Professional Documents

Culture Documents

Heights Safe Working at

Uploaded by

Hendrias Ari SujarwoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heights Safe Working at

Uploaded by

Hendrias Ari SujarwoCopyright:

Available Formats

# Enter site: Fill = Green 204

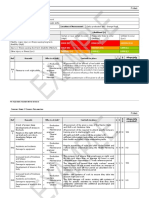

SAFE WORK PROCEDURE

Workplace: Branch Locations throughout Australia Page: 1 of 7

Overall Risk 4 Acute 3 High

TASK / OPERATION: Safe Working at Heights Rating After

Controls 2 Moderate 1 Low

Personal Protective Equipment Fill = Green 204

Foot Head Hearing High Eye Hand

Protection Protection Protection Visibility Protection Protection

Normal Requirements:

Safety footwear, hard hat.

As Required:

Hearing protection, high visibility shirt or vest, sun protection (broad brim hat, sun screen, tinted safety glasses), eye protection (goggles),

hand protection (gloves)

Safety Notes Fill = Green 204

1. Falling from height can often result in serious incapacity or a fatality.

2. Fall protection should be provided regardless of the height where a person could fall onto/into something dangerous. Example An open

manhole or lift well.

3. Avoid workers working alone if they will be involved in height work. In the event of an accident rescue procedures will need to be carried out.

Potential Hazards or Responsible

Sequence RB Control Measures - Actions to be Taken RA

Risks of Each Step. officer

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented.

Employee requirements Legislation breach. 2M Training: 1L

Should include:

Use of untrained Legislative Requirements.

operators. Safe work procedures.

Fitting of personal protective equipment.

Incorrect use of fall arrest Recognition and control of falling hazards.

systems. Nature of fall hazards within the work area.

Correct procedures for erecting, maintaining,

Unable to perform rescue disassembling and inspecting fall arrest systems.

procedures. Correct fitting of the harness. - Incorrectly fitted

harnesses can cause serious injury in the event of

Unknown site hazards. a fall.

Limitations of the equipment.

Rescue procedures in the event of a fall.

Correct procedure for handling equipment and

materials while working at heights

Manual handling.

Site induction.

Risk Assessment Personal injury. 2M Hazards to be assessed: 1L

Falls. Height of work.

Stress and Strain. Ground hazards rocks, reinforcing steel etc.

Electric shock. Lack of guard rails or other edge protection.

Pitch of roof (if relevant).

Legislation breach. Surface materials brittle sheeting.

Weather conditions high winds (Example erecting

directional signs outdoors.)

Use of power tools (location of leads, congestion in

work area etc.)

Authorised by OHS Training & Consultancy Services SafetyCulture 2004 - 2007

Page 2 Version 5.0

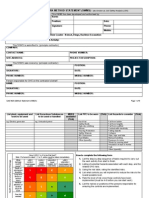

Potential Hazards or Responsible

Sequence RB Control Measures - Actions to be Taken RA

Risks of Each Step. officer

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented.

Risk control order Legislation breach. 2M Provision and maintenance of: 1L

1. Secure stable work platform.

2. Secure perimeter screens, fencing or handrails

or other forms of physical barriers.

3. Other forms of restraint such as harnesses,

lanyards etc.

Planning Personal injury. 2M General - Identify: 1L

Slips and Falls. All tasks that could involve someone falling

Struck by falling Example working within 3 metres of a roof

objects. edge.

Any objects that could fall onto someone.

Lack of warnings of Possible adverse climate conditions Example

overhead work being rain or heavy dew.

carried out. Risks to other workers on site Example objects

that could fall onto others.

Warning signs and/or barricades must be in place

where persons:

Can gain access to the work area if any part of the

work area is known to be incomplete, unsound,

fragile or brittle.

There is a risk of anyone being injured by

materials or equipment falling from above.

Authorised by OHS Training & Consultancy Services SafetyCulture 2004 - 2007

Page 3 Version 5.0

Potential Hazards or Responsible

Sequence RB Control Measures - Actions to be Taken RA

Risks of Each Step. officer

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented.

Site Awareness Personal injury. 2M Review where applicable: 1L

Falls. Availability and effectiveness of fall prevention

Stress and Strain. equipment.

