storage Temperature Range TJ, Tstg - 55 to 150 C

Notes:

a. Pulse width limited by maximum junction temperature.

b. Surface Mounted on FR4 board.

* Pb containing terminations are not RoHS compliant, exemptions may apply.

Document Number: 71333 www.vishay.com

S09-0857-Rev. E, 18-May-09 1

2N7002K

Vishay Siliconix

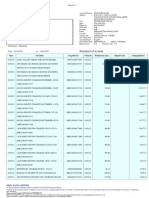

SPECIFICATIONS TA = 25 C, unless otherwise noted

Limits

Parameter Symbol Test Conditions Min. Typ.a Max. Unit

Static

Drain-Source Breakdown Voltage VDS VGS = 0 V, ID = 10 A 60

V

Gate-Threshold Voltage VGS(th) VDS = VGS, ID = 250 A 1 2.5

VDS = 0 V, VGS = 20 V 10

A

VDS = 0 V, VGS = 15 V 1

Gate-Body Leakage IGSS VDS = 0 V, VGS = 10 V 150 nA

VDS = 0 V, VGS = 10 V, TJ = 85 C 1000

VDS = 0 V, VGS = 5 V 100

VDS = 60 V, VGS = 0 V 1

Zero Gate Voltage Drain Current IDSS A

VDS = 60 V, VGS = 0 V , TJ = 125 C 500

VGS = 10 V, VDS = 7.5 V 800

On-State Drain Currenta ID(on) mA

VGS = 4.5 V, VDS = 10 V 500

VGS = 10 V, ID = 500 mA 2

Drain-Source On-Resistancea RDS(on)

VGS = 4.5 V, ID = 200 mA 4

Forward Transconductancea gfs VDS = 10 V, ID = 200 mA 100 mS

Diode Forward Voltage VSD IS = 200 mA, VGS = 0 V 1.3 V

Dynamica

VDS = 10 V, VGS = 4.5 V

Total Gate Charge Qg 0.4 0.6 nC

ID 250 mA

Input Capacitance Ciss 30

VDS = 25 V, VGS = 0 V

Output Capacitance Coss 6 pF

f = 1 MHz

Reverse Transfer Capacitance Crss 2.5

Switchinga, b, c

Turn-On Time td(on) VDD = 30 V, RL = 150 25

ns

Turn-Off Time td(off) ID 200 mA, VGEN = 10 V, RG = 10 35

Notes:

a. For DESIGN AID ONLY, not subject to production testing.

b. Pulse test: PW 300 s duty cycle 2 %.

c. Switching time is essentially independent of operating temperature.

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings only, and functional operation

of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute maximum

rating conditions for extended periods may affect device reliability.

www.vishay.com Document Number: 71333

2 S09-0857-Rev. E, 18-May-09

2N7002K

Vishay Siliconix

TYPICAL CHARACTERISTICS 25 C, unless otherwise noted

1.0 1200

7V 6V

VGS = 10 V TJ = - 55 C

0.8 5V

900

I D - Drain Current (mA)

I D - Drain Current (A)

25 C

0.6

125 C

600

0.4 4V

300

0.2

3V

0.0 0

0 1 2 3 4 5 0 1 2 3 4 5 6

VDS - Drain-to-Source Voltage (V) VGS - Gate-to-Source Voltage (V)

Output Characteristics Transfer Characteristics

4.0 40

3.5 VGS = 0 V

32

R DS(on) - On-Resistance ()

3.0

C - Capacitance (pF)

2.5

24 Ciss

2.0 VGS = 4.5 V

16

1.5 VGS = 10 V

Coss

1.0

8

Crss

0.5

0.0 0

0 200 400 600 800 1000 0 5 10 15 20 25

ID - Drain Current (mA) VDS - Drain-to-Source Voltage (V)

On-Resistance vs. Drain Current Capacitance

7 2.0

6 VDS = 10 V VGS = 10 V at 500 mA

VGS - Gate-to-Source Voltage (V)

ID = 250 mA 1.6

R DS(on) - On-Resistance

5

(Normalized)

