Professional Documents

Culture Documents

WAPA Tech Bulletin Porous Asphalt Pavements 2015-09 PDF

Uploaded by

Muhamad Hafid AOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WAPA Tech Bulletin Porous Asphalt Pavements 2015-09 PDF

Uploaded by

Muhamad Hafid ACopyright:

Available Formats

TECHNICAL BULLETIN

Porous Asphalt Pavements

Introduction

Porous asphalt pavements with stone reservoirs are a TABLE OF CONTENT S

multifunctional, low impact development technology that

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

integrate ecological and environmental goals for a site with

land development goals, reducing the net environmental Benefits and Advantages . . . . . . . . . . . . . . . . . . . . 2

impact for a project. Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Design of Porous Asphalt Pavements . . . . . . . . . . . . . 3

Not only do they provide a strong pavement surface for

Site Considerations . . . . . . . . . . . . . . . . . . . . . . 3

parking, walkways, trails, and roadways, they are designed to

Hydrological Design . . . . . . . . . . . . . . . . . . . . . 3

manage and treat stormwater runoff. With proper design and

installation, porous asphalt pavements can provide a cost- Structural Design . . . . . . . . . . . . . . . . . . . . . . . 4

effective solution for stormwater management in an environ- Aggregate Storage Reservoir . . . . . . . . . . . . . . . . . . 4

mentally friendly way. Porous Asphalt Mixtures . . . . . . . . . . . . . . . . . . . . . 5

Mixture Test Methods . . . . . . . . . . . . . . . . . . . . . . 5

As a result, they are recognized as a best practice by the U.S.

Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Environmental Protection Agency (U.S. EPA) and many state

agencies (New Jersey Department of Environmental Pro- Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

tection, 2009; Pennsylvania Department of Environmental Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Protection, 2006; U.S. EPA, n.d.). Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Acknowledgments . . . . . . . . . . . . . . . . . . . . . . . . 7

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Appendices

1. Porous Asphalt Fact Sheet . . . . . . . . . . . . . . . . . 9

2. Porous Asphalt Maintenance Guide . . . . . . . . . . .10

3. Porous Asphalt Inspection Checklist . . . . . . . . . . .11

4. Porous Asphalt Winter Maintenance . . . . . . . . . . .12

LIST OF FIGURES

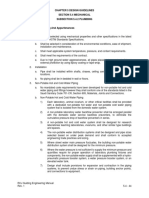

1. Cross section of typical porous asphalt

pavement with stone reservoir cross . . . . . . . . . . . 1

2. Stone edge and drop inlet designs . . . . . . . . . . . . 4

3. Recommended minimum compacted

Figure 1. Cross section of typical porous asphalt pavement with porous asphalt thicknesses . . . . . . . . . . . . . . . . 4

stone reservoir (Image courtesy of FHWA)

Unlike conventional pavements, porous asphalt pavements LIST OF TABLES

(Figure 1) are typically built over an uncompacted subgrade

to maximize infiltration through the soil. Above the uncom- 1. Recommended layer coefficients . . . . . . . . . . . . . 4

pacted subgrade is a geotextile fabric, which prevents the 2. WAPA porous asphalt mix design

migration of fines from the subgrade into the stone recharge recommended specifications . . . . . . . . . . . . . . . 5

bed while still allowing for water to pass through.

September 2015

POROUS ASPHALT PAVEMENTS

The next layer is a stone reservoir consisting of uniformly deicing salts. While the system does not remove chloride, the

graded, clean crushed stone with 40% voids serving as a drastic reduction of deicing chemicals required is an effective

structural layer and temporarily storing water as it infiltrates method for reducing chloride pollution (Roseen, Ballestero,

into the soil below. Houle, Heath, & Houle, 2014).

To stabilize the surface for paving, a thin (about 1 inch thick) Following is a list of benefits and advantages of porous

layer of clean, smaller, single-size crushed stones is often asphalt pavements with stone reservoirs:

placed on top; this is called the stabilizing course or choker

Faster melting of snow and ice, reducing the need for

course.

deicing salts (Lebens, 2012).

The last layer consists of one or more layers of porous

Cools stormwater temperature during summertime be-

asphalt mixes with interconnected voids that allow water to

fore discharge and mitigates heat island effects (Lebens,

flow through the pavement into the stone reservoir. These

2012).

porous asphalt layers consist of asphalt binder, aggregates,

sands, and recycled materials and are much like a dense- Reduction in contamination in water runoff and sedi-

graded hot mix asphalt mixture. By limiting the amount of ment loading (Lebens, 2012; Houle, Roseen, Ballestero,

fines, the porous mixture allows for more air voids. (Typically Puls, & Sherrard, 2013).

between 16% and 22% is recommended.)

Recharging of groundwater supplies (UNHSC, 2012).

It should also be noted that in Figure 1, an optional stone

edge is shown resting on the stone reservoir. This would Low-impact development and cost-effective technol-

allow rain to infiltrate into the stone reservoir if the porous ogy for stormwater management by reducing need for

asphalt surface becomes ineffective due to improper drainage drainage structures and rights of way (Houle, Roseen,

(which could be caused by plugged air voids, for example). Ballestero, Puls, & Sherrard, 2013; UNHSC, 2011; U.S.

EPA, 2014).

Improved wet-weather visibility, tire spray, and hydro-

Benefits and Advantages planing (Lebens, 2012).

