Professional Documents

Culture Documents

CFA Piling Method

Uploaded by

Anonymous 1HFV185Sl4Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CFA Piling Method

Uploaded by

Anonymous 1HFV185Sl4Copyright:

Available Formats

pp22-25CFA 7/12/08 12:15 PM Page 22

CFA Method of Drilled

Shaft Construction

Continuous flight augering can reduce costs and By Michael Zeman

accelerate project schedules.

FA is a method in which shafts with the exception that the finished and concrete placement, as well as many

C are drilled using a continuous

flight auger with concrete

placement occurring by pump-

ing through the augers hollow stem

product is much more like that of a con-

ventional drilled shaft. This is for two

reasons: First, high strength concrete

containing coarse aggregate is used in

other drill functions, to ensure that piles

are constructed to the proper depth and

that concrete is placed to the full diam-

eter of the specified pile. The quality

while it is extracted. There are numerous lieu of the sand/cement grout mixes control of these piles is extremely high

benefits to this approach, including common to ACIP piles. Second, CFA and can be monitored instantly not only

immediate replacement, zero subsi- piles utilize full length, standard rebar by the drill operator, but also by the

dence, lack of free water within the cages instead of short top cages and cen- engineers through offsite links to the

shaft, computer monitoring of depth ter bars. These differences are signifi- computer in the drill rig.

and concrete placement, and no need cant, as they increase the load capacity To better understand the CFA

for casing/slurry. This is the most com- of the piles, allow use in applications method and how it can be implemented

mon drilling method in the UK for with high lateral loads or seismic design to reduce cost and schedule duration of

small to medium diameter shafts and is criteria, and do not require significant public projects, it is important to under-

being heavily used by D. J. Scheffler a modification to standard drilled shaft stand the method in which a CFA shaft

specialist in deep foundation drilling designs or specifications. In addition to is constructed, as well as how it differs

and earth shoring work in difficult envi- the use of high strength concrete and from a conventional drilled shaft. At the

ronmentsin both California and the full length rebar cages, CFA piles also beginning of a shift, the pumping lines

Northwest. differ from ACIP piles in that the connecting the concrete pump to the

The CFA installation method is simi- onboard computer in the drill rigs cab rigs auger are primed and pre-charged

lar to auger cast piling systems (ACIP), continuously measures depth, rotation, with concrete. The drill rig is then posi-

tioned with its auger carefully centered

over the pin marking the shaft center

and the mast and auger are checked for

verticality. Drilling commences and as

the auger penetrates the ground, a small

quantity of soil rises to the surface. The

operator monitors the drilling process

using the real-time information on the

overhead screen; this information

includes drill resistance, torque, depth,

and penetration rate. The process con-

tinues until the preset tip elevation is

met.

Once the auger has reached the pile

tip, concrete is immediately pumped

through the auger. The auger is slowly

raised as concrete continues to flow, with

the operator monitoring the concrete

pressure and oversupply to ensure com-

plete replacement. During this part of

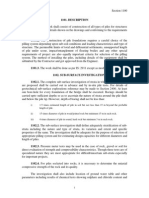

A steel elementeither a cage or steel beamis lowered into the fluid concrete by a the process, the soil is removed continu-

support crane. Note the heavy plastic wheel centralizers designed to center the steel ously from the auger as it is extracted. A

within the shaft. support excavator keeps the area around

22 GOVERNMENT ENGINEERING JULY-AUGUST 2008 www.govengr.com

pp22-25CFA 7/12/08 12:15 PM Page 23

6 Another significant difference is that

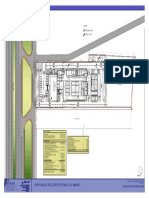

SOUTH WALL

MIRABELLA, Contract Number: 0800 there is no free water within a CFA

Length 10.04 m

610 mm diam CFA

Revs

Energy

99.5

7.04 MJ

Vol :

Excess :

3.7 m

26.12 %

Rig R516

Operator : STEVE 29/04/2008

shaft. In a conventional drilled shaft in

24in foundation

wet conditions, free water enters the

Penetration per rev Torque (MJm) Extraction Rate Oversupply Pressure Flow Profile

