Professional Documents

Culture Documents

PE Fluid Compatibility

Uploaded by

GerryCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PE Fluid Compatibility

Uploaded by

GerryCopyright:

Available Formats

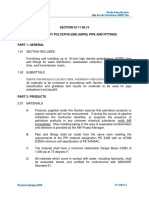

CDF Technical Memo

Number 1 July 2004

Polyethylene Chemical Resistance Chart

CDF Corporation uses only the highest quality raw materials available. These raw materials have out-

standing resistance to both physical and chemical attack. The following chart should be used as a guide

for evaluating the suitability of our products with the chemical agent you plan to use. Special considera-

tion must be given to the expected service temperature, stress involved in the application, as well as the

length and type of exposure (i.e. intermittent or continuous).

CODES REAGENT CONC. LDPE HDPE

70 140 70 140

A Resistant no indication that

serviceability would be

impaired.

Acetone B C B C

B Variable resistance, depending Acetaldehyde* 100% B C B C

on conditions of use. Acetic Acid* 10% A A A A

C Unresistant, not recommended Acetic Acid* 60% A B A B

for service applications under Acetic Anhydride* C C C C

any conditions. Air A A A A

Aluminum Chloride all conc A A A A

- Information not available.

Aluminum Fluoride all conc A A A A

Aluminum Sulphate all conc A A A A

Alums all types A A A A

Ammonia 100% dry gas A A A A

# Plasticizer. Ammonium Carbonate A A A A

Certain types of chemicals are Ammonium Chloride satd A A A A

absorbed to varying degrees by poly- Ammonium Fluoride satd A A A A

ethylene causing swelling, weight-gain,

Ammonium Hydroxide 10% A A A A

softening and some loss of yield

strength. These plasticizing materials Ammonium Hydroxide 28% A A A A

cause no actual chemical degrada- Ammonium Nitrate satd A A A A

tion of the resin. Several of these Ammonium Persulphate satd A A A A

chemicals have a strong plasticizing

Ammonium Sulphate satd A A A A

effect (e.g. aromatic hydrocarbons

benzene), whereas others have weaker Ammonium Metaphosphate satd A A A A

effects (e.g. gasoline). Certain plasti- Ammonium Sulfide satd A A A A

cizers are sufficiently volatile that if Amyl Acetate#* 100% C C C C

they are removed from contact with

Amyl Alcohol#* 100% A A A A

the polyethylene, the part will dry out

and return to its original condition with Amyl Chloride# 100% C C C C

no loss of properties. Aniline#* 100% A C C B

Aqua Regia+ C C C C

Arsenic Acid all conc A A A A

Aromatic Hydrocarbons#* C C C C

+ Oxidizers.

Ascorbic Acid 10% A A A A

Oxidizers are the only group of materi-

als capable of chemically degrading

Barium Carbonate satd A A A A

polyethylene. The effects on the poly- Barium Chloride satd A A A A

ethylene may be gradual even for Barium Hydroxide A A A A

strong oxidizers and short-term effects Barium Sulphate satd A A A A

may not be measurable. However, if

continuous long-term exposure is

Barium Sulphide satd A A A A

intended, the chemical effects should Beer A A A A

be checked regularly. Benzene#* C C C C

CODES Benzoic Acid all conc A A A A

Bismuth Carbonate satd A A A A

A Resistant no indication that Bleach Lye 10% A A A A

serviceability would be

impaired. Borax satd A A A A

Boric Acid all conc A A A A

B Variable resistance, depending Boron Trifluoride A A A A

on conditions of use. Brine A A A A

C Unresistant, not recommended Bromine+ liquid C C C C

for service applications under Bromine Water# satd C C C C

any conditions. Butanediol* 10% A A A A

Butanediol* 60% A A A A

- Information not available.