One of the greatest benefits of porous asphalt pavements is Absorption of noise from tires and engines (Lebens,

its effectiveness for stormwater management, improving wa- 2012).

ter runoff quality, reducing stormwater runoff, and restoring

Reduction in stormwater runoff volume (Lebens, 2012).

groundwater supplies.

Improved water and oxygen transfer to nearby plant

Stormwater drains through the porous asphalt surface; is

roots (Minnesota Department of Transportation, 2012).

temporarily held in the voids of the stone reservoir, reducing

stormwater runoff; and then slowly drains into the underly- Credits in green construction rating systems, such as

ing, uncompacted subgrade to eventually restore groundwa- Leadership in Energy and Environmental Design,

ter supplies. As stormwater drains, contaminants are filtered Greenroads, and International Green Construction

and microbial activity decomposes pollutants, improving Code.

water quality.

For roadways, other major benefits include reduced noise,

Several studies have quantified high removal rates of total increased wet-weather friction and visibility, and reduced

suspended solids, metals, oil, and grease, as well as moder- stormwater temperatures before discharge (Lebens, 2012).

ate removal rates for phosphorus, from using porous asphalt

Recent research has identified permeable pavements as a

pavements (Cahill, Adams, & Marm, 2005; Roseen, Balles-

cool pavement technology. Due to their high air void struc-

tero, Houle, Briggs, & Houle, 2012).

ture, porous asphalt can mitigate urban heat island effect

During the winter, porous asphalt pavements have excellent by reducing stored pavement energy and allowing for rapid

performance since water drains quickly through the surface. cooling via evaporation (Li, Harvey, Holland, & Kayhanian,

They are a potential strategy for minimizing use of deicing 2013; Stempihar, Pourshams-Manzouri, Kaloush, & Rodez-

chemicals. The University of New Hampshire Stormwater no, 2012; U.S. EPA, 2008).

Center (UNHSC) reports a 75% or greater reduction of

WISCONSIN ASPHALT PAVEMENT ASSOCIATION 2

POROUS ASPHALT PAVEMENTS

Applications Minimum depth to bedrock or seasonal high ground-

water should be greater than 2 feet, and frost depth

Porous asphalt pavements are typically recommended for should be taken into consideration.

parking areas and low-volume roadways (Roseen, Ballestero,

Houle, Briggs, & Houle, 2012). Additional applications of Conduct a site evaluation of sufficient detail to estab-

porous asphalt are for pedestrian walkways, pathways, sports lish site-specific conditions, including soil type.

complex applications, sidewalks, driveways, bike lanes, and The bottom of the infiltration bed should be flat. For

shoulders (Hein, Strecker, Poresky, Roseen, & Venner, 2013). roadways it may be necessary to construct berms under

Porous asphalt pavements have also been used successfully the pavement surface to retain water on slopes and

for residential and urban streets as well as highways. install drains/overflows at low points (Roseen, Janeski,

Porous asphalt pavements can be installed as whole or in & Gunderson, 2011).

part with traditional impervious asphalt pavements. When For parking areas, the slope of the porous pavement

installed in combination with impervious pavements or adja- surface should be less than 5%. For slopes greater than

cent to building roofs, porous asphalt can sufficiently contain 5%, the parking areas should be terraced with berms in

and treat the additional runoff generated. between.

Seek opportunities to route runoff from nearby imper-

vious areas to infiltration bed.

Design of Porous Asphalt

Pavements Impervious to pervious areas should be less than a

5:1 ratio for most conditions or 3:1 for sinkhole-

There are three considerations required when determining susceptible areas (karst formations).

the thickness of the layers of porous pavements:

For systems that will infiltrate water into the soil subgrade,

Site considerations to ensure that the site is accept- evaluate the site in accordance with Wisconsin Department

able. of Natural Resources (WDNR) Conservation Practice Stan-

dards 1002, Site Evaluation for Stormwater Infiltration, and

Hydrological design to ensure the porous pavement

1008, Permeable Pavement (WDNR, 2004; WDNR, 2014).

meets the potential stormwater runoff demands.

Structural design to ensure that the porous pavement

withstands the anticipated traffic loading. Hydrological Design

Most often, the thickness of the stone recharge bed will be Hydrological design determines what layer thicknesses are re-

controlled by soil infiltration rates (site considerations) and quired to sufficiently infiltrate, store, and release the expected

water quantity (hydrological design) rather than structural inflow of water, which includes both rainfall and excess

requirements, while the porous asphalt surface layer will be stormwater runoff from any adjacent impervious surfaces.

determined by the traffic loads (structural design). This requires information regarding the layer thicknesses

and subgrade permeability along with precipitation intensity

levels.

Site Considerations

The hydrologic design of porous pavements should be

The location of porous pavements should be considered performed by a licensed engineer. The two most common

early during the design process. methods for modeling stormwater runoff are the U.S. De-

partment of Agricultures Natural Resources Conservation

Contrary to conventional construction pavement siting, po-

Service (formerly Soil Conservation Service) Curve Number

rous pavements perform best on upland soils (Cahill, Adams,

method and the Rational method. The Rational method is

& Marm, 2005). Additional site considerations include soil

not recommended for evaluation of porous pavement sys-

types, depth of bedrock, pavement slope, and additional

tems. Specific details on hydrological design are beyond the

sources of runoff. General site guidelines include:

scope of this report. If a hydraulic connection is possible,

Soil infiltration rates of 0.1 to 10 inches/hour porous asphalt pavement systems shall be located per the

(0.5 inches/hour is recommended by U.S. EPA). Do requirements of WDNR Conservation Practice Standards

not place over known sinkholes. 1002, Site Evaluation for Stormwater Infiltration, and

1008, Permeable Pavement (WDNR, 2004; WDNR, 2014).