Electric shock. Crane placement schedule If relevant to the

job.

Access to the work area (Example roof) and

Any personal protective equipment.

Locate:

Any existing power cables, water pipes, air

conditioning ducts etc. prior to work commencing.

Preparations - Personal injury. 3H Fall arrest scaffolding: 2M

Scaffolding Falls. When required fall arrest scaffolding should be installed

Stress and Strain. around the perimeter of the building.

Electric shock.

Fall arrest scaffolding will:

Legislation breach. (a) be unobstructed and at least 675 mm wide for the

length of the platform;

(b) be able to withstand the impact of a fall onto it;

and

(c) have edge protection erected:

i. along the outer edge of the length of the

platform; and

ii. along the edges of each end of the fall

arresting platform.

Mobile scaffolding:

Mobile scaffolding must be positioned as close as

practicable to the underside of the roof and not

more than two metres below the working surface.

Authorised by OHS Training & Consultancy Services SafetyCulture 2004 - 2007

Page 4 Version 5.0

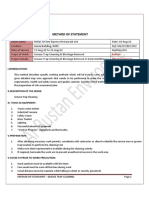

Potential Hazards or Responsible

Sequence RB Control Measures - Actions to be Taken RA

Risks of Each Step. officer

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented.

Preparations - 3H Power cables: 2M

Electricity Depending upon the risk of electrocution to on site

workers (roof workers, crane operators, labourers etc.)

the following must be considered:

1. Tiger Tails can be installed. (Note: Tiger tails

ONLY give a visual warning of the proximity of power

lines.)

2. Power cables can be redirected or power

isolated for the duration of the work.

Preparations - Ladders Personal injury. 2M Ladders: 1L

Slips and falls. All ladders must be:

Stress and strains. 1. Identifiable as being of commercial quality.

Electric shock. 2. Inspected before use and periodically there after.

3. Removed from use immediately if damaged.

4. Have non slip feet and be secured at the top.

5. Elevated at an appropriate angle. (Horizontal

distance from base to vertical plane of support

should be one-quarter the ladder height.)

6. Extend to at least one metre above the stepping off

point.

7. Positioned away from power lines.

Note:

Employees must NOT carry tools while climbing or

descending ladders.

Authorised by OHS Training & Consultancy Services SafetyCulture 2004 - 2007

Page 5 Version 5.0

Potential Hazards or Responsible

Sequence RB Control Measures - Actions to be Taken RA

Risks of Each Step. officer

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented.

Daily Checks Personal injury. 3H Ensure: 2M

Falls. Scaffold is erected as per the plan (where

required).

All bracing used is as per the manufacturers

specifications.

All guard rails, mid rails and toe boards are in

place to prevent a person falling. (2 m or more.)

There are no damaged planks. If found they

must be removed from the site.

Suitable access ways to working platforms.

Working platforms are fully planked.

Scaffold is suitably tied to prevent collapse from

load or wind.

Working surfaces:

Must be checked to ensure that they have the

strength and structural integrity to safely support

workers.

Site Safety 2M Work areas must be kept clean and tidy. 1L

There MUST be a safe system for collecting, storing

and disposing of waste materials.

Rubbish and other items should not be thrown from the

roof to the ground.

A safe means of removal must be used such as placing

waste in skips and having a general clean up once

a day.

Authorised by OHS Training & Consultancy Services SafetyCulture 2004 - 2007

Page 6 Version 5.0

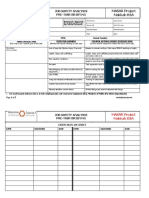

References:

Tasmania Play it safe Working at Heights A guide to reducing the risk of injury while working.

Queensland Workplace Health and Safety Rural Plant Code of Practice 2004.

New South Wales WorkCover - Safe Working at Heights Guide 2006.

United States Department of Labor OSHA Fall protection.

SafetyCulture Safe Work Procedure Working on Roofs.

SafetyCulture Safe Work Procedure Elevating Work Platforms.

SafetyCulture Safe Work Procedure Ladders Safe Use.

SafetyCulture Safe Work Procedure Trestles Safe Use.

SafetyCulture Safe Work Procedure Scaffolding.

