Professional Documents

Culture Documents

Bisoprolol Fumarate Optizorb Dispersible Tablet PDF

Uploaded by

mailtorubal2573Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bisoprolol Fumarate Optizorb Dispersible Tablet PDF

Uploaded by

mailtorubal2573Copyright:

Available Formats

WORLD JOURNAL OF PHARMACY AND PHARMACEUTICAL SCIENCES

Lavanya et al. World Journal of Pharmacy and Pharmaceutical Sciences

SJIF Impact Factor 2.786

Volume 4, Issue 1, 561-576. Research Article ISSN 2278 4357

FORMULATION AND EVALUATION OF BISOPROLOL FUMARATE

OPTIZORB DISPERSIBLE TABLET TO IMPROVE TABLET

DISINTEGRATION

B. Lavanya*1 and V. Shanmugam2

1

Department of Pharmaceutics, Sri Padmavathi School of Pharmacy, Tiruchanur- 517503,

Tirupati, Andhra Pradesh, India.

2

Faculty in Pharmaceutics, Sri Padmavathi School of Pharmacy, Tiruchanur- 517503,

Tirupati, Andhra Pradesh, India.

ABSTRACT

Article Received on

23 Oct 2014, The present research work was aimed the formulation and evaluation

Revised on 18 Nov 2014,

of OptiZorb dispersible tablets of bisoprolol fumarate, an

Accepted on 14 Dec 2014 antihypertensive agent. The OptiZorb technology is based on the use of

excipients of Alginic acid and calcium carbonate. Alginic acid absorbs

lot of water, swells and leads to decay effect brought about. Calcium

*Correspondence for

Author

carbonate reacts with the stomach acid, within 3 minutes it releases

B. Lavanya 90% of the active ingredient this compared with only 10-15% in

Department of marketed paracetamol. Optizorb technology is five times faster in

Pharmaceutics, Sri tablet disintegration and thus gets to work much more quickly.

Padmavathi School of

Dispersible tablets were prepared by wet granulation method by using

Pharmacy, Tiruchanur-

517503, Tirupati, Andhra

Alginic acid and calcium carbonate as disintegrants in different

Pradesh, India. concentrations. Compatibility studies of drug and excipients were

carried out by using FT- IR spectroscopy and DSC. The formulations

were evaluated for precompressional parameters such as bulk density, tapped density, angle

of repose, Carrs index and Hausners ratio. The tablets were evaluated for weight variation,

thickness, hardness, friability, drug content, dispersion time, disintegration time and invitro

dissolution study. Invitro dissolution studies were performed by using USP dissolution

apparatus type II paddle in 900 ml of 0.1N Hydrochloric acid at 50 rpm. No chemical

interaction between drug and excipients was confirmed by FTIR studies. After study of all

formulations F9 showed short dispersion time with maximum drug release in 15 min and it

contains Alginic acid and calcium carbonate (1:1).

www.wjpps.com Vol 4, Issue 1, 2015. 561

Lavanya et al. World Journal of Pharmacy and Pharmaceutical Sciences

KEYWORDS: Alginic acid, antihypertensive, Bisoprolol fumarate, calcium carbonate,

dispersible tablet, OptiZorb technology.

INTRODUCTION

A novel tablet concept which offers ease of oral administration and benefits of increased

patient compliance is the fast dissolving/disintegrating tablet (FDDT). Dispersible tablets are

uncoated or film-coated tablets that can be dispersed in liquid before administration giving a

homogenous dispersion. Technology which allows the tablet to start disintegrating in as little

as 5 minutes is called Optizorb. OptiZorb disintegration technology is five times faster and

thus gets to work much more quickly. It is easily dispersed in stomach and work faster, relief

faster. OptiZorb technology is based on the use of super-disintegrants as alginic acid and

calcium carbonate that make it act within five minutes. Alginic acid is a hydrophilic that

draws acidic gastrointestinal fluid into the tablet as calcium carbonate reacts with gastric acid

to liberate carbon dioxide to help it disintegrate to provide faster relief. [1-6]

MATERIALS AND METHODS

Bisoprolol fumarate was obtained as gift sample from A-Z pharmaceuticals, Chennai. Alginic

acid and calcium carbonate were obtained from Himedia Pvt. Ltd, Mumbai. All other

chemicals used were of analytical grade.

Preformulation

Identification of the drug was carried out by FTIR (Analytical Technologies, Mumbai,

Standardization of the drug was carried out using UV/Vis spectrophotometer (Shimadzu,

Japan). FTIR and DSC spectral analysis of the formulations was performed to assess drug

excipients compatibility. Preliminary studies were carried out on the tablets using different

concentrations of superdisintegrants. Thus, after evaluation of the quality parameters and

subjecting to in vitro disintegration and in vitro dissolution studies the final concentrations of

the superdisintegrants were optimized. Based on this Preformulation data the optimized

formulations for further investigations were decided.

Preparation of OptiZorb Dispersible Tablets

Dispersible tablets of Bisoprolol fumarate were prepared by wet granulation method. The

drug and excipients were passed through sieve (#22) to ensure better mixing. Super

disintegrant like Alginic acid and calcium carbonate were used in different concentrations.

All the ingredients were mixed in mortar and pestle starch paste is added then magnesium

www.wjpps.com Vol 4, Issue 1, 2015. 562

Lavanya et al. World Journal of Pharmacy and Pharmaceutical Sciences

stearate and talc were added. The formulations were compressed with a sixteen station rotary

tablet punching machine.

Table No 1: Composition of different formulations of Bisoprolol fumarate.

Formulation code

S.NO Ingredients (mg)

F1 F2 F3 F4 F5 F6 F7 F8 F9

Bisoprolol

1 10 10 10 10 10 10 10 10 10

fumarate

2 Alginic acid 3 6 9 - - - 3 6 9

3 Calcium carbonate - - - 10 20 30 3 6 9

4 Lactose 159 156 153 152 142 132 156 150 144

5 Starch paste (Q.S) 20 20 20 20 20 20 20 20 20

Magnesium

6 4 4 4 4 4 4 4 4 4

stearate

7 Talc 4 4 4 4 4 4 4 4 4

Precompression Technological Parameters

Density Measurement

1. Bulk Density

10 g of Bisoprolol fumarate granules were weighed separately and transferred into a

graduated measuring cylinder via a large funnel and measure the volume of the powder. The

bulk densities of the granules were calculated by given formula. [7]

Bulk density = Weight of powder / Bulk volume.

2. Tapped Density

The tapped density is calculated by the following formula. [8]

Tapped density = Weight of powder / Tapped volume.