WISCONSIN ASPHALT PAVEMENT ASSOCIATION 3

POROUS ASPHALT PAVEMENTS

Figure 3. Recommended minimum compacted porous

asphalt thicknesses (Image courtesy of FHWA)

minimum thicknesses of the compacted porous asphalt layer

for different truck loadings are shown in Figure 3.

WDNR states that a pavement surface infiltration design

analysis shall be conducted using an accepted continuous

simulation model (e.g., WinSLAMM) per the requirements

of WDNR Conservation Practice Standards 1002, Site

Evaluation for Stormwater Infiltration, and 1008, Perme-

able Pavement (WDNR, 2004; WDNR, 2014). Those docu-

Figure 2. Stone edge (top) and drop inlet (bottom) designs ments also provide prohibited source areas, impervious/

(Image courtesy of FHWA) pervious source areas with equations, and clogging potential

ratios.

Porous pavements are often not designed to store and

infiltrate the maximum precipitation at the site. Therefore

overflow should be included in the design to prevent stored

stormwater from reaching the surface layers. This will typi-

Aggregate Storage Reservoir

cally involve perforated pipes in the stone reservoir that are Aggregate storage reservoirs shall be designed to achieve

connected to the discharge pipe, as shown in Figure 2. It is site-specific pavement structural requirements and storm-

also recommended that an alternative path for stormwater water management goals. The aggregate specifications are as

to enter the stone reservoir be provided in case the surface follows per WDNR Conservation Practice Standards 1002,

should become plugged. Figure 2 shows examples of designs Site Evaluation for Stormwater Infiltration, and 1008,

using a stone edge or drop inlet to manage overflows. Permeable Pavement (WDNR, 2004; WDNR, 2014):

Use open-graded base consisting of crushed stone or

Structural Design crushed gravel with no greater than 5% passing the

No. 200 sieve.

While limited structural information is available, some

porous pavements have lasted for more than 20 years. For Provide a minimum porosity of 30% per ASTM C29,

porous pavements carrying light automobile traffic only, the Standard Test Method for Bulk Density (Unit Weight)

structural requirements are not significant, and the mate- and Voids in Aggregate.

rial thicknesses are determined by the hydrological design Comply with soundness, wear, and fracture require-

and minimum thicknesses required for porous asphalts. For ments listed in Wisconsin Department of Transpor-

porous asphalt pavements expected to carry truck loads, tation (WisDOT) Standard Specifications Section

structural design should follow standard design procedures. 301.2.4.5, Aggregate Base Physical Properties.

Recommended layer coefficients for porous asphalt pave-

ments are shown in Table 1 (Hansen, 2008). Recommended Comply with construction requirement in WisDOT

Standard Specifications Section 301.3, Construction,

Table 1. Recommended layer coefficients or administering authority.

Material Layer Structural Coefficients Selection of smaller-size aggregate (e.g., -inch No. 57

Porous Asphalt 0.400.42 stone rather than 3-inch No. 2 stone) will reduce the rate of

Asphalt-Treated Permeable Base 0.300.35 discharge along the subgrade slope and the rate of accumula-

Porous Aggregate Base

0.100.14

tion at the downgradient end of the system.

(Stone Recharge Bed)

WISCONSIN ASPHALT PAVEMENT ASSOCIATION 4

POROUS ASPHALT PAVEMENTS

Table 2. WAPA porous asphalt mix design recommended specifications

Porous asphalt mixes designed in accordance with these specifications are compatible with WisDOT-approved warm mix asphalt technologies. Road

authorities that adopt these specifications may provide for allowances based on a contractors track record and experience with porous pavements.

MIX

Property Value Notes

Binder Content 5.5% 5.26.0% is recommended depending on Nmas gradation.

Minimum high temperature of 64C is recommended. PG 64-28 or

Binder Grade 28 PG 70-28 modified binders can be specified in an effort to provide improved

mix stability and durability.

Percent Binder Replacement 25 max

% Air Voids (Va @ 50 gyrations) 1622

Dust to Effective Binder Ratio 1.0 max

Tensile Strength Ratio (TSR @ 50 gyrations

70% min

and design air voids) [ASTM D4867]

Effective measures to reduce draindown include the use of manufactured

Draindown at Production Temperature 0.3% max sand in lieu of crusher screenings as well as the use of fibers or recycled

asphalt shingles.

NOTE: It is also considered to be acceptable practice to follow ASTM D6752, Standard Test Method for Bulk Specific Gravity and Density of Compacted

Bituminous Mixtures Using Automatic Vacuum Sealing Method, as the method to determine the bulk specific gravity for the air voids determination.

