Professional Documents

Culture Documents

Fan Engineer Over PDF

Uploaded by

lahsivlahsiv6840 ratings0% found this document useful (0 votes)

18 views2 pagesOriginal Title

fan engineer over.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views2 pagesFan Engineer Over PDF

Uploaded by

lahsivlahsiv684Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

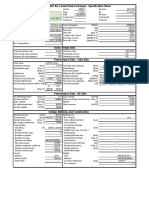

FAN ENGINEERING

Information and Recommendations for the Engineer FE-2200

Spark Resistant Fan Construction

Introduction Type A: This requires a nonferrous airstream. Also, the

extra locking systems are required as in Type B.

Fans are often used to handle a variety of gases, dusts

and materials other than clean air. Some of these gases All spark resistant types require the fan to be electri-

and solid particles are combustible. When mixed at cer- cally grounded so as to prevent static electricity from

tain concentrations, ignition can result in an explosion. building up. The end user is responsible for installing the

Even systems which are normally safe can become ground strap.

explosive under abnormal conditions. System designers A common material used by fan manufacturers in

must consider the safety hazard that each component achieving spark resistance is aluminum. The AMCA stan-

of the system carries. This discussion presents some dard provides a warning that aluminum rubbing on rusty

considerations that must be given to the fan. steel will create sparks. It is the end users responsibil-

Almost any fan could serve in explosive environments ity to ensure that steel surfaces are suitably coated, and

under normal operation. The temperatures encountered that fans are kept clean from iron oxides.

are low enough that few (if any) materials will ignite. The AMCA standard allows fans to be constructed of

However, fans have been involved with causing explo- any material which has demonstrated ability to be spark

sions since the fan operating integrity varies over its life. resistant. Metals containing less than 5% iron are

In order to reduce the risk of explosion, fan construction allowed. Although aluminum is the most common con-

is modified. struction material, copper, brass, Monel, and other met-

als are used where corrosion and temperature limit the

suitability of aluminum. NOTE: Stainless steel does NOT

AMCA Standards comply.

Non-metallics are often avoided as a construction

A widely used standard for specifying these modifica-

material for the fan impeller due to the potential for

tions is the Air Movement and Control Associations

buildup of static electricity. Some fan wheels are con-

(AMCA) Standard 99-0401, Classification for Spark

structed of fiber reinforced plastic (FRP) which has an

Resistant Construction. This standard has the following

electrically conductive surface coat. This coating should

characteristics:

be electrically grounded to the shaft.

1. It identifies who is responsible for what.

2. It allows for three different levels of construction:

Type A, B, and C.

Alternative Standards

The AMCA standard is widely used in the United States,

3. It is general in nature to allow different fan manufac- and is referenced by other standards. An equipment

turers to comply using alternative methods. specifier need only state AMCA Spark Resistant Type

4. It provides disclaimers and warnings to users con- B to convey a multitude of fan design requirements.

cerning residual risks. The standard is effective in that the risks of fan-induced

explosion can be dramatically reduced without excessive

5. It does not require qualification testing. cost additions.

While not explicitly stated, AMCA 99-0401 is limited Internationally there are other standards which are

to applications for which the explosive materials are used. At the time of writing this article there is a devel-

present in a sealed ducted airstream, but not present oping European CEN standard. This standard is

on the outside of the fan housing. attempting a much more comprehensive approach to

For all classes of spark resistance, bearings and this subject. While the AMCA standard does not claim

electrical devices (motors, sensors, etc.) are not allowed to make fans truly explosion proof, the CEN standard

in the direct airstream. From the lowest level of protec- may well make that claim. It could do this by including

tion to the highest, the classifications of spark resistant many more considerations that may be relevant in

construction are: reducing the likelihood of an explosion, including:

Type C: The fan is designed so that if the impeller or 1. Fan modifications required to accommodate the

shaft comes loose and shifts during operation, two fer- presence of explosive environments outside the air-

rous parts will not come into contact. stream.

Type B: In general, this requires a nonferrous impeller 2. A more limited set of construction materials.

and a nonferrous rubbing ring around the shaft hole. 3. Specifications on design durability and other

Also, extra locking systems are required to prevent the mechanical aspects.

fan impeller, shaft, and bearings from shifting.

2003 Twin City Fan Companies, Ltd.

4. Requirements on gas stream sealing, motor con-

struction, bearing design and shafting design.