Flow properties

1. Carrs Index [Compressibility Index]

It is one of the most important parameter to characterize the nature of powders and granules.

It can be calculated from the following equation. [9]

Carrs index = (Tapped density - Bulk density) X 100

Tapped density

2. Hausners Ratio

Hausners ratio is an important character to determine the flow property of powder and

granules. This can be calculated by the following formula. [10]

Hausners ratio = Tapped density / Bulk density

www.wjpps.com Vol 4, Issue 1, 2015. 563

Lavanya et al. World Journal of Pharmacy and Pharmaceutical Sciences

3. Angle of Repose

The angle of repose is defined as the maximum angle possible between the surfaces of pile of

powder and the horizontal plane. Angle of repose of granules is done by fixed funnel method

and is calculated by using following formula. [11]

= tan-1 h/r

Where, h = height of the pile; r = radius of the pile

The tangent of the angle is equal to the coefficient of friction (M) between the particles.

Post Compression Technological Parameters

1. Weight Variation Test

From each batch twenty tablets were selected at a random and average weight was

determined. Then individual tablets were weighed and the individual weight was compared

with an average weight, the variation in the weight was expressed in terms of % deviation [12].

2. Hardness

Ten tablets from each formulation were selected for the hardness and it was determined by

using Monsanto hardness tester. [13]

3. Thickness

Ten tablets form each formulation was taken for thickness and it was measured using Vernier

callipers. [14]

4. Friability Test

The friability of the tablet was determined by Friabilator. Initially weighed 10 tablets after

dusting and placing them in a friability tester, which was rotated for 5 min at 25 rpm. After

dusting, the total remaining mass of tablets was recorded and the percent friability was

calculated by using the formula. [15]

Intial weight final Weight

Friability = 100

Intial weight

5. Content Uniformity

Ten tablets were weighed individually and powdered. The powder equivalent to 20 mg of

Bisoprolol fumarate was weighed and extracted in water (100 ml) and the concentration of

drug was determined by measuring absorbance at 222 nm by spectrophotometer. [16]

www.wjpps.com Vol 4, Issue 1, 2015. 564

Lavanya et al. World Journal of Pharmacy and Pharmaceutical Sciences

6. Disintegration Time

The test was carried out on 5 tablets using the Disintegration Test Apparatus. Distilled water

at 37oC was used as a disintegration media and the time in second taken for complete

disintegration of the tablet by no palatable mass remaining in the apparatus was measured. [17]

7. Wetting Time

A piece of tissue paper folded twice was placed in a small Petri dish containing 6 ml of water.

A tablet was put on the paper and time required for complete wetting was measured. [18]

8. Invitro Drug Release

Dissolution rate of fast disintegrating tablet of Bisoprolol fumarate was studied by using USP

Type-II apparatus at 50rpm using 900 ml of 0.1N HCl as dissolution medium. Temperature of

the dissolution medium was maintained at 370C an aliquot of dissolution medium was

withdrawn at every specific time interval and filtered. The absorbance of filtered solution was

checked by UV spectrophotometer at 222 nm and concentration of the drug was determined

from standard calibration curve. [19]

Drug Release Kinetics

As a model-independent approach, comparison of the time taken for the given proportion of

the active drug to be dissolved in the dissolution medium and figures such as T50 and T90

calculated by taking the time points of 50% and 90% of the drug dissolved and another

parameter Dissolution Efficiency (DE) suggested by Khan were employed. DE is defined as

the area under the dissolution curve up to the time t expressed as a percentage of the area of

the rectangle described by 100% dissolution in the same time. [20]

t

y.dt

Dissolution Efficiency (DE) = 0

y .t 100

100

The dissolution efficiency can have a range of values depending on the time interval chosen.

In any case constant time intervals should be chosen for comparison. For example, the index

DE30 would relate to the dissolution of the drug from a particular formulation after 30

minutes could only be compared with DE30 of other formulations. Summation of the drug

dissolution data into a single figure DE enables ready comparison to be made between a large

numbers of formulations.

www.wjpps.com Vol 4, Issue 1, 2015. 565

Lavanya et al. World Journal of Pharmacy and Pharmaceutical Sciences

Characterization of Dispersible Tablets

FTIR Studies for drug

FTIR spectra are recorded from KBr disks. This ground KBr powder was use because the

background in the measurements beneath identical conditions. The measured wave number

range was from 4000 to 400cm-1.

DSC Thermal Analysis

Thermal analysis of Bisoprolol fumarate and their drug and excipients were recorded with

Netzsch DSC 200PC (Netzsche, Selb, German). The temperature axis and cell constant of

DSC were previously calibrated with Indium. A heating rate of 5/min was employed over a

temperature range of 0- 3500C with nitrogen purging. The sample was weighed into an

aluminium pan was used as reference.

Bioequivalence Studies

Bioequivalence study was performed between the marketed products Carvedilol-3.125mg

(coreg) tablets and prepared OptiZorb dispersible tablets of bisoprolol fumarate.

The Bioequivalence study was done by performing disintegration, invitro studies between

marketed products and prepared OptiZorb dispersible tablets.

Stability Studies

The purpose of stability testing is to provide evidence on how the quality of a drug substance

or drug product varies with time under the influence of a variety of environmental factors

such as temperature, humidity and light, enabling recommended storage conditions, re-test

periods and shelf-lives. Generally, the observation of the rate at which the product degrades

under normal room temperature requires a long time. To avoid this undesirable delay, the

principles of accelerated stability studies are adopted. [21]

ICH specifies the length of study and storage conditions.

Long-Term Testing: 250 C 20 C / 60% RH 5% for 12 Months

Accelerated Testing: 400 C 20 C /75% RH 5% for 6 Months

Stability studies were carried out at 400C 20C /75% RH 5% for all the formulations for a

period of 3 months.

The selected formulations were closely packed in amber colour bottles and then stored at 400

C 20 C /75% RH 5% in stability chamber for 3 months and evaluated for their physical

www.wjpps.com Vol 4, Issue 1, 2015. 566

Lavanya et al. World Journal of Pharmacy and Pharmaceutical Sciences

appearance, drug content and in-vitro drug release studies at intervals of 1month. The shelf

life period of the prepared dispersible tablets is determined by using similarity factor.

RESULTS AND DISCUSSION

Table No.2: Precompression studies of granules of bisoprolol fumarate.

