Professional Documents

Culture Documents

Plate Feeder

Uploaded by

Anonymous 8t0V9SCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plate Feeder

Uploaded by

Anonymous 8t0V9SCopyright:

Available Formats

C AT.

REPLACEABLE ELECTRO-MECHANICAL VA R I A B L E

SPROCKET SEGMENTS FREQUENCY DRIVE

TENSIONABLE TA I L E N D H E AV Y D U T Y M A I N F R A M E

S H A F T A S S E M B LY A N D I M PA C T SECTION

D 9 C AT. SEALED

A N D L U B R I C AT E D

COMPONENTS

ROLLED A L L OY STEEL

T R AY SECTIONS

HGGLUNDS

M A R ATHON

HYDRAULIC

DRIVE

World Leaders In MINERAL SIZERS

MMD heavy duty Apron Plate Feeders are often arranged beneath tipping points,

transporting raw material to the crushing plant, where their combination of

reliability and robustness have proven to give many years of trouble free

operation with minimal maintenance.

The mainframe is a fully welded one piece fabrication,

utilising rolled steel beams, ribbed and stiffened.

The frame is designed for optimal strength,

both transversely and longditudinally,

so that supporting steelwork can be

minimised, enabling ease of on

The thickness of the site installation.

conveyor plates and

the size of the CAT chain

and rollers are all increased

proportionally. Standard widths

available are 1500, 2000, 3000, and

4000mm on D4, D7, D9, and D11 chains.

All MMD Feeders use two strands of heavy duty

Caterpillar tractor chain. Close toleranced

sealed and lubricated track links are used to

eliminate internal pin and bush wear.

The elimination of the impact energy is of special

importance. In this case, the impact force is ini-

tially absorbed by the conveyor plates, which

deform within their elastic limit. The impact

The conveyor

rails will then transmit the forces which

plates have overlap-

are dissipated into the main frame

ping edges, manufac-

construction.

tured from especially rolled

sections. The conveyor plates

are bolted to the chains with bolts

that are positioned between the

grousers so that the bolt heads are pro-

tected from damage by the material being

conveyed.

The head shaft assembly

has special discs in line with the

impact rails to provide additional support to the

conveyor plates as they go around the head

shaft.

Sizing Minerals Around The World

1500 1500

1200

1970 1970

D4 D4 F/R*

2000 2000

1480

2470 2470

D7 D7 F/R*

3000 3000

1957

3720 3720

D9 D9 F/R*

4000 4000

2259

4720 4720

D11 D11 F/R*

* With MMD Fines Retrieval System

MMD Mining Machinery Developments Limited - Head Office

Cotes Park Lane, Cotes Park Industrial Estate, Somercotes, Derbyshire. DE55 4NJ. UK.

Tel: +44 (0)1773 835533 Fax: +44 (0)1773 837818 http://www.mmdsizers.com/

South Africa India USA France

Tel +27 11 826 2491 Tel +91 44 828 0778 Tel +1 865 977 6600 Tel +33 1304 16868

Fax +27 11 826 6487 Fax +91 44 828 0725 Fax +1 865 977 4306 Fax +33 1304 15953

osborn@osborn.boartlongyear.co.za mmdindia@md3.vsnl.net.in sizers@mmdusa.com ddebuc@aol.com

Australia Middle East Canada Germany

Tel +61 242 718011 Tel +961 1 215860 Tel +1 403 799 4600 Tel +21 73 969190

Fax +61 242 718314 Fax +961 1 602790 Fax +1 403 791 5178 Fax +21 73 969197

mmdaus@magna.com.au inserve@sodetel.net.lb sizers@mmdcanada.com udiv@aol.com

China South East Asia Europe South America

Tel +86 106 7621056 Tel +66 2636 1976 Tel +44 1773 835533 Tel +55 214 714019

Fax +86 106 7620926 Fax +66 2636 1980 Fax +44 1773 835593 Fax +55 214 713233

mmd@public.east.cn.net mmdsea@loxinfo.co.th sales@mmdsizers.com sizers@mmdlatinamerica.com