1.2 VGS = 4.5 V

4

at 200 mA

3

0.8

2

0.4

1

0 0.0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 - 50 - 25 0 25 50 75 100 125 150

Qg - Total Gate Charge (nC) TJ - Junction Temperature (C)

Gate Charge On-Resistance vs. Junction Temperature

Document Number: 71333 www.vishay.com

S09-0857-Rev. E, 18-May-09 3

2N7002K

Vishay Siliconix

TYPICAL CHARACTERISTICS 25 C, unless otherwise noted

1000 5

VGS = 0 V

4

R DS(on) - On-Resistance ()

I S - Source Current (A)

100

3

TJ = 125 C

ID = 200 mA ID = 500 mA

2

10 TJ = 25 C

1

TJ = - 55 C

1 0

0.0 0.3 0.6 0.9 1.2 1.5 0 2 4 6 8 10

VSD - Source-to-Drain Voltage (V) VGS - Gate-to-Source Voltage (V)

Source-Drain Diode Forward Voltage On-Resistance vs. Gate-Source Voltage

0.4 3

0.2 2.5

ID = 250 A

VGS(th) Variance (V)

0.0 2

Power (W)

- 0.2 1.5

- 0.4 1

TA = 25 C

- 0.6 0.5

- 0.8 0

- 50 - 25 0 25 50 75 100 125 150 0.01 0.1 1 10 100 600

TJ - Junction Temperature (C) Time (s)

Threshold Voltage Variance Over Temperature Single Pulse Power, Junction-to-Ambient

1

Normalized Effective Transient

Duty Cycle = 0.5

Thermal Impedance

0.2

Notes:

0.1

0.1 PDM

0.05

t1

t2

0.02 t1

1. Duty Cycle, D =

t2

2. Per Unit Base = R thJA = 350 C/W

3. T JM - TA = PDMZthJA(t)

Single Pulse

4. Surface Mounted

0.01

10-4 10-3 10-2 10-1 1 10 100 600

Square Wave Pulse Duration (s)

Normalized Thermal Transient Impedance, Junction-to-Ambient

www.vishay.com Document Number: 71333

4 S09-0857-Rev. E, 18-May-09

2N7002K

Vishay Siliconix

TYPICAL CHARACTERISTICS 25 C, unless otherwise noted

2

1

Normalized Effective Transient

Duty Cycle = 0.5

Thermal Impedance

0.2

0.1

0.1

0.05

0.02

Single Pulse

0.01

10-4 10-3 10-2 10-1 1 10

Square Wave Pulse Duration (s)

Normalized Thermal Transient Impedance, Junction-to-Foot

Vishay Siliconix maintains worldwide manufacturing capability. Products may be manufactured at one of several qualified locations. Reliability data for Silicon

Technology and Package Reliability represent a composite of all qualified locations. For related documents such as package/tape drawings, part marking, and

reliability data, see www.vishay.com/ppg?71333.

Document Number: 71333 www.vishay.com

S09-0857-Rev. E, 18-May-09 5

Package Information

Vishay Siliconix

SOT-23 (TO-236): 3-LEAD

3

E1 E

1 2

S e

e1

0.10 mm

C

0.004" C 0.25 mm

A A2 q

Gauge Plane

Seating Plane Seating Plane

A1 C

L

L1

MILLIMETERS INCHES

Dim

Min Max Min Max

A 0.89 1.12 0.035 0.044

A1 0.01 0.10 0.0004 0.004

A2 0.88 1.02 0.0346 0.040

b 0.35 0.50 0.014 0.020

c 0.085 0.18 0.003 0.007

D 2.80 3.04 0.110 0.120

E 2.10 2.64 0.083 0.104

E1 1.20 1.40 0.047 0.055

e 0.95 BSC 0.0374 Ref

e1 1.90 BSC 0.0748 Ref

L 0.40 0.60 0.016 0.024

L1 0.64 Ref 0.025 Ref

S 0.50 Ref 0.020 Ref

q 3 8 3 8

ECN: S-03946-Rev. K, 09-Jul-01

DWG: 5479

Document Number: 71196 www.vishay.com

09-Jul-01 1

AN807

Vishay Siliconix

Mounting LITTLE FOOTR SOT-23 Power MOSFETs

Wharton McDaniel

Surface-mounted LITTLE FOOT power MOSFETs use integrated ambient air. This pattern uses all the available area underneath the

circuit and small-signal packages which have been been modified body for this purpose.

to provide the heat transfer capabilities required by power devices.