Angle of Bulk density Tapped Carrs Hausner

Formulations

repose(0) (g/ml) density (g/ml) index (%) s, ratio

F1 32.15 0.40 0.45 11.11 1.12

F2 30.44 0.40 0.44 09.09 1.10

F3 28.85 0.43 0.50 14.00 1.16

F4 32.35 0.43 0.49 12.24 1.13

F5 29.45 0.41 0.47 12.76 1.14

F6 29.30 0.38 0.43 11.62 1.13

F7 33.60 0.40 0.45 11.11 1.12

F8 32.22 0.41 0.46 10.86 1.12

F9 28.65 0.41 0.47 12.76 1.13

The bulk density of all formulations powder containing drug and excipients was found to be

in the range of 0.40 to 0.43gm/ml, whereas the tapped density was observed between 0.43 to

0.50gm/ml. From the values of bulk density and tapped density the values for Carrs index

and Hausners ratio were calculated. The values for Carrs index were found between 09.09

and 14.00 %. The values for Hausners ratio were found to be between 1.10 and 1.16. All

these values are within the specified limits which indicate good flow properties. Angle of

repose was found to be less than 32 which indicate good flow of powder. Overall these values

indicate good flow properties of powder blend, uniform die fill and better compression

ability. Therefore, from this data so obtained, it was decided to go for compression of tablets

from the powder blends.

Table No.3: Evaluation of bisoprolol fumarate tablets.

Formulation code

Parameters

F1 F2 F3 F4 F5 F6 F7 F8 F9

%Wt. Variation PASS PASS PASS PASS PASS PASS PASS PASS PASS

Hardness (kg/cm2) 3.6 3.5 3.6 3.5 3.8 3.8 3.7 3.8 3.8

Thickness (mm) 3.3 3.4 3.3 3.5 3.2 3.5 3.3 3.2 3.3

Friability (%w/w) 0.24 0.21 0.24 0.35 0.27 0.27 0.25 0.24 0.25

Disintegration (mins) 6 7 7 6 5 4 4 3 2

Dispersion Time (mins) 7 8 8 7 6 3 4 2 2

Wetting Time min) 6 7 7 6 5 4 4 3 2

Drug content (%) 84.86 86.12 88.20 86.40 86.30 98.30 98.23 98.32 98.50

The weight variation of all formulations was found to be passes as per I.P guidelines. None of

the tablet was found to deviate from the average weight of tablets (variation with deviation

www.wjpps.com Vol 4, Issue 1, 2015. 567

Lavanya et al. World Journal of Pharmacy and Pharmaceutical Sciences

less than 7.5, which complies with I.P specification) signifies that there is uniformity in

flow of powder blend which leads to uniform die fill. Hardness test for all formulations was

carried out and observations obtained were in the range of 3.5 to 3.8 kg/cm2. Hardness for all

formulations was observed to be proper, which signify that tensile strength of all formulations

was maintained after compression. Test for friability was conducted for all formulations, %

friability was found to be in the range of 0.21 to 0.35. Friability test for all formulations

indicated that % friability was less than 1%, which compiles the I.P specification and reveals

that all formulations have possessed good physical strength and can withstand the mechanical

shocks that can be observed during handling, shipping and transportation. The thickness of all

formulations was found to be uniform as it was obtained in the range of 3.2 to 3.7 mm. The

values for thickness and diameter signify uniformity and it was due to uniformity in die fill,

good flow properties, uniform pressure and appropriate punch movement.

Table No.4: Dissolution profile of F1-F9

Time (min) F1 F2 F3 F4 F5 F6 F7 F8 F9

5 13.92 22.41 28.07 32.32 35.15 37.98 42.22 46.47 50.71

10 26.80 38.19 41.03 45.30 48.15 50.99 63.80 69.49 76.61

15 46.87 56.90 61.18 65.47 69.76 72.62 78.38 85.53 92.68

20 52.82 65.75 67.21 70.10 75.83 78.71 85.93 90.27 94.61

25 58.80 70.38 71.85 73.33 79.09 81.99 92.09 95.03 97.98

30 67.66 73.61 76.51 78.00 82.37 85.28 94.01 96.97 98.51

Fig. 1: Dissolution profile of F1-F9.

Bisoprolol fumarate dispersible tablets were prepared by wet granulation method. All the

formulations viz. F1-F9 has shown increased cumulative dissolution profiles as shown in

Table No.4 and Fig. 1.

www.wjpps.com Vol 4, Issue 1, 2015. 568

Lavanya et al. World Journal of Pharmacy and Pharmaceutical Sciences

In-vitro drug release studies were performed in 0.1N HCl for all the prepared formulations by

using USP dissolution test apparatus-Type II, Rotating Paddle method. The data for in-vitro

release profile of the entire prepared tablet formulations were shown in table No4, and the

graphs showing drug release profile for formulations were shown in the fig. 1. In-vitro

dissolution studies were conducted over a period of 30 mins. In formulations F1 to F3

containing Alginic acid, an increase in concentration was observed. In formulations F4 to F6

containing calcium carbonate an increase in concentration was observed. Formulations F7 to

F9 showed quick release as the concentration of disintegrants increased tablets alginic acid

and calcium carbonate.

Drug Release Kinetics

Table No 5: Correlation coefficient (r) & rate constant (k) values of dispersible tablet.

Kinetic

F1 F2 F3 F4 F5 F6 F7 F8 F9

model

First r 0.9939 0.9872 0.9842 0.9702 0.9745 0.9771 0.9971 0.9978 0.9900

order k 0.0369 0.0483 0.0518 0.0553 0.0639 0.0699 0.0969 0.1170 0.1453

Zero r 0.9777 0.9355 0.9100 0.8706 0.8651 0.8518 0.8299 0.7835 0.7160

order k 2.4506 2.9042 3.0255 3.1438 3.3616 3.4947 3.8869 4.0778 4.2566

Hixson- r 0.9923 0.9758 0.9674 0.9463 0.9498 0.9498 0.9713 0.9651 0.9431

Crowell k 0.0106 0.0134 0.0142 0.0150 0.0168 0.0180 0.0226 0.0255 0.0290

r 0.9650 0.9855 0.9915 0.9906 0.9895 0.9892 0.9901 0.9810 0.9643

Higuchi

k 11.3686 13.6717 14.3233 14.9744 16.0227 16.6863 18.6138 19.6182 20.5928

r 0.9875 0.9850 0.9852 0.9809 0.9792 0.9795 0.9845 0.9735 0.9499

Peppas

k 3.5092 7.8546 11.2679 14.6060 15.9892 17.9278 21.5435 25.5588 30.4857

n 0.8915 0.6867 0.5812 0.5094 0.5017 0.4768 0.4525 0.4128 0.3698

DE 30 37.55 40.67 45.17 39.84 43.96 46.9 56.96 51.04 67.72

DE 60 50.43 51.48 57.75 53.32 56.35 58.95 70.19 71.82 76.88

T 50 13.13 11.52 10.24 12.33 10.26 9.50 7.14 6.73 5.53

Fig. 2: Correlation coefficient (r) & rate constant (k) values of dispersible tablet.

www.wjpps.com Vol 4, Issue 1, 2015. 569

Lavanya et al. World Journal of Pharmacy and Pharmaceutical Sciences

The drug release profiles from the bisoprolol fumarate dispersible tablets were fitted to

various kinetic models. The values of correlation coefficient (r) and release rate constants (K)

from different models for bisoprolol fumarate dispersible tablets are given in Table 1. From

the data of correlation coefficient and rate constant values, it was found that bisoprolol

fumarate release from their tablets has obeyed the first order release followed by the Peppas

model.

