Professional Documents

Culture Documents

Exhaust Chimney

Uploaded by

Designer ForeverOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exhaust Chimney

Uploaded by

Designer ForeverCopyright:

Available Formats

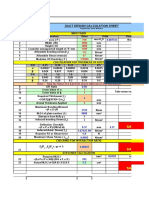

Generator Exhaust Pipe Diameter Calculations Project No.

Date

Version A Sheet No. Computed by

Checked by Approved by

'file:///conversion/tmp/scratch/360037073.xls'#$CATERPILLAR

Project: MARINA TOWERS

Project No. L9959

REFERENCE METHOD: CATERPILLAR

ENTER INSTALLATION PARAMETERS:

Model: CUMMINS, KTA50G3, prime

max. allowable back pressure: 10.15 kPa 76.1 mm Hg 3.0 in Hg

generator exhaust outlet: 6 in 153.0 mm

No. of exhaust outlets: 1 Nr.

length of pipe, L: 40 m 132.0 ft

No. of 90 deg. bend in pipe: 3 Nr.

exhaust temperature: 499 deg. C 930.2 deg. F

exhaust gas flow, Q: 6,464 cfm 10,975.9 m3/hour 182.9 m3/min

ENTER PIPE DIAMETER TRIAL VALUES:

inside diameter of exhaust pipe,

D: 12 in

CALCULATED VALUES:

specific weight of gas, S: 0.0296 pounds per cubic ft

additional length of pipe due to

the 90deg bends: 45 ft

total equivalent straight length of

pipe: 177.0 ft

backpressure in pipes:

(LxSxQ2)/(5184xD5) 0.17 psi 1.17 kPa

add muffler pressure drop from chart:

velocity of exhaust at exhaust

temperature, V2: 8,234.4 fpm

velocity of exhaust at 70deg F:

V1 3,139.3 fpm

ENTER PRESSURE DROP IN MUFFLER @ V2:

PICK VALUE FROM MUFFLER CHARTS/SPECS:

pressure drop in muffler at

velocity V1: 4.00 in H2O 0.9954 kPa

FINAL RESULT OF PRESSURE DROP:

total pressure drop: 2.16 kPa

Generator Exhaust Pipe Diameter Calculations Project No. Date

Version A Sheet No. Computed by

Checked by Approved by

'file:///conversion/tmp/scratch/360037073.xls'#$KOHLER

Project: MARINA TOWERS

Project No. L9959

REFERENCE METHOD: KOHLER

ENTER INSTALLATION PARAMETERS:

Model: CUMMINS, KTA50G3, prime

max. allowable back pressure: 6.8 kPa 51.0 mm Hg 2.0 in Hg

generator exhaust outlet: 10 in 255.0 mm

No. of exhaust outlets: ?? Nr.

length of pipe, L: 145 m 478.5 ft

No. of 90 deg. bend in pipe: 2 Nr.

exhaust temperature: 518 deg. C 964.4 deg. F

exhaust gas flow, Q: 8,003 cfm 13,589.1 m3/hour 226.5 m3/min

ENTER PIPE DIAMETER TRIAL VALUES:

inside diameter of exhaust pipe,

D: 12 in

CALCULATED VALUES:

velocity of exhaust V: 10,194.9 fpm

ENTER PRESSURE DROP IN MUFFLER @ V2:

PICK VALUE FROM MUFFLER CHARTS/SPECS:

pressure drop in muffler at

velocity V: 0.700 in Hg 2.3638 kPa

ENTER PRESSURE DROP IN PIPES PER FT:

PICK VALUE FROM CHARTS:

pressure drop in pipes per foot: 0.0025 in Hg 0.0084 kPa

CALCULATED VALUES:

additional length of pipe due to

the 90deg bends: 32.0 ft

total equivalent straight length of

pipe: 510.5 ft

backpressure in pipes: 1.276 in Hg 4.31 kPa

add muffler pressure drop from chart:

FINAL RESULT OF PRESSURE DROP:

total pressure drop: 1.976 in Hg 6.67 kPa

Generator Exhaust Pipe Diameter Calculations Project No. Date

Version A Sheet No. Computed by

Checked by Approved by

'file:///conversion/tmp/scratch/360037073.xls'#$SUMMARY

Project: MARINA TOWERS

Project No. L9959

COMPARISON OF GENERATOR EXHAUST BACKPRESSURE CALCULATIONS

AS GIVEN BY TWO METHODS, CATERPILLAR'S & KOHLER'S

REFERENCE METHOD CATERPILLAR KOHLER CATERPILLAR KOHLER CATERPILLAR KOHLER

Model: CUMMINS KTA50G3 CATERPILLAR 3512 KOHLER, 1200RFOZD

max. allowable back pressure: 6.8 kPa 5.0 kPa 4.7 kPa

pipes diameter: 10 in 10 in 10 in 10 in 10 in 10 in

pressure drop in pipes:

pressure drop in muffler:

