Professional Documents

Culture Documents

Astm F1506 PDF

Uploaded by

xanilomOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm F1506 PDF

Uploaded by

xanilomCopyright:

Available Formats

Designation: F 1506 02ae1

Standard Performance Specification for

Flame Resistant Textile Materials for Wearing Apparel for

Use by Electrical Workers Exposed to Momentary Electric

Arc and Related Thermal Hazards1

This standard is issued under the fixed designation F 1506; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e1 NOTEEditorial changes were made in February 2004.

1. Scope 1.6 The values stated in SI units are to be regarded as the

1.1 This performance specification covers the flame resis- standard. The values given in parentheses are for information

tance of textile materials to be used for wearing apparel for use only.

by electrical workers exposed to momentary electric arc and 1.7 The following precautionary caveat pertains only to the

related thermal hazards. test methods portion, Section 7, of this performance specifica-

tion: This standard does not purport to address all of the safety

NOTE 1This performance specification does not cover coated fabrics concerns, if any, associated with its use. It is the responsibility

commonly used in rainwear.

of the user of this standard to establish appropriate safety and

NOTE 2At present, a bench scale arc test for laboratory use is not

available. It is the intent of the committee to continue the search for an health practices and determine the applicability of regulatory

acceptable laboratory test based on either an electric arc exposure or an limitations prior to use.

acceptable alternative, which will form the basis of a modification of this

performance specification. 2. Referenced Documents

1.2 Materials used for basic protection levels are covered. 2.1 ASTM Standards: 2

1.3 Protective properties relate to thermal exposure from D 123 Terminology Relating to Textiles

momentary arc and associated exposure to open flame and D 434 Test Method for Resistance to Slippage of Yarns in

radiant heat. (See Appendix X1.) Woven Fabrics Using a Standard Seam

1.4 This performance specification covers wearing apparel D 1424 Test Method for Tearing Strength of Fabrics by

design characteristics that relate specifically to protection from Falling-Pendulum Type (Elmendorf) Apparatus

exposure to momentary electric arc and that relate to the utility D 2262 Test Method for Tearing Strength of Woven Fabrics

of the wearing apparel. by the Tongue (Single Rip) Method (Constant-Rate-of-

Traverse Tensile Testing Machine)

NOTE 3A number of other thermal test methods are under consider- D 2724 Test Methods for Bonded, Fused, and Laminated

ation and development and, when evaluated and proved effective by

Committee F18, will be incorporated in either this performance specifi-

Apparel Fabrics

cation or an appropriate alternative test method or specification. D 3786 Test Method for Hydraulic Bursting Strength of

Knitted Goods and Nonwoven FabricsDiaphragm

1.5 This standard should be used to evaluate and describe Bursting Strength Tester Method

the properties of materials, products, or assemblies in response D 5034 Test Method for Breaking Strength and Elongation

to heat and flame under controlled laboratory conditions. It of Textile Fabrics (Grab Test)

should not be used to describe or appraise the fire hazard or D 6413 Test Method for Flame Resistance of Textiles (Ver-

fire risk of materials, products, or assemblies under actual fire tical Test)

conditions. F 1449 Guide for Care and Maintenance for Flame Resis-

1.5.1 The results of this evaluation may be used as elements tant and Thermally Protective Clothing

of a fire-risk assessment that takes into account all of the F 1959 Test Method for Determining the Arc Thermal

factors that are pertinent to an assessment of the fire hazard of Performance Value of Materials for Clothing

a particular end use.

--`,,`,`,`,,,,,,,,,,,``,```````-`-`,,`,,`,`,,`---

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This performance specification is under the jurisdiction of ASTM Committee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

F18 on Electrical Protective Equipment for Workers and is the direct responsibility Standards volume information, refer to the standards Document Summary page on

of Subcommittee F18.65 on Wearing Apparel. the ASTM website.

Current edition approved May 10, 2002. Published July 2002. Originally

published as F 150694. Last previous edition F 150602.

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International 1

Provided by IHS under license with ASTM Licensee=Universidad Nacional de Colombia/5965511001

No reproduction or networking permitted without license from IHS Not for Resale, 12/10/2007 11:45:54 MST

F 1506 02ae1

2.2 AATCC Test Methods:3 3.2.8 design test, nfor arc and flame resistant textile

Method 61 Colorfastness to Washing, Domestic and Laun- materials, one made on a sample treated as representative of an

dering, Commercial: Accelerated industrial product; these tests will not generally be repeated in

Method 132 Colorfastness to Dry-Cleaning quantity production.