Authorised by OHS Training & Consultancy Services SafetyCulture 2004 - 2007

Page 7 Version 5.0

You might also like

- Daily Safety Task Instruction (DSTI) : Supervisor/Manager/Team LeaderDocument25 pagesDaily Safety Task Instruction (DSTI) : Supervisor/Manager/Team LeaderAVENON Mardochee0% (1)

- Safe Work Method Procedure AC InstallationDocument9 pagesSafe Work Method Procedure AC InstallationDevan Sanmugam50% (2)

- Estimation Man HourDocument241 pagesEstimation Man HourAnonymous ynJByUs52% (42)

- Heights Safe Working atDocument7 pagesHeights Safe Working atHendrias Ari SujarwoNo ratings yet

- Idoc - Pub Night and Shift Worker Risk Assessment ExampleDocument4 pagesIdoc - Pub Night and Shift Worker Risk Assessment Examplesoliman fathy100% (2)

- Safe Work Procedure, Gem MaintenanceDocument46 pagesSafe Work Procedure, Gem MaintenanceAsif Khanzada100% (1)

- Working at Heights ProcedureDocument16 pagesWorking at Heights ProcedureHendrias Ari SujarwoNo ratings yet

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 pagesTower Crane Dismantling JSA HSE ProfessionalsnabeelNo ratings yet

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatemahmoudmakladNo ratings yet

- 7-Block Work Risk Assessment ReportDocument7 pages7-Block Work Risk Assessment ReportSyed Ali Hassan100% (4)

- OHS SWMS Form 005 ExcavationDocument8 pagesOHS SWMS Form 005 Excavationazlinaz100% (2)

- RA Roof Work 0006 July 2017Document6 pagesRA Roof Work 0006 July 2017pugal maniNo ratings yet

- Toolbox Talk Register (Yard)Document14 pagesToolbox Talk Register (Yard)jumansyahamid1988No ratings yet

- Steel FixingDocument5 pagesSteel Fixingrishanmulky88% (8)

- Skillbuild Risk Assessment: Competition Organising Partner: Citb /skillbuild Competition Skills: BricklayingDocument6 pagesSkillbuild Risk Assessment: Competition Organising Partner: Citb /skillbuild Competition Skills: BricklayinguknandiNo ratings yet

- SRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578Document9 pagesSRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578kkalvi100% (1)

- Guide For The Design and Production of LV Power Factor Correction CubiclesDocument76 pagesGuide For The Design and Production of LV Power Factor Correction CubiclesGunadevan Chandrasekaran100% (1)

- Risk Assessment for Excavation WorksDocument3 pagesRisk Assessment for Excavation WorksEdgard Laurenz Montellano GeronimoNo ratings yet

- Risk Assisment For Fence WorkDocument2 pagesRisk Assisment For Fence Workashishakare100% (1)

- Boom Lift PDFDocument2 pagesBoom Lift PDFcityofdarwingisNo ratings yet

- Safe Work Method Statement - PlumbingDocument4 pagesSafe Work Method Statement - PlumbingJohn KurongNo ratings yet

- Master Builders SA - Safe Work Method Statement - Roof Metal InstallationDocument7 pagesMaster Builders SA - Safe Work Method Statement - Roof Metal InstallationvictorNo ratings yet

- Job Hazard Analysis DemolitionDocument2 pagesJob Hazard Analysis DemolitionvinothNo ratings yet

- Safe Work Method StatementDocument7 pagesSafe Work Method StatementianllagasNo ratings yet

- Project HS Risk Assessment for Sandvik Pvt Ltd Ceiling WorkDocument8 pagesProject HS Risk Assessment for Sandvik Pvt Ltd Ceiling WorkParasNo ratings yet

- Job Safety Analysis: JSA Reference #: DateDocument3 pagesJob Safety Analysis: JSA Reference #: DateLi QiNo ratings yet

- Coates Truck Drivers GuideDocument66 pagesCoates Truck Drivers GuideSebastian ZarzyckiNo ratings yet

- Risk assessment identifies hazards of installing cables and excavationDocument6 pagesRisk assessment identifies hazards of installing cables and excavationMohammed Shiful0% (1)