Total pressure drop:

max. allowable back pressure:

pipes diameter: 12 in 12 in 12 in 12 in 12 in 12 in

pressure drop in pipes:

pressure drop in muffler:

Total pressure drop:

max. allowable back pressure:

pipes diameter: 13 in 13 in 13 in 13 in 13 in 13 in

pressure drop in pipes:

pressure drop in muffler:

Total pressure drop:

max. allowable back pressure:

pipes diameter: 14 in 14 in 14 in 14 in 14 in 14 in

pressure drop in pipes:

pressure drop in muffler:

Total pressure drop:

N.B.: results are based on the following assumptions:

1-the dual eshaust pipes, if provided, are combined into one

pipe at the generator before running into the muffler.

2- the flow of exhaust, Q, as given by generator spec. sheets,

is the net exhaust through both exhaust outlets.

i.e., Q per generator set = Q/2 per exhaust pipe (for dual outlets)

rather than 2Q per generator set =Q per exhaust pipe (for dual outlets)

3-the muffler diameter is the same as that of the exhaust pipe.

Generator Exhaust Pipe Diameter Calculations Project No. Date

Version A Sheet No. Computed by

Checked by Approved by

'file:///conversion/tmp/scratch/360037073.xls'#$UNITS

Project: MARINA TOWERS

Project No. L9959

UNITS CONVERSION TABLES

To change from To Input Output

psi kPa Multiply by 6.89475 1 psi = 6.89475 kPa

in Hg psi Multiply by 0.49115 1 in Hg = 0.49115 psi

in Hg kPa Multiply by 3.3768 1 in Hg = 3.3768 kPa

mm Hg psi Multiply by 0.01934 1 mm Hg = 0.01934 psi

mm Hg kPa divide by 7.50062 1 mm Hg = 0.133322 kPa

in H2O kPa Multiply by 0.24884 1 in H2O = 0.24884 kPa

1 =

kPa mm Hg Multiply by 7.50062 1 kPa = 7.50062 mm Hg

kPa in Hg divide by 3.3768 1 kPa = 0.296138 in Hg

cfm m3/min Multiply by 0.0283 1 cfm = 0.0283 m3/min

cfm m3/hr Multiply by 0.0283*60 1 cfm = 1.698 m3/hr

m3/min cfm divide by 0.0283 212.6 m3/min = 7512.367 cfm

m3/hr m3/min divide by 60 1 m3/hr = 0.016667 m3/min

m3/hr cfm divide by 0.0283*60 13590 m3/hr = 8003.534 cfm

deg. C deg. F deg. C*1.8+32 1 deg. C = 33.8 deg. F

deg. F deg. C 0.5555 (deg. F - 32) 1 deg. F = -17.2205 deg. C

You might also like

- Ventilation DesignDocument4 pagesVentilation DesignPhyu Mar Thein KyawNo ratings yet

- Static Pressure FansDocument35 pagesStatic Pressure FansarifkhadeerNo ratings yet

- Design Calculation Sheet: Chilled Water Secondary PumpsDocument2 pagesDesign Calculation Sheet: Chilled Water Secondary PumpsgerrydimayugaNo ratings yet

- Sewer Pumpstation Design Calculations For AlqiDocument7 pagesSewer Pumpstation Design Calculations For AlqiTahirJabbarNo ratings yet

- Thermal Insulation Thickness Calculation (By James)Document1 pageThermal Insulation Thickness Calculation (By James)Ah BengNo ratings yet

- Trunnion CalculationDocument92 pagesTrunnion CalculationkarunaNo ratings yet

- Time To Empty Out Vessel No Dished EndsDocument2 pagesTime To Empty Out Vessel No Dished EndsHeiner PalaciosNo ratings yet

- Center Vent & Peripheral Vent CalDocument1 pageCenter Vent & Peripheral Vent CalrichardchiamNo ratings yet

- 2.4 Static Pressure Spreadsheet 1Document4 pages2.4 Static Pressure Spreadsheet 1Jitendra KadamNo ratings yet