Method 135 Dimensional Changes Automatic Home Laun- 3.2.8.1 DiscussionPerform the design test only when a

dering of Woven and Knitted Fabrics new or modified textile material, that is, fabric, is used to

Method 158 Dimensional Changes on Drycleaning in Per- manufacture apparel. A modification in the fabric could be, but

chloroethylene: Machine Method is not limited to, any of the following: the supplier, composi-

2.3 Federal Standard:4 tion, weave type, weight, or dyeing and finishing process.

Test Method 191A, 1534 3.2.9 findingsmiscellaneous fabrics in garments such as

zipper tapes, linings, pockets, waistbands, and facings.

3. Terminology 3.2.10 momentary electric arca discharge of electricity

3.1 DefinitionsFor definitions of textile terms used in this through a gaseous media, normally characterized by a voltage

performance specification, refer to Terminology D 123. drop in the immediate vicinity of the electrodes, approximately

3.2 Definitions of Terms Specific to This Standard: equal to the ionization potential of the gaseous media.

3.2.1 afterflame, npersistent flaming of a material after 3.2.11 radiant heatheat communicated by energy propa-

the ignition source has been removed. gated through space and transmitted by electromagnetic waves.

3.2.1.1 DiscussionIn arc testing, a visible flaming on or 3.2.12 thermal hazardthe heat energy sufficient to cause

near a test specimen which persists after the arc exposure has burn injury to human tissue subjected to a momentary electric

--`,,`,`,`,,,,,,,,,,,``,```````-`-`,,`,,`,`,,`---

ended. The afterflame ceases when flaming is no longer visible. arc.

3.2.2 afterflame time, nthe length of time for which a 3.2.13 userthe employer or entity purchasing the equip-

material continues to flame after the ignition source has been ment to be utilized by workers for their protection; in the

removed. absence of such an employer or entity, the individual purchas-

3.2.2.1 DiscussionIn arc testing, the length of time for ing and utilizing the protective equipment.

which a specimen continues to exhibit a visible flaming as

4. Significance and Use

determined by a time display video recording of the specimen

during arc testing. 4.1 This performance specification provides performance

3.2.3 arc rating, nthe maximum incident energy (E1) properties for textile materials used in wearing apparel that

resistance demonstrated by a material prior to breakopen or at represent initial minimum requirements for basic protection

the onset of a seconddegree burn. levels.

3.2.3.1 DiscussionWhen the Arc Thermal Performance 4.1.1 The performance properties have been selected based

Value (ATPV) of the material cannot be determined due to on materials in use and take into consideration durability

breakopen, the arc rating is determined by measuring the requirements for specific apparel.

Breakopen Threshold Energy (EBT) according to Test Method 4.2 Work practices vary from user to user depending upon

F 1959. When the arc rating represents the Arc Thermal many factors. These may include, but are not limited to,

Performance Value, it is indicated as arc rating (ATPV); when operating system voltages, construction design, work proce-

representing the Breakopen Threshold Energy, it is indicated as dure or techniques, and weather conditions. Therefore, except

arc rating (EBT). for the restrictions set forth in this performance specification

3.2.4 arc thermal performance value (ATPV), nin arc because of design limitations, the use and maintenance of this

testing, the incident energy on a fabric or material that results equipment is beyond the scope of this performance specifica-

in sufficient heat transfer through the fabric or material to cause tion.

the onset of a second-degree burn based on the Stoll curve. 4.2.1 It is common practice and the responsibility of the user

3.2.5 basic protection levelthe level of protection pro- of this type of protective equipment to prepare complete

vided by flame-resistant materials that do not continue to burn instructions and regulations to govern in detail the correct and

after exposure to and removal of a source of ignition (see 7.6). safe use of such equipment.

3.2.6 basic protection level wearing apparelclothing in- 5. Materials and Manufacture

tended for continuous wear for work activities in designated

locations in which exposure to momentary electric arc and 5.1 Material tests shall be performed on textile materials as

related radiant heat and open-flame sources is possible. they are delivered to the clothing manufacturer.

3.2.7 breakopen threshold energy (EBT), nin electric arc 5.1.1 Material tests may be performed on samples taken

testing, the average of the five highest E1 values that did not from finished garments.

cause specimen breakopen and did not cause sensor tempera- 5.2 Lot size for the initial (without laundering) flammability

ture rise to exceed the Stoll curve. test shall be 4572 m (5000 yd) of manufactured fabric or the

manufactured yardage, whichever is less. One sample of 1.0 m

shall be taken from each lot.

3

5.3 Lot size for all other tests except design tests shall be 45

AATCC Technical Manual, available from American Association of Textile

Chemists and Colorists, PO Box 12215, Research Triangle Park, NC 27709-2215.