FT-IR spectroscopy

Fig. 3: FT-IR spectrum of bisoprolol fumarate.

Fig. 4: FT-IR spectrum of bisoprolol fumarate with Alginic acid.

www.wjpps.com Vol 4, Issue 1, 2015. 570

Lavanya et al. World Journal of Pharmacy and Pharmaceutical Sciences

Fig. 5: FT-IR spectrum of bisoprolol fumarate with Calcium carbonate.

Fig. 6: FT-IR spectrum of bisoprolol fumarate with Alginic acid and Calcium

carbonate.

From the FT-IR results, Pure bisoprolol fumarate showed principal absorption peaks at

3348.61cm-1, NH (stretching), 3402.62cm-1OH (stretching), 1091.77cm-1 (stretching) and

1145.78 cm-1C-O (stretching). Same peaks of NH, O-H, C-O-C, and C-0 bonds were present

as that of pure drug without much shifting in the spectra of bisoprolol fumarate suggested no

chemical interaction between the drug and disintegrants.

www.wjpps.com Vol 4, Issue 1, 2015. 571

Lavanya et al. World Journal of Pharmacy and Pharmaceutical Sciences

Differential Scanning Calorimetry

0.000

10.5mJ/mg 50.9mJ/mg

350.0

-1.000

80.1Cel

-2.000

-1.718mW 300.0

-3.000

DDSC mW/min

250.0

DSC mW

-4.000

-5.000

200.0

-6.000

150.0

-7.000

-8.000

100.0

102.4Cel

-8.163mW

0.0 50.0 100.0 150.0 200.0 250.0

Temp Cel

Fig. 7: DSC of bisoprolol fumarate.

2.000

300.0

1.000 280.0

0.000 28.8mJ/mg 260.0

10.9mJ/mg

240.0

-1.000

220.0

-2.000 80.3Cel

-1.601mW

DDSC mW/min

200.0

DSC mW

-3.000

180.0

-4.000

160.0

-5.000 140.0

101.5Cel

-6.000 120.0

-5.651mW

100.0

-7.000

80.0

-8.000

-100.0 -50.0 0.0 50.0 100.0 150.0 200.0 250.0 300.0 350.0

Temp Cel

Fig. 8: DSC of optimized formulation.

From DSC thermograms the melting point of pure drug bisoprolol fumarate was found to be

102.4C which the value reported in literature hence the procured drugs are pure forms and

were shown in Fig No.7. The dispersible tablets DSC thermograms of bisoprolol fumarate

indicate that there are no interaction between the drugs and excipients which can be accessed

from the peaks in the DSC thermograms (Fig. No. 8).

www.wjpps.com Vol 4, Issue 1, 2015. 572

Lavanya et al. World Journal of Pharmacy and Pharmaceutical Sciences

Bioequivalence Studies

Disintegration Time

Table No.6: Bioequivalence studies of Disintegration time.

Time Marketed products Prepared dispersible

S. NO

(min) Carvedilol tablets (B.F)

1 5 4 3

2 10 5 2

3 15 4 2

4 20 4 3

5 25 5 2

6 30 4 2

The prepared dispersible tablets are having disintegration time between 2-3 min and the

marketed tablet of Carvedilol-1.325 mg (coreg) dispersible tablet having disintegration time

between 4-5min. Hence the prepared dispersible tablets are having less disintegration time

than that of marketed formulation.

Table No.7: Bioequivalence studies invitro drug release studies.

Time Marketed products Prepared dispersible

S.NO

(min) Carvedilol tablets (B.F)

1 5 45.39 50.71

2 10 65.62 76.61

3 15 75.36 92.68

4 20 85.25 94.61

5 25 91.25 97.98

6 30 95.52 98.51

Fig. 9: Bioequivalence studies invitro drug release studies.

www.wjpps.com Vol 4, Issue 1, 2015. 573

Lavanya et al. World Journal of Pharmacy and Pharmaceutical Sciences

Stability Studies

The optimized F9 formulation was kept for stability studies. Accelerated stability studies

were carried out at 400/75%RH for 3 months. The tablets were then evaluated for weight

variation for the period of initial, disintegration, hardness and drug content for initial, 1

month, 2 month and 3 month. The results indicated that there was no significant change in

physical evaluation. Evaluations of formulations by parameters including Weight Variation,

hardness, friability, disintegration were within the limits as per prescribed specifications. The

optimized F9 formulation is evaluated for In-vitro drug release studies; the results indicated

that there was no significant change in In-vitro drug release studies which is similar to the

formulations under optimum conditions.

CONCLUSION

OptiZorb dispersible tablets of bisoprolol fumarate were prepared by wet granulation method.

From the present work it concludes that the OptiZorb technology is based on the use of

excipients of Alginic acid and calcium carbonate as disintegrants in different concentrations.

Alginic acid absorbs lot of water, swells and leads to decay effect brought about. Calcium

carbonate reacts with the stomach acid, within 3 minutes it releases 90% of the active

ingredient. OptiZorb technology is five times faster and thus gets to work much more

quickly. After study of all formulations F9 showed short dispersion time with maximum drug

release in 15 min and it contains alginic acid and calcium carbonate (1:1). FT-IR study

reveals that there is no interaction between drug and excipients and can be used for

preparation of OptiZorb dispersible tablets of bisoprolol fumarate.

ACKNOWLEDGEMENT

The authors extend their deep sense of thanks to the Principal, Dr. D. Ranganayakulu and

the Management, Sri Padmavathi School of Pharmacy for their extended support during this

project work.

REFERENCES

1. Wilson C.G, Cyril P. Clarke, Yan Yan L, Starkey, Geoffrey D. Clarke. Comparison of a

novel fast-dissolving acetaminophen tablet formulation (FD-APAP) and standard

acetaminophen tablets using gamma scintigraphy and pharmacokinetic studies. Drug

Develop Ind Pharm, 2011; 37(7): 747-753.