Conclusion

Until such time as a uniformly accepted code clearly

5. Fan qualification testing. defines all specifications of a safe system, system

6. Operating temperature limits. designers must decide on their own. The fan manufac-

turer can usually accommodate the fan modifications

7. Maintenance and cleaning requirements. necessary to comply with more comprehensive specifica-

8. Limiting the ability of foreign materials to enter the tions. However, the system designer must assess the

fan (by use of screens). risks and identify what is needed. Fan manufacturers

usually are not in a position to advise what modifications

9. Use of larger internal clearances for the fan rotor. are necessary to make a system acceptably safe for

10. Other safety equipment and sensors. every possible environment.

The AMCA spark resistant standard is adequate for

If adapted internationally, this standard would likely the vast majority of all fans used in potentially explosive

reduce the likelihood of explosions. However, it would environments. However, where the hazards are extreme-

also add to the first cost, installation cost, and the ly severe, consider adding more detailed specifications

operating cost of a fan system. to reduce the potential for explosion to exceptionally low

levels.

Twin city fan & blower | www.tcf.com

5959 Trenton Lane N | Minneapolis, MN 55442 | Phone: 763-551-7600 | Fax: 763-551-7601

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- LSD-NEERI - Water Quality AnalysisDocument68 pagesLSD-NEERI - Water Quality AnalysisSubrahmanyan EdamanaNo ratings yet

- Rotary Kiln Handbook NEWDocument56 pagesRotary Kiln Handbook NEW117511750% (1)

- Mouse of The CountryDocument13 pagesMouse of The Countrylahsivlahsiv684No ratings yet

- Marketing Opportunities for Bio-Toilets in Rural IndiaDocument9 pagesMarketing Opportunities for Bio-Toilets in Rural Indialahsivlahsiv684No ratings yet

- Low Cost Sanitary Toilets: (Minimum Water Use)Document6 pagesLow Cost Sanitary Toilets: (Minimum Water Use)lahsivlahsiv684No ratings yet

- Cable DataDocument3 pagesCable Datalahsivlahsiv684No ratings yet

- Chapter 10 - CirclesDocument20 pagesChapter 10 - CirclesshaunakaleleNo ratings yet

- Disposable Paper Plates Project PDFDocument4 pagesDisposable Paper Plates Project PDFsuryanathNo ratings yet

- Utilityconservation 508 PDFDocument54 pagesUtilityconservation 508 PDFlahsivlahsiv684No ratings yet

- Garbage ScreeningDocument5 pagesGarbage Screeninglahsivlahsiv684No ratings yet

- Rats PencilsDocument9 pagesRats Pencilslahsivlahsiv684No ratings yet

- Ladders of Success: An Empirical Approach To Trust: Pınar Yolum Pyolum@eos - Ncsu.edu Munindar P. Singh Singh@ncsu - EduDocument2 pagesLadders of Success: An Empirical Approach To Trust: Pınar Yolum Pyolum@eos - Ncsu.edu Munindar P. Singh Singh@ncsu - Edulahsivlahsiv684No ratings yet

- Cable Sizing CalculationDocument1 pageCable Sizing CalculationhafizheryNo ratings yet

- Stair LaddersDocument4 pagesStair Ladderslahsivlahsiv684No ratings yet

- Multiple CircleDocument18 pagesMultiple Circlelahsivlahsiv684No ratings yet

- Biodiversity DonkeyDocument22 pagesBiodiversity Donkeylahsivlahsiv684No ratings yet

- India Weather Data and Climate AnalysisDocument39 pagesIndia Weather Data and Climate Analysislasrador0% (1)

- Man Tiger ConflictDocument17 pagesMan Tiger Conflictlahsivlahsiv684No ratings yet

- CH 11Document5 pagesCH 11anil.gelra5140No ratings yet

- Dawn of InsectsDocument11 pagesDawn of Insectslahsivlahsiv684No ratings yet

- Crow and CowDocument2 pagesCrow and Cowlahsivlahsiv684No ratings yet

- Gujarati VocabularyDocument25 pagesGujarati Vocabularysnkelkar16531No ratings yet

- Section XX Chapter-95: ITC (HS), 2012 Schedule 1 - Import PolicyDocument6 pagesSection XX Chapter-95: ITC (HS), 2012 Schedule 1 - Import Policylahsivlahsiv684No ratings yet

- Wind of ParkDocument2 pagesWind of Parklahsivlahsiv684No ratings yet

- Common TreesDocument61 pagesCommon TreesGary BhullarNo ratings yet

- Potato TopDocument12 pagesPotato Toplahsivlahsiv684No ratings yet

- Jewellery Production ProceduresDocument15 pagesJewellery Production Procedureslahsivlahsiv684No ratings yet

- My ThesisDocument117 pagesMy Thesisshrinivas407No ratings yet

- I DonkeyDocument3 pagesI Donkeylahsivlahsiv684No ratings yet

- Themed Gift Basket IdeasDocument7 pagesThemed Gift Basket Ideaslahsivlahsiv684No ratings yet

- Water DonkeyDocument29 pagesWater Donkeylahsivlahsiv684No ratings yet

- Effect of Synthesis Temperature On Catalytic Activity and Coke Resistance of Ni-Bio-Char During CO2 Reforming of TarDocument12 pagesEffect of Synthesis Temperature On Catalytic Activity and Coke Resistance of Ni-Bio-Char During CO2 Reforming of Tarabhishek_ictNo ratings yet