- Design Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeDocument2 pagesDesign Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeFernando CabreraNo ratings yet

- Line SizingDocument1,287 pagesLine SizingShantanu JalgaonkarNo ratings yet

- Heat ExchangerDocument53 pagesHeat ExchangerNurulHidayahNo ratings yet

- Skirt Support Analysis Per en 13445Document13 pagesSkirt Support Analysis Per en 13445karthik1amarNo ratings yet

- Gas Line Capacity CalcDocument2 pagesGas Line Capacity CalcMario Mendoza100% (1)

- Horizontal Cylindrical Tank Volume and Level CalculatorDocument5 pagesHorizontal Cylindrical Tank Volume and Level CalculatorWaleed EmaraNo ratings yet

- Piping CalculationsDocument3 pagesPiping CalculationsAkhilesh Dhar DiwediNo ratings yet

- Duct CalculationDocument1 pageDuct CalculationDan Nugraha100% (1)

- Insulated PipeDocument54 pagesInsulated Pipedeion29No ratings yet

- Pump and Line Calculation SheetDocument7 pagesPump and Line Calculation SheetNghiaNo ratings yet

- 01 - Fresh Air Unit Esp CalculationDocument2 pages01 - Fresh Air Unit Esp Calculationmefaisal750% (1)

- Duct Stiffener DesignDocument8 pagesDuct Stiffener DesignXplore Engg100% (1)

- Nozzle CalculationDocument13 pagesNozzle Calculationaqilah liyanaNo ratings yet

- Calculate Exhaust Fan Size (1.1.19)Document6 pagesCalculate Exhaust Fan Size (1.1.19)jiguparmar1516100% (1)

- Heat Exchanger Shell Id CalculationsDocument7 pagesHeat Exchanger Shell Id CalculationsmanojNo ratings yet

- Welded Beam CalculationDocument2 pagesWelded Beam CalculationVeenoyNo ratings yet

- Excel Fire Calc F Mowrer Templates REV 2.0Document39 pagesExcel Fire Calc F Mowrer Templates REV 2.0Argile-assholeNo ratings yet

- Smoke - Ventilation CalculationsDocument8 pagesSmoke - Ventilation CalculationsdasmechNo ratings yet

- Calculate Size of Anchor Fastener For Water Pipe Support (19.1.20)Document4 pagesCalculate Size of Anchor Fastener For Water Pipe Support (19.1.20)jiguparmar1516No ratings yet

- Centrifugal Pump SizingDocument11 pagesCentrifugal Pump SizingDavid Muñoz CastroNo ratings yet

- Fan Noise EstimateDocument5 pagesFan Noise EstimateBen ClackNo ratings yet

- SP SP VP V PR) : Velocity Pressure Method Calculation SheetDocument6 pagesSP SP VP V PR) : Velocity Pressure Method Calculation SheetAnkit LonareNo ratings yet

- Hvac CalcsDocument34 pagesHvac CalcsTando Tsepane0% (1)

- Shell Tube Heat Exchanger DesignDocument7 pagesShell Tube Heat Exchanger DesignAbhijeet JhaNo ratings yet

- Design CalculationsDocument50 pagesDesign CalculationsSandi ApriandiNo ratings yet

- Air N2 Receiver Size EstimationDocument4 pagesAir N2 Receiver Size EstimationParthi DatchinamoorthyNo ratings yet

- Line SizingDocument2 pagesLine SizingHarryBouterNo ratings yet

- Pipe Thickness Calculation Data SheetDocument1 pagePipe Thickness Calculation Data SheetAnonymous 6ZWS6IG2J9No ratings yet

- Heat Loss From An Insulated Pipe: ParametersDocument4 pagesHeat Loss From An Insulated Pipe: ParametersMohan BabuNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line SizingAnonymous oVRvsdWzfBNo ratings yet

- Design Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectDocument1 pageDesign Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectAbdelfatah NewishyNo ratings yet

- Calculation AgitatorDocument3 pagesCalculation AgitatorKrishnaAgarwalNo ratings yet

- Optional Integral With Hub Type Body Flange CalculationDocument13 pagesOptional Integral With Hub Type Body Flange Calculation9913489806No ratings yet

- Calculation Authored and Generated by CTC Design, Inc. Fan Laws and Fan HPDocument3 pagesCalculation Authored and Generated by CTC Design, Inc. Fan Laws and Fan HPmisdi habibiNo ratings yet