Butanediol* 100% A A A A

Butter* A A A A

n-Butyl Acetate#* 100% B C A B

n-Butyl Alcohol* 100% A A A A

# Plasticizer. Butyric Acid# conc C C C C

Certain types of chemicals are Calcium Bisulphide A A A A

absorbed to varying degrees by poly- Calcium Carbonate satd A A A A

ethylene causing swelling, weight-gain,

softening and some loss of yield

Calcium Chlorate satd A A A A

strength. These plasticizing materials Calcium Chloride satd A A A A

cause no actual chemical degrada- Calcium Hydroxide conc A A A A

tion of the resin. Several of these Calcium Hypochloride bleach sol A A A A

chemicals have a strong plasticizing

effect (e.g. aromatic hydrocarbons

Calcium Nitrate 50% A A A A

benzene), whereas others have weaker Calcium Oxide satd A A A A

effects (e.g. gasoline). Certain plasti- Calcium Sulphate A A A A

cizers are sufficiently volatile that if Camphor Oil#* C C B C

they are removed from contact with

the polyethylene, the part will dry out

Carbon Dioxide all conc A A A A

and return to its original condition with Carbon Disulphide C C C C

no loss of properties. Carbon Monoxide A A A A

Carbon Tetrachloride# C C B C

Carbonic Acid A A A A

Castor 0il* conc A A A A

+ Oxidizers.

Chlorine+ 100% dry gas B C C C

Oxidizers are the only group of materi-

als capable of chemically degrading

Chlorine Liquid+ C C C C

polyethylene. The effects on the poly- Chlorine Water+ 2% satd sol A A A A

ethylene may be gradual even for Chlorobenzene#* C C C C

strong oxidizers and short-term effects Chloroform*# C C B C

may not be measurable. However, if

continuous long-term exposure is

Chlorosulphonic Acid 100% C C C C

intended, the chemical effects should Chrome Alum satd A A A A

be checked regularly. Chromic Acid 80% - - - -

Chromic Acid 50% A B A B

Chromic Acid 10% A A A A

Cider* A A A A

Citric Acid* satd A A A A

Coconut 0il Alcohols* A A A A

Coffee A A A A

Cola Concentrate* A A A A

Copper Chloride satd A A A A

Copper Cyanide satd A A A A

Copper Fluoride 2% A A A A

Copper Nitrate satd A A A A

Copper Sulphate satd A A A A

Corn 0il* A A A A

Cottonseed 0il* A A A A

Cuprous Chloride satd A A A A

Detergents Synthetic* A A A A

Developers Photographic A A A A

Dextrin satd A A A A

Dextrose satd A A A A

CODES Diazo Salts A A A A

Dibutylphthalate* B B B B

A Resistant no indication that Dichlorobenzene#* C C C C

serviceability would be

impaired.

Diethyl Ketone#* B C B B

Diethylene Glycol* A A A A

B Variable resistance, depending Diglycolic Acid* A A A A

on conditions of use. Dimethylamine C C C C

C Unresistant, not recommended

Disodium Phosphate A A B A

for service applications under Emulsions, Photographic* A A A A

any conditions. Ethyl Acetate#* 100% B C B C

Ethyl Alcohol* 100% A A A A

- Information not available.

Ethyl Alcohol* 35% A A A A

Ethyl Benzene#* C C C C

Ethyl Chloride# C C C C

Ethyl Ether# C C C C

# Plasticizer. Ethylene Chloride#* C C C C

Certain types of chemicals are Ethylene Glycol* A A A A

absorbed to varying degrees by poly- Fatty Acids* A A A A

ethylene causing swelling, weight-gain,

Ferric Chloride satd A A A A

softening and some loss of yield

strength. These plasticizing materials Ferric Nitrate satd A A A A

cause no actual chemical degrada- Ferrous Chloride satd A A A A

tion of the resin. Several of these Ferrous Sulphate A A A A

chemicals have a strong plasticizing

Fish Solubles* A A A A

effect (e.g. aromatic hydrocarbons

benzene), whereas others have weaker Fluoboric Acid A A A A

effects (e.g. gasoline). Certain plasti- Fluosillcic Acid conc A B A B

cizers are sufficiently volatile that if Fluosillcic Acid 32% A A A A

they are removed from contact with

Formic Acid all conc A A A A

the polyethylene, the part will dry out

and return to its original condition with Fructose satd A A A A

no loss of properties. Fruit Pulp* A A A A

Furtural# 100% C C B C

Furturyl Alcohol#* C C B C

Gallic Acid* satd A A A A

+ Oxidizers.