720 m (50 000 yd) or at least every three months, whichever is

4

Available from Standardization Documents Order Desk, Bldg. 4, Section D, more frequent. One sample of 4.0 m shall be taken from each

700 Robbins Ave., Philadelphia, PA 191115094, Attn: NPODS. lot.

Copyright ASTM International 2

Provided by IHS under license with ASTM Licensee=Universidad Nacional de Colombia/5965511001

No reproduction or networking permitted without license from IHS Not for Resale, 12/10/2007 11:45:54 MST

F 1506 02ae1

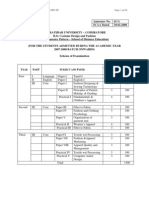

5.4 Design tests shall be run on the original and when TABLE 2 Requirements, Knit Fabrics

changes are made to flame resistant textile materials, for Fabric Weight Ranges, oz/yd2 Section

example, fiber type, yarn type, weaving style, fabric weight, 3.08.0 8.116.0 Reference

dyeing, or finishing procedure. Characteristic:

Bursting strength, min, N (lbf) 179 (40) 268 (60) 7.7

6. Requirements Colorfastness:

Laundering shade change, min Class 3 Class 3 7.4.1

6.1 Thread, findings, and closures used in garment construc- Dry-cleaning shade change, min Class 3 Class 3 7.4.2

tion shall not contribute to the severity of injuries to the wearer Dimensional change, max ... ... 7.5

Initial Flammability: A,B

in the event of a momentary electric arc and related thermal Char length, max, mm (in.) 152 (6.0) 152 (6.0) 7.6

exposure. Afterflame, max, s 2 2 7.6

6.1.1 Sewing thread utilized in the construction of garments Flammability After 25 Washes/Dry

Cleaning:

shall be made of an inherently flame-resistant fiber and shall Char length, max, mm (in.) 152 (6.0) 152 (6.0) 7.6

not melt when tested at a temperature of 260C (500F) in Afterflame, max, s 2 2 7.6

Arc Test Results:

accordance with Federal Test Method Standard 191A, 1534. Afterflame time, max, s (for 5 5 7.8.1

NOTE 4If fasteners or closures, for example, zippers, snaps, or single layer arc test specimens)

buttons, or a combination thereof, are used in a manner in which they are Reported Values Arc Rating,C cal/ Report measured valuesC 7.8

in contact with the skin, they can increase heat transfer and burn injury cm2

due to heat conduction or melting onto the skin. Fasteners or closures that A

Certain treated fabrics exhibit afterglow during the flammability test. This has

are used in this manner should be covered with a layer of fabric between been judged not a serious hazard. When afterglow occurs, extinguish it after 10 s.

the fastener or closure and the skin. The fabric used for this purpose shall Then measure char length and record either the actual time, or greater than 10 s

meet the requirements of this performance specification. for afterglow in the report.

B

No melting and dripping of the test material is permitted.

C

6.2 The properties of materials for basic protection level When the arc rating represents the ATPV, it shall be designated as arc rating

(ATPV). When arc rating represents the EBT, it shall be designated as arc rating

wearing apparel shall conform to the specifications in Table 1 (EBT). Arc rating is determined and reported for a fabric that meets all the

and Table 2, when evaluated in accordance with Section 7. requirements of this performance specification to provide guidance on the perfor-

mance of the fabric in arc exposure testing. There is no minimum required value

NOTE 5Physical characteristic tests and values in Section 7 and Table for arc rating. For additional information on ATPV and EBT, see Test Method

1 and Table 2 are based on experience from woven and knit fabrics F 1959.

currently in use and may not be applicable to other fabric types.

NOTE 6Characteristics (for example, clothing ensembles, design, and

laundry maintenance) of protective garments for basic protection level 6.3.2 Meets requirements of Performance Specification

wearing apparel should be guided by the information contained in F 1506,

Appendix X1. 6.3.3 Manufacturers name,

6.3 Garments shall be labeled with the following informa- 6.3.4 Size and other associated standard labeling,

tion: 6.3.5 Care instructions and fiber content, and

6.3.1 Tracking identification code system, 6.3.6 Arc rating (ATPV) or arc rating (EBT).

TABLE 1 Requirements, Woven Fabrics

Fabric Weight Ranges, oz/yd 2 Section

3.05.9 6.08.4 8.5 and higher Reference

Characteristic:

Breaking load, min, N (lbf) 134 (30) 179 (40) 223 (50) 7.1

--`,,`,`,`,,,,,,,,,,,``,```````-`-`,,`,,`,`,,`---

Tear resistance, min, N (lbf) 11 (2.5) 18 (4.0) 22 (5.0) 7.2

Seam slippage, max 6 mm at 134 N 6 mm at 179 N 6 mm at 223 N 7.3

(0.25 in. at 30 lbf) (0.25 in. at 40 lbf) (0.25 in. at 50 lbf)

Colorfastness:

Laundering shade change, min Class 3 Class 3 Class 3 7.4.1

Dry-cleaning shade change, min Class 3 Class 3 Class 3 7.4.2

Dimensional change, max 3.0 % 3.0 % 3.0 % 7.5

Initial Flammability: A,B

Char length, max, mm (in.) 152 (6.0) 152 (6.0) 152 (6.0) 7.6

Afterflame, max, s 2 2 2 7.6

Flammability After 25 Washes/Dry Cleaning:

Char length, max, mm (in.) 152 (6.0) 152 (6.0) 152 (6.0) 7.6

Afterflame, max, s 2 2 2 7.6

Arc Test Results:

Afterflame time, max, s (for single layer arc test specimens) 5 5 5 7.8.1

Reported Values Arc Rating,C cal/cm2 Report measured valuesC 7.8

A

Certain treated fabrics exhibit afterglow during the flammability test. This has been judged not a serious hazard. When afterglow occurs, extinguish it after 10 s. Then

measure char length and record either the actual time, or greater than 10 s for afterglow in the report.

B

No melting and dripping of the test material is permitted.

C

When the arc rating represents the ATPV, it shall be designated as arc rating (ATPV). When arc rating represents the EBT, it shall be designated as arc rating (EBT).

Arc rating is determined and reported for a fabric that meets all the requirements of this performance specification to provide guidance on the performance of the fabric

in arc exposure testing. There is no minimum required value for arc rating. For additional information on ATPV and EBT, see Test Method F 1959.

Copyright ASTM International 3

Provided by IHS under license with ASTM Licensee=Universidad Nacional de Colombia/5965511001

No reproduction or networking permitted without license from IHS Not for Resale, 12/10/2007 11:45:54 MST

F 1506 02ae1

6.3.6.1 When garments are made with a different number of 7.6.2 Fabrics labeled Dry Clean Only shall be dry-cleaned

fabric layers in different areas of the garment, the arc rating for 25 times using the procedure in Test Methods D 2724, Section

each area shall be designated. Pockets, trim, closures, seams, 6.1.

labels, and heraldry shall not be considered as extra layers. 7.7 Bursting StrengthDetermine the bursting strength of

knitted fabrics in accordance with Test Method D 3786.

7. Test Methods

7.8 Arc RatingIf the material meets the flammability

7.1 Breaking LoadDetermine the breaking load in accor- requirements in 7.6 and Tables 1 and 2, determine the arc rating

dance with Test Methods D 5034 (Grab test G: CRT or CRE). of the material in accordance with Test Method F 1959. Test

7.2 Tear ResistanceDetermine the tear resistance in ac- Method F 1959 is a design test.

cordance with Test Method D 1424.

7.2.1 As an option for selected materials, Test Method NOTE 9Arc rating values below 10 cal/cm2 shall be reported to the

D 2262 may be employed. This option may be exercised upon nearest 0.1 cal/cm2, and arc rating values above 10 cal/cm2 shall be

reported to the nearest 1 cal/cm2.

agreement between the buyer and the seller. However, corre-

lation between this test method and Test Method D 1424 is not 7.8.1 When arc testing in accordance with Test Method

expected. F 1959, for single layer systems only, afterflame time shall be

7.3 Seam SlippageDetermine the seam slippage in accor- determined by calculating the average afterflame time of at

dance with Test Method D 434. least three arc test specimens for which the incident energy is

7.4 Colorfastness: equal to or greater than the ATPV or EBT (which ever is

7.4.1 LaunderingDetermine the colorfastness to launder- applicable). All arc test specimen exposures for which the

ing in accordance with AATCC Method 61, IIA. incident energy is equal to or greater than the ATPV or EBT

7.4.2 Dry CleaningDetermine the colorfastness to dry shall be reported and used in the determination of afterflame

cleaning in accordance with AATCC Method 132. time. Afterflame time shall not be more than 5 s.

NOTE 7Launderable fabrics are expected to be dry-cleanable except

where all or part of the fabric is not dry-cleanable and is so labeled. Goods 8. Report

labeled Dry Clean Only are to be only dry-cleaned. 8.1 Report the following information:

7.5 Dimensional ChangeFor laundry shrinkage, deter- 8.1.1 Results of testing as required in Sections 5, 6, and 7,

mine dimensional change as directed in AATCC Method 135, 8.1.2 Lot number,

using Conditions for Machine Cycle 3, Wash Cycle IV, Drying 8.1.3 Size of lot,

Procedure A iii, five washes. For dry-cleanable shrinkage, use 8.1.4 Sample identification, and

AATCC Test Method 158. 8.1.5 Number of samples tested in accordance with 6.2.