AGGREGATE

Property Value

100 revolutions 13 max

LA Abrasion (% Loss) [AASHTO T96]

500 revolutions 45 max

Soundness (% Loss) Using Sodium Sulfate [AASHTO T104] 12 max

Freeze/Thaw Soundness (% Loss) [AASHTO T103] 18 max

2 faces 90 min

Fractured Faces (% by Count) [ASTM D5821]

1 face 100 min

Flat and Elongated (% by Weight) [ASTM D7064M] 5% max; 5:1 ratio

BLENDED AGGREGATE GRADATION

Property Value

12.5 mm NMAS 9.5 mm NMAS

3/4" 100 n/a

1/2" 85100 100

3/8" 5575 90100

Sieve (% Passing)

#4 1025 1540

#8 315 520

#200 14 26

Voids in Mineral Aggregate (%) 24 min 25 min

Porous Asphalt Mixtures Mixture Test Methods

Porous asphalt mixtures are designed using the Superpave Because porous asphalt surfaces do not hold water, they have

method (50 gyrations) with requirements for higher air voids a very low risk of moisture-related damage. Despite this, it is

and low draindown to assure permeability and performance. still recommended to add an anti-stripping agent to the mix if

To reduce draindown and provide resistance to scuffing, it would be required for dense-graded mixtures using the same

mixes are typically designed with polymer-modified binders. materials. If there is no history determining whether an anti-

Fibers are often added to the mix to reduce draindown. Mix stripping agent would be required, then a moisture susceptibil-

design recommended specifications are presented in Table 2 ity test may be run on a dense-graded mix with the same ag-

(Hansen, 2008). gregate and binder per ASTM D4867, Standard Test Method

for Effect of Moisture on Asphalt Concrete Paving Mixtures.

WISCONSIN ASPHALT PAVEMENT ASSOCIATION 5

POROUS ASPHALT PAVEMENTS

Construction The porous asphalt should be placed in 1- to 4-inch-

thick lifts, and tracked pavers are recommended.

One of the most important concerns during the construc-

tion of porous asphalt pavements is the clogging of the The porous asphalt should be compacted with two to

surface or filling of the voids in the stone reservoir. As a four passes of a 10-ton roller.

result, protecting the pavement during construction from un- Restrict traffic for at least 24 hours after final rolling.

controlled runoff in adjacent areas and the surrounding soil

from compaction is critical. This includes having temporary

stormwater controls in place until the site is stabilized and

clear, specific guidance for construction procedures.

Maintenance

In order to maintain long-term performance of porous

Typical guidelines for construction procedures for porous asphalt pavements stormwater management capabilities, it is

pavement include the following: recommended that the surface infiltration rates be inspected

Plan to construct the porous pavement as late as pos- annually during rain events to observe any changes in effec-

sible in the construction schedule. tiveness of infiltrating stormwater.

Protect site area from excessive heavy equipment run- To remove any solids and debris that could lead to more per-

ning on the subgrade, compacting soil, and reducing manent clogging of the pavement, it is recommended that

permeability. If the subgrade soil is overcompacted porous asphalt pavements be vacuumed two to four times a

during construction, consider refracturing or ripping year or power-washed (UNHSC, 2012; Palmer, 2012). Best

the soil subgrade to a depth of 12 to 20 inches. Ad- practice is to recommend conducting surface cleaning opera-

ditional base/subbase aggregate may be needed, as well tions during spring and fall.

as additional compaction of these materials, to reduce During winter months, there are no special requirements

the risk of surface settlement and to render a stable for plowing. Deicing chemicals may be used to melt ice and

structure for supporting vehicular traffic. snow from the surface, but the amount of deicing chemi-

Excavate the subgrade soil using equipment with over- cals will be significantly less than for impervious pavements.

size tires or tracks to minimize compaction to soil. Do not use sand or cinders as they will clog up the air void

spaces within the pavement structure.

As soon as the bed has been excavated to the final

grade, the fabric filter should be placed with an overlap The appendices to this publication include more detailed

of a minimum of 16 inches. Use the excess fabric (at inspection and maintenance guidance for porous pavements.

least 4 feet) to fold over the stone bed to temporarily These appendices were adapted from materials published by

protect it from sediment. UNHSC (UNHSC, 2011; UNHSC, n.d.; Hall, n.d.).

Install drainage pipes, if required per WDNR Conser-

vation Practice Standards 1002, Site Evaluation for

Stormwater Infiltration, and 1008, Permeable Pave-

ment (WDNR, 2004; WDNR, 2014).

Caution

Place the aggregate stone recharge bed carefully to Porous asphalt pavements should never be seal coated or

avoid damaging the fabric. The aggregate should be crack sealed. If patching is necessary, conventional mixes

dumped at the edge of the bed and placed in layers of may be used if less than 15% of the pavement area is af-

8 to 12 inches using tracked equipment and compacted fected.

with a single pass of a light roller or vibratory plate

Porous asphalt may not be used in industrial storage and

compactor.

loading areas or vehicle fueling and maintenance areas. See

When using a stabilizer course, it is important that the WDNR Conservation Practice Standards 1002, Site Evalu-

aggregate be sized properly to interlock with the aggre- ation for Stormwater Infiltration, and 1008, Permeable

gate in the recharge bed. The stabilizer course should Pavement (WDNR, 2004; WDNR, 2014).

be placed at a thickness of about 1 inch. Some larger

stones from the stone reservoir should be visible at the

surface.

WISCONSIN ASPHALT PAVEMENT ASSOCIATION 6

POROUS ASPHALT PAVEMENTS

Summary Li, H., Harvey, J. T., Holland, T. J., & Kayhanian, M. (2013).

The Use of Reflective and Permeable Pavements as a Po-

Porous asphalt pavements have been successfully used tential Practice for Heat Island Mitigation and Stormwater

for more than 35 years in a variety of climates around the Management. Environmental Research Letters, 8(1).