Gasoline#* C C B B

Oxidizers are the only group of materi-

als capable of chemically degrading Glucose A A A A

polyethylene. The effects on the poly- Glycerine* A A A A

ethylene may be gradual even for Glycol* A A A A

strong oxidizers and short-term effects Glycolic Acid* 30% A A A A

may not be measurable. However, if

continuous long-term exposure is Grape Sugar A A A A

intended, the chemical effects should n-Heptane#* C C B B

be checked regularly. Hexachlorobenzene A A A -

Hexanol Tertiary* A A A A

Hydrobromic Acid 50% A A A A

Hydrochloric Acid all conc A A A A

Hydrocyanic Acid satd A A A A

Hydrofluoric Acid* 60% A A A A

Hydrogen 100% A A A A

Hydrogen Chloride dry gas A A A A

Hydrogen Peroxide 30% A A A A

Hydrogen Peroxide 10% A A A A

Hydrogen Sulphide A A A A

Hydroquinone A A A A

Hypochlorous Acid conc. A A A A

Inks* A A A A

lodine+ in Kl soln B C B -

Isopropyl Alcohol 100% - - - -

Lead Acetate satd A A A A

Lead Nitrate A A A A

Lactic Acid* 20% A A A A

Linseed Oil* 100% B C B C

CODES Magnesium Carbonate satd A A A A

Magnesium Chloride satd A A A A

A Resistant no indication that Magnesium Hydroxide satd A A A A

serviceability would be

impaired. Magnesium Nitrate satd A A A A

Magnesium Sulphate satd A A A A

B Variable resistance, depending Mercuric Chloride 40% A A A A

on conditions of use. Mercuric Cyanide satd A A A A

C Unresistant, not recommended Mercury A A A A

for service applications under Methyl Alcohol* 100% A A A A

any conditions. Methylethyl Ketone#* 100% B C B C

Methylene Chloride#* 100% C C B B

- Information not available.

Milk A A A A

Mineral Oils# B C B C

Molasses A A A A

Naphtha#* B C B C

# Plasticizer. Naphthalene#* C C B -

Certain types of chemicals are Nickel Chloride conc A A A A

absorbed to varying degrees by poly- Nickel Nitrate satd A A A A

ethylene causing swelling, weight-gain,

softening and some loss of yield

Nickel Sulphate conc A A A A

strength. These plasticizing materials Nicotine* dilute A A A A

cause no actual chemical degrada- Nitric Acid 0-30% A A A A

tion of the resin. Several of these Nitric Acid+ 30-50% A B A B

chemicals have a strong plasticizing

effect (e.g. aromatic hydrocarbons

Nitric Acid+ 70% A B A B

benzene), whereas others have weaker Nitric Acid+ 95-98% C C C C

effects (e.g. gasoline). Certain plasti- Nitrobenzene#* 100% C C C C

cizers are sufficiently volatile that if n-Octane A A A A

they are removed from contact with

the polyethylene, the part will dry out

Oleic Acid B C B C

and return to its original condition with Oxalic Acid* satd A A A A

no loss of properties. Perchloroethylene# C C C C

Phosphoric Acid 95% A B A A

Photographic Solutions A A A A

Plating Solutions*

+ Oxidizers.

Brass A A A A

Oxidizers are the only group of materi-

als capable of chemically degrading Cadmium A A A A

polyethylene. The effects on the poly- Chromium A A A A

ethylene may be gradual even for Copper A A A A

strong oxidizers and short-term effects Gold A A A A

may not be measurable. However, if

continuous long-term exposure is Indium A A A A

intended, the chemical effects should Lead A A A A

be checked regularly. Nickel A A A A

Rhodium A A A A

Sliver A A A A

Tin A A A A

Zinc A A A A

Potassium Bicarbonate satd A A A A

Potassium Bromide satd A A A A

Potassium Bromate 10% A A A A

Potassium Carbonate A A A A

Potassium Chlorate satd A A A A

Potassium Chloride satd A A A A

Potassium Chromate 40% A A A A

Potassium Cyanide satd A A A A

Potassium Dichromate 40% A A A A

Potassium Ferri/Ferro

Cyanide satd A A A A

Potassium Fluoride A A A A

Potassium Hydroxide conc A A A A

Potassium Nitrate satd A A A A

Potassium Perborate satd A A A A

CODES Potassium Perchlorate 10% A A A A

Potassium Permanganate 20% A A A A

A Resistant no indication that Potassium Persulphate satd A A A A

serviceability would be

impaired.

Potassium Sulphate conc A A A A

Potassium Sulphide conc A A A A

B Variable resistance, depending Potassium Sulphite conc A A A A

on conditions of use. Propargyl Alcohol* A A A A

C Unresistant, not recommended

n-Propyl Alcohol* A A A A

for service applications under Propylene Dichloride#* 100% C C C -

any conditions. Propylene GlyCol* A A A A

Pyridine* A - A -

- Information not available.