- Half Coil For VersselDocument1 pageHalf Coil For VersselhuangjlNo ratings yet

- Gas Pipe SizingDocument3 pagesGas Pipe SizingthecodekingNo ratings yet

- Heat Exchanger Calculation Version 2Document2 pagesHeat Exchanger Calculation Version 2huangjlNo ratings yet

- Sizing Stack HeightDocument1 pageSizing Stack Heightashwini_kumar19840% (1)

- Double Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterDocument3 pagesDouble Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterBagusRekaNo ratings yet

- DbA CalculationDocument4 pagesDbA Calculationthanh_79No ratings yet

- Psychrometry. Heat Recovery Air Handling Unit (Ahu) - by Ömer Faruk DDocument13 pagesPsychrometry. Heat Recovery Air Handling Unit (Ahu) - by Ömer Faruk DKarl WeierstrassNo ratings yet

- Steam Pipe SizingDocument16 pagesSteam Pipe SizingsamvendanNo ratings yet

- Max Allowable Nozzle LoadDocument1 pageMax Allowable Nozzle Loaddskr fkshNo ratings yet

- Centrifugal Pump Temperature Rise CalculationDocument1 pageCentrifugal Pump Temperature Rise CalculationJohn PacelloNo ratings yet

- VentCalc V1.0.xlsmDocument20 pagesVentCalc V1.0.xlsmRaju KsnNo ratings yet

- Generator Exhaust Pipe Diameter Calculations: Marina Towers L9959Document4 pagesGenerator Exhaust Pipe Diameter Calculations: Marina Towers L9959febousNo ratings yet

- Pressure DropDocument36 pagesPressure DropdesignselvaNo ratings yet

- A. Summary of The Heat Balance For Turbine Hall, Temperature and EnthalpiesDocument9 pagesA. Summary of The Heat Balance For Turbine Hall, Temperature and EnthalpiesXype LanderNo ratings yet

- CW Pump CalculationDocument22 pagesCW Pump Calculationzamijaka100% (1)

- Centrifugal Pumps: Process Calculation / Data SheetDocument3 pagesCentrifugal Pumps: Process Calculation / Data SheetMurali MuthuNo ratings yet

- Exhaust Back Pressure CalculationDocument1 pageExhaust Back Pressure Calculationccssaa123No ratings yet

- Cir 02 Chiller - Motor Loads Connected To DEWA's TransformerDocument1 pageCir 02 Chiller - Motor Loads Connected To DEWA's TransformermajortayNo ratings yet

- Public - Health Mechanical - CIBSE Dubai - MINIMUM DESIGN STANDARD - PDFDocument19 pagesPublic - Health Mechanical - CIBSE Dubai - MINIMUM DESIGN STANDARD - PDFDesigner Forever100% (1)

- LNG Fire Protection and Emergency Response - 4MechEngineer LNG Fire Protection and Emergency ResponseDocument6 pagesLNG Fire Protection and Emergency Response - 4MechEngineer LNG Fire Protection and Emergency ResponseDesigner ForeverNo ratings yet

- Org - pdi.PDI WH 201 011810 PDFDocument37 pagesOrg - pdi.PDI WH 201 011810 PDFEslam ElsayedNo ratings yet

- LNG Fire Protection and Emergency ResponseDocument152 pagesLNG Fire Protection and Emergency ResponseDesigner Forever100% (2)

- Method Statement Noise Level Testing 4 Genset EnclosureDocument13 pagesMethod Statement Noise Level Testing 4 Genset EnclosureDesigner ForeverNo ratings yet

- 1a Domestic Water Meter Installation in Villas and Sheds DrawingPEWSTDAMI001Document1 page1a Domestic Water Meter Installation in Villas and Sheds DrawingPEWSTDAMI001Designer ForeverNo ratings yet

- CIBSE Dubai Electrical - MINIMUM DESIGN STANDARD - PDFDocument28 pagesCIBSE Dubai Electrical - MINIMUM DESIGN STANDARD - PDFDesigner Forever100% (2)

- Connections and TransitionsDocument1 pageConnections and TransitionsDesigner ForeverNo ratings yet

- DP 99 2017 CircularDocument2 pagesDP 99 2017 CircularJayabalan R KNo ratings yet

- CALCULATIONDocument1 pageCALCULATIONDesigner ForeverNo ratings yet

- Project: Ho-Mep Dept Monthly Staff Attendance For The Month of 2020Document3 pagesProject: Ho-Mep Dept Monthly Staff Attendance For The Month of 2020Designer ForeverNo ratings yet