United States. They provide a pavement surface that is also

part of the stormwater management system, reducing storm- Minnesota Department of Transportation. (2012). Porous

water runoff and pollutants and replenishing groundwater. A Asphalt Performance in Cold Regions. Report 2012-12TS. Re-

number of porous asphalt parking lots have lasted more than trieved from http://www.dot.state.mn.us/research/

20 years with no maintenance other than routine cleaning. TS/2012/201212TS.pdf.

New Jersey Department of Environmental Protection.

(2009). New Jersey Stormwater Best Management Practices Manual.

Acknowledgments Retrieved from http://www.njstormwater.org/

bmp_manual2.htm.

WAPA wishes to acknowledge the U.S. Federal Highway Ad-

ministration and the University of New Hampshire Storm- Palmer, M. A. (2012). Design and Construction of Porous

water Center, whose guidance was drawn from extensively Asphalt Pavements. Permeable Paving Design workshop at

in the development of this guide (FHWA, 2015; Hall, n.d.; Washington State UniversityPuyallup. April 24, 2012.

UNHSC, n.d.; UNHSC, 2011; UNHSC, 2012). Pennsylvania Department of Environmental Protection.

(2006). Pennsylvania Stormwater Best Management Practices Manual.

Retrieved from http://www.elibrary.dep.state.pa.us/

References dsweb/View/Collection-8305.

Cahill, T. H., Adams, M., & Marm, C. (MarchApril 2005). Roseen, R. M., Ballestero, T. P., Houle, J. J., Briggs, J., &

Stormwater Management with Porous Pavements. Government Houle, K. (2012). Water Quality and Hydrologic Perfor-

Engineering, 1419. Retrieved from http://www.smscland. mance of a Porous Asphalt Pavement as a Storm-Water

org/pdf/PorousCahill.pdf. Treatment Strategy in a Cold Climate. Journal of Environmental

Hall, G. (n.d.). Winter Maintenance Guidelines for Porous Pave- Engineering, 138(1), 8189.

ments. University of New Hampshire Stormwater Center. Roseen, R. M., Ballestero, T. P., Houle, K., Heath, D., &

Retrieved from http://www.unh.edu/unhsc/sites/ Houle, J. J. (2014). Assessment of Winter Maintenance of

unh.edu.unhsc/files/pubs_specs_info/winter_mainte- Porous Asphalt and Its Function for Chloride Source Con-

nance_fact_sheet.pdf. trol. Journal of Transportation Engineering, 140(2), 18.

Hansen, K. R. (2008). Porous Asphalt Pavements for Stormwater Roseen, R. M., Janeski, T. V., & Gunderson, J. (2011).

Management. Report IS 131. National Asphalt Pavement As- Economics and LID Practices, Chapter 3, Forging the Link:

sociation. Linking the Economic Benefits of Low Impact Development and Com-

Hein, D. K., Strecker, E., Poresky, A., Roseen, R. M., munity Decisions: Boulder Hills, N.H., 3-43-8. Retrieved from

& Venner, M. (2013). Permeable Shoulders with Stone Res- http://www.unh.edu/unhsc/sites/unh.edu.unhsc/

ervoirs. NCHRP Project 25-25, Task 82. Retrieved from files/docs/FTL_Chapter3%20LR.pdf.

http://onlinepubs.trb.org/onlinepubs/nchrp/docs/ Stempihar, J. J., Pourshams-Manzouri, T., Kaloush, K. E., &

NCHRP25-25(82)_FR.pdf. Rodezno, M. C. (2012). Porous Asphalt Pavement Tempera-

Houle, J. J., Roseen, R. M., Ballestero, T. P., Puls, T. A., & ture Effects for Urban Heat Island Analysis. Transportation Re-

Sherrard Jr., J. (2013). Comparison of Maintenance Cost, search Record: Journal of the Transportation Research Board, (2293),

Labor Demands, and System Performance for LID and Con- 123130.

ventional Stormwater Management. Journal of Environmental U.S. Environmental Protection Agency (2008). Cool Pave-

Engineering, 139(7), 932938. ments. Reducing Urban Heat Islands: Compendium of Strategies.

Lebens, M. (2012). Porous Asphalt Pavement Performance in Cold Retrieved from http://www.epa.gov/heatisland/

Regions. Report 2012-12. Minnesota Department of Trans- resources/compendium.htm.

portation. Retrieved from http://www.dot.state.mn.us/

research/documents/201212.pdf.

WISCONSIN ASPHALT PAVEMENT ASSOCIATION 7

POROUS ASPHALT PAVEMENTS

U.S. Environmental Protection Agency. (2014). The Economic

Benefits of Green Infrastructure: A Case Study of Lancaster, PA.

Report EPA 800-R-14-007. Retrieved from http://water.

epa.gov/infrastructure/greeninfrastructure/upload/

CNT-Lancaster-Report-508.pdf.

U.S. Environmental Protection Agency. (n.d.). Water: Best

Management Practices: Porous Asphalt Pavements. Retrieved from

http://water.epa.gov/polwaste/npdes/swbmp/

Porous-Asphalt-Pavement.cfm.

U.S. Federal Highway Administration. (2015). TechBrief:

Porous Asphalt Pavements with Stone Reservoirs. Report FHWA-

HIF-15-009. Retrieved from http://www.fhwa.dot.gov/

pavement/asphalt/pubs/hif15009.pdf.

University of New Hampshire Stormwater Center. (2011).

Regular Inspection and Maintenance Guidance for Porous Pavements.