- SWMS - PlumberDocument7 pagesSWMS - PlumberSiddiqueShaikhNo ratings yet

- JHA Stacks EDG Substation r0 14 August 2017 EdittedDocument5 pagesJHA Stacks EDG Substation r0 14 August 2017 EdittedJeniffer Ong100% (1)

- One Direct Method Statement: Preventative MeasuresDocument4 pagesOne Direct Method Statement: Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Motor of Pump HandbookDocument252 pagesMotor of Pump Handbookhithr1No ratings yet

- Rebar Job Hazard AnalysisDocument1 pageRebar Job Hazard Analysisjoker batmanNo ratings yet

- Diesel Filling JSADocument6 pagesDiesel Filling JSAMohammed Ali QaziNo ratings yet

- Steel Erection JSADocument5 pagesSteel Erection JSASalah Abd Eldayem100% (1)

- Very Very Good Risk Assessment EnvironmentDocument8 pagesVery Very Good Risk Assessment EnvironmentSalley Bukhari100% (1)

- 340AJ Risk AssessmentDocument7 pages340AJ Risk AssessmentMyaIdzaharNo ratings yet

- 22 Hazard Noise PDFDocument40 pages22 Hazard Noise PDFamirq4No ratings yet

- Manual C1100 D5 PDFDocument138 pagesManual C1100 D5 PDFListrik Hasanuddin100% (1)

- Shifting of Material & Equipment.: Job Safety Analysis JobDocument6 pagesShifting of Material & Equipment.: Job Safety Analysis JobPrabir PujariNo ratings yet

- RA For Plumbing and HeatingDocument8 pagesRA For Plumbing and HeatingAngela DaveyNo ratings yet

- Incident Report: Proj. N. Unit Document Code Serial NDocument1 pageIncident Report: Proj. N. Unit Document Code Serial NSyed Ali HassanNo ratings yet

- Piling Safety PlanDocument8 pagesPiling Safety PlanBalogun Isaac100% (1)

- Peter Tanner - The City & Guilds Textbook - Book 1 Electrical Installations For The Level 3 Apprenticeship (5357), Level 2 Technical Certificate (8202) & Level 2 Diploma (2365) - Hodder EducDocument601 pagesPeter Tanner - The City & Guilds Textbook - Book 1 Electrical Installations For The Level 3 Apprenticeship (5357), Level 2 Technical Certificate (8202) & Level 2 Diploma (2365) - Hodder EducLuis Fraire75% (4)

- Fencing Installation Risk AssessmentDocument6 pagesFencing Installation Risk AssessmentVictorNo ratings yet

- 241-267 - CT and VT Basics - QuazvinDocument27 pages241-267 - CT and VT Basics - Quazvincarlos vidalNo ratings yet

- JSARA - Fire Detection System InstallationDocument13 pagesJSARA - Fire Detection System InstallationUtku Can KılıçNo ratings yet

- JHA ConcretePlacingOperationDocument3 pagesJHA ConcretePlacingOperationAnonymous XJ9663C6N4No ratings yet

- Risk Assessment For Elevator Shaft Slab Demolition (C01, S10)Document1 pageRisk Assessment For Elevator Shaft Slab Demolition (C01, S10)rayNo ratings yet

- JSA ScaffoldingDocument2 pagesJSA Scaffoldingmyco samNo ratings yet

- Method of Statement - Grease Trap CleaningDocument2 pagesMethod of Statement - Grease Trap CleaningAbdul Rahman75% (4)

- Confined Spaces Toolbox TalkDocument3 pagesConfined Spaces Toolbox TalkWaSim AKramNo ratings yet

- Jsa Water Proofing For DHADocument13 pagesJsa Water Proofing For DHAAnonymous YmINeSIFNo ratings yet

- How To Select Genset PDFDocument25 pagesHow To Select Genset PDFSaraswatapalit100% (1)

- Crane Assembly and Dismantling and ModificationDocument1 pageCrane Assembly and Dismantling and Modificationsrinibas mohapatraNo ratings yet

- Working Near WaterDocument46 pagesWorking Near WaterNikil KPNo ratings yet

- Brick Masonry - EHS Risk AssessmentDocument2 pagesBrick Masonry - EHS Risk Assessmentnagarjuna100% (3)