2. 2011-06-28, English, Article, Journal or magazine article edition: Glaxo launches fast-

acting crocin (the company has used the OptiZorb disintegration technology).

www.wjpps.com Vol 4, Issue 1, 2015. 574

Lavanya et al. World Journal of Pharmacy and Pharmaceutical Sciences

3. www.gsk-ch.in/crocin.aspx.

4. www.pharmacynz.co.nz/panadol-optizorb-100s.html.

5. Dongzhou J, Liu, Mitchell Kotler, Scott Sharples. Pharmacokinetic and Bioequivalence

Study Evaluating a New Paracetamol/Caffeine Formulation in Healthy Human

Volunteers. JBB, 2011; 3(11): 251-257.

6. Patel Badalkumar R, Jatav Rajesh K, Jatav Rakesh K, Sheorey Rajendra V. Formulation

development & evaluation of Cefpodoxime Proxetil Dispersible Tablets. Int. J. Drug Dev.

& Res, 2012; 4(2): 124-131.

7. Mundad A, Meshram D, Banbale H, Bhalekar M, Avari J. Formulation and evaluation of

dispersible taste masked tablet of Roxithromycin. Asian J Pharm, 2008: 116-119.

8. Sawarikar PP, Sridhar BK and Shivkumar S. Formulation and evaluation of fast

dissolving tablets of isoxsuprine hydrochloride. J Curr Pharm Res, 2010; 3(1): 41-46.

9. Puttewar TY, Kshirsagar MD, Chandewar AV and Chikhale RV. Formulation and

evaluation of orodispersible tablet of taste maskeddoxylamine succinate using ion

exchange resin. J King Saud Univ Sci, 2010; 22: 229240.

10. Simone S and Peter CS. Fast dispersible ibuprofen tablets. Eur J Pharm Sci, 2002; 15:

295-305.

11. Schiermeier S, Schmidt PC. Fast dispersible ibuprofen tablets. Eur J Pharm, 2002; 15:

295305.

12. Sureh Bhandari, Rajendra Kumar Mittapali, Ramesh Gannu, Yamsai Madhusudhan Rao.

Orodispersable tablet. Asian J Pharm, 2008: 1-11.

13. Furtado S, Deveswaran R, Bharath S, Basavaraj BV, Abraham S. and Madhavan V.

Development and characterization of Orodispersible tablets of famotidine containing a

subliming agent, Trop J Pharm Res, 2009; 8(2): 153-159.

14. Polli JE, Rekha GS, Augsburger LL, Shah VP. Methods to compare dissolution profiles

and a rationale for wide dissolution specifications for metaprolol tartrate tablets. Int J

Pharm, 1997; 86(6): 690-700.

15. Brittain H. Spectral methods for the characterization of polymorphs and solvates. Int J

Pharm, 1997; 2(6): 405412.

16. Kakumanu V and Bansal A. Enthalpy relaxation studies of celecoxib amorphous

mixtures. Int J Pharm Tech Res, 2002; 1(9): 18731878.

17. Seager H. Drug Delivery Products and Zydus Fast Dissolving Dosage Forms: J Pharm

Pharmacol, 1998; 50: 375-382.

www.wjpps.com Vol 4, Issue 1, 2015. 575

Lavanya et al. World Journal of Pharmacy and Pharmaceutical Sciences

18. Schiermer S., Schmidt P.C. Fast dispersible Ibuprofen tablets. Eur J Pharm Sci, 2002; 15:

295-305.

19. Harish R, Lukkad, Pravin K, Bhoyar, Jagdish R, Baheti, Nitin D, Somnathe Dhanashri B,

Nagulwar, Prasad P, Kathade. Formulation and evaluation of aceclofenac orodispersible

tablets using natural disintegrant. WJPPS, 2012; 1(2): 601-609.

20. Tiwari Bhupendra R, Rane Bhushan R, Pawar Sunil P. Formulation and evaluation of

cefadroxil disprsible tablet. Int J Pharm Sci, 2013; 4(4): 1.

21. Shashidhar KR, Anup Kumar Roy, Roopa Kark, Kebajyoti Bhattacharya, Ruchi shakya.

Formulation and evaluation of fast dispersible tablets of Prochlorperazine maleate using

natural disintegrants. Int J Pharm Tech, 2013: 234-249.

www.wjpps.com Vol 4, Issue 1, 2015. 576

You might also like

- Usmle Pharmacology Quiz Multiple ChoiceDocument42 pagesUsmle Pharmacology Quiz Multiple ChoiceSamer Khodor83% (6)

- Formulation, Development and Evalution of An Immediate Release Tablet of MethotrexateDocument22 pagesFormulation, Development and Evalution of An Immediate Release Tablet of MethotrexateDarlianaMelloSouzaNo ratings yet

- Master Formula RecordDocument39 pagesMaster Formula RecordAbhijit kanavaje100% (1)

- Water Vapor Transmission of Materials: Standard Test Methods ForDocument12 pagesWater Vapor Transmission of Materials: Standard Test Methods Formailtorubal2573No ratings yet

- Blend Content Uniformity Process Flow Diagram Design Validation PDFDocument1 pageBlend Content Uniformity Process Flow Diagram Design Validation PDFmarwaNo ratings yet

- Article Wjpps 1420087262Document16 pagesArticle Wjpps 1420087262ainNo ratings yet

- Jurnal CarbamazepinDocument9 pagesJurnal CarbamazepinRosamaria Yuni UtamiNo ratings yet

- Formulation and Evaluation of Voglibose Mouth Dissolving Tablets by Direct Compression MethodDocument5 pagesFormulation and Evaluation of Voglibose Mouth Dissolving Tablets by Direct Compression Methodanto_pharma7784No ratings yet

- JDDR 139Document11 pagesJDDR 139Earthjournal PublisherNo ratings yet

- Formulation Development and Evaluation of Immediate Release Tablets Containing Antihypertensive Agent Amlodipine Besylate and ValsartanDocument8 pagesFormulation Development and Evaluation of Immediate Release Tablets Containing Antihypertensive Agent Amlodipine Besylate and ValsartanDược K45 Trần Dũng TâmNo ratings yet

- Solubility Enhancement of Poorly Aqueous Soluble Furosemide Using Peg-4000 by Solid DispersionDocument9 pagesSolubility Enhancement of Poorly Aqueous Soluble Furosemide Using Peg-4000 by Solid Dispersionnha.99No ratings yet

- Formulation Development and Invitro Evaluation of Ranolazine Extended Release TabletsDocument6 pagesFormulation Development and Invitro Evaluation of Ranolazine Extended Release TabletsBaru Chandrasekhar RaoNo ratings yet

- Formulation and in Vitro Evaluation of Mucoadhesive Tablets of Ofloxacin Using Natural GumsDocument6 pagesFormulation and in Vitro Evaluation of Mucoadhesive Tablets of Ofloxacin Using Natural Gumsabdi100% (1)

- Pioglitazone NaopaticlesDocument11 pagesPioglitazone NaopaticlesAtiq Ur-RahmanNo ratings yet

- Formulation and Evaluation of Enteric CoatedDocument13 pagesFormulation and Evaluation of Enteric Coatedvanvu buiNo ratings yet

- Formulation and Evaluation of Mouth Dissolving Tablets of OxcarbazepineDocument12 pagesFormulation and Evaluation of Mouth Dissolving Tablets of OxcarbazepineTyas Apa TyasNo ratings yet

- 2013 Design and Development of Mucoadhesive Buccal Delivery For Pantoprazole With Stability Enhancement in Human SalivaDocument6 pages2013 Design and Development of Mucoadhesive Buccal Delivery For Pantoprazole With Stability Enhancement in Human SalivaGanesh BharskarNo ratings yet

- FORMULATION AND IN-VITRO EVALUATION OF ZOLMITRIPTAN ORO-DISPERSIBLE TABLETS Arigela Bharathi, Vemugunta Ramakrishna, Baratam Anupama, Chukkapalli ManishaDocument9 pagesFORMULATION AND IN-VITRO EVALUATION OF ZOLMITRIPTAN ORO-DISPERSIBLE TABLETS Arigela Bharathi, Vemugunta Ramakrishna, Baratam Anupama, Chukkapalli ManishaiajpsNo ratings yet

- PlantagoovataDocument8 pagesPlantagoovataAli RizieqNo ratings yet

- Preparation and Evaluation of Sustained Release Pellets of Saxagliptin by Extrusion-SpheronizationDocument14 pagesPreparation and Evaluation of Sustained Release Pellets of Saxagliptin by Extrusion-SpheronizationNishane balasahebNo ratings yet

- Fast dissolving tablets of salbutamol sulphateDocument9 pagesFast dissolving tablets of salbutamol sulphateAtraoNo ratings yet

- Taste-masked orally disintegrating tablets of paracetamolDocument6 pagesTaste-masked orally disintegrating tablets of paracetamolDyla FaradhylaNo ratings yet

- MucoadhesifDocument26 pagesMucoadhesifFeny RafnasariNo ratings yet

- JURNAL PEDIATRI 19-Vol.-3-Issue-1-Jan.-2012-RA-963-Paper-19Document3 pagesJURNAL PEDIATRI 19-Vol.-3-Issue-1-Jan.-2012-RA-963-Paper-19AnditapitalokaNo ratings yet

- Design and Evaluation of An Extended Release Tablet Dosage Form of Class-Ii Drug, Quetiapine FumarateDocument5 pagesDesign and Evaluation of An Extended Release Tablet Dosage Form of Class-Ii Drug, Quetiapine FumarateErlita Nur ArifanaNo ratings yet

- Biofar TerapanDocument4 pagesBiofar TerapanWelly IrwandaNo ratings yet

- 18.rajiv Kumar Parminder Nain Jaspreet Kaur Vipin Saini and Varinder SoniDocument11 pages18.rajiv Kumar Parminder Nain Jaspreet Kaur Vipin Saini and Varinder Sonidesi imastutiNo ratings yet

- ROSIGDocument8 pagesROSIGSeptiani MarthaNo ratings yet

- Formulation and Evaluation of Atenolol Oral Dispersible Tablets by Using Different Super DisintegrantsDocument5 pagesFormulation and Evaluation of Atenolol Oral Dispersible Tablets by Using Different Super Disintegrantsزيد هشام السيدNo ratings yet

- Formulation and Evaluation of Metronidazole Tableted Microspheres For Colon Drug DeliveryDocument6 pagesFormulation and Evaluation of Metronidazole Tableted Microspheres For Colon Drug DeliveryarunmahatoNo ratings yet

- Formulation and Evaluation of Transdermal TopicalDocument6 pagesFormulation and Evaluation of Transdermal TopicalRitika PrasadNo ratings yet

- CAPTOPRIL COMPLEXDocument13 pagesCAPTOPRIL COMPLEXMareta Ovy YuliaNo ratings yet

- Protocol For Dissertation Work - NITROFURANTOIN 26-10-2018Document20 pagesProtocol For Dissertation Work - NITROFURANTOIN 26-10-2018dasarathramNo ratings yet

- Formulation and Evaluation of Quinapril Sustained Release Matrix TabletsDocument14 pagesFormulation and Evaluation of Quinapril Sustained Release Matrix TabletsSyed Qasim MehmoodNo ratings yet

- Sun Screen 2Document12 pagesSun Screen 2Apt Fitri RosdianaNo ratings yet

- Formulation and Evaluation of Floating Tablet of Metoprolol SuccinateDocument13 pagesFormulation and Evaluation of Floating Tablet of Metoprolol SuccinateEditor IJTSRDNo ratings yet

- Formulation and Design of Taste Masked Quetiapine Fumarate Orally Fast Disintegrating Tablets by Sublimation MethodDocument16 pagesFormulation and Design of Taste Masked Quetiapine Fumarate Orally Fast Disintegrating Tablets by Sublimation MethodJuan IgnacioNo ratings yet

- Formulation Development and Evaluation of Mouth Dissolving Tablet of ThiocolchicosideDocument18 pagesFormulation Development and Evaluation of Mouth Dissolving Tablet of ThiocolchicosideEditor IJTSRDNo ratings yet

- Pharmaceutical Sciences: Formulation, Evaluation and Optimization of Floating Matrix Tablets of CarvedilolDocument13 pagesPharmaceutical Sciences: Formulation, Evaluation and Optimization of Floating Matrix Tablets of CarvedilolBaru Chandrasekhar RaoNo ratings yet

- Development and evaluation of paracetamol lozenges for fever and pain reliefDocument5 pagesDevelopment and evaluation of paracetamol lozenges for fever and pain reliefDhanang Prawira NugrahaNo ratings yet

- Formulation Development and Evaluation of Pantoprazole Delayed Release TabletsDocument13 pagesFormulation Development and Evaluation of Pantoprazole Delayed Release TabletsAnish Kumar A0% (1)