--`,,`,`,`,,,,,,,,,,,``,```````-`-`,,`,,`,`,,`---

NOTE 8AATCC Method 135 should not be employed for fabrics 8.2 For each sample fabric that meets the requirements of

marked Do Not Wash. this performance specification, a report similar to the format

7.6 FlammabilityThe flammability of the material shall shown in Table 1 for woven fabrics or Table 2 for knit fabrics

be tested in accordance with Test Method D 6413 for samples shall be used to report the results of testing that is required in

both initially and after washing as specified in 7.6.1 or dry Sections 5, 6, and 7. In addition, a description of the fabric

cleaning as specified in 7.6.2. No melting and dripping of the composition, weight, color, and weave or knit construction

test material is permitted. shall be included. This report shall be made available to the

7.6.1 Fabrics suitable for washing shall be washed 25 times purchaser of garments meeting this performance specification

using the AATCC Method 135 (3, IV, A iii). by the garment manufacturer.

APPENDIX

(Nonmandatory Information)

X1. GUIDELINES FOR PROTECTIVE WEARING APPAREL

X1.1 Although this performance specification for basic X1.1.2 Garments that meet this performance specification

protection level wearing apparel for electrical workers is may be used for a layered system for added protection. A

written for single-layer work clothing, it is recognized that typical layering system may include an undershirt, a shirt,

optimum protective performance to severe exposure (for ex- trousers, and a flash jacket or may include a shirt and trouser

ample, high currents, closeness to the arc, long time periods) and coverall. Specific tasks that may involve high-energy

involves the use of an appropriate system. levels, for example switching, grounding, and jumpering, may

X1.1.1 Garments worn as underlayers (underwear) that require specialized clothing.

neither ignite nor melt and drip in the course of an exposure to X1.1.3 Additional factors that may contribute to injury are

the electric arc and related thermal hazard may provide under consideration and may result in the need to consider

additional thermal insulation. other specifications for protective systems.

Copyright ASTM International 4

Provided by IHS under license with ASTM Licensee=Universidad Nacional de Colombia/5965511001

No reproduction or networking permitted without license from IHS Not for Resale, 12/10/2007 11:45:54 MST

F 1506 02ae1

X1.2 Design ConsiderationsThe following are some of overall area should be minimized on the garment. For example,

the principles that should be considered in the design and use large company logos across the back of the garment should not

of wearing apparel for protection from momentary electric arc be applied. In addition, the use of several logos over the entire

and related thermal hazards: garment should be avoided.

X1.2.1 Clothing should cover potentially exposed areas as

completely as practicable. This should include proper interfac- X1.3 Laundering:

ing of related items. X1.3.1 The garment manufacturer in conjunction with the

X1.2.2 Garment design should permit easy and rapid re- fiber and fabric supplier should provide instructions for the

moval. Closure design should be appropriate for easy removal care and maintenance of protective wearing apparel. See Guide

of the garment. F 1449 concerning care and maintenance of protective gar-

--`,,`,`,`,,,,,,,,,,,``,```````-`-`,,`,,`,`,,`---

X1.2.3 Garment design should be such that the garment ments.

interferes the least with work function but still provides the X1.3.2 Because of the variety of different types of knitted

necessary protection. fabrics that might be used in different configurations of

X1.2.4 The fit of all garments is important to acceptance and protective wearing apparel, it is not possible to provide a

function. A sizing document for protective wearing apparel is meaningful value for shrinkage in Table 2. Values of 10 to

under consideration by Subcommittee F18.40. 12 % shrinkage are not uncommon. It is suggested that knitted

X1.2.5 Logos, name tags, and other heraldry, such as flag garments expected to shrink significantly be purchased appro-

patches and company award insignias, are used to identify the priately oversized and that they be washed one time by the

organization and individual. If these items are constructed of wearer in accordance with the instructions of the manufacturer

non-flame resistant materials (such as polyester or rayon), their prior to use to thus reach a more stable configuration.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

Copyright ASTM International 5

Provided by IHS under license with ASTM Licensee=Universidad Nacional de Colombia/5965511001

No reproduction or networking permitted without license from IHS Not for Resale, 12/10/2007 11:45:54 MST

You might also like

- Astm F1506-22 PDFDocument12 pagesAstm F1506-22 PDFEnrique Valdez ArévaloNo ratings yet