- Science Answer Key Class IxDocument7 pagesScience Answer Key Class IxLakshay BansalNo ratings yet

- Xdcixz2u1wgmgwoavm1gwjvasvj G9vcs39xeb2vi34mccaalbrb7asbodbb3wsn6ujqmqwv8twty Qf4a3jjeqwik Af6q 4mhxyludDocument2 pagesXdcixz2u1wgmgwoavm1gwjvasvj G9vcs39xeb2vi34mccaalbrb7asbodbb3wsn6ujqmqwv8twty Qf4a3jjeqwik Af6q 4mhxyludAbou Tebba SamNo ratings yet

- MPI Report SWL 5 Ton BoxDocument2 pagesMPI Report SWL 5 Ton BoxYusuf bagewadiNo ratings yet

- Prof. Dr. Zainul Huda: Resume ofDocument31 pagesProf. Dr. Zainul Huda: Resume ofMuhammed ThanzeelNo ratings yet

- Polyurethanes From Renewable ResourcesDocument46 pagesPolyurethanes From Renewable ResourcesMohammad R ChandanNo ratings yet

- Environmental I AssDocument15 pagesEnvironmental I AssAbel TayeNo ratings yet

- Effectiveness of Sootblowers in Boilers Thermal Power StationDocument7 pagesEffectiveness of Sootblowers in Boilers Thermal Power Stationdillipsh123No ratings yet

- MSDS Quickmast 341-BaseDocument5 pagesMSDS Quickmast 341-BaseM.FAIZAN ARSHAD100% (1)

- An Introduction To The Study of ElectricalEngineeringDocument468 pagesAn Introduction To The Study of ElectricalEngineeringsajeewa990% (1)

- Global Packaging Report for Peruvian Table Grape ExportsDocument11 pagesGlobal Packaging Report for Peruvian Table Grape ExportsFelipe IllanesNo ratings yet

- Hot IceDocument4 pagesHot IceeunoiasantosNo ratings yet

- By Todd Harvey at 10:31 Am, Sep 30, 2013: API 661 Air-Cooled Heat Exchanger - Specification SheetDocument12 pagesBy Todd Harvey at 10:31 Am, Sep 30, 2013: API 661 Air-Cooled Heat Exchanger - Specification SheetPackage RotaryNo ratings yet

- OPGWDocument74 pagesOPGWAnonymous 3y4Z5cUNo ratings yet

- E00159 EZ11 ManualDocument30 pagesE00159 EZ11 ManualRuddy MariusNo ratings yet

- Dokumen - Tips - Din 8555 Welding StandardDocument5 pagesDokumen - Tips - Din 8555 Welding StandardHenry León HenaoNo ratings yet

- Mineral Dressing PDFDocument40 pagesMineral Dressing PDFArijit MondalNo ratings yet

- Low-Bias Transport in Graphene:an IntroductionDocument57 pagesLow-Bias Transport in Graphene:an IntroductionLIAKMANNo ratings yet

- CS2 - Carbon Steel Bars For The Reinforcement of Concrete (1995)Document36 pagesCS2 - Carbon Steel Bars For The Reinforcement of Concrete (1995)don2hmrNo ratings yet

- E1225-13 Standard Test Method For Thermal Conductivity of Solids Using The Guarded - Comparative PDFDocument10 pagesE1225-13 Standard Test Method For Thermal Conductivity of Solids Using The Guarded - Comparative PDFFernando Gastañaga Flores100% (2)

- DIPRA Member Companies Design Ductile Iron Pipe Thrust Restraint SystemsDocument10 pagesDIPRA Member Companies Design Ductile Iron Pipe Thrust Restraint SystemsSaravanan MuthuramanNo ratings yet

- BIOREMDIATIONDocument9 pagesBIOREMDIATIONMae Nielyn PadilloNo ratings yet

- Superfrac BrochureDocument16 pagesSuperfrac Brochureunknownx_XNo ratings yet

- Smart, Eco-Friendly, Money-Saving Home Tips by Kevin ReganDocument1 pageSmart, Eco-Friendly, Money-Saving Home Tips by Kevin ReganKathy Irene ReganNo ratings yet

- British Standards CableDocument2 pagesBritish Standards CableVarun Chandran100% (1)

- Requirement For Crown Industrial ParkDocument1 pageRequirement For Crown Industrial ParkAbdul RafaeNo ratings yet

- Liquid-Solid Extraction (Exp 3)Document13 pagesLiquid-Solid Extraction (Exp 3)Ahmed Sameer100% (2)

- Mastics, Glues For Marble, Granite, StoneDocument6 pagesMastics, Glues For Marble, Granite, StoneNaveen GuptaNo ratings yet

- Tablet Coating PDFDocument6 pagesTablet Coating PDFAsif Hasan Niloy100% (1)