- KT Hình Cầu Của ItraconazoleDocument11 pagesKT Hình Cầu Của ItraconazoleDương TrungNo ratings yet

- Colon-Specific Flurbiprofen TabletsDocument11 pagesColon-Specific Flurbiprofen TabletsFahriz HibatullahNo ratings yet

- Achhra, 2015 Formulation Development and Evaluation of Sucrose Free Lozenges of CurcuminDocument10 pagesAchhra, 2015 Formulation Development and Evaluation of Sucrose Free Lozenges of Curcuminmalinda prihantiniNo ratings yet

- Formulation and Invitro Evaluation of Solid Dispersion Tablets of SilymarinDocument7 pagesFormulation and Invitro Evaluation of Solid Dispersion Tablets of SilymarinIJAR JOURNALNo ratings yet

- Ajptr8gholves BDocument11 pagesAjptr8gholves BChương PhanNo ratings yet

- Formulation and Evaluation of Mouth Dissolving Tablets of Losartan PotassiumDocument10 pagesFormulation and Evaluation of Mouth Dissolving Tablets of Losartan PotassiumEditor IJTSRDNo ratings yet

- Formulation and in-VITRO Evaluation of Losartan Potassium Sustained Release Matrix TabletsDocument13 pagesFormulation and in-VITRO Evaluation of Losartan Potassium Sustained Release Matrix TabletsVidyavardhini UshirNo ratings yet

- Pharma Ceu TicDocument33 pagesPharma Ceu TicPankaj SharmaNo ratings yet

- Formulation and Evaluation of Fast Dissolving Tablets of Aceclofenac by Using Ispaghula Husk Powder As Natural Super DisintegrantDocument9 pagesFormulation and Evaluation of Fast Dissolving Tablets of Aceclofenac by Using Ispaghula Husk Powder As Natural Super DisintegrantBaru Chandrasekhar RaoNo ratings yet

- Rada 2018Document10 pagesRada 2018AdewaleNo ratings yet

- 10 B Ciprofloxacin PDFDocument9 pages10 B Ciprofloxacin PDFDeandra Havannah Rahmadhani RolosNo ratings yet

- Monte LukastDocument6 pagesMonte LukastPham XuanNo ratings yet

- Formulation and Evaluation of Medicated Chewing Gum of Ondancetron Hclfor Chemotherapy Induced Nausea and Vomiting PDFDocument7 pagesFormulation and Evaluation of Medicated Chewing Gum of Ondancetron Hclfor Chemotherapy Induced Nausea and Vomiting PDFMuhammad JamilNo ratings yet

- Formulation and Evaluation of Montelukast Sodium and Levocetirizine Dihydrochloride Sublingual TabletsDocument5 pagesFormulation and Evaluation of Montelukast Sodium and Levocetirizine Dihydrochloride Sublingual TabletsNeerajNo ratings yet

- Formulation and Evaluation of Floating Tablet of Captopril: Sameer Singh, Kalpana Prajapati, A K Pathak, A MishraDocument9 pagesFormulation and Evaluation of Floating Tablet of Captopril: Sameer Singh, Kalpana Prajapati, A K Pathak, A Mishraamalia shaldaNo ratings yet

- Formulation and in Vitro Evaluation of Lansoprazole MicropelletsDocument11 pagesFormulation and in Vitro Evaluation of Lansoprazole MicropelletsVaibhavi JangdeNo ratings yet

- WJPPS PDFDocument12 pagesWJPPS PDFwaelNo ratings yet

- Comparative Study of In-Vitro Release of Fluconazole Tablet As Generic and BrandedDocument3 pagesComparative Study of In-Vitro Release of Fluconazole Tablet As Generic and BrandedInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Formulation and Evaluation of Zolpidem Nasal in SituDocument12 pagesFormulation and Evaluation of Zolpidem Nasal in SituGopalasatheeskumar KNo ratings yet

- IntroductionDocument16 pagesIntroductionprema koliNo ratings yet

- Design, Optimisation and Evaluation of Piroxicam Fast Dissolving Tablets Employing Starch Tartrate-A New SuperdisintegrantDocument9 pagesDesign, Optimisation and Evaluation of Piroxicam Fast Dissolving Tablets Employing Starch Tartrate-A New SuperdisintegrantStevanus HiendrawanNo ratings yet

- Available Online Through: ISSN 2321 - 6328Document7 pagesAvailable Online Through: ISSN 2321 - 6328Novitra DewiNo ratings yet

- Practical Handbook of Pharmaceutical Chemistry for M.PharmFrom EverandPractical Handbook of Pharmaceutical Chemistry for M.PharmNo ratings yet

- Excel For Data Analysis 1658535367Document19 pagesExcel For Data Analysis 1658535367Di Antonella G. BrunoNo ratings yet

- Terminal Sterilization of Pharmaceutical ProductsDocument8 pagesTerminal Sterilization of Pharmaceutical Productsmailtorubal2573No ratings yet

- Rfailure ManagemetnDocument12 pagesRfailure Managemetnmailtorubal2573No ratings yet

- TRS961 - Annex6 Who Technical Report No.961 2011 GMP Sterile ProductsDocument24 pagesTRS961 - Annex6 Who Technical Report No.961 2011 GMP Sterile ProductsWilliamWang19100% (1)

- Excipient Risk AssessmentDocument6 pagesExcipient Risk Assessmentmailtorubal2573No ratings yet

- Powder Testing and Hopper Design For FormulatoDocument8 pagesPowder Testing and Hopper Design For Formulatomailtorubal2573No ratings yet

- Fda On Statistical ApproachesDocument33 pagesFda On Statistical Approachesmailtorubal2573No ratings yet

- PI 045 1 PICS Guideline On Excipient GMP Risk AssessmentDocument7 pagesPI 045 1 PICS Guideline On Excipient GMP Risk Assessmentmailtorubal2573No ratings yet

- Rabeprazole Sodium Delayed-Release TabletsDocument5 pagesRabeprazole Sodium Delayed-Release TabletsHuynh Thanh PhongNo ratings yet

- Amide ImpurityDocument11 pagesAmide Impuritymailtorubal2573No ratings yet

- Stratified Sampling of CapsuleDocument23 pagesStratified Sampling of Capsulemailtorubal2573No ratings yet

- HARMONIZED TITLEDocument3 pagesHARMONIZED TITLEmailtorubal2573No ratings yet

- INN FileDocument14 pagesINN Filemailtorubal2573No ratings yet

- PharmTech Europe Feb2018 PDFDocument52 pagesPharmTech Europe Feb2018 PDFpermata bundaNo ratings yet