- Live Line and Measuring Telescoping Tools: Standard Specification ForDocument6 pagesLive Line and Measuring Telescoping Tools: Standard Specification Formasoud100% (1)

- ASTM D470. Crosslinked Insulations and Jackets For Wire and Cable1Document25 pagesASTM D470. Crosslinked Insulations and Jackets For Wire and Cable1sanrris4503090% (1)

- Astm F711Document10 pagesAstm F711okocha85No ratings yet

- Dielectric Breakdown Voltage of Insulating Liquids Using Disk ElectrodesDocument6 pagesDielectric Breakdown Voltage of Insulating Liquids Using Disk ElectrodesEliecer Emilio Carvajal Santos100% (1)

- Visual Inspection of Electrical Protective Rubber Products: Standard Guide ForDocument14 pagesVisual Inspection of Electrical Protective Rubber Products: Standard Guide Forjuanita_0403No ratings yet

- Counting Scale: FC-50Ki FC-20Ki FC-10Ki FC-5000iDocument64 pagesCounting Scale: FC-50Ki FC-20Ki FC-10Ki FC-5000iHigo UcNo ratings yet

- Ieee 516Document89 pagesIeee 516Jenna MckeeNo ratings yet

- Astm D1048Document7 pagesAstm D1048Avinash K. Sadhu100% (1)

- Infrared Flash Thermography of Composite Panels and Repair Patches Used in Aerospace ApplicationsDocument6 pagesInfrared Flash Thermography of Composite Panels and Repair Patches Used in Aerospace ApplicationsAnbarasan PerumalNo ratings yet

- ASTM D 149 Standard Test Method Dielectric Breakdown VoltageDocument1 pageASTM D 149 Standard Test Method Dielectric Breakdown VoltageLaurence MalanumNo ratings yet

- Ieee C62.22Document2 pagesIeee C62.22NataGBNo ratings yet

- Automotive Electronics Council-Q200 Stress Test Qualification For Passive Components Syfer AEC-Q200-Rev C QualificationDocument7 pagesAutomotive Electronics Council-Q200 Stress Test Qualification For Passive Components Syfer AEC-Q200-Rev C QualificationgubiliNo ratings yet

- Ansi C29.2aDocument22 pagesAnsi C29.2afecasNo ratings yet

- Electrical Safety ClearanceDocument23 pagesElectrical Safety ClearanceJeya Kannan100% (1)

- The Dielectric Voltage Withstand Test - Benefits and LimitationsDocument7 pagesThe Dielectric Voltage Withstand Test - Benefits and LimitationsJoeDabidNo ratings yet

- Astm F496-14Document8 pagesAstm F496-14James Albeiro Sánchez NarváezNo ratings yet

- En 55022Document3 pagesEn 55022rosebifNo ratings yet

- Iec 60214 1 PreviewDocument9 pagesIec 60214 1 PreviewSreeram Panigrahi0% (1)

- Ul 913 1988Document69 pagesUl 913 1988Jesus OrtizNo ratings yet

- APECB 245 - 300 Instructions NKT 4280,0122,0CDocument40 pagesAPECB 245 - 300 Instructions NKT 4280,0122,0CWenceslao EscorzaNo ratings yet

- Associations and Reference StandardsDocument13 pagesAssociations and Reference StandardsgaburrNo ratings yet

- Astm D880Document4 pagesAstm D880keberso1602100% (1)

- Hi POT Test BasicsDocument6 pagesHi POT Test BasicsdeepakNo ratings yet

- D 6054 - 97 - Rdywntq - PDFDocument3 pagesD 6054 - 97 - Rdywntq - PDFwilliamNo ratings yet

- Ul 1561Document8 pagesUl 1561marco valencia100% (1)

- Ansi C57 12 50 1981 PDFDocument26 pagesAnsi C57 12 50 1981 PDFdiscovered213No ratings yet

- ICEA S-93-639-2017 - UnlockedDocument108 pagesICEA S-93-639-2017 - UnlockedFelipeandres Lizana BastiasNo ratings yet

- Astm f1197 1989Document6 pagesAstm f1197 1989RajkumarNo ratings yet

- ASTM D2303 DC Inclined-Plane Tracking and Erosion Test of Insulating MaterialsDocument10 pagesASTM D2303 DC Inclined-Plane Tracking and Erosion Test of Insulating MaterialsMohamed Ahmed AfifiNo ratings yet

- Icea T 26 Nema WC 54Document12 pagesIcea T 26 Nema WC 54vadmanhNo ratings yet

- Iec 60115-1-2008Document80 pagesIec 60115-1-2008amer100% (1)

- Astm D4496Document5 pagesAstm D4496Sampath WeragodaNo ratings yet

- BS6883&BS7917 Offshore & Marine CableDocument49 pagesBS6883&BS7917 Offshore & Marine CableAhmed H. HassanNo ratings yet

- Standard Test Method For Electrical InsulationDocument18 pagesStandard Test Method For Electrical InsulationKian ChuanNo ratings yet

- En 50160Document1 pageEn 50160cool_saklshpurNo ratings yet

- Astm F2249 PDFDocument7 pagesAstm F2249 PDFAngel Navarro100% (1)

- Astm D 4169Document11 pagesAstm D 4169Angus CHUNo ratings yet

- Astm f2320Document6 pagesAstm f2320Leandro CostaNo ratings yet

- VRLA Battery TestingDocument3 pagesVRLA Battery TestingedgardNo ratings yet

- Doble Test ProceduresDocument21 pagesDoble Test Proceduresdsfas100% (1)

- American National Standard Requirements For Power-Line Carrier Coupling Capacitors and Coupling Capacitor Voltage Transformers (CCVT)Document47 pagesAmerican National Standard Requirements For Power-Line Carrier Coupling Capacitors and Coupling Capacitor Voltage Transformers (CCVT)LuisManuelTrujilloMartínezNo ratings yet

- EN 60204-1 - Summary - PresentationDocument15 pagesEN 60204-1 - Summary - PresentationFakhri Alibol100% (1)

- Cable Trays NEMA ClassificationsDocument2 pagesCable Trays NEMA ClassificationsJoel Alcantara100% (1)

- Nes 526 PDFDocument4 pagesNes 526 PDFDIPAKNo ratings yet

- 7.3.2 Cables, Low-Voltage, 600-Volt MaximumDocument2 pages7.3.2 Cables, Low-Voltage, 600-Volt MaximumGlen PolandNo ratings yet

- NEMA VE 1 2017 Contents and ScopeDocument7 pagesNEMA VE 1 2017 Contents and ScopeShehiryar MuzamalNo ratings yet

- BS en 61557-12-2008Document82 pagesBS en 61557-12-2008Linh TruongNo ratings yet

- Astm D257-99Document18 pagesAstm D257-99Demian Pereira100% (1)

- Astm d470 Crosslinked Insulations and Jackets ForDocument25 pagesAstm d470 Crosslinked Insulations and Jackets ForYimmy VelasquezNo ratings yet

- IEC 60950 Rev1Document3 pagesIEC 60950 Rev1Rip_BarNo ratings yet

- Astm B 263Document3 pagesAstm B 263Ryan Lasaca100% (1)

- ASTM F 1506-10aDocument5 pagesASTM F 1506-10aaft.tiagokosNo ratings yet

- Flame Resistant and Arc Rated Textile Materials For Wearing Apparel For Use by Electrical Workers Exposed To Momentary Electric Arc and Related Thermal HazardsDocument7 pagesFlame Resistant and Arc Rated Textile Materials For Wearing Apparel For Use by Electrical Workers Exposed To Momentary Electric Arc and Related Thermal HazardsJuan Cho MejiaNo ratings yet

- Astm F1506-22Document12 pagesAstm F1506-22Laura Ruiz EspinelNo ratings yet

- Flame Resistant and Electric Arc Rated Protective Clothing Worn by Workers Exposed To Flames and Electric ArcsDocument9 pagesFlame Resistant and Electric Arc Rated Protective Clothing Worn by Workers Exposed To Flames and Electric ArcsLaura Ruiz EspinelNo ratings yet

- F2621 PDFDocument8 pagesF2621 PDFAhmad Zubair Rasuly0% (1)

- ESD Controlled Garments Required in Cleanrooms and Controlled Environments For Spacecraft For Non-Hazardous and Hazardous OperationsDocument12 pagesESD Controlled Garments Required in Cleanrooms and Controlled Environments For Spacecraft For Non-Hazardous and Hazardous Operationsjun floresNo ratings yet

- Rubber Insulating Sleeves: Standard Specification ForDocument10 pagesRubber Insulating Sleeves: Standard Specification ForPavan KumarNo ratings yet

- D 5591 - 02 Rdu1oteDocument4 pagesD 5591 - 02 Rdu1oteJuanNo ratings yet

- Astm d1785 1986Document11 pagesAstm d1785 1986天王华No ratings yet

- Astm A106 - 2004 PDFDocument10 pagesAstm A106 - 2004 PDFIuliana ChilăNo ratings yet

- Astm A106 PDFDocument13 pagesAstm A106 PDFDanny Milton Silva VasquezNo ratings yet

- Guide To Voltage DipsDocument1 pageGuide To Voltage Dipsadebowale olaoluNo ratings yet

- D 140 - 00 Rde0mc1sruqDocument7 pagesD 140 - 00 Rde0mc1sruqRufo CascoNo ratings yet

- Astm - Standard Test Method For Penetration of Bituminous MaterialsDocument3 pagesAstm - Standard Test Method For Penetration of Bituminous Materialsnica tamNo ratings yet

- 1 Core 630Document2 pages1 Core 630xanilomNo ratings yet

- A-Z of Embroidery Stitches PDFDocument67 pagesA-Z of Embroidery Stitches PDFLiran Shani89% (28)

- Stitches TheoryDocument9 pagesStitches Theorysunita nasta100% (1)

- Buzz Lightyear AmigurumiDocument10 pagesBuzz Lightyear AmigurumiDaniela100% (6)

- Industrialattachmentofviyellatexgroup 140511100625 Phpapp02 PDFDocument106 pagesIndustrialattachmentofviyellatexgroup 140511100625 Phpapp02 PDFNazmul Alam ShameemNo ratings yet

- Final Report IndustrialDocument48 pagesFinal Report IndustrialHacked Dev HackedNo ratings yet

- Internship Report On Concepts of Modern Merchandising Tools and Techniques in Sweater (Woolen & Wool LTD) Industry.Document130 pagesInternship Report On Concepts of Modern Merchandising Tools and Techniques in Sweater (Woolen & Wool LTD) Industry.RahatSaifNo ratings yet

- Internship Report of Subrata RoyDocument61 pagesInternship Report of Subrata RoyMahbubur RahmanNo ratings yet

- Slub YarnDocument15 pagesSlub YarnMoustafa Abdeltwab100% (2)

- Iris Inglish PDFDocument17 pagesIris Inglish PDFtamaraiivana100% (2)

- Dimensional Properties of Fleece FabricDocument5 pagesDimensional Properties of Fleece Fabricmac2022No ratings yet

- Amigurumi Penguin PatternDocument8 pagesAmigurumi Penguin PatternBrittany KapjonNo ratings yet

- Interloop Annual Report 2021Document178 pagesInterloop Annual Report 2021maria aghaNo ratings yet

- Moi University School of Engineering Department of Mechanical and Production EngineeringDocument8 pagesMoi University School of Engineering Department of Mechanical and Production Engineeringhr maNo ratings yet

- Art Appreciation Book Final Pub. 2018 1Document83 pagesArt Appreciation Book Final Pub. 2018 1한서린85% (172)

- User S Manual Synthetic Mooring TailsDocument13 pagesUser S Manual Synthetic Mooring TailsGökhan UlukuzNo ratings yet

- South Park Cartman Amigurumi PatternDocument7 pagesSouth Park Cartman Amigurumi PatternDascaliuc DanielNo ratings yet

- B.SC SubjectsDocument24 pagesB.SC Subjectsranju93No ratings yet

- Amelia ENDocument16 pagesAmelia ENБогдана Михалочкіна100% (1)

- Crochet Pattern Miniature Schnauzer: LittleowlshutDocument24 pagesCrochet Pattern Miniature Schnauzer: LittleowlshutNancy Huipio100% (5)

- Crochet BeeDocument4 pagesCrochet BeeHydra Jvr100% (1)

- Fabric: Standard Terminology Relating ToDocument7 pagesFabric: Standard Terminology Relating ToJuanNo ratings yet

- Linen and Uniform RoomDocument30 pagesLinen and Uniform Roomchefjaved100% (17)

- Abs Nandan DenimDocument165 pagesAbs Nandan DenimashokNo ratings yet

- Indian Textile IndustryDocument0 pagesIndian Textile Industrydianty_marienkafergsNo ratings yet

- Class 12Document12 pagesClass 12Ramasubramaniam PalaniswamyNo ratings yet

- 07 Chapter 2Document103 pages07 Chapter 2Mukesh Manwani100% (1)

- Amigurumi Bunny Pofoo Crochet Free PDF PatternDocument6 pagesAmigurumi Bunny Pofoo Crochet Free PDF Patternhartmannandrew260No ratings yet

- Garment Costing SheetDocument1 pageGarment Costing Sheetkannra75% (4)

- A-A-52084D 2018 Aramid Lacing and Tying TapeDocument5 pagesA-A-52084D 2018 Aramid Lacing and Tying TapebabshuagNo ratings yet

- Raw Silk Reeling SourceDocument8 pagesRaw Silk Reeling SourceChelsea Chloe CaldinoNo ratings yet