Resorcinol satd A A A A

Salicylic Acid satd A A A A

Sea Water A A A A

Selenic Acid A A A A

# Plasticizer. Shortening* A A A A

Certain types of chemicals are Sliver Nitrate Soln A A A A

absorbed to varying degrees by poly- Soap Solutions* any conc A A A A

ethylene causing swelling, weight-gain,

Sodium Acetate satd A A A A

softening and some loss of yield

strength. These plasticizing materials Sodium Benzoate 35% A A A A

cause no actual chemical degrada- Sodium Biscarbonate satd A A A A

tion of the resin. Several of these Sodium Bisulphate satd A A A A

chemicals have a strong plasticizing

Sodium Bisulphite satd A A A A

effect (e.g. aromatic hydrocarbons

benzene), whereas others have weaker Sodium Borate A A A A

effects (e.g. gasoline). Certain plasti- Sodium Bromide dilute A A A A

cizers are sufficiently volatile that if Sodium Carbonate conc A A A A

they are removed from contact with

Sodium Chlorate satd A A A A

the polyethylene, the part will dry out

and return to its original condition with Sodium Chloride satd A A A A

no loss of properties. Sodium Cyanide A A A A

Sodium Dichromate satd A A A A

Sodium Ferri/Ferro

Cyanide satd A A A A

+ Oxidizers.

Sodium Fluoride satd A A A A

Oxidizers are the only group of materi-

als capable of chemically degrading

Sodium Hydroxide conc A A A A

polyethylene. The effects on the poly- Sodium Hypochlorite A A A A

ethylene may be gradual even for Sodium Nitrate A A A A

strong oxidizers and short-term effects Sodium Sulphate A A A A

may not be measurable. However, if

continuous long-term exposure is

Sodium Sulphide satd A A A A

intended, the chemical effects should Sodium Sulphite satd A A A A

be checked regularly. Stannic Chloride satd A A A A

Stannous Chloride satd A A A A

Starch Solution* satd A A A A

Stearic Acid* 100% A A A A

Sulphuric Acid 0-50% A A A A

Sulphuric Acid+ 70% A B A B

Sulphuric Acid+ 80% A C A C

Sulphuric Acid+ 96% B C B C

Sulphuric Acid+ 98-conc B C B C

Sulphuric Acid+ fuming C C C C

Sulphurous Acid A A A A

Tallow# A B A -

Tannic Acid* satd A A A A

Tartaric Acid A A A A

Tetrolydrofuran#* C C B C

Titanium Tetrochloride satd C C C -

Toluene#* C C B B

Trichloroethylene#* C C C C

Triethylene Glycol* A A A A

Trisodium Phosphate satd A A A A

CODES Turpentine# C C B B

Urea 0-30% A A A A

A Resistant no indication that Urine A A A A

serviceability would be

impaired. Vanilla Extract* A A A A

Vinegar A A A A

B Variable resistance, depending Water A A A A

on conditions of use. Wetting Agents* A A A A

C Unresistant, not recommended Whiskey* A A A A

for service applications under Wines* A A A A

any conditions. Xylene# C C B B

Yeast A A A A

- Information not available.

Zinc Bromide satd A A A A

Zinc Carbonate satd A A A A

Zinc Chloride satd A A A A

Zinc Oxide satd A A A A

# Plasticizer. Zinc Stearate A A A A

Certain types of chemicals are Zinc Sulphate satd A A A A

absorbed to varying degrees by poly-

ethylene causing swelling, weight-gain,

softening and some loss of yield

strength. These plasticizing materials

cause no actual chemical degrada-

tion of the resin. Several of these "All statements, technical information and recommendations contained herein are based on data CDF

chemicals have a strong plasticizing believes to be reliable, but the accuracy or completeness thereof is not guaranteed. Neither CDF nor its

effect (e.g. aromatic hydrocarbons suppliers shall be liable for any injury, loss, or damage, direct or consequential, arising out of the use of

benzene), whereas others have weaker or inability to use the data contained herein. The user assumes all risk and liability whatsoever in

effects (e.g. gasoline). Certain plasti- connection therewith."

cizers are sufficiently volatile that if

they are removed from contact with

the polyethylene, the part will dry out

and return to its original condition with

no loss of properties.