- GMP Question and Answer GuideDocument182 pagesGMP Question and Answer Guidesab ben100% (1)

- Method Development and Column Selection: How The Fluorophenyl Phase Provides The Power of Hilic and Reversed-Phase Modes in One ColumnDocument10 pagesMethod Development and Column Selection: How The Fluorophenyl Phase Provides The Power of Hilic and Reversed-Phase Modes in One Columnmailtorubal2573No ratings yet

- Sample Sizes in Uniformity Measurements - The Role of USPDocument25 pagesSample Sizes in Uniformity Measurements - The Role of USPmailtorubal2573No ratings yet

- A Guide To Blend Uniformity: Overview of Blending Process and EquipmentDocument6 pagesA Guide To Blend Uniformity: Overview of Blending Process and Equipmentmailtorubal2573100% (1)

- AbbreviationsDocument2 pagesAbbreviationslovely2886No ratings yet

- Dissolution Rate Enhancement of Fenofibrate Using Liquisolid Tablet TechniqueDocument7 pagesDissolution Rate Enhancement of Fenofibrate Using Liquisolid Tablet Techniquemailtorubal2573No ratings yet

- Deviation WHODocument28 pagesDeviation WHOk.p.No ratings yet

- Uniformity of Dosage Units, Part 1: Acceptance Value: Peer-ReviewedDocument10 pagesUniformity of Dosage Units, Part 1: Acceptance Value: Peer-Reviewedmailtorubal2573No ratings yet

- Note Guidance Use Stability Testing Human Medicinal Products - en PDFDocument3 pagesNote Guidance Use Stability Testing Human Medicinal Products - en PDFcindi saputriNo ratings yet

- Hand Sanitizing Gel Formula PDFDocument1 pageHand Sanitizing Gel Formula PDFmailtorubal2573No ratings yet

- Validation GuideDocument1 pageValidation Guidemailtorubal2573No ratings yet

- Regulatory compliance eBOOK explores FDA's Alzheimer's approval mazeDocument28 pagesRegulatory compliance eBOOK explores FDA's Alzheimer's approval mazemailtorubal2573No ratings yet

- How To Make Hand Sanitiser GelDocument1 pageHow To Make Hand Sanitiser Gelmailtorubal2573No ratings yet

- Compounding Alcohol-Based Hand Sanitizer During COVID-19 PandemicDocument3 pagesCompounding Alcohol-Based Hand Sanitizer During COVID-19 PandemicFujia YunitaNo ratings yet

- SUPAC Guidelines PPT - 1Document24 pagesSUPAC Guidelines PPT - 1Sparsh SharmaNo ratings yet

- AmayuDocument1 pageAmayuPranoy MayuriNo ratings yet

- FDA Most Used LawsDocument10 pagesFDA Most Used LawsRodolfo Lastimoso Diaz Jr.No ratings yet

- MQA103T LECTURE-3 ICH OverviewDocument19 pagesMQA103T LECTURE-3 ICH OverviewShyam Sunder PancholiNo ratings yet

- CPOBDocument51 pagesCPOBKenzi AlvarioNo ratings yet

- MAPP 5200 14 Filing Checklist 9 1 17Document43 pagesMAPP 5200 14 Filing Checklist 9 1 17Krazyboy KhmNo ratings yet

- World Congress On Pharmaceutical Sciences WCPS 2017 BrochureDocument8 pagesWorld Congress On Pharmaceutical Sciences WCPS 2017 BrochureYuppie RajNo ratings yet

- Berno 1Document24 pagesBerno 1Try AdipradanaNo ratings yet

- Bilastine: A New H1-Antihistamine With An Optimal Profile For Updosing in UrticariaDocument7 pagesBilastine: A New H1-Antihistamine With An Optimal Profile For Updosing in UrticariaIkmalaozhar 79No ratings yet

- Clotrimazole: Clotrimazole, Sold Under The Brand Name Canesten Among OthersDocument6 pagesClotrimazole: Clotrimazole, Sold Under The Brand Name Canesten Among OthersMunna SahaniNo ratings yet

- Metered Dose Inhaler MdiDocument2 pagesMetered Dose Inhaler MdicmenikarachchiNo ratings yet

- 12-05-09 SOP Controlled Drugsreview V004Document18 pages12-05-09 SOP Controlled Drugsreview V004scribd-844801No ratings yet

- Vioxx and The Merck Team Effort: Institutions in CrisisDocument22 pagesVioxx and The Merck Team Effort: Institutions in CrisisRebecca LiuNo ratings yet

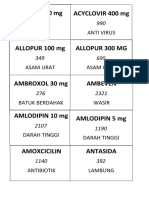

- Nica Chua - Hospital Pharmacy Internship Daily Activity Report-Day 9 Major RevDocument2 pagesNica Chua - Hospital Pharmacy Internship Daily Activity Report-Day 9 Major RevMa Victoria ChuaNo ratings yet

- Fast Dissolving TabletsDocument17 pagesFast Dissolving TabletsKamesh TripathiNo ratings yet

- Hospital drug distribution systemsDocument18 pagesHospital drug distribution systemsAnushka Mani tripathiNo ratings yet

- Paparan FGD - GP JamuDocument49 pagesPaparan FGD - GP JamuDewita AgusNo ratings yet

- Weekly Planner: Department: Pharmaceutics Academic Week No.Document2 pagesWeekly Planner: Department: Pharmaceutics Academic Week No.Huma Hameed DogarNo ratings yet

- Nama Obat Berserta HargaDocument8 pagesNama Obat Berserta HargaRossa patria NandaNo ratings yet

- PhytosomesDocument3 pagesPhytosomesSingh TaminderjitNo ratings yet

- Rekapitulasi Januari 2020Document12 pagesRekapitulasi Januari 2020Nani ManullangNo ratings yet

- PT. RUBEL ANUGERAH MEDICATAMA DAFTAR HARGADocument33 pagesPT. RUBEL ANUGERAH MEDICATAMA DAFTAR HARGAMalik TeamNo ratings yet

- HTTPDocument23 pagesHTTPNancy L. AriwodoNo ratings yet

- Life Orientation ProjectDocument16 pagesLife Orientation ProjectZola MasingeNo ratings yet

- Cover Page PDFDocument14 pagesCover Page PDFMinh TuyềnNo ratings yet

- DapusDocument3 pagesDapusNur Zahratul JannahNo ratings yet

- Medical supplies and equipment inventory listDocument90 pagesMedical supplies and equipment inventory listfiannysjahjadiNo ratings yet

- PDSADocument50 pagesPDSAMary Wish Beatrice PayodNo ratings yet