- Mns Ecp Self Audit Wet ProcessingDocument5 pagesMns Ecp Self Audit Wet ProcessingShahab Ud Din Shakeel0% (1)

- Subject: Work at Height: Unit: Maihar Cement WorksDocument3 pagesSubject: Work at Height: Unit: Maihar Cement Workskaka100% (1)

- Shielded Metal Arc Welding (Smaw) Grades 7-10Document20 pagesShielded Metal Arc Welding (Smaw) Grades 7-10Claire Absin Pastelero100% (2)

- Questionnaire HousekeepingDocument8 pagesQuestionnaire HousekeepingTiffany Ruth Rebolledo-quinitip100% (2)

- Furse Total Solution Catalogue LrsDocument300 pagesFurse Total Solution Catalogue Lrsvikramjeet singhNo ratings yet

- RISK ASSESSMENT - Tower Crane DraftDocument12 pagesRISK ASSESSMENT - Tower Crane Draftloveson70933% (3)

- Electrical EngineerDocument44 pagesElectrical EngineerHendrias Ari SujarwoNo ratings yet

- Power LV CopperDocument52 pagesPower LV CopperBeny Indrawan SNo ratings yet

- Process Safety Conference Presentation - Benoy JosephDocument16 pagesProcess Safety Conference Presentation - Benoy JosephBenoy Johnson JosephNo ratings yet

- Win713en 00Document34 pagesWin713en 00MohamedAbdelnasserNo ratings yet

- NGC GuideDocument69 pagesNGC GuideNasim AkhtarNo ratings yet

- Working HeightDocument64 pagesWorking Heightandresboy123No ratings yet

- Working HeightDocument64 pagesWorking Heightandresboy123No ratings yet

- Job Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSADocument2 pagesJob Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSAmahammed saleem100% (2)

- Working at Height Training ModuleDocument41 pagesWorking at Height Training ModuleYudha kurniawanNo ratings yet

- Daily JSADocument4 pagesDaily JSAumn_mlkNo ratings yet

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Work at Height Safety AnalysisDocument2 pagesWork at Height Safety AnalysiszebmechNo ratings yet

- Job Hazard AssessmentDocument26 pagesJob Hazard AssessmentGeherson AbustanNo ratings yet

- 04 Jsa For Camp Constn & Associated FacilitysDocument5 pages04 Jsa For Camp Constn & Associated FacilitysHilbrecht De Pedro100% (1)

- Method Statement For Worker WelfereDocument4 pagesMethod Statement For Worker WelfereMohamad Hidayat Zainul MasriNo ratings yet

- Jsa PCC & RCCDocument2 pagesJsa PCC & RCCNilesh koliNo ratings yet

- Re-Calculation Lighting Indoor WarehouseDocument1 pageRe-Calculation Lighting Indoor WarehouseHendrias Ari SujarwoNo ratings yet

- Grounding System Design'Document88 pagesGrounding System Design'Hendrias Ari SujarwoNo ratings yet

- Re-Calculation Lighting Indoor WarehouseDocument1 pageRe-Calculation Lighting Indoor WarehouseHendrias Ari SujarwoNo ratings yet

- Re-Calculation Lighting Indoor WarehouseDocument1 pageRe-Calculation Lighting Indoor WarehouseHendrias Ari SujarwoNo ratings yet

- Bridge Maintenance HandbookDocument203 pagesBridge Maintenance HandbookHermann PankowNo ratings yet

- Elevasi Tanah DKC 1-2Document1 pageElevasi Tanah DKC 1-2Hendrias Ari SujarwoNo ratings yet

- Rough Terrain Crane RK 500 SpesificationDocument8 pagesRough Terrain Crane RK 500 SpesificationMuhammad KurniawanNo ratings yet

- Of FG 1-1993 FROM: NEMA Communications Director: Also BeenDocument23 pagesOf FG 1-1993 FROM: NEMA Communications Director: Also BeenHendrias Ari SujarwoNo ratings yet

- Ahmeda - Thesis FinalDocument176 pagesAhmeda - Thesis FinalfateofmountainsNo ratings yet