Retrieved from http://www.unh.edu/unhsc/sites/unh.

edu.unhsc/files/UNHSC%20Porous%20Pavement%20

Routine%20Maintenance%20Guidance%20and%20

Checklist%202-11.pdf.

University of New Hampshire Stormwater Center.

(2012). University of New Hampshire Stormwater Cen-

ter 2012 Biennial Report. Retrieved from http://www.

unh.edu/unhsc/sites/unh.edu.unhsc/files/docs/

UNHSC.2012Report.10.10.12.pdf.

University of New Hampshire Stormwater Center. (n.d.).

Porous Asphalt Pavement for Stormwater Management. Retrieved

from http://www.unh.edu/unhsc/sites/unh.edu.

unhsc/files/porous_ashpalt_fact_sheet.pdf.

Wisconsin Department of Natural Resources. (2004).

Conservation Practice Standard 1002: Site Evaluation for

Stormwater Infiltration. Retrieved from http://dnr.wi.gov/

topic/stormwater/documents/dnr1002-infiltration.pdf.

Wisconsin Department of Natural Resources. (2014).

Conservation Practice Standard 1008: Permeable Pavement.

Retrieved from http://dnr.wi.gov/topic/stormwater/

documents/PermeablePavement1008.pdf.

WISCONSIN ASPHALT PAVEMENT ASSOCIATION 8

POROUS ASPHALT PAVEMENTS APPENDIX 1

P O RO U S A S P H A LT

FACT SHEET

Porous Asphalt Pavement for Stormwater Management

Porous asphalt can be used in place of traditional stormwater management measures given the

proper conditions. Porous asphalts primary advantages are:

Quantity and flood control.

Water quality treatment.

Recharges groundwater to underlying aquifers.

Allows for reduction of stormwater infrastructure (piping, catch basins, retention ponds,

Benefits and Uses curbing, etc.).

Suitable for cold-climate applications; maintains recharge capacity when frozen.

Allows for reduced salt usage due to low/no black ice development.

Maintains traction while wet.

Reduced spray from traveling vehicles; reduced roadway noise.

Extended pavement life due to well-drained base and reduced freeze/thaw.

Requires routine vacuum sweeping/pressure washing.

Disadvantages Proper construction stabilization and erosion control are required to prevent clogging.

Seal coating or similar surface treatment will cause failure.

Total project cost for porous asphalt with reduced stormwater infrastructure is comparable

to standard pavement applications where typical stormwater infrastructure is required.

Materials cost is more than traditional asphalt but can be offset by deicing costs.

Cost and Maintenance

Long-term maintenance is required by routine vacuum sweeping.

Sweeping cost may be offset by reduced deicing costs.

Repairs can be made with standard asphalt, not to exceed 15% of surface area.

Recommended drainage time of 2448 hours.

Sub-drains should be used to minimize frost damage where proper drainage may be an

Design Criteria

issue.

Most appropriate for use with low-volume roadways, pathways, and parking lots.

For More Information See WAPAs Porous Asphalt Pavements Design Guide.

WISCONSIN ASPHALT PAVEMENT ASSOCIATION 9

POROUS ASPHALT PAVEMENTS APPENDIX 2

P O RO U S A S P H A LT

MAINTENANCE GUIDE

Regular Inspection and Maintenance Guidance for Porous Pavements

Regular inspection and maintenance are critical to the effective operation of porous pavement. It is the responsibility of the owner to

maintain the pavement in accordance with the minimum design standards. This page provides guidance on maintenance activities that are

typically required for these systems along with the suggested frequency for each activity. Individual systems may have more or less frequent

maintenance needs, depending on a variety of factors, including the occurrence of large storm events, seasonal changes, and traffic condi-

tions.

Inspection Activities

Visual inspections are an integral part of system maintenance. This includes monitoring pavement to ensure water drainage, debris ac-

cumulation, and surface deterioration.

ACTIVITY FREQUENCY

Check for standing water on the surface of the pavement after a precipitation event.

Vacuum sweeper shall be used regularly to remove sediment and organic debris on the pavement

surface. The sweeper may be fitted with water jets.

Pavement vacuuming should occur during spring cleanup following the last snow event to remove

accumulated debris, at a minimum. 24 times per year; more frequently

for high-use sites or sites with higher

Pavement vacuuming should occur during fall cleanup to remove dead leaves, at a minimum.

potential for run-on

Power washing can be an effective tool for cleaning clogged areas.

Check for debris accumulating on pavement, especially debris buildup in winter. For loose debris,

a power/leaf blower or gutter broom can be used to remove leaves and trash.

Check for damage to porous pavements from nondesign loads.

Maintenance Activities

Routine preventative cleaning is more effective than corrective cleaning.

ACTIVITY FREQUENCY

Controlling run-on and debris tracking is key to extending the life of porous surfaces. Erosion and

sedimentation control of adjacent areas is crucial.

Repairs may be needed following utility repairs. Repairs can be made using standard (nonporous)

asphalt for most damages. Repairs using standard asphalt should not exceed 15% of total area.

Do not store materials such as sand/salt, mulch, soil, yard waste, and other stockpiles on porous

surfaces.

As needed

Stockpiled snow areas on porous pavements will require additional maintenance and vacuuming.

Stockpiling snow on porous pavements is not recommended and will lead to premature clogging.

Posting of signage is recommended indicating presence of porous pavement. Signage should

display limitations of design loads (i.e., passenger vehicles only, light truck traffic, etc., as per

pavement durability rating).

Damage can occur to porous pavement from nondesign loads.