(mm/rev) (kN.m) Drill Resistance (m/min) (%) (bars) (mm) shaft and drilling is performed under a

0

0 100 0 20 40 0 2 4 0 5 10 0 20 0 1 2 3 -305 0 305 water or slurry head. However with

CFA, very little soil is removed from the

shaft until concrete placement begins,

2

only enough to displace the volume of

the auger flights. Concrete is placed

4 immediately as the auger is withdrawn,

preventing the accumulation of free

6

water in the shaft. This eliminates the

need for collection, storage, and dispos-

al of contaminated drilling fluids,

8

important concerns on many shaft proj-

ects.

10 From an efficiency standpoint, the

Depth (m)

0

1

2

largest difference is that the shaft is con-

3

4

5 structed in a continuous operation. In

6

7

8

9

CFA shafts, the auger is advanced to tip

10

12:58

104

12:59 13:00 13:01 13:02 13:03 13:04 13:05 13:06 13:07 13:08 13:09

in a single pass, concrete is placed as the

Auger Revs

95

86

77

auger is extracted, and the rebar cage is

68

59

50

immediately set into place. This differs

41

32

23

14

greatly from a conventional shaft in soft

5

12:58 12:59 13:00 13:01 13:02 13:03 13:04 13:05 13:06 13:07 13:08 13:09 or wet ground, in which the process of

drilling a single shaft includes advancing

Concrete Vol (m3)

2

casing, taking multiple passes with a

1 drill tool, cleaning the shaft bottom,

0

12:58 12:59 13:00 13:01 13:02 13:03 13:04 13:05 13:06 13:07 13:08 13:09

placing reinforcement, placing concrete

time

13:04

via tremie, extracting casing, and pump-

Piling instrumentation and control system. ing off displaced fluids. The elimination

of these extra steps often allows CFA

the auger free of excavated material. This While the final product is nearly shafts to be completed three to five

process continues until the auger is fully identical to a conventionally drilled times as quickly as a conventional

extracted from the shaft. The support shaft, there are significant differences in drilled shaft.

excavator clears away the remaining the installation process, each of which is One of the greatest advantages of the

spoils, and then the crew carefully hand important to consider when evaluating CFA method is improved safety for the

excavates any spoils or contaminated this method for a given project. Most drill crew and inspection team.

concrete at the top of the shaft until a importantly, there is never an open hole Every year, throughout the U. S.,

perfect circle of concrete is exposed to when drilling with the CFA method. there is a worker in our industry lost to

the full diameter of the pile. A support With conventional drilling techniques, a cave-in of a drilled shaft during con-

crane then lowers the steel element, the drill tool repeatedly enters and exits struction of conventional drilled shafts

whether it is a cage or steel beam, into the shaft, each time slowly advancing in less than ideal soil conditions. CFA

the fluid concrete of the shaft. In deep towards design tip elevation. To prevent methods significantly reduce these risks

shafts, or shafts drilled in dry granular the shaft from caving during this by immediately replacing soil with con-

material, it is often necessary to apply a process, slurry and/or casing is used to crete during extraction of the auger,

small amount of vibration to the steel provide support for the sidewalls in soft Dale Scheffler, president, D. J. Scheffler

element to assist with the cage insertion. or wet conditions. However, with the (www.djscheffler.com) says. This is a

The intent of this is not to force the steel CFA method, there is no open drill much safer method since there is never

into the concrete, but rather to simply hole, as it is fully supported by the auger an empty shaft.

assist the flow of the concrete around the and spoils during drilling, and support-

cage or beam. It should be noted that ed by the concrete as the auger is Design Considerations

centralizers, either rebar skids or heavy extracted. This eliminates the need for Typically, a CFA pile of equal depth

plastic wheels, are used to centralize the casing and slurry, both of which signifi- and diameter will have equal or slightly

steel within the shaft and to ensure prop- cantly add to the time and cost of shafts better load capacity when compared to a

er steel coverage. in soft or wet conditions. conventional drilled shaft. On projects

www.govengr.com GOVERNMENT ENGINEERING JULY-AUGUST 2008 23

pp22-25CFA 7/12/08 12:17 PM Page 24

eter shafts are often best constructed an invaluable benefit to Caltrans and the

using conventional methods. local community as a whole.

Pacific City Development,

Case Studies Huntington Beach, CA, Makar

The Scheffler companies have suc- Development, 2007. Pacific City is a

cessfully completed numerous projects large mixed use development located

using the CFA method, and are prepar- directly across from the famous

ing to start construction on several oth- Huntington Beach. The original foun-

ers within the next 12 months. The fol- dation design for the multiple structures

lowing are just a few examples, but they was based upon the use of precast con-

provide a range of applications under crete piles driven into the dense sands

which CFA is an ideal method to con- located at a depth of about 40 ft from

struct drilled shafts. ground surface. However, before con-

PCH Emergency Stabilization, struction of the residential portion of

Malibu, CA, Caltrans, 2005. Heavy the site, the developer became con-

runoff compromised a 50-year old cerned about the use of the driven pile

drainage pipe located 45 ft below grade, foundation system due to noise and

creating a depression in the Pacific Coast vibration levels in close proximity to

Highway. D. J. Scheffler was selected to existing homes and the adjacent hotel.

construct a secant pile wall with tiebacks Scheffler evaluated the load require-

along the centerline of the historic road- ments of the original foundation sys-

way. A series of overlapping 30-in. diam- tem, as well as the geotechnical condi-

Among the reasons CFA was used at eter piles were drilled to depths of up to tions of the site and determined that

Pacific City was the developer was 65 ft using the CFA method, creating a while a conventional drilled shaft foun-

concerned about the use of the driven pile continuous wall without the need for dation would be cost and schedule pro-

foundation system due to noise and wood lagging. In five working days, 61 hibitive, piles drilled using the CFA

vibrations so close to existing homes and

total piles were installed, less than one- method could easily achieve the

the adjacent hotel.

third the time it would have taken with required capacity at a lower cost than

that have already been designed for conventional methods. In addition, the the original driven foundation system.

drilled shafts, there is no need to switch company installed 32 tiebacks, each with After a series of pile tests, it was deter-

engineering methodology in order to an average length of 60 ft. Given the crit- mined not only that the CFA piles

benefit from the use of the CFA meth- ical nature of this roadway and the poten- exceeded the capacity of the driven piles

ods. Even in cases where redesign is tial impacts to motorists, the time in by a factor ratio of 2:1 (30-in. diameter,

required, the design effort is often more which this wall was constructed provided 55-in. depth), but that they also signifi-

than offset by the cost and time savings

during actual construction.

Despite the advantages of the CFA

method, there are some things that need

to be considered before specifying or

utilizing this method on a particular

project. First, the method does not allow

for efficient drilling though hard

bedrock conditions or large boulders.

Second, there is an effective limit in how

deep full length steel elements can be

wet set into a CFA shaft. While

advanced mix designs do allow cage

installation as deep as 80 ft, shafts

beyond this depth are typically best suit-

ed for conventional methods. Third, the

diameter of the shaft needs to be con-

sidered. CFA is commonly used on

drilled shafts up to 48 in. in diameter,

and occasionally up to 60 in. in diame-

ter. Beyond that, concrete supply limita-

tions typically reduce the efficiency of As opposed to auger cast piling systems, CFA delivers a finished product that is much

the method. For this reason, large diam- more like that of a conventional drilled shaft.

24 GOVERNMENT ENGINEERING JULY-AUGUST 2008 www.govengr.com

pp22-25CFA 7/12/08 12:18 PM Page 25

ing the poor quality, saturated soils pres-

ent in the upper 40 ft of the site.

Installation of roughly 800 piles, rang-

ing in depth from 40 to 55 ft, began this

spring.

BNSF Rail Expansion, Vancouver,

WA, 2008. This project includes the

construction of a 200-ft long secant pile

wall with 48-in. diameter primary and

secondary piles placed on 60-in. centers.

The ground conditions generally consist

of loose sandy silts over dense saturated

gravels. The primary secant piles con-

tain full length reinforcement cages with

up to 24 #11 bars and #5 spiral with

five-in. pitch. The reinforced piles range

from 35 ft to 80.5 ft in depth.

Construction began in May 2008 and

the use of CFA is expected to reduce the

construction schedule by roughly 40

At Pacific City the use of CFA easily achieved the required capacity at less cost than the working days. GE

original driven foundation system. Mr. Zeman is president of Scheffler

Northwest, a partner company of D. J.

cantly exceeded the calculated capacity sion to 1500 kips, with no sign of rap- Scheffler, Inc. located in Vancouver, WA. He

of conventional drilled shafts. Thirty-in. idly increasing settlement or other fail- can be reached at 360-818-0070 or

diameter piles were tested in compres- ure characteristics, remarkable consider- mzeman@schefflernw.com.

www.govengr.com GOVERNMENT ENGINEERING JULY-AUGUST 2008 25

You might also like

- Base Plate Connection DesignDocument4 pagesBase Plate Connection DesignAnonymous 1HFV185Sl4No ratings yet

- Rubble ConcreteDocument537 pagesRubble ConcreteRoshan Nanjundaiah100% (3)

- Ground improvement vs. pile foundations? Which is bestDocument66 pagesGround improvement vs. pile foundations? Which is best_seeNo ratings yet

- Instruction Manual for Capacitor Voltage TransformersDocument22 pagesInstruction Manual for Capacitor Voltage Transformerst.o.i.n.gNo ratings yet

- Deepa CVDocument3 pagesDeepa CVDeepa M PNo ratings yet

- On-Premise Family Stack Washer DryerDocument2 pagesOn-Premise Family Stack Washer Dryermairimsp2003No ratings yet

- Design and Construction of Auger Cast PilesDocument75 pagesDesign and Construction of Auger Cast PilesVetriselvan ArumugamNo ratings yet

- Libya Hotel DFI May-June-17Document7 pagesLibya Hotel DFI May-June-17Maurizio SiepiNo ratings yet

- Dymocks - Fundamentals of Engineering Fe Civil All-In-One Exam Guide by Indranil Goswami, 9781260011340, PaperBack BookDocument4 pagesDymocks - Fundamentals of Engineering Fe Civil All-In-One Exam Guide by Indranil Goswami, 9781260011340, PaperBack BookAnonymous 1HFV185Sl4No ratings yet

- Dymocks - Fundamentals of Engineering Fe Civil All-In-One Exam Guide by Indranil Goswami, 9781260011340, PaperBack BookDocument4 pagesDymocks - Fundamentals of Engineering Fe Civil All-In-One Exam Guide by Indranil Goswami, 9781260011340, PaperBack BookAnonymous 1HFV185Sl4No ratings yet

- Column Design Check SummaryDocument2 pagesColumn Design Check SummaryAnonymous 1HFV185Sl4No ratings yet

- Design Basis r0Document31 pagesDesign Basis r0Anonymous 1HFV185Sl4100% (1)

- Spreadsheets To BS 8110: RCA Pole Foundation RMW 113Document1 pageSpreadsheets To BS 8110: RCA Pole Foundation RMW 113Anonymous 1HFV185Sl4No ratings yet

- Load Tests Jet Grouting MacauDocument8 pagesLoad Tests Jet Grouting MacauMatteoTrigliaReatoNo ratings yet

- Effortless by Greg McKeownDocument6 pagesEffortless by Greg McKeownNaison StanleyNo ratings yet

- Brief of Evidence Tunnelling Construction: 1.1 Knowledge of The Site and Related ActivitiesDocument26 pagesBrief of Evidence Tunnelling Construction: 1.1 Knowledge of The Site and Related ActivitiesBhaskar ReddyNo ratings yet

- O-Cell® Load Testing For Drilled Shafts and Acip PilesDocument53 pagesO-Cell® Load Testing For Drilled Shafts and Acip PilesJose Eduardo GomezNo ratings yet

- Productivity Analysis of Diaphragm Wall Construction in Jurong FormationDocument8 pagesProductivity Analysis of Diaphragm Wall Construction in Jurong FormationAdeLyNo ratings yet

- PT. PAKUBUMI SEMESTA Bored Piling MethodDocument19 pagesPT. PAKUBUMI SEMESTA Bored Piling MethodjimdabrondNo ratings yet

- Diaphragm Wall Paper Hershey2005-Rev - NicholsonDocument18 pagesDiaphragm Wall Paper Hershey2005-Rev - NicholsonTargetRockNo ratings yet

- BS en 13139 PDFDocument10 pagesBS en 13139 PDFanilkumar_bojja97600% (1)

- Vertebrates and InvertebratesDocument4 pagesVertebrates and InvertebratesJane Aubrey Saligan100% (2)

- Report On Expansion Joint R-0Document15 pagesReport On Expansion Joint R-0Anonymous 1HFV185Sl4No ratings yet

- Report On Expansion Joint R-0Document15 pagesReport On Expansion Joint R-0Anonymous 1HFV185Sl4No ratings yet

- Kirby Erection ManualDocument56 pagesKirby Erection ManualHari PrasathNo ratings yet

- Diaphragm Wall - Soletanch BachyDocument4 pagesDiaphragm Wall - Soletanch BachymlakkissNo ratings yet

- CS - P08-1186 International Tower Capital CentreDocument4 pagesCS - P08-1186 International Tower Capital Centrefrog15No ratings yet

- Wittke, W, Pierau, B and Erichsen, C - New Austrian Tunneling Method (NATM) Stability PDFDocument419 pagesWittke, W, Pierau, B and Erichsen, C - New Austrian Tunneling Method (NATM) Stability PDFCalin MateiNo ratings yet

- Lahore ResolutionDocument6 pagesLahore ResolutionMZCHOHAN100% (1)

- Effect of Duration of Curing On Compressive Strength of ConcreeeteDocument50 pagesEffect of Duration of Curing On Compressive Strength of ConcreeetealexomputuNo ratings yet

- Soil NailedDocument13 pagesSoil NailedBina QSNo ratings yet

- SLS-T Allgemein VMT - JMDocument65 pagesSLS-T Allgemein VMT - JMjmtexla680% (1)

- 1.8 Method Statement - Soil Nailing and Guniting SursbDocument5 pages1.8 Method Statement - Soil Nailing and Guniting SursbfatinNo ratings yet

- Improving Soil with Stone ColumnsDocument6 pagesImproving Soil with Stone ColumnsmooolkaNo ratings yet

- Manufacture of Precast Tunnel LiningDocument14 pagesManufacture of Precast Tunnel LiningvolminkNo ratings yet

- TenCate GeocontainerDocument30 pagesTenCate GeocontainerpjgomezdNo ratings yet

- Expansive Cements PDFDocument33 pagesExpansive Cements PDFbardha50% (2)

- 4880 - 6-Tunnel Support PDFDocument12 pages4880 - 6-Tunnel Support PDFGarg TjNo ratings yet

- 1974 - CivilEng - Seminars - Reinforced Concrete PipeDocument52 pages1974 - CivilEng - Seminars - Reinforced Concrete PipeChen YishengNo ratings yet

- Tunnel Boring MachineDocument2 pagesTunnel Boring MachineAshfaq AminNo ratings yet

- DGMS Circular No7 (1997) - IndiaDocument4 pagesDGMS Circular No7 (1997) - IndiaAntónio Nôro0% (1)

- During Tremie Concreting The Following Precautions Are To Be Taken While Doing The WorkDocument2 pagesDuring Tremie Concreting The Following Precautions Are To Be Taken While Doing The WorkRaghavendraNo ratings yet

- Evaluation of Grouting For Hydraulic Barriers in RockDocument13 pagesEvaluation of Grouting For Hydraulic Barriers in RockshenNo ratings yet

- Construction of Concrete Pavement in Packages II-A, II-B and II-C (World Bank Project) at Kanpur - A Case StudyDocument51 pagesConstruction of Concrete Pavement in Packages II-A, II-B and II-C (World Bank Project) at Kanpur - A Case StudyRavindra Babu SivapuNo ratings yet

- Dectecting Defects in Diaphragm Walls Prior To ExcavationDocument14 pagesDectecting Defects in Diaphragm Walls Prior To ExcavationbobbyccwNo ratings yet

- Seepage and Contraction Joints in Concrete Canal LiningDocument25 pagesSeepage and Contraction Joints in Concrete Canal LiningRohan ShivasundarNo ratings yet

- Laying Asphaltic Concrete MethodDocument3 pagesLaying Asphaltic Concrete MethodFa DylaNo ratings yet

- Detailed Estimate of Stree Shakti BhavanDocument9 pagesDetailed Estimate of Stree Shakti BhavanObuladas MNo ratings yet

- Method Statement For Prestressing of HT StrandsDocument3 pagesMethod Statement For Prestressing of HT StrandsBhanu Prasad EdemNo ratings yet

- Bill of Quantity For Drilling of Twenty BoreholesDocument1 pageBill of Quantity For Drilling of Twenty BoreholesAnonymous OeoeVBmwNo ratings yet

- Code of Practice For Reinforcement of Rock Slopes With Plane Wedge FailureDocument16 pagesCode of Practice For Reinforcement of Rock Slopes With Plane Wedge FailurePabloNo ratings yet

- Standards Manuals of Mechanized TunnellingDocument2 pagesStandards Manuals of Mechanized TunnellingproectNo ratings yet

- ..-HKIE-download-Tunnel Related Failures PDFDocument11 pages..-HKIE-download-Tunnel Related Failures PDFAbdelali SolNo ratings yet

- Piling Equipments DMC Augur PDFDocument11 pagesPiling Equipments DMC Augur PDFgeosnovaNo ratings yet

- Aker Wirth - Tunnel Boring Machines, Raise Boring and Full-Face Shaft Boring Machines - Mining Technology PDFDocument2 pagesAker Wirth - Tunnel Boring Machines, Raise Boring and Full-Face Shaft Boring Machines - Mining Technology PDFFord cellNo ratings yet

- Construction of Slurry WallsDocument22 pagesConstruction of Slurry WallsJOE G PHILIP CENo ratings yet

- CCECC MAX DCRP BR 18 F 0062 General Method StatementDocument140 pagesCCECC MAX DCRP BR 18 F 0062 General Method StatementArman ShohelNo ratings yet

- Methodology For PQC (00) Toll Plaza L&TDocument4 pagesMethodology For PQC (00) Toll Plaza L&TDeven PatleNo ratings yet

- Construction Joints in RaftDocument1 pageConstruction Joints in RaftS.m. MoniruzzamanNo ratings yet

- Wbi Print6 0Document13 pagesWbi Print6 0milan_popovic_2100% (1)

- SCC Guide: Self-Compacting Concrete Mix Design and PropertiesDocument27 pagesSCC Guide: Self-Compacting Concrete Mix Design and PropertiesAbsiye Aden0% (1)

- Common Defects in Concrete Form Work SystemsDocument4 pagesCommon Defects in Concrete Form Work Systemsvenkateswara rao pothinaNo ratings yet

- Clay BlanketDocument2 pagesClay BlanketAhmed Tarek100% (1)

- Plate Load Test Execution 4.1 Equipment: 20.11.12 Structural Backfilling - Tech. Specs 2249 88 01 12 16Document3 pagesPlate Load Test Execution 4.1 Equipment: 20.11.12 Structural Backfilling - Tech. Specs 2249 88 01 12 16mohammad.a.d94No ratings yet

- Method Statement Horizontal DrainDocument1 pageMethod Statement Horizontal DrainAlsonChin100% (1)

- 11.sec.1100 (Pile Foundations)Document18 pages11.sec.1100 (Pile Foundations)Rakesh ParaliyaNo ratings yet

- Pradhan Mantri Gram Sadak Yojana Cost Estimate For Road Construction Package CG03-234Document4 pagesPradhan Mantri Gram Sadak Yojana Cost Estimate For Road Construction Package CG03-234Lucky TraderNo ratings yet

- When has soil liquefaction occurred in the pastDocument11 pagesWhen has soil liquefaction occurred in the pastAhmed AbbasNo ratings yet

- Inh Eurock 04Document16 pagesInh Eurock 04elisa02No ratings yet

- CFA Piles: A Concise Guide to Continuous Flight Auger Pile ConstructionDocument16 pagesCFA Piles: A Concise Guide to Continuous Flight Auger Pile ConstructionwefNo ratings yet

- Cast-in-Situ Bored Piles ProcedureDocument2 pagesCast-in-Situ Bored Piles ProcedureKhin Sandi KoNo ratings yet

- Full Displacement Screwpile Installation Sequence: D C B ADocument1 pageFull Displacement Screwpile Installation Sequence: D C B AAlexander SkywalkerNo ratings yet

- Case StudyDocument4 pagesCase StudyShekharNo ratings yet

- Vertical Drain Coir FiberDocument7 pagesVertical Drain Coir FiberKyle Johnson ChuaNo ratings yet

- Mst-Civ-001 r1 Ug TankDocument18 pagesMst-Civ-001 r1 Ug TankAnonymous 1HFV185Sl4No ratings yet

- Report Zone 7 - Duct Only R0Document104 pagesReport Zone 7 - Duct Only R0Anonymous 1HFV185Sl4No ratings yet

- Site Instructon 44 (Civil)Document1 pageSite Instructon 44 (Civil)Anonymous 1HFV185Sl4No ratings yet

- NSPE Code of Ethics For EngineersDocument2 pagesNSPE Code of Ethics For EngineersYob YnnosNo ratings yet

- Devajith USA Visa FormDocument5 pagesDevajith USA Visa FormAnonymous 1HFV185Sl4No ratings yet

- Exam 1 - 001Document26 pagesExam 1 - 001Jose Carlos ArgeñalNo ratings yet

- Proposed 3S Facilities For Sba at Al AmaratDocument1 pageProposed 3S Facilities For Sba at Al AmaratAnonymous 1HFV185Sl4No ratings yet

- Structural analysis reportDocument4 pagesStructural analysis reportAnonymous 1HFV185Sl4No ratings yet

- Report On Expansion Joint R-0Document13 pagesReport On Expansion Joint R-0Anonymous 1HFV185Sl4No ratings yet

- Crack Width Check BS5400 4Document6 pagesCrack Width Check BS5400 4Anonymous 1HFV185Sl4No ratings yet

- Seismicity UAEDocument22 pagesSeismicity UAEabdulmananNo ratings yet

- 24-May-19 11-Jun-2019 00:57 Pipesupport4M - B.STD: Job No Sheet No RevDocument6 pages24-May-19 11-Jun-2019 00:57 Pipesupport4M - B.STD: Job No Sheet No RevAnonymous 1HFV185Sl4No ratings yet

- My 19 Aveo e Brochure enDocument2 pagesMy 19 Aveo e Brochure enAnonymous 1HFV185Sl4No ratings yet

- Diet ChartDocument2 pagesDiet ChartAnonymous 1HFV185Sl4No ratings yet

- Sultanate of Oman: Foundation Reinforcement - Cross SectionDocument2 pagesSultanate of Oman: Foundation Reinforcement - Cross SectionAnonymous 1HFV185Sl4No ratings yet

- Design CalculationDocument228 pagesDesign CalculationAnonymous 1HFV185Sl4No ratings yet

- Design CalculationDocument228 pagesDesign CalculationAnonymous 1HFV185Sl4No ratings yet

- My 19 Aveo e Brochure enDocument2 pagesMy 19 Aveo e Brochure enAnonymous 1HFV185Sl4No ratings yet

- Minutes of MeetingDocument2 pagesMinutes of MeetingAnonymous 1HFV185Sl4No ratings yet

- 02-Jul-16 04-May-2019 01:30 Pole10m - 0.std: Job No Sheet No RevDocument1 page02-Jul-16 04-May-2019 01:30 Pole10m - 0.std: Job No Sheet No RevAnonymous 1HFV185Sl4No ratings yet

- Structural Design Brief: PreambleDocument6 pagesStructural Design Brief: PreambleAnonymous 1HFV185Sl4No ratings yet

- MR - Abhishek JiDocument4 pagesMR - Abhishek Jimalikgaurav01No ratings yet

- Industrial Training, at DCCPPDocument26 pagesIndustrial Training, at DCCPPGaganil SharmaNo ratings yet

- Lesson 5 The 19th Century PhilippinesDocument5 pagesLesson 5 The 19th Century PhilippinesJoquem PamesaNo ratings yet

- WHIRLPOOL AWE 2214 User ManualDocument19 pagesWHIRLPOOL AWE 2214 User ManualSilvestru NemorovNo ratings yet

- Kiribati, Gilbertese BibleDocument973 pagesKiribati, Gilbertese BibleAsia BiblesNo ratings yet

- Right to Personal Liberty and Judicial Process in IndiaDocument636 pagesRight to Personal Liberty and Judicial Process in IndiaDrDiana PremNo ratings yet

- National Artists of the PhilippinesDocument66 pagesNational Artists of the Philippinesshey mahilumNo ratings yet

- An Evaluation of Maglev Technology and Its Comparison With High Speed Rail PDFDocument20 pagesAn Evaluation of Maglev Technology and Its Comparison With High Speed Rail PDFJohanFaqar ZainNo ratings yet

- Sexual ExtacyDocument18 pagesSexual ExtacyChal JhonnyNo ratings yet

- Using The 12c Real-Time SQL Monitoring Report History For Performance AnalysisDocument39 pagesUsing The 12c Real-Time SQL Monitoring Report History For Performance AnalysisJack WangNo ratings yet

- Laplace Transform solved problems explainedDocument41 pagesLaplace Transform solved problems explainedduchesschloeNo ratings yet

- Importance of Decision Tree AnalysisDocument3 pagesImportance of Decision Tree AnalysisJean Grace Agustin BelmonteNo ratings yet

- Sujet Dissertation Sciences PolitiquesDocument7 pagesSujet Dissertation Sciences PolitiquesDoMyPaperSingapore100% (1)

- Tauros TBM Guidance SystemDocument3 pagesTauros TBM Guidance SystemMiloš StanimirovićNo ratings yet

- Yealink Device Management Platform: Key FeaturesDocument3 pagesYealink Device Management Platform: Key FeaturesEliezer MartinsNo ratings yet

- Symbolic Calculus Sage ReferenceDocument25 pagesSymbolic Calculus Sage ReferenceLn Amitav BiswasNo ratings yet

- Role and Function of Government As PlanningDocument6 pagesRole and Function of Government As PlanningakashniranjaneNo ratings yet

- Orbeez Sorting and Patterns Learning ExperienceDocument5 pagesOrbeez Sorting and Patterns Learning Experienceapi-349800041No ratings yet

- Lab ReportDocument11 pagesLab Reportkelvinkiplaa845No ratings yet

- Advanced Java Thread Lab ExercisesDocument9 pagesAdvanced Java Thread Lab ExercisesafalonsoNo ratings yet

- Inner Ear Balance ProblemsDocument6 pagesInner Ear Balance ProblemsaleiyoNo ratings yet

- Durgah Ajmer Sharif 1961Document19 pagesDurgah Ajmer Sharif 1961Deepanshu JharkhandeNo ratings yet

- Holiday Tradition Lesson PlanDocument2 pagesHoliday Tradition Lesson Planapi-458585393No ratings yet

- ZetaPlus EXT SP Series CDocument5 pagesZetaPlus EXT SP Series Cgeorgadam1983No ratings yet

- Basic Brake System: Group 35ADocument26 pagesBasic Brake System: Group 35AJBNo ratings yet