Professional Documents

Culture Documents

NSK Cat E3162d 2014 Z-8 TW

Uploaded by

jose mondacaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NSK Cat E3162d 2014 Z-8 TW

Uploaded by

jose mondacaCopyright:

Available Formats

B-3-3.7 TW Series for Twin-Drive Systems B-3-3.8.

1 Hollow Shaft Ball Screw for High Precision Machine Tools

(1) Features 60 The increase in speed of the feeding mechanism screw is equal to the hollow shaft ball screw

Variations in the lead accuracy and preload torque for highly accurate positioning may require thanks to the optimized nut internal design for

40

between two ball screws, which consist of a unit some measures against thermal expansion of cooling. Please refer to nut cooling ball screws

the ball screw (forced cooling using hollow ball (page B545) for more details.

Motion errors, m

of TW Series, are controlled, resulting improved 20

travel accuracy and ball screw operating lifetime. 0 screw). NSK standardized hollowed screw shafts

Fig. 1 shows measured variation in lead accuracy

20

and shaft ends configuration (sealing section 2. Design precautions

while Fig. 2 displays an example of variation in Variation 5 m

and support bearing seat). NSK recommends Refer to HMC type, end-deflector recirculation

40

thermal expansion between the two ball screws. this as the most effective measure against system, return tube recirculation system, and

Specified value

Fig. 3 is a schematic diagram comparing the 60 thermal expansion. deflector(bridge type) recirculation system

0 200 400 600 800 1 000 1 200

travel accuracy between the TW Series and Effective length of ball thread for ball screw specifications. If the overall ball

conventional model.

Fig. 1 Example of measured variation in lead accuracy

1. Features screw length exceeds 3 000 mm, contact NSK.

A High rigidity and long lifetime AStable positioning accuracy For general precautions regarding ball screw,

Twin-drive systems are superior to single-drive 0.12 Suppresses expansion of the ball screw shaft by refer to "Design Precautions" (page B83) and

Maximum variation in thermal

systems in system rigidity, supporting the expansion with a existing model

rising temperature, and provides stable, precise "Handling precautions" (page B103).

design of long-life feeding mechanism even if 0.10 positioning.

they make the shaft diameter one size smaller. Thermal expansion, mm A Prevents displacement of various sections

A High responsiveness to positioning commands 0.08 Minimizes deformation of the ball screw support 30

Ball screw specification

Twin-drive systems permit the use of screw shaft bearings as well as of the machine base which Screw shaft diameter : 32 mm

Lead : 10 mm

diameters that are one size smaller, thereby 0.06 is caused by thermal expansion of ball screw. Preload : 1 500 N

TW/ Hollow Shaft Ball Screw

Operating condition

reducing screw shaft inertia by up to 50%, Forced cooling keeps the heat from spreading Travel speed : 10 m/min.

Variation in thermal Stroke : 500 mm

offering high responsiveness to positioning 0.04 to other sections, and prevents the processing

expansion for TW Series

commands. table from deforming due to heat. 20

A Improved high-speed capability and noise level 0.02 A Reduces warm-up time

Temperature rise (C)

Twin-drive systems allow the use of smaller screw Temperature does not rise high, therefore cuts Forced cooling

0 Coolant oil volume : 3 liter/min.

diameters, resulting in no increase in the level machine warm-up period.

0 2 4 6 8 10 Non-forced cooling

of noise. The end-deflector recirculation system A Maintains lubricant's effect

Time t, h

significantly improves high-speed capability and Removes heat from the ball screw, deterring

10

CBall screw specifications and other conditions

noise level compared with the existing return tube Shaft dia.: 40 mm

lubricant deterioration.

recirculation system, offering high-speed feeding Lead: 20 mm A Easy designing for installation

Torque: 51106 Ncm

of up to 1 200 mm/min (shaft dia. 40 mm, lead 30 Stroke: 1 000 mm

Use support bearing unit exclusive for NSK ball

mm, rotational speed 4 000 min-1). Maximum rotational speed: 3 000 min

1

1

screws (high speed and high load capacity for

Average rotational speed: 230 min

machine tools, see page B405) and seal unit

(2) Specifications Fig. 2 Calculation example of the variation of thermal expansion (page B543) to standardized shaft end. This 0 1 2

Hours (h)

Table 1 Specifications of twin-drive systems makes designing of mounting ball screw easy.