WISCONSIN ASPHALT PAVEMENT ASSOCIATION 10

POROUS ASPHALT PAVEMENTS APPENDIX 3

P O RO U S A S P H A LT

INSPECTION CHECKLIST

Inspection Checklist for Porous Pavements

LOCATION INSPECTOR

DATE TIME SITE CONDITIONS

DATE SINCE LAST RAIN EVENT

Satisfactory (S) or Comments/

Inspection Items

Unsatisfactory (U) Corrective Action

1. Salt/Deicing

Use salt only for ice management S or U

Piles of accumulated salt removed in spring S or U

2. Debris Cleanup (24 times a year minimum, spring and fall)

Clean porous pavement to remove sediment and organic debris on the

S or U

pavement surface via vacuum street sweeper

Adjacent nonporous pavement vacuumed S or U

Clean catch basins (if available) S or U

3. Controlling Run-On (24 times a year)

Adjacent vegetated areas show no signs of erosion and run-on to porous

S or U

pavement

4. Outlet/Catch Basin Inspection (if available) (2 times a year and after large storm events)

No evidence of blockage S or U

Good condition; no need for cleaning/repair S or U

5. Poorly Draining Pavement (24 times a year)

Pavement has been pressure washed and vacuumed S or U

6. Pavement Condition (24 times a year minimum, spring and fall)

No evidence of deterioration S or U

No evidence of improper design load applied S or U

7. Signage/Stockpiling (as needed)

Proper signage posted indicating usage for traffic load S or U

No stockpiling and no seal coating S or U

Corrective Action Needed Due Date

1.

2.

3.

4.

5.

WISCONSIN ASPHALT PAVEMENT ASSOCIATION 11

POROUS ASPHALT PAVEMENTS APPENDIX 4

P O RO U S A S P H A LT

WINTER MAINTENANCE

Winter Maintenance Guidelines for Porous Pavements

If possible, plow with a slightly raised blade; while not necessary, this will help prevent

pavement scarring.

Up to approximately 75% salt reduction for porous asphalt can be achieved. Salt reduction

amounts are site-specific and are affected by degree of shading.

Apply anti-icing treatments prior to storms if possible. Anti-icing has the potential to pro-

vide the benefit of increased traffic safety at the lowest cost and with less environmental

impact.

Maintenance Guidelines

Deicing is NOT required for black ice development. Meltwater readily drains through porous

surfaces thereby preventing black ice.

Apply deicing treatments during and after storms as necessary to control compact snow

and ice not removed by plowing.

Vacuum porous areas a minimum of 24 times per year, especially after winter and fall

seasons when debris accumulation and deposition are greatest.

If ponding water is observed during precipitation, cleaning is recommended.

Mixed precipitation and compact snow or ice are problematic for all paved surfaces, but

are particularly problematic for porous surfaces. This is corrected by application of ad-

ditional deicing materials.

Deicing materials work by lowering the freezing point of water. Generally, the longer a

Winter Maintenance Challenges deicing chemical has to react, the greater the amount of melting. Meltwater readily drains

through porous surfaces thereby reducing chemical contact time. This is corrected by ap-

plication of additional deicing materials.

Additional salt application in these instances is offset by the overall reduced salt during

routine winter maintenance.

For More Information See WAPAs Porous Asphalt Pavements Design Guide.

WISCONSIN ASPHALT PAVEMENT ASSOCIATION 12

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Porous Asphalt Association Guidance DocumentDocument10 pagesPorous Asphalt Association Guidance DocumentwillypraviantoNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Dr. Mohamed Lachemi, P.Eng. Department of Civil Engineering Ryerson UniversityDocument54 pagesDr. Mohamed Lachemi, P.Eng. Department of Civil Engineering Ryerson UniversitydineshkateNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- 341 1309 1 PBDocument6 pages341 1309 1 PBMuhamad Hafid ANo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Wibowo & Purnawan GunawanDocument10 pagesWibowo & Purnawan GunawanSumarni Kala'No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 522 032806 Attachment CDocument2 pages522 032806 Attachment CMuhamad Hafid ANo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 06103Document188 pages06103Veio MacieiraNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Ultra-High Performance Concrete Properties and TechnologyDocument11 pagesUltra-High Performance Concrete Properties and TechnologyMuhamad Hafid ANo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Recycled Aggregates in New ConcreteDocument49 pagesRecycled Aggregates in New Concreteashu_gbpec2005100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- HPC Fundamentals and ApplicationDocument20 pagesHPC Fundamentals and ApplicationPrakash CharryNo ratings yet

- Asset Management Guide Specs - 2004 Csi Format (Div 01-33) Guide Spec - 2004 Csi Format Division 32 Exterior Improvements 32 1343 Pervious Concrete Pavement 120726Document12 pagesAsset Management Guide Specs - 2004 Csi Format (Div 01-33) Guide Spec - 2004 Csi Format Division 32 Exterior Improvements 32 1343 Pervious Concrete Pavement 120726Muhamad Hafid ANo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Fracture Properties and Brittleness of High-Strength ConcreteDocument11 pagesFracture Properties and Brittleness of High-Strength ConcreteMuhamad Hafid ANo ratings yet