- HTTP WWW - Sayfa.com - Au Docs Sayfa Working at Heights ManualDocument20 pagesHTTP WWW - Sayfa.com - Au Docs Sayfa Working at Heights ManualHendrias Ari SujarwoNo ratings yet

- Practical Project Planning and Tracking Using Microsoft Project v2.7Document47 pagesPractical Project Planning and Tracking Using Microsoft Project v2.7Nelson Aguirre BravoNo ratings yet

- Practical Project Planning and Tracking Using Microsoft Project v2.7Document47 pagesPractical Project Planning and Tracking Using Microsoft Project v2.7Nelson Aguirre BravoNo ratings yet

- HTTP WWW - Sayfa.com - Au Docs Sayfa Working at Heights ManualDocument20 pagesHTTP WWW - Sayfa.com - Au Docs Sayfa Working at Heights ManualHendrias Ari SujarwoNo ratings yet

- Working Above 2metreDocument5 pagesWorking Above 2metreHendrias Ari SujarwoNo ratings yet

- Document Pemasangan ScaffoldingDocument3 pagesDocument Pemasangan ScaffoldingHendrias Ari SujarwoNo ratings yet

- Working MethodDocument16 pagesWorking MethodHendrias Ari SujarwoNo ratings yet

- Heights Safe Working atDocument8 pagesHeights Safe Working atHendrias Ari SujarwoNo ratings yet

- Line Construction NC IIDocument77 pagesLine Construction NC IIAljon BalanagNo ratings yet

- Nalco 9901 Anionic FlocuulantDocument9 pagesNalco 9901 Anionic FlocuulantMohsin ModiNo ratings yet

- Bilingual Healthcare Clinical Specialist in United States Resume Cecilia Jimenez GonzalezDocument1 pageBilingual Healthcare Clinical Specialist in United States Resume Cecilia Jimenez GonzalezCecilia Jimenez GonzalezNo ratings yet

- HSE evaluation of PT. Supraco Lines dredging servicesDocument4 pagesHSE evaluation of PT. Supraco Lines dredging serviceshannyNo ratings yet

- MEM 603 PO8 Individual Assigment Sept 2019 AssesmentDocument11 pagesMEM 603 PO8 Individual Assigment Sept 2019 Assesmentsyafiq syazwanNo ratings yet

- MSDS for Water-Soluble Anti-Corrosive CoatingDocument9 pagesMSDS for Water-Soluble Anti-Corrosive Coatingabhishek yadavNo ratings yet

- L - Tham Khao 2 PDFDocument156 pagesL - Tham Khao 2 PDFNgười Chiến Sĩ ẤyNo ratings yet

- MSDS - Pluricid - 2015Document11 pagesMSDS - Pluricid - 2015smic3904No ratings yet

- MSDS Duct SealantDocument6 pagesMSDS Duct SealantbuddhikasatNo ratings yet

- Smaw 8 Module 3 - V5Document23 pagesSmaw 8 Module 3 - V5Mary Antoinette MagallanesNo ratings yet

- Basic ICS Training Report for Sipalay CityDocument18 pagesBasic ICS Training Report for Sipalay CityElynde Guitche - OrbigosoNo ratings yet

- Industrial Relations & Labour Laws: ObjectivesDocument40 pagesIndustrial Relations & Labour Laws: ObjectivesAditya KulkarniNo ratings yet

- Material Safety Data Sheet: AES-A-350-RBDocument7 pagesMaterial Safety Data Sheet: AES-A-350-RBSajidawan. OlineNo ratings yet

- Behavior Based Job Safety ObservationsDocument11 pagesBehavior Based Job Safety Observationsakshay pradeepNo ratings yet

- Final - LNG PDFDocument19 pagesFinal - LNG PDFMahdiNo ratings yet

- Method Statement and Risk Assessment GeneralDocument16 pagesMethod Statement and Risk Assessment GeneralDwi Windi AjiNo ratings yet

- Quiz Midterm Exam Ni Poging JayDocument6 pagesQuiz Midterm Exam Ni Poging JayMYKE MIGGYL MORALESNo ratings yet

- MMW450 4319 SdseDocument2 pagesMMW450 4319 Sdsesuwit nongNo ratings yet