+ Oxidizers.

Oxidizers are the only group of materi-

als capable of chemically degrading

polyethylene. The effects on the poly-

ethylene may be gradual even for

strong oxidizers and short-term effects

may not be measurable. However, if

continuous long-term exposure is

intended, the chemical effects should

be checked regularly.

M-163-0704 RevA 7/2004

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Construction of Automatic Bell Siphons For Backyard Aquaponic SystemsDocument11 pagesConstruction of Automatic Bell Siphons For Backyard Aquaponic SystemsAquaponicsNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- FRIATEC 2019 Products RangeDocument108 pagesFRIATEC 2019 Products RangeGerryNo ratings yet

- EN 1092-1-Flange PDFDocument18 pagesEN 1092-1-Flange PDFSimona Adriana100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 33 11 00.13 - High Density Polyethylene (HDPE) PipeDocument7 pages33 11 00.13 - High Density Polyethylene (HDPE) PipeGerryNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Tutorial-Asme b311 With HdpeDocument42 pagesTutorial-Asme b311 With HdpeFabio Miguel100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- BR PE Spigot Products Range 2017Document27 pagesBR PE Spigot Products Range 2017GerryNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Isogen SupDocument1 pageIsogen SupGerryNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- InstruCalc Process Engineering PDFDocument1 pageInstruCalc Process Engineering PDFGerryNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- AquaDocument13 pagesAquaAnonymous 6EW2MsFbkNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Structural Lesson OneDocument17 pagesStructural Lesson OneCristhian Solano BazalarNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Adding Custom Pipe Supports To The CADWorx Specification EditorDocument15 pagesAdding Custom Pipe Supports To The CADWorx Specification Editordannilosky100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Introduction To CFD ModuleDocument46 pagesIntroduction To CFD ModulegeorgD2010No ratings yet

- Order Information Postage Address Order TotalDocument1 pageOrder Information Postage Address Order TotalGerryNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Intergraph CAS Knowledge Base Article CADWorxDocument4 pagesIntergraph CAS Knowledge Base Article CADWorxkemo10No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Vantec NST-610NU-N1 NexStar FX Gigabit NAS Enclosure ManualDocument37 pagesVantec NST-610NU-N1 NexStar FX Gigabit NAS Enclosure ManualGerryNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Vortex Tube PDFDocument9 pagesVortex Tube PDFGerryNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- CFDDocument7 pagesCFDwahtoiNo ratings yet

- Solexx Installation GuideDocument8 pagesSolexx Installation GuideGerryNo ratings yet

- README - Cadworx 2019 PDFDocument7 pagesREADME - Cadworx 2019 PDFGerryNo ratings yet

- Dell Driver Installation OrderDocument2 pagesDell Driver Installation OrderGerryNo ratings yet

- Eigenvalue Analysis of A Crankshaft: Solved With COMSOL Multiphysics 5.1Document6 pagesEigenvalue Analysis of A Crankshaft: Solved With COMSOL Multiphysics 5.1GerryNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Models - Ssf.forchheimer FlowDocument12 pagesModels - Ssf.forchheimer FlowGerryNo ratings yet

- Avity TutorialDocument10 pagesAvity TutorialgeorgD2010No ratings yet

- Subm Guidelines CAD2008Document14 pagesSubm Guidelines CAD2008Lim Kang HaiNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Subm Guidelines CAD2008Document14 pagesSubm Guidelines CAD2008Lim Kang HaiNo ratings yet

- 10a.spool - Municipal Project - Sample PDF.00.JPKDocument1 page10a.spool - Municipal Project - Sample PDF.00.JPKGerryNo ratings yet

- Subm Guidelines CAD2008Document14 pagesSubm Guidelines CAD2008Lim Kang HaiNo ratings yet

- 3D To 2D WorkflowDocument1 page3D To 2D WorkflowGerryNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Final Sent Technical Specification 14.03.2019Document16 pagesFinal Sent Technical Specification 14.03.2019harishNo ratings yet

- Dhulikhel RBB PDFDocument45 pagesDhulikhel RBB PDFnepalayasahitya0% (1)

- Portfolio Sandwich Game Lesson PlanDocument2 pagesPortfolio Sandwich Game Lesson Planapi-252005239No ratings yet

- Digital-To-Analog Converter - Wikipedia, The Free EncyclopediaDocument8 pagesDigital-To-Analog Converter - Wikipedia, The Free EncyclopediaAnilkumar KubasadNo ratings yet