You might also like

- Terex Jaques - Apron FeederDocument12 pagesTerex Jaques - Apron FeederJoseph Amoateng Appiah-kubi WadaadaNo ratings yet

- Buyersguide Asbrandparts PDFDocument237 pagesBuyersguide Asbrandparts PDFADJIMGARNo ratings yet

- Boletin Vsi SvedalaDocument5 pagesBoletin Vsi SvedalaAnonymous 8t0V9S100% (4)

- 84 039 Liquid Limit ASTM D423 66Document6 pages84 039 Liquid Limit ASTM D423 66Haftari HarmiNo ratings yet

- Introduction To SolidificationDocument30 pagesIntroduction To Solidificationpsenthil5657_9223896No ratings yet

- UV Printing Inks Technical Training of Umesh KumarDocument47 pagesUV Printing Inks Technical Training of Umesh Kumarplast_adesh33% (3)

- Ypt Paletli Brosur 3 PDFDocument4 pagesYpt Paletli Brosur 3 PDFarsanioseNo ratings yet

- Apron Feeders: High Return On Investment Low Maintenance Costs Low Production CostsDocument8 pagesApron Feeders: High Return On Investment Low Maintenance Costs Low Production CostsarsanioseNo ratings yet

- Liner Development Process SummaryDocument3 pagesLiner Development Process SummaryJorge VillalobosNo ratings yet

- Heavy Duty Apron Feeder PDFDocument2 pagesHeavy Duty Apron Feeder PDFNova HeriNo ratings yet

- Hazemag Hrs HVW en DD LowDocument4 pagesHazemag Hrs HVW en DD Lowjose gomezNo ratings yet

- Maxwell v16 L08 OptimetricsDocument35 pagesMaxwell v16 L08 OptimetricsBahadır AkbalNo ratings yet

- Book13 - Roller Screen RR1439 - P0EBD72 (TR 1-59)Document59 pagesBook13 - Roller Screen RR1439 - P0EBD72 (TR 1-59)Cuộc Sống MàNo ratings yet

- Shimpo Circulute 3000 CatalogDocument36 pagesShimpo Circulute 3000 CatalogElectromateNo ratings yet

- En Hammer CrushersDocument3 pagesEn Hammer CrusherspeymanNo ratings yet

- Non Contact SealDocument24 pagesNon Contact Sealsetiadi pratondoNo ratings yet

- S BX Cone CrusherDocument4 pagesS BX Cone CrusherLuis Miguel Añasco CorimayhuaNo ratings yet

- Trio TC51 Series Cone Crusher.Document2 pagesTrio TC51 Series Cone Crusher.Enso E Rosales FNo ratings yet

- Complete Track RangeDocument17 pagesComplete Track RangeBenjamin MurphyNo ratings yet

- Conveyorchains HitachiDocument173 pagesConveyorchains HitachiLLNo ratings yet

- High Performance: Vertical Machining CentersDocument6 pagesHigh Performance: Vertical Machining CentersSandeep SNo ratings yet

- Chain ConveyorsDocument4 pagesChain ConveyorsrakicNo ratings yet

- Montaje IndustrialDocument149 pagesMontaje IndustrialOscar Delgado NaviaNo ratings yet

- Lubricantes - HPGR StartupDocument1 pageLubricantes - HPGR StartupElios TorreblancaNo ratings yet

- Papers - Some Design Aspects For Selection of Heavy Duty Apron FeedersDocument5 pagesPapers - Some Design Aspects For Selection of Heavy Duty Apron FeedersarsanioseNo ratings yet

- SuspensionDocument12 pagesSuspensionvivek kumarNo ratings yet

- QMS Jaw Crusher BrochureDocument4 pagesQMS Jaw Crusher BrochureArpit VermaNo ratings yet

- Ecuaciones en DiferenciaDocument57 pagesEcuaciones en DiferenciaJuan PabloNo ratings yet

- Analysis of Spiral Power SpringDocument4 pagesAnalysis of Spiral Power SpringMuhd IlhamNo ratings yet

- Materi PPT Secondary EngDocument5 pagesMateri PPT Secondary EngFanya arifantiNo ratings yet

- Ill I: SlopeDocument10 pagesIll I: SlopeMohit MehtaNo ratings yet

- Hydraulic Cone Crusher PDFDocument16 pagesHydraulic Cone Crusher PDFJanethDeNunuraNo ratings yet

- Renold Chain CatalogueDocument24 pagesRenold Chain CatalogueThang NguyenNo ratings yet

- 11,42 Catti: EquationDocument17 pages11,42 Catti: EquationMohit MehtaNo ratings yet

- Equation TX: ParametricDocument3 pagesEquation TX: ParametricNguyễn Lê Quốc HưngNo ratings yet

- TV Series Vertical Shaft Impact Crushers: Highly Efficient Crushing SolutionsDocument4 pagesTV Series Vertical Shaft Impact Crushers: Highly Efficient Crushing SolutionsJose grievis Giron pericheNo ratings yet

- TS GyratoryCrusher 8.5x11-PageResolutionDocument1 pageTS GyratoryCrusher 8.5x11-PageResolutionMaxx Ccoñas RamosNo ratings yet

- ECT Symons 7s For SaleDocument2 pagesECT Symons 7s For SaleOrlando MelipillanNo ratings yet

- With A Neat Schematic Block Diagram of A Digital Computer Describe Its Functional Units. Central Processing UnitDocument10 pagesWith A Neat Schematic Block Diagram of A Digital Computer Describe Its Functional Units. Central Processing UnitSrinivasan SriniNo ratings yet

- Shineking Cone Crusher Manual BookDocument32 pagesShineking Cone Crusher Manual BookRiki D. PrastyoNo ratings yet

- Purchased Part Specification: Extended DescriptionDocument1 pagePurchased Part Specification: Extended DescriptionWilliam VillamizarNo ratings yet

- Vsi 2Document9 pagesVsi 2Vivek AgrawalNo ratings yet

- Silent Tools: Productivity With Slender ToolsDocument12 pagesSilent Tools: Productivity With Slender Toolsxmen norNo ratings yet

- H-E Parts Case Study C160 & C200 Jaw PerformanceDocument1 pageH-E Parts Case Study C160 & C200 Jaw PerformanceJorge VillalobosNo ratings yet

- Anvita SharmaDocument45 pagesAnvita SharmaJay MehtaNo ratings yet

- Installation, Operation and Maintenance of Airflex Model VC Grinding Mill ClutchesDocument33 pagesInstallation, Operation and Maintenance of Airflex Model VC Grinding Mill Clutchesdennis_schoonhovenNo ratings yet

- H-E Parts Brochure ServiceDocument12 pagesH-E Parts Brochure ServiceJorge VillalobosNo ratings yet

- Analysis of Stress and Deflection of Spur Gear by Using New Analytical Method Based On Taguchi Method and Finite Element AnalysisDocument7 pagesAnalysis of Stress and Deflection of Spur Gear by Using New Analytical Method Based On Taguchi Method and Finite Element AnalysisEditor IJTSRDNo ratings yet

- Bearings FinalDocument8 pagesBearings FinalThiyagarajan RajkumarNo ratings yet

- Catalogue V20 PDFDocument404 pagesCatalogue V20 PDFUstad Remy0% (1)

- FLSmidth - HPGR - High Pressure Grinding Roll - BrochureDocument9 pagesFLSmidth - HPGR - High Pressure Grinding Roll - BrochureTHAKARAR HARSHILNo ratings yet

- PCS Algebra I Quiz 4 Chapter Review KEYDocument1 pagePCS Algebra I Quiz 4 Chapter Review KEYTim Ricchuiti100% (1)

- MANUAL DE CONO SYMONS DESDE EMCC - Archivo PDFDocument27 pagesMANUAL DE CONO SYMONS DESDE EMCC - Archivo PDFGuillermo BalarinniNo ratings yet

- Modulare Systems For Conveyor PlantsDocument36 pagesModulare Systems For Conveyor Plantsado31No ratings yet

- Series: The Reliable Brand!Document6 pagesSeries: The Reliable Brand!Cristian J. MejíaNo ratings yet

- Design of The Drive Mechanism For A Reciprocating Coal FeederDocument81 pagesDesign of The Drive Mechanism For A Reciprocating Coal FeederemersonNo ratings yet

- Eaton VC Clutch PDFDocument43 pagesEaton VC Clutch PDFJuan C. Gonzalez ArayaNo ratings yet

- 2011 Rittal Cat33 APMDocument648 pages2011 Rittal Cat33 APMgoodgranitNo ratings yet

- U 4 Surface Finishing Process PDFDocument37 pagesU 4 Surface Finishing Process PDFSubhadip MaliNo ratings yet

- Book13 - Roller Screen RR1439 - P0EBD72 PDFDocument552 pagesBook13 - Roller Screen RR1439 - P0EBD72 PDFNguyen Canh AnNo ratings yet

- 123456Document34 pages123456ankitsarvaiyaNo ratings yet

- 02 Training Program Gear 2013Document56 pages02 Training Program Gear 2013amrit002No ratings yet

- Specialty Bearings: Electric Motor QualityDocument29 pagesSpecialty Bearings: Electric Motor QualityHenry Wilson AlvaradoNo ratings yet

- Oct20 - 2 NovDocument3 pagesOct20 - 2 NovAnonymous 8t0V9SNo ratings yet

- 1Document1 page1Anonymous 8t0V9SNo ratings yet

- 23-5 AbrilDocument4 pages23-5 AbrilAnonymous 8t0V9SNo ratings yet

- HORARIO1Document8 pagesHORARIO1Anonymous 8t0V9SNo ratings yet

- Declaration of ConformityDocument4 pagesDeclaration of ConformityAnonymous 8t0V9SNo ratings yet

- Sheet BevelDocument1 pageSheet BevelAnonymous 8t0V9SNo ratings yet

- Declaration of ConformityDocument1 pageDeclaration of ConformityTiago GomesNo ratings yet

- 1 Al 14 DicDocument3 pages1 Al 14 DicAnonymous 8t0V9SNo ratings yet

- Part No.: 100B20 Note: - Drawing Not To Scale - All Dimensions Are Nominal Values and For Reference OnlyDocument1 pagePart No.: 100B20 Note: - Drawing Not To Scale - All Dimensions Are Nominal Values and For Reference OnlyAnonymous 8t0V9SNo ratings yet

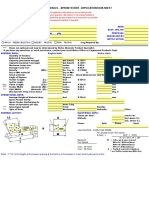

- Metso Minerals - Apron Feeder - Application Data SheetDocument2 pagesMetso Minerals - Apron Feeder - Application Data SheetAnonymous 8t0V9SNo ratings yet

- Crusher Cross-Section (Symons) PDFDocument1 pageCrusher Cross-Section (Symons) PDFAnonymous 8t0V9S100% (1)

- Excel Components For Symons Templates PDFDocument1 pageExcel Components For Symons Templates PDFAnonymous 8t0V9SNo ratings yet

- 4 Jaw Independent Chuck - K72 Series PDFDocument1 page4 Jaw Independent Chuck - K72 Series PDFAnonymous 8t0V9SNo ratings yet

- 32-IFE Vibrating Grizzly PDFDocument2 pages32-IFE Vibrating Grizzly PDFAnonymous 8t0V9SNo ratings yet

- Cardan ShaftsDocument2 pagesCardan ShaftsAnonymous 8t0V9SNo ratings yet

- Introduction To EOR ProcessesDocument23 pagesIntroduction To EOR Processesحسين رامي كريم A 12No ratings yet

- Pro Form - Plywood Formwork For Exposed Concrete AreaDocument2 pagesPro Form - Plywood Formwork For Exposed Concrete AreaĐức Anh NguyễnNo ratings yet

- Test 1 (GC F 03) W AnsDocument4 pagesTest 1 (GC F 03) W AnsLuis glezNo ratings yet

- CHM256 - Tutorial 6Document2 pagesCHM256 - Tutorial 6Fatimah Azzahrah0% (1)

- 1963-Nucleate Boiling Characteristics and The Critical Heat Flux Occurrence in Subcooled Axial-Flow Water Systems PDFDocument36 pages1963-Nucleate Boiling Characteristics and The Critical Heat Flux Occurrence in Subcooled Axial-Flow Water Systems PDFTahok24No ratings yet

- 11 KV Line Erection PracticesDocument90 pages11 KV Line Erection PracticesBoson FreelancerNo ratings yet

- Wa0084Document33 pagesWa0084miteshNo ratings yet

- TK Chap 5-2Document7 pagesTK Chap 5-2Tito EcheverriaNo ratings yet

- Instruction Manual (METAREFRE-O)Document4 pagesInstruction Manual (METAREFRE-O)dhanamvijayakumarNo ratings yet

- Astm B444Document3 pagesAstm B444AbabNo ratings yet

- Pressure Testing Methods DVGW G 469Document14 pagesPressure Testing Methods DVGW G 469koulis1386% (7)

- KD-213 TDSDocument3 pagesKD-213 TDSalpesh.samruddhigroupNo ratings yet

- Shale Mechanical Properties Influence FactorsDocument24 pagesShale Mechanical Properties Influence FactorsIntan Nur DaniaNo ratings yet

- TPP Mini ProjectDocument2 pagesTPP Mini Projectraden adibNo ratings yet

- First Periodical Test in Science V SY: 2018-2019 Table of Specifications Placement of Item/ Level Total No. of Test Items R U AP AN E CDocument4 pagesFirst Periodical Test in Science V SY: 2018-2019 Table of Specifications Placement of Item/ Level Total No. of Test Items R U AP AN E CCely Lopez Madriaga0% (1)

- RohsDocument49 pagesRohssyladrianNo ratings yet

- KOL16 RevDocument117 pagesKOL16 RevAman DubeyNo ratings yet

- Bwa Belgard Ev2050 Gpi - WFDocument2 pagesBwa Belgard Ev2050 Gpi - WFdalton2004No ratings yet

- Product Data - Windsock Fitting Type D Rev 3.5Document10 pagesProduct Data - Windsock Fitting Type D Rev 3.5anis.abNo ratings yet

- CH 9 WorksheetsDocument5 pagesCH 9 Worksheetsadaglio001100% (1)

- Luminol™ / - : TR TRI High Efficiency Electrical Insulation FluidsDocument2 pagesLuminol™ / - : TR TRI High Efficiency Electrical Insulation FluidsDenny PanjaitanNo ratings yet

- BOQDocument100 pagesBOQJohn Philip GarciaNo ratings yet

- Specifications For Tarang Villas: Sno. Item Tile Name/size Image of Improved Specs 1 FlooringDocument13 pagesSpecifications For Tarang Villas: Sno. Item Tile Name/size Image of Improved Specs 1 FlooringSiddhartha DubeyNo ratings yet

- CM Practical Sieve Tube TestDocument20 pagesCM Practical Sieve Tube TestChan Xing KhuanNo ratings yet

- Tunnel Added Beam On SupportDocument9 pagesTunnel Added Beam On SupportНемања Караклајић100% (1)

- Threshold Voltage of Thin-Film Silicon-on-Insulator (Sol) MOSFET SDocument8 pagesThreshold Voltage of Thin-Film Silicon-on-Insulator (Sol) MOSFET SArnab HazraNo ratings yet