Leadframe materials and design, molding compounds, and die

attach materials have been changed, while the footprint of the

packages remains the same. 0.114

2.9

0.081

2.05

See Application Note 826, Recommended Minimum Pad

0.150

Patterns With Outline Drawing Access for Vishay Siliconix 3.8

MOSFETs, (http://www.vishay.com/doc?72286), for the basis

of the pad design for a LITTLE FOOT SOT-23 power MOSFET 0.059

footprint . In converting this footprint to the pad set for a power 1.5

device, designers must make two connections: an electrical

connection and a thermal connection, to draw heat away from the

0.0394 0.037

package. 1.0 0.95

FIGURE 1. Footprint With Copper Spreading

The electrical connections for the SOT-23 are very simple. Pin 1 is

the gate, pin 2 is the source, and pin 3 is the drain. As in the other

LITTLE FOOT packages, the drain pin serves the additional Since surface-mounted packages are small, and reflow soldering

function of providing the thermal connection from the package to is the most common way in which these are affixed to the PC

the PC board. The total cross section of a copper trace connected board, thermal connections from the planar copper to the pads

to the drain may be adequate to carry the current required for the have not been used. Even if additional planar copper area is used,

application, but it may be inadequate thermally. Also, heat spreads there should be no problems in the soldering process. The actual

in a circular fashion from the heat source. In this case the drain pin solder connections are defined by the solder mask openings. By

is the heat source when looking at heat spread on the PC board. combining the basic footprint with the copper plane on the drain

pins, the solder mask generation occurs automatically.

Figure 1 shows the footprint with copper spreading for the SOT-23 A final item to keep in mind is the width of the power traces. The

package. This pattern shows the starting point for utilizing the absolute minimum power trace width must be determined by the

board area available for the heat spreading copper. To create this amount of current it has to carry. For thermal reasons, this

pattern, a plane of copper overlies the drain pin and provides minimum width should be at least 0.020 inches. The use of wide

planar copper to draw heat from the drain lead and start the traces connected to the drain plane provides a low-impedance

process of spreading the heat so it can be dissipated into the path for heat to move away from the device.

Document Number: 70739 www.vishay.com

26-Nov-03 1

Application Note 826

Vishay Siliconix

RECOMMENDED MINIMUM PADS FOR SOT-23

0.037 0.022

(0.950) (0.559)

(2.692)

(1.245)

0.106

0.049

(0.724)

0.029

0.053

(1.341)

0.097

(2.459)

Recommended Minimum Pads

Dimensions in Inches/(mm)

Return to Index Return to Index

APPLICATION NOTE

Document Number: 72609 www.vishay.com

Revision: 21-Jan-08 25

Legal Disclaimer Notice

www.vishay.com

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

Vishay), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishays knowledge of typical

requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements

about the suitability of products for a particular application. It is the customers responsibility to validate that a particular

product with the properties described in the product specification is suitable for use in a particular application. Parameters

provided in datasheets and/or specifications may vary in different applications and performance may vary over time. All

operating parameters, including typical parameters, must be validated for each customer application by the customers

technical experts. Product specifications do not expand or otherwise modify Vishays terms and conditions of purchase,

including but not limited to the warranty expressed therein.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk. Please

contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document or by

any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

Material Category Policy

Vishay Intertechnology, Inc. hereby certifies that all its products that are identified as RoHS-Compliant fulfill the

definitions and restrictions defined under Directive 2011/65/EU of The European Parliament and of the Council

of June 8, 2011 on the restriction of the use of certain hazardous substances in electrical and electronic equipment

(EEE) - recast, unless otherwise specified as non-compliant.

Please note that some Vishay documentation may still make reference to RoHS Directive 2002/95/EC. We confirm that

all the products identified as being compliant to Directive 2002/95/EC conform to Directive 2011/65/EU.