Inclination

NSK also provides nut cooling ball screws. The Fig. 1 Effect of forced cooling by hollow shaft ball screw

Recirculation End-deflector recirculation system,

level of temperature rise for nut cooling ball

systems Return tube system, Deflector(bridge type) system

Shaft dia. j32 63 mm 3. Model example of dimension table

Lead 10 30 mm

A model number that indicates specification

Accuracy grade C5

factors is structured as shown below.

Screw shaft length 3 m or less

eExample of model

(3) Optional specifications

Hollow shaft ball screw and nut cooling ball screw H 32 -

10

Provides high accuracy through the use of

Hollow bore (mm)

forced cooling. Please refer to ball screws for

Existing model TW Series Screw shaft model H Screw shaft diameter (mm)

high precision machine tools (page B540 to

Fig. 3 Schematic diagram of travel accuracy

B548) for more details.

B539 B540

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 4857 GFTJ PreJoining Fitness Plan PDF 2020 v2Document3 pages4857 GFTJ PreJoining Fitness Plan PDF 2020 v2jose mondacaNo ratings yet

- Ultra II Version 1.2Document32 pagesUltra II Version 1.2jose mondacaNo ratings yet

- Target Hydraulics Catalog 2018-Die Casting-Manifold-500050-2 and Stacked Manifold BlocksDocument16 pagesTarget Hydraulics Catalog 2018-Die Casting-Manifold-500050-2 and Stacked Manifold Blocksjose mondacaNo ratings yet

- Grundfosliterature 6859682Document2 pagesGrundfosliterature 6859682jose mondacaNo ratings yet

- Condition Based Monitoring Brochure: Test The TPI AdvantageDocument8 pagesCondition Based Monitoring Brochure: Test The TPI Advantagejose mondacaNo ratings yet

- TPI VibTrend User Guide Version 1Document32 pagesTPI VibTrend User Guide Version 1jose mondacaNo ratings yet

- 10 - Operating Instruction - DSC... - CAN Bus, Serial Bus - BEA - 209283-En-03Document8 pages10 - Operating Instruction - DSC... - CAN Bus, Serial Bus - BEA - 209283-En-03jose mondacaNo ratings yet

- Diagram ServoDocument2 pagesDiagram Servojose mondacaNo ratings yet

- (Osprey) Knight Hospitaller Part 1Document68 pages(Osprey) Knight Hospitaller Part 1jose mondacaNo ratings yet

- 8 - Operating Instruction - Control Card RK 4004 - BEA - 250482-En-14Document66 pages8 - Operating Instruction - Control Card RK 4004 - BEA - 250482-En-14jose mondaca0% (1)

- Sensor de Borde UltrasonicoDocument10 pagesSensor de Borde Ultrasonicojose mondacaNo ratings yet

- Dab Alp 800T PDFDocument5 pagesDab Alp 800T PDFjose mondacaNo ratings yet

- Bombas para Fluido TermicoDocument24 pagesBombas para Fluido Termicojose mondacaNo ratings yet

- TDi Installation Instructions 080219Document20 pagesTDi Installation Instructions 080219jose mondacaNo ratings yet

- Mac 800 UserIO ManualDocument8 pagesMac 800 UserIO Manualjose mondacaNo ratings yet

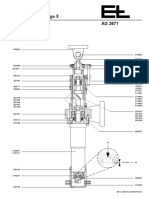

- 5 - Operating Instruction - Reel Station WS With DC Actuator AG 2571 AG 2671 AG 4571 AG 4671 - BEADocument8 pages5 - Operating Instruction - Reel Station WS With DC Actuator AG 2571 AG 2671 AG 4571 AG 4671 - BEAjose mondacaNo ratings yet

- Dresser Water Pipeline Repair BrochureDocument20 pagesDresser Water Pipeline Repair Brochurejose mondacaNo ratings yet

- Belden Catalog EnglishDocument23 pagesBelden Catalog Englishjose mondacaNo ratings yet

- 1 Pentax SA PDFDocument48 pages1 Pentax SA PDFjose mondaca0% (1)