- Bearing Pad ElastomerDocument1 pageBearing Pad ElastomerMuhamad Hafid ANo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Welded Wire ReinforcementDocument8 pagesWelded Wire ReinforcementMuhamad Hafid ANo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Fusion-Bonded Epoxy Coatings, A Technology For Rebar Corrosion PreventionDocument13 pagesFusion-Bonded Epoxy Coatings, A Technology For Rebar Corrosion PreventionMuhamad Hafid ANo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Sustainable Development Guidelines for Scott-Town and Green Bay Joint Planning AreaDocument81 pagesSustainable Development Guidelines for Scott-Town and Green Bay Joint Planning AreaMuhamad Hafid ANo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Motorway Bridge D1Document4 pagesMotorway Bridge D1Muhamad Hafid ANo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Sem Piter NalDocument5 pagesSem Piter NalMuhamad Hafid ANo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Half Wave 3 Phasa ControlledDocument1 pageHalf Wave 3 Phasa ControlledMuhamad Hafid ANo ratings yet

- Biodiesel Production by A Continuous Process Using Hetergenous CatalystDocument3 pagesBiodiesel Production by A Continuous Process Using Hetergenous Catalystdstar13No ratings yet

- Feasibility Study of Hydrogen Chloride ProductionDocument4 pagesFeasibility Study of Hydrogen Chloride ProductionIntratec SolutionsNo ratings yet

- Suspended Solids: Unequal Results From Equal Methods: MDL's and Sample VolumesDocument6 pagesSuspended Solids: Unequal Results From Equal Methods: MDL's and Sample VolumesDaniel ZamoraNo ratings yet

- Copper-Nickel Alloys, Properties and ApplicationsDocument28 pagesCopper-Nickel Alloys, Properties and Applicationsismail hakimNo ratings yet

- Opto Semi Koth0001eDocument17 pagesOpto Semi Koth0001eAnurag ChadhaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Me F211 1083 PDFDocument3 pagesMe F211 1083 PDFPranjal SrivastavaNo ratings yet

- Chromatography Lab ReportDocument6 pagesChromatography Lab ReportMohamad MerhabiNo ratings yet

- Is.7638.1999 Sampling For Plywood For ShutteringDocument16 pagesIs.7638.1999 Sampling For Plywood For ShutteringsuryakantameNo ratings yet

- SOBM Calculation SheetDocument15 pagesSOBM Calculation SheetChintan GohelNo ratings yet

- HFY-PIP-SP-00004 X Specification For Sour Service - A-CommentedDocument9 pagesHFY-PIP-SP-00004 X Specification For Sour Service - A-CommentedVignesh PanchabakesanNo ratings yet

- Ageing Phenomena of CelluloseDocument9 pagesAgeing Phenomena of CellulosedchyNo ratings yet

- Salt Analysis PDFDocument9 pagesSalt Analysis PDFNisheethNo ratings yet

- Water Jet Reed Best Manufacturer & Supplier in Ahmedabad, IndiaDocument8 pagesWater Jet Reed Best Manufacturer & Supplier in Ahmedabad, IndiaVijay PanchalNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Fsci Assignment ADocument29 pagesFsci Assignment ARaj PrateekNo ratings yet

- Readymix ProfileDocument33 pagesReadymix ProfileAyman HammodehNo ratings yet

- ABC SoilDocument5 pagesABC SoilAlliah MendozaNo ratings yet

- Underwater Concreting With Rescon TDocument12 pagesUnderwater Concreting With Rescon TPrateek JainNo ratings yet

- V0L2 PDFDocument4 pagesV0L2 PDFJohannie Nina ClaridadNo ratings yet

- Moles and Equations WorksheetDocument3 pagesMoles and Equations WorksheetArshad KhanNo ratings yet

- THEORITICAL RAW MIX DESIGNDocument3 pagesTHEORITICAL RAW MIX DESIGNVaibhav Khodake100% (4)

- Chapter 5 Design Guidelines Section 5.4 Mechanical Subsection 5.4.2 PlumbingDocument4 pagesChapter 5 Design Guidelines Section 5.4 Mechanical Subsection 5.4.2 PlumbingkapsarcNo ratings yet

- Fractionation of Wood TarDocument10 pagesFractionation of Wood TarThomas JacobsenNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Preliminary Welding Procedure Specification Pwps PDF FreeDocument1 pagePreliminary Welding Procedure Specification Pwps PDF FreeFirozNo ratings yet

- Programme CMSS17 2Document18 pagesProgramme CMSS17 2Mongi Ben OuezdouNo ratings yet

- 1.2 Structure and PropertiesDocument15 pages1.2 Structure and PropertiesLuisa Fernanda Sanchez ZambranoNo ratings yet

- 750-302 Models D, DL and DLDDocument31 pages750-302 Models D, DL and DLDrickNo ratings yet

- Structural Analysis Problems and Solutio PDFDocument22 pagesStructural Analysis Problems and Solutio PDFjay balagotNo ratings yet

- A Predictive Approach To Fitness-For-Service Assessment of Pitting CorrosionDocument9 pagesA Predictive Approach To Fitness-For-Service Assessment of Pitting CorrosionMaría Vaquero TxapartegiNo ratings yet

- Class 7 Science: Chapter 14 - Elements, Compounds and MixturesDocument6 pagesClass 7 Science: Chapter 14 - Elements, Compounds and MixturesRiddhi RaneNo ratings yet

- MSDS Intersorb Nonindicating Diving GradeDocument5 pagesMSDS Intersorb Nonindicating Diving GradeEdward BennettNo ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Transportation Engineering: Theory, Practice, and ModelingFrom EverandTransportation Engineering: Theory, Practice, and ModelingNo ratings yet

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet