Professional Documents

Culture Documents

Quality assurance plan for structural & mechanical couplings

Uploaded by

umashankarsinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality assurance plan for structural & mechanical couplings

Uploaded by

umashankarsinghCopyright:

Available Formats

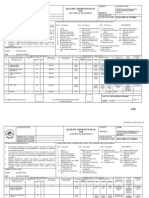

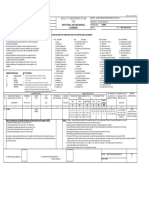

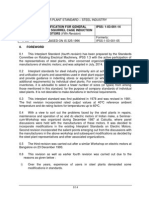

Annexure II

CONTRACTOR Bhilai Engineering Corporation Ltd. CLIENT NMDC Ltd. Nagarnar, Chhatishgarh(India)

CONTRACT NO .& Coke Oven Complex (PKG-02) OF 3.0 MTA INTEGRATED STEEL PLANT

HO(Contracts)NISP/CO/09 DT.06.09.2011 PROJECT

Date QUALITY ASSURANCE PLAN AT NAGARNAR

FOR PACKAGE

SUB/CONTRACTOR - STRUCTURAL & MECHANICAL EQUIPMENT 2

NAME

(COUPLINGS)

ORDER NO.& Date -

INSTRUCTIONS FOR FILLING UP : CODES FOR EXTENT OF INSPECTION, TESTS, TEST CERTIFICATES & DOCUMENTS :

QAP shall be submitted for each of the equipment separately with break-up of assembly/ sub - Description DOCUMENTS

1 Code Description Code Code Description

assembly & part/component or for group of equipment having the same specification.

1 Visual ( Welding etc.) 16 Balancing 31 Surface preparation D1 Approved G.A drawings

2 Dimensional 17 Vibration Test 32 Manufacture's test certifi- D2 Information & Other

3 Fitness & Alignment 18 Amplitude Test cates for boughtouts items reference drg. / stamped

2 4 Physical Test (Sample) 19 Sponge Test 33 IBR/Other Statutory drgs.released for drg.

Use numerical codes as indicated for extent of inspection & tests and submission of test

certificateds & documents. Additional codes & description for extent of inspection & tests may be 5 Chemical Test (Sample) 20 Dust water integral Test Agencies Complaince D3 Relevant Catalogues

added as applicable for the plants & equipment.

6 Ultrasonic Test 21 Friction factor Test certificates D4 Bill of matl./item No./

7 Magnetic Particle Test 22 Adhesion Test 34 Internal inspection report by Identification Relevant

3 8 Radiography Test 23 Performance test / contractor catalogues

Separate indentification number with quantity for each equipment shall be furnished. Wherever

9 Dye Penetration Test Characteristic curve 35 Hardness Test D5 Match mark details.

equipment having same specifications but belonging to different facilities are grouped together.

10 Metallographic Exam. 24 No Load/Free running Test 36 Spark Test for Lining D6 Line / Layout diagram.

11 Welder Qualification & 25 Load/Over Load test 37 Calibration D7 Approved Erection

4 Weight in tonnes (T) must be indicated under column 5 for each item. Examined weights may be weld procedure test. 26 Measurement of speed 38 Safety Device Test procedures.

indicated whenever actual weights are not available. Approval of Test and Unpriced sub p.o. with specification

12 27 Acquistical test 39 Ease of maintenance D8

Repair procedure and

13 Heat treatment 28 Geometrical Accuracy 40 Thickness Mesurement of ammendments if any.

zinc Coating

Repeatability & Positioning Calibration Certificate of all measuring

14 Pressure test 29 D9

Accuracy instruments & Gauges

ABBREVIATIONS USED : 15 Leakage test 30 Proving test 41 D10 Ordering Specification

Operational and Functional

CONTR : CONTRACTOR W : Witness D11 Test Certificate from MFR

MFR : MANUFACTURER R : Review 42 Deflection Test D12 Test Specification

43 Stress Reliving D13 Gurantee Cirtificate

Test Certificates & Acceptance criteria

Documents to be Standards (IS/BS

EQUIPMENT DETAILS INSPECTION AND TESTS REMARKS / Sampling plan.

submitted to /ASME/ Norms

NMDC. and documents)

Description (with

Equipment Heading, QUANTITY Raw Material and inProcess

Manufacture's Expected Final Inspection / Test by

Identification No/ Stage inspection

SL.No Place of use & brief NO./ M Tons Name & Schedule For

specifications. BS NO.

Address Final Insp. MECON/

MFR BEC MFR BEC MECON/ NMDC

(MT) NMDC

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12) (13) (14) (15) (16)

Conveyor

32,34,D9,D11,

1 GEAR COUPLING NB 04 Nos - Approve Make May-16 1,2,4,5,6 - - 1,2, - R D1,D2,D3

D13

2 FLUID COUPLING NB 04 Nos - Approve Make May-16 2,3,4,5,6 - - 2,3,15,16,24 - R 32,34,D13 D1,D4,D10

QAP No. NMDC/BEC/02/00/00/DE/8038

REV. 0

SHEET 1 OF 1

For MECON (Stamp & Signature) For BEC MECON QAP No.

You might also like

- 12 - 254624-400-Pl-Int-001 QapDocument2 pages12 - 254624-400-Pl-Int-001 QapNerudaArarNo ratings yet

- QAP Plan Elect.Document2 pagesQAP Plan Elect.insap_dineshNo ratings yet

- Annexure - 1 User Manual For IMSDocument221 pagesAnnexure - 1 User Manual For IMSSumantrra ChattopadhyayNo ratings yet

- Quality assurance plan for upper material flow control wallDocument1 pageQuality assurance plan for upper material flow control walluday narayan singhNo ratings yet

- JSW COB#3B and COB#4B Quality Assurance PlanDocument1 pageJSW COB#3B and COB#4B Quality Assurance PlanMd ArshadNo ratings yet

- Qap - LR BendDocument1 pageQap - LR BendMecon LtdNo ratings yet

- Qap - TCP-PCP-HPCLDocument2 pagesQap - TCP-PCP-HPCLAashish MoyalNo ratings yet

- Blustar NMDC Qap R0 14 01 2017Document1 pageBlustar NMDC Qap R0 14 01 2017koushik42000No ratings yet

- Qap - LR BendDocument1 pageQap - LR BendSachin KumarNo ratings yet

- 6 - Testing & Commissioning Data - ItpDocument10 pages6 - Testing & Commissioning Data - ItpzainahmedscribdNo ratings yet

- Qap-Bv, PV, GVDocument10 pagesQap-Bv, PV, GVSachin KumarNo ratings yet

- Inspection Test Plan Fuel Gas Conditioning SkidDocument19 pagesInspection Test Plan Fuel Gas Conditioning SkidDin AizuNo ratings yet

- Project Logo Inspection Test Plan for Plastering WorksDocument5 pagesProject Logo Inspection Test Plan for Plastering WorksMohasin KhanNo ratings yet

- Test Form - FormatDocument1 pageTest Form - FormatThiraviam AyyappanNo ratings yet

- Manual valve inspection data sheetDocument2 pagesManual valve inspection data sheetkais rguiguiNo ratings yet

- MRR NO.021 Jetec PO 962922446 PT. Multitek Electrical Pressure Switch PrintDocument3 pagesMRR NO.021 Jetec PO 962922446 PT. Multitek Electrical Pressure Switch PrintSuhendrik Abi NayaNo ratings yet

- Form No. 11.20 Quality Assurance PlanDocument2 pagesForm No. 11.20 Quality Assurance PlanPooja TripathiNo ratings yet

- QAP IP Format Electrical Instrumentation APEDocument2 pagesQAP IP Format Electrical Instrumentation APEKoushik DeyNo ratings yet

- QAP for Flange InspectionDocument2 pagesQAP for Flange InspectionGOPINATH KRISHNAN NAIRNo ratings yet

- Construct Facilities Support MH-60R AircraftDocument3 pagesConstruct Facilities Support MH-60R AircraftAlvene TagocNo ratings yet

- Dokumen - Tips 3itp-ElectricalDocument28 pagesDokumen - Tips 3itp-ElectricalKyle WadsworthNo ratings yet

- Loop Test ProcedureDocument13 pagesLoop Test ProcedureAlia RedhaNo ratings yet

- Technical - Specification 2021 10 26 10 - 03 - 02Document30 pagesTechnical - Specification 2021 10 26 10 - 03 - 02adigupt2003No ratings yet

- Client:: Sritech Electronics Systems PVT LTDDocument2 pagesClient:: Sritech Electronics Systems PVT LTDESHWAR CHARYNo ratings yet

- QAP For MS FittingsDocument2 pagesQAP For MS FittingsMrityunjoy BarNo ratings yet

- Material Requisition For Instrument and Fire & Gas Cables Rev. CDocument1 pageMaterial Requisition For Instrument and Fire & Gas Cables Rev. CPrabhat RanjanNo ratings yet

- Tank Erection Itp Org ChartDocument34 pagesTank Erection Itp Org Chartvasantha kumar100% (1)

- Gas Engine Generator ITRDocument210 pagesGas Engine Generator ITRShawn RainNo ratings yet

- DR Documents_Rev 7 updated (1)Document171 pagesDR Documents_Rev 7 updated (1)Rakesh SNo ratings yet

- 0297 - Deluge SystemsDocument11 pages0297 - Deluge SystemsMohamed ElsayedNo ratings yet

- TECH_FINAL-1Document200 pagesTECH_FINAL-1dhruba30No ratings yet

- FOR Approval Specification: 32.0" Wxga TFT LCD TitleDocument41 pagesFOR Approval Specification: 32.0" Wxga TFT LCD TitleJesusNo ratings yet

- BorWin6 Page 5Document1 pageBorWin6 Page 5Kiran VargheseNo ratings yet

- Itp For Installation of Ahu FahuDocument1 pageItp For Installation of Ahu FahuSamer AliNo ratings yet

- 10p125-I0001-001-0-Instrument IndexDocument137 pages10p125-I0001-001-0-Instrument IndexMonaNo ratings yet

- QAP ITP Bhogat - REV-01Document8 pagesQAP ITP Bhogat - REV-01Ramkunwar YadavNo ratings yet

- GM 1927-16b Injection Molding Process AuditDocument6 pagesGM 1927-16b Injection Molding Process AuditfernandoNo ratings yet

- Binh Nguyen Solar Power Plant Electrical System ITPDocument184 pagesBinh Nguyen Solar Power Plant Electrical System ITPbinhnguyen dmtNo ratings yet

- (Itp for Cast Insitu Foundation )4172-Genon-1!25!0002-ADocument45 pages(Itp for Cast Insitu Foundation )4172-Genon-1!25!0002-ARajesh SinghNo ratings yet

- Nozzle LoadDocument14 pagesNozzle LoadOluwachidi100% (3)

- ITP-Joint Box - FAT PDFDocument3 pagesITP-Joint Box - FAT PDFPrabhakar SvNo ratings yet

- ITP-Joint Box - FATDocument3 pagesITP-Joint Box - FATPrabhakar SvNo ratings yet

- R03 C03B01 Mag MTS Ci 0006 - 01Document26 pagesR03 C03B01 Mag MTS Ci 0006 - 01Syed AliNo ratings yet

- Technical Specification for Wet Limestone FGD AgitatorsDocument74 pagesTechnical Specification for Wet Limestone FGD Agitatorsnaresh kumarNo ratings yet

- Technical Doc. - Coated Steel Pipe LayingDocument420 pagesTechnical Doc. - Coated Steel Pipe Layingrex0% (1)

- Company Logo Project Name / No.: Inspection & Test PlanDocument3 pagesCompany Logo Project Name / No.: Inspection & Test PlanAmr HamedNo ratings yet

- Itp STR Slpg-Q-0000-24001-032-001-4-ADocument11 pagesItp STR Slpg-Q-0000-24001-032-001-4-AsivagnanamNo ratings yet

- ACDEDE PR-136 Test Pack HT Dossier Front CoverDocument1 pageACDEDE PR-136 Test Pack HT Dossier Front CoverMassimo FumarolaNo ratings yet

- Etihad Towers Project: Inspection & Test Plan - Hollow Core SlabsDocument2 pagesEtihad Towers Project: Inspection & Test Plan - Hollow Core SlabsjiniNo ratings yet

- Tbe Field Joint Coating For TialDocument3 pagesTbe Field Joint Coating For TialPer Bagus HandokoNo ratings yet

- Epcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitDocument7 pagesEpcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitKunalNo ratings yet

- PaintingDocument22 pagesPaintingAmit Kumar MilanNo ratings yet

- 6143-MAR-EU-1029 - R0 (1) Approved MAR For Terminal Lug & Cable Accessories (Speedwell)Document55 pages6143-MAR-EU-1029 - R0 (1) Approved MAR For Terminal Lug & Cable Accessories (Speedwell)NAVANEETHNo ratings yet

- GroutingDocument1 pageGroutingAlif Rahmat FebriantoNo ratings yet

- Saic L 2008Document4 pagesSaic L 2008babjihanumanthuNo ratings yet

- QCTR-A-2013 Rev 0Document2 pagesQCTR-A-2013 Rev 0Madhan KannanNo ratings yet

- MR For DRA Injection Package Rev-ADocument60 pagesMR For DRA Injection Package Rev-AvaibhavNo ratings yet

- FOR Approval Specification: 32.0" Wxga TFT LCD TitleDocument41 pagesFOR Approval Specification: 32.0" Wxga TFT LCD Titlehugoroberto393No ratings yet

- Microturbines: Applications for Distributed Energy SystemsFrom EverandMicroturbines: Applications for Distributed Energy SystemsRating: 5 out of 5 stars5/5 (1)

- TATAMOTORS Share Price Target - Tata Motors Limited NSE INDIA Chart AnalysisDocument4 pagesTATAMOTORS Share Price Target - Tata Motors Limited NSE INDIA Chart AnalysisumashankarsinghNo ratings yet

- EICHERMOT Share Price Target - Eicher Motors Limited NSE INDIA Chart AnalysisDocument4 pagesEICHERMOT Share Price Target - Eicher Motors Limited NSE INDIA Chart AnalysisumashankarsinghNo ratings yet

- Skipper Mobile Dual Dumper Placer 3m3 and 5 m3Document4 pagesSkipper Mobile Dual Dumper Placer 3m3 and 5 m3umashankarsinghNo ratings yet

- Equivalent TableDocument1 pageEquivalent Tableliamcs88% (8)

- EICHERMOT Share Price Target - Eicher Motors Limited NSE INDIA Chart AnalysisDocument4 pagesEICHERMOT Share Price Target - Eicher Motors Limited NSE INDIA Chart AnalysisumashankarsinghNo ratings yet

- PumpDocument1 pagePumpumashankarsinghNo ratings yet

- Phisibility Report in DairyDocument8 pagesPhisibility Report in DairyumashankarsinghNo ratings yet

- EICHERMOT Share Price Target - Eicher Motors Limited NSE INDIA Chart AnalysisDocument4 pagesEICHERMOT Share Price Target - Eicher Motors Limited NSE INDIA Chart AnalysisumashankarsinghNo ratings yet

- TR-4 ExcelDocument2 pagesTR-4 ExcelumashankarsinghNo ratings yet

- Dairy FarmingDocument104 pagesDairy FarmingumashankarsinghNo ratings yet

- XL Dairy v2015Document790 pagesXL Dairy v2015umashankarsinghNo ratings yet

- QhlogsDocument1 pageQhlogsMohit KoladiaNo ratings yet

- Boiler StructureDocument100 pagesBoiler StructureumashankarsinghNo ratings yet

- HydDocument1 pageHydumashankarsinghNo ratings yet

- Eligibility Criteria EngDocument4 pagesEligibility Criteria EngumashankarsinghNo ratings yet

- Is 3443 Crane RailsDocument18 pagesIs 3443 Crane RailsramyaNo ratings yet

- Hemant ResumeDocument3 pagesHemant ResumeumashankarsinghNo ratings yet

- Tool SDocument3 pagesTool SumashankarsinghNo ratings yet

- Project Report Dary FarmDocument7 pagesProject Report Dary FarmAbdul Hakim ShaikhNo ratings yet

- Farm Model Project of Dairy Unit of 10 Buffaloes: OwnerDocument4 pagesFarm Model Project of Dairy Unit of 10 Buffaloes: OwnerumashankarsinghNo ratings yet

- Farm Model Project of Dairy Unit of 10 Buffaloes: OwnerDocument4 pagesFarm Model Project of Dairy Unit of 10 Buffaloes: OwnerumashankarsinghNo ratings yet

- Project Report For Dairy Farm Ten CowsDocument10 pagesProject Report For Dairy Farm Ten CowsumashankarsinghNo ratings yet

- 1 03 001 14Document14 pages1 03 001 14umashankarsinghNo ratings yet

- Farm Model Project of Dairy Unit of 10 Buffaloes: OwnerDocument4 pagesFarm Model Project of Dairy Unit of 10 Buffaloes: OwnerumashankarsinghNo ratings yet

- Static CalcDocument24 pagesStatic CalcReba PratamaNo ratings yet

- Book 1Document3 pagesBook 1umashankarsinghNo ratings yet

- 10bffaloe Farm (Private Loan)Document6 pages10bffaloe Farm (Private Loan)umashankarsinghNo ratings yet

- 1 03 001 14Document14 pages1 03 001 14umashankarsinghNo ratings yet

- UMA 001 ActivitiesDocument4 pagesUMA 001 ActivitiesumashankarsinghNo ratings yet

- Filters and Beam Restrictors in RadiologyDocument19 pagesFilters and Beam Restrictors in RadiologyPratap singhNo ratings yet

- Electrostatic PrecipitatorDocument12 pagesElectrostatic PrecipitatorchandraNo ratings yet

- Chem16 LE3 SamplexDocument3 pagesChem16 LE3 SamplexmariemfranciscoNo ratings yet

- Solar Oven Challenge ReportDocument7 pagesSolar Oven Challenge Reportapi-311233754No ratings yet

- ASTM B333 Ni-Mo PlateDocument5 pagesASTM B333 Ni-Mo PlateElankumaran PeriakaruppanNo ratings yet

- Stoichiometry Notes - 2014 KEYDocument10 pagesStoichiometry Notes - 2014 KEY5020NitinNo ratings yet

- 2018 Gen Ed Reviewer: Chemistry: Welcome To LET Exam Questions and Answers!!!Document28 pages2018 Gen Ed Reviewer: Chemistry: Welcome To LET Exam Questions and Answers!!!Christine Grace IlanNo ratings yet

- Experimental Investigation of Optimum Feed Hole Position For Plain Journal Bearing With Central CircumferentialDocument17 pagesExperimental Investigation of Optimum Feed Hole Position For Plain Journal Bearing With Central CircumferentialSuren SirohiNo ratings yet

- The Accurate Measurement of Contact Angle, Phase ContactDocument8 pagesThe Accurate Measurement of Contact Angle, Phase ContactaleiviNo ratings yet

- Hytrel Extrusion Manual PDFDocument28 pagesHytrel Extrusion Manual PDFashkansoheylNo ratings yet

- Waste Management: Ala Khodier, Karl Williams, Neil DallisonDocument8 pagesWaste Management: Ala Khodier, Karl Williams, Neil DallisonGillyn CalaguiNo ratings yet

- Buried Pipe Calculation Report: Title Name Date Report NameDocument3 pagesBuried Pipe Calculation Report: Title Name Date Report NameDenis OhwofadaNo ratings yet

- Superabsorbent PolymerDocument21 pagesSuperabsorbent PolymerIsha MeshramNo ratings yet

- Fao 01-09Document15 pagesFao 01-09Camille Joyce PatricioNo ratings yet

- Gas Flotation Package (Asbea-A-2703) 32294 Ponticelli - Al Shaheen PWTDocument54 pagesGas Flotation Package (Asbea-A-2703) 32294 Ponticelli - Al Shaheen PWTTĩnh Hồ TrungNo ratings yet

- Pour Point TestingDocument10 pagesPour Point TestingAAKASHNo ratings yet

- Safety Data Sheet (SDS) : According To GHSDocument7 pagesSafety Data Sheet (SDS) : According To GHSzejackalNo ratings yet

- 5 Separatopn of Substances: MixtureDocument7 pages5 Separatopn of Substances: MixtureCris CNo ratings yet

- Pressure Vessel Manual-M.asgaRZADEGANDocument79 pagesPressure Vessel Manual-M.asgaRZADEGANH BNo ratings yet

- TZM LAB Equipment-原件Document15 pagesTZM LAB Equipment-原件Emily AiNo ratings yet

- Ingredients and Formulation of Laundry DetergentDocument34 pagesIngredients and Formulation of Laundry DetergentMuhammad Usman Hameed80% (5)

- Aqua SilencerDocument18 pagesAqua SilencerManideep AlluNo ratings yet

- Final Final PDFDocument117 pagesFinal Final PDFMalik Abdul GhaffarNo ratings yet

- 2019FA-Organic CHEM-2423-61310Document10 pages2019FA-Organic CHEM-2423-61310Lissette RegisNo ratings yet

- Drinking Water Treatment Design CalculationsDocument13 pagesDrinking Water Treatment Design Calculationssalil dubey100% (1)

- Bock PDFDocument147 pagesBock PDFjuliaNo ratings yet

- Sanitery EngineeringDocument56 pagesSanitery EngineeringTAJUL ISLAMNo ratings yet

- MSDS 419 BulkDocument3 pagesMSDS 419 BulkEliasNo ratings yet

- Smith, P. R., Jardine, R. J., & Hight, D. W. (1992) - The Yielding of Bothkennar Clay.Document18 pagesSmith, P. R., Jardine, R. J., & Hight, D. W. (1992) - The Yielding of Bothkennar Clay.Daniel Felipe Rodriguez RamirezNo ratings yet

- AMMONIA PROCESS SIMULATIONDocument8 pagesAMMONIA PROCESS SIMULATIONChecoCastilloNo ratings yet