Vishay Intertechnology, Inc. hereby certifies that all its products that are identified as Halogen-Free follow Halogen-Free

requirements as per JEDEC JS709A standards. Please note that some Vishay documentation may still make reference

to the IEC 61249-2-21 definition. We confirm that all the products identified as being compliant to IEC 61249-2-21

conform to JEDEC JS709A standards.

Revision: 02-Oct-12 1 Document Number: 91000

You might also like

- Preventing failures in lift-up motor operationDocument2 pagesPreventing failures in lift-up motor operationKST5No ratings yet

- Datasheet PDFDocument29 pagesDatasheet PDFKST5No ratings yet

- GL3233Document28 pagesGL3233KST5No ratings yet

- Dsa Zsa A 0008182Document23 pagesDsa Zsa A 0008182JoseNo ratings yet

- 2n7002l Sot-23 OnDocument4 pages2n7002l Sot-23 OnKST5No ratings yet

- Product Profile: 60 V, 0.3 A N-Channel Trench MOSFETDocument13 pagesProduct Profile: 60 V, 0.3 A N-Channel Trench MOSFETKST5No ratings yet

- MX25L8006EDocument57 pagesMX25L8006EKST5No ratings yet

- Discontinued service simulations and firmware changes for Kyocera Mita printersDocument1 pageDiscontinued service simulations and firmware changes for Kyocera Mita printersKST5No ratings yet

- USB Logo Usage GuideDocument29 pagesUSB Logo Usage GuideKST5No ratings yet

- STK 6713 BMK 4Document10 pagesSTK 6713 BMK 4KST5No ratings yet

- SENS X15-Schematic PDFDocument123 pagesSENS X15-Schematic PDFKST5No ratings yet

- 2n7002 Sot-23 PanjitDocument8 pages2n7002 Sot-23 PanjitKST5No ratings yet

- LTV817A DatasheetDocument5 pagesLTV817A DatasheetKST5No ratings yet

- Samsung r560 SchematicsDocument77 pagesSamsung r560 SchematicsDuzardoNo ratings yet

- Samsung k2200nd PDFDocument2 pagesSamsung k2200nd PDFKST5No ratings yet

- F20LC30 DatasheetDocument6 pagesF20LC30 DatasheetKST5No ratings yet

- KX f910bx PDFDocument237 pagesKX f910bx PDFsaito36No ratings yet

- FAX 2840 BrochureDocument2 pagesFAX 2840 BrochureKhan Mohammad Mahmud HasanNo ratings yet

- FAX 2840 BrochureDocument2 pagesFAX 2840 BrochureKhan Mohammad Mahmud HasanNo ratings yet

- Panasonic kx-f206 SMDocument33 pagesPanasonic kx-f206 SMKST5No ratings yet

- Datasheet PDFDocument29 pagesDatasheet PDFKST5No ratings yet

- MFC J6510DW BrochureDocument2 pagesMFC J6510DW BrochureKST5No ratings yet

- Al2020 Bro Leaflet GBDocument2 pagesAl2020 Bro Leaflet GBKST5No ratings yet

- Compact AL-2040 MFPDocument1 pageCompact AL-2040 MFPKST5No ratings yet

- Service Parts List Sharp AL-2040cs, 2030, 2040, 2050cs, 2060Document45 pagesService Parts List Sharp AL-2040cs, 2030, 2040, 2050cs, 2060Ramón Colón100% (1)

- Epson ActionPrinter 5000 User's ManualDocument154 pagesEpson ActionPrinter 5000 User's ManualKST5No ratings yet

- Epson ActionPrinter 4000 User's ManualDocument290 pagesEpson ActionPrinter 4000 User's ManualKST5No ratings yet

- EPSON Expression 1640xl TPU Service ManualDocument46 pagesEPSON Expression 1640xl TPU Service ManualKST5No ratings yet

- Star NX-1500TMDocument106 pagesStar NX-1500TMKST5No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Title of Research PaperDocument9 pagesTitle of Research Paperpooja guptaNo ratings yet

- Columbia Aaltius: Columbia Developers Private LimitedDocument4 pagesColumbia Aaltius: Columbia Developers Private LimitedRishav GoyalNo ratings yet

- Haripriya SoniDocument1 pageHaripriya SoniKamlesh PrajapatiNo ratings yet

- Boss v. CVS Health - Notice of Voluntary DismissalDocument35 pagesBoss v. CVS Health - Notice of Voluntary DismissalThe Type 1 Diabetes Defense FoundationNo ratings yet

- Schedule of Classes (2nd Sem AY 18-19)Document2 pagesSchedule of Classes (2nd Sem AY 18-19)Anne Lorraine DioknoNo ratings yet

- Premachandra and Dodangoda v. Jayawickrema andDocument11 pagesPremachandra and Dodangoda v. Jayawickrema andPragash MaheswaranNo ratings yet

- 13 GARCIA v. VILLARDocument1 page13 GARCIA v. VILLARGSSNo ratings yet

- Jurnal Deddy RandaDocument11 pagesJurnal Deddy RandaMuh Aji Kurniawan RNo ratings yet

- The Star News June 18 2015Document36 pagesThe Star News June 18 2015The Star NewsNo ratings yet

- Donation: Concept, Nature, and Effect of DonationDocument3 pagesDonation: Concept, Nature, and Effect of DonationJim M. MagadanNo ratings yet

- DH - DSS Professional V8.1.1 Fix Pack - Release NotesDocument5 pagesDH - DSS Professional V8.1.1 Fix Pack - Release NotesGolovatic VasileNo ratings yet

- City Limits Magazine, January 1991 IssueDocument24 pagesCity Limits Magazine, January 1991 IssueCity Limits (New York)No ratings yet

- IBPS Clerk RecruitmentDocument47 pagesIBPS Clerk RecruitmentTopRankersNo ratings yet

- 32A Registration LegalDocument1 page32A Registration LegalChaitram200920% (5)

- Guide To Plan Management PDFDocument20 pagesGuide To Plan Management PDFArrigo Lupori100% (1)

- 90 Cameron Granville V ChuaDocument1 page90 Cameron Granville V ChuaKrisha Marie CarlosNo ratings yet

- Skill Assessment Evidence GuideDocument13 pagesSkill Assessment Evidence Guiderahul.ril1660No ratings yet

- JLL MX Office Report Mexico City 3q 2023Document21 pagesJLL MX Office Report Mexico City 3q 20231234567qwertzuiNo ratings yet

- Motion to Mark Exhibits PermanentlyDocument3 pagesMotion to Mark Exhibits PermanentlyEm Mangulabnan100% (1)

- History of Freemasonry Throughout The World Vol 6 R GouldDocument630 pagesHistory of Freemasonry Throughout The World Vol 6 R GouldVak AmrtaNo ratings yet

- Charles Taylor.Document17 pagesCharles Taylor.Will PalmerNo ratings yet

- Jaya Holdings Annual Report 2010Document112 pagesJaya Holdings Annual Report 2010wctimNo ratings yet

- Summary - Best BuyDocument4 pagesSummary - Best BuySonaliiiNo ratings yet

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument4 pagesStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceSiraj PNo ratings yet

- Gallagher Bill to Sanction Chinese Firms Supporting PutinDocument18 pagesGallagher Bill to Sanction Chinese Firms Supporting PutinJennifer Van LaarNo ratings yet

- Obligations of The VendeeDocument55 pagesObligations of The VendeerchllmclnNo ratings yet

- VAT: Value-Added Tax BasicsDocument42 pagesVAT: Value-Added Tax BasicsRobert WeightNo ratings yet

- Actifio Copy Data ManagementDocument92 pagesActifio Copy Data ManagementmahalinNo ratings yet

- NBIMS-US V3 2.4.4.7 OmniClass Table 31 PhasesDocument8 pagesNBIMS-US V3 2.4.4.7 OmniClass Table 31 Phasesmahmoud mokhtarNo ratings yet

- 13-07-26 Microsoft-Motorola Agreed Jury InstructionsDocument45 pages13-07-26 Microsoft-Motorola Agreed Jury InstructionsFlorian MuellerNo ratings yet