- Annual Presentation 18 19 EILDocument41 pagesAnnual Presentation 18 19 EILPartha Pratim GhoshNo ratings yet

- Ref Drawing 2. Ref Code: 3. Design DatasDocument3 pagesRef Drawing 2. Ref Code: 3. Design DatasJoe Nadakkalan100% (3)

- Topic 3 Module 2 Simple Annuity (Savings Annuity and Payout Annuity)Document8 pagesTopic 3 Module 2 Simple Annuity (Savings Annuity and Payout Annuity)millerNo ratings yet

- Phrasal Verbs en Inglés.Document2 pagesPhrasal Verbs en Inglés.David Alexander Palomo QuirozNo ratings yet

- I. Ifugao and Its TribeDocument8 pagesI. Ifugao and Its TribeGerard EscandaNo ratings yet

- Law MCQ 25Document3 pagesLaw MCQ 25nonoNo ratings yet

- Computerised Project Management PDFDocument11 pagesComputerised Project Management PDFsrishti deoli50% (2)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SrsDocument7 pagesSrsRahul Malhotra50% (2)

- PTEG Spoken OfficialSampleTest L5 17mar11Document8 pagesPTEG Spoken OfficialSampleTest L5 17mar11Katia LeliakhNo ratings yet

- Biology Concepts and Applications 9th Edition Starr Solutions ManualDocument9 pagesBiology Concepts and Applications 9th Edition Starr Solutions Manualscarletwilliamnfz100% (31)

- 0apageo Catalogue Uk 2022Document144 pages0apageo Catalogue Uk 2022Kouassi JaurèsNo ratings yet

- 2062 TSSR Site Sharing - Rev02Document44 pages2062 TSSR Site Sharing - Rev02Rio DefragNo ratings yet

- IFE Level 4 Certificate in Fire InvestigationDocument16 pagesIFE Level 4 Certificate in Fire InvestigationMarlon FordeNo ratings yet

- Python PyDocument19 pagesPython Pyakhilesh kr bhagatNo ratings yet

- Applied Social Research A Tool For The Human Services 9th Edition Monette Test Bank 1Document36 pagesApplied Social Research A Tool For The Human Services 9th Edition Monette Test Bank 1wesleyvasquezmeoapcjtrb100% (25)

- UTM Firewalls: AR3050S and AR4050SDocument8 pagesUTM Firewalls: AR3050S and AR4050SChristian Javier Lopez DuranNo ratings yet

- International Beach Soccer Cup Bali 2023 October 4-7 - Ver 15-3-2023 - Sponsor UPDATED PDFDocument23 pagesInternational Beach Soccer Cup Bali 2023 October 4-7 - Ver 15-3-2023 - Sponsor UPDATED PDFPrincess Jasmine100% (1)

- Trading Book - AGDocument7 pagesTrading Book - AGAnilkumarGopinathanNairNo ratings yet

- Authenticating Digital EvidenceDocument36 pagesAuthenticating Digital Evidenceatty_gie3743No ratings yet

- 12 Layer PCB Manufacturing and Stack Up OptionsDocument12 pages12 Layer PCB Manufacturing and Stack Up OptionsjackNo ratings yet

- Statement 1680409132566Document11 pagesStatement 1680409132566úméshNo ratings yet

- Caracterisation D'une Entreprise anglosaxonne-ETLV - STMG1.Document2 pagesCaracterisation D'une Entreprise anglosaxonne-ETLV - STMG1.meredith.licagaNo ratings yet

- Course Specifications: Fire Investigation and Failure Analysis (E901313)Document2 pagesCourse Specifications: Fire Investigation and Failure Analysis (E901313)danateoNo ratings yet

- RAMSCRAM-A Flexible RAMJET/SCRAMJET Engine Simulation ProgramDocument4 pagesRAMSCRAM-A Flexible RAMJET/SCRAMJET Engine Simulation ProgramSamrat JanjanamNo ratings yet

- 面向2035的新材料强国战略研究 谢曼Document9 pages面向2035的新材料强国战略研究 谢曼hexuan wangNo ratings yet

- Genstat Release 10.3de (Pc/Windows 7) 28 May 2012 06:35:59Document6 pagesGenstat Release 10.3de (Pc/Windows 7) 28 May 2012 06:35:59Anna Nur HidayatiNo ratings yet