- Guide BritIR - Cheap Tool-Like Thermographic InfraredDocument2 pagesGuide BritIR - Cheap Tool-Like Thermographic Infraredjose mondacaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 2015 No A Catalog For PrintoutDocument582 pages2015 No A Catalog For Printoutnicoss69No ratings yet

- Die Cast Chill VentsDocument6 pagesDie Cast Chill VentsSunil SharmaNo ratings yet

- Leopard CouriorDocument14 pagesLeopard CouriorMuhammad Rizwan AliNo ratings yet

- Cable Trench Installation Guide PDFDocument12 pagesCable Trench Installation Guide PDFecruz_yhwhNo ratings yet

- AMACS Accuflow Inlet Feed Devices Web1Document1 pageAMACS Accuflow Inlet Feed Devices Web1SHINo ratings yet

- Storage Tank Day Tank: From Daihatsu Diesel Genset CatalogueDocument34 pagesStorage Tank Day Tank: From Daihatsu Diesel Genset CatalogueEdmil Jhon Ariquez100% (1)

- Wheel Chair (Spec) (R)Document1 pageWheel Chair (Spec) (R)Andri StyaNo ratings yet

- Lowara PumpDocument84 pagesLowara Pumpmih4iNo ratings yet

- Raise Borer EpirocDocument8 pagesRaise Borer EpirocDiego Ignacio VelizNo ratings yet

- Hydro Jetting PumpDocument7 pagesHydro Jetting PumpTools & EquipmentsNo ratings yet

- HSC HowigDocument2 pagesHSC HowigNurdin Sudrajat SasrabahuNo ratings yet

- Description: Cu/Mica/Xlpe/Oscr/Lszh/Gswa/LszhDocument4 pagesDescription: Cu/Mica/Xlpe/Oscr/Lszh/Gswa/LszhTarek FawzyNo ratings yet

- Pneumatic Scissor Lift ManualDocument14 pagesPneumatic Scissor Lift ManualGptc ChekkanuraniNo ratings yet

- 5SDocument61 pages5SRitu AgarwalNo ratings yet

- Murphy PDFDocument3 pagesMurphy PDFeduardo100% (1)

- Automatic Circuit Recloser BrochDocument12 pagesAutomatic Circuit Recloser BrochsanNo ratings yet

- Witl 86Document24 pagesWitl 86davorko_tNo ratings yet

- Contract No. Bapex/Admin/1528: Shipping MarkDocument7 pagesContract No. Bapex/Admin/1528: Shipping MarkhaosfNo ratings yet

- Case Study: Capacity Expansion For Transportation Project - San Antonio's Project, BoliviaDocument3 pagesCase Study: Capacity Expansion For Transportation Project - San Antonio's Project, BoliviaMuhammad ImranNo ratings yet

- Ronan Point Tower CollapseDocument22 pagesRonan Point Tower CollapseMairu CheeMaNo ratings yet

- FenderDocument76 pagesFendernestor mospanNo ratings yet

- BHEL Reference Manuals S.No Manual DescriptionDocument4 pagesBHEL Reference Manuals S.No Manual DescriptionShubhamPrinceNo ratings yet

- Ashutosh Jaiswal Resume (NEW)Document2 pagesAshutosh Jaiswal Resume (NEW)api-3707632No ratings yet

- Em534mvi3 InstallationandoperatinginstructionsDocument36 pagesEm534mvi3 InstallationandoperatinginstructionscipyyyyNo ratings yet

- Handout t1124f 1511 3869 Onb Bus Das Srs TNDocument37 pagesHandout t1124f 1511 3869 Onb Bus Das Srs TNlequangthongNo ratings yet

- Report & Discrimination SLDDocument10 pagesReport & Discrimination SLDAnonymous SOQFPWBNo ratings yet

- 100KW GeneratorDocument3 pages100KW GeneratorNicole PalomaresNo ratings yet

- 116r - 90-Cement and Concrete Terminology PDFDocument68 pages116r - 90-Cement and Concrete Terminology PDFjuan carlos alvarez gomezNo ratings yet

- German Level 2 - Student Workbook PDFDocument100 pagesGerman Level 2 - Student Workbook PDFAndrew Antwan100% (3)

- With Ieee STD Ieee Standard Digital Interface ForDocument144 pagesWith Ieee STD Ieee Standard Digital Interface ForhaythemNo ratings yet