- CALCULATIONDocument1 pageCALCULATIONDesigner ForeverNo ratings yet

- 20 % Additional Staff To Perform Remote Duty From Home - Location (MEP Division)Document1 page20 % Additional Staff To Perform Remote Duty From Home - Location (MEP Division)Designer ForeverNo ratings yet

- Yacth Crew Mechanical Design CommentsDocument13 pagesYacth Crew Mechanical Design CommentsDesigner ForeverNo ratings yet

- Mechanical - CIBSE Dubai - MINIMUM DESIGN STANDARD - PDFDocument12 pagesMechanical - CIBSE Dubai - MINIMUM DESIGN STANDARD - PDFDesigner Forever100% (1)

- Personal Spelling MistakesDocument2 pagesPersonal Spelling MistakesDesigner ForeverNo ratings yet

- REMOTE PLAN WORK DAILY ACCOMPLISHMENTS As of 04.6.2020Document12 pagesREMOTE PLAN WORK DAILY ACCOMPLISHMENTS As of 04.6.2020Designer ForeverNo ratings yet

- Fire-Fighting: No False Ceiling - There Is A Skylight in The Shown AreaDocument13 pagesFire-Fighting: No False Ceiling - There Is A Skylight in The Shown AreaDesigner ForeverNo ratings yet

- EWHDocument1 pageEWHDesigner ForeverNo ratings yet

- Al Fallah Scenario C 7.11.2019Document31 pagesAl Fallah Scenario C 7.11.2019Designer ForeverNo ratings yet

- Shortlisting 0002-Pending Log - Shop Drawing Log - (Updated 24-03-2020)Document900 pagesShortlisting 0002-Pending Log - Shop Drawing Log - (Updated 24-03-2020)Designer ForeverNo ratings yet

- Water Demand CalculationDocument1 pageWater Demand CalculationDesigner ForeverNo ratings yet

- LPDDocument2 pagesLPDDesigner ForeverNo ratings yet

- BTU Measurement System: Foshan AKE Electronic Engineering Co., LTDDocument34 pagesBTU Measurement System: Foshan AKE Electronic Engineering Co., LTDblindjaxxNo ratings yet

- CHW Pipe Straight Pressure DropDocument2 pagesCHW Pipe Straight Pressure DropDesigner ForeverNo ratings yet

- Hydra Btu MeterDocument16 pagesHydra Btu MeterDesigner ForeverNo ratings yet

- NAFFCO Smoke Management PresentationDocument54 pagesNAFFCO Smoke Management PresentationDesigner ForeverNo ratings yet

- Dantherm Dehumidification Swimming Pool Selection GuideDocument44 pagesDantherm Dehumidification Swimming Pool Selection GuideDesigner ForeverNo ratings yet

- SPZ BtumeterDocument18 pagesSPZ BtumeterqbdelhqdiNo ratings yet

- Empirical Equations For Pressure Drop in Crude Oil and White Oil Pipelines - CheresourcesDocument5 pagesEmpirical Equations For Pressure Drop in Crude Oil and White Oil Pipelines - CheresourcesPrakash WarrierNo ratings yet

- JAQUAR NEW PRICE LIST Effective From January 2021Document17 pagesJAQUAR NEW PRICE LIST Effective From January 2021JITESH GUPTANo ratings yet

- Titan Flow Control, Inc.: Installation, Operation, and MaintenanceDocument5 pagesTitan Flow Control, Inc.: Installation, Operation, and MaintenanceAHMEDMALAHYNo ratings yet

- Well Intervention Operation FlyerDocument21 pagesWell Intervention Operation Flyerfakhrurrozi arbianNo ratings yet

- VvaDocument4 pagesVvaSONU PRAVEENNo ratings yet

- Ce6303-Mechanics of FluidsDocument10 pagesCe6303-Mechanics of FluidsDineshNo ratings yet

- Fancoil ConnectionsDocument1 pageFancoil Connectionsbadmike71No ratings yet

- Extracted Pages From FOAM-SYSTEMDocument1 pageExtracted Pages From FOAM-SYSTEMAziz UllahNo ratings yet

- TP-WMS-05940-SPC-A4-D1-L-Specification For ValvesDocument34 pagesTP-WMS-05940-SPC-A4-D1-L-Specification For Valvesbmanojkumar16No ratings yet

- XVVP502P 16 08 Parker Brass Ball ValveDocument2 pagesXVVP502P 16 08 Parker Brass Ball ValveMROstop.comNo ratings yet

- Hazop Distillation ColumnDocument5 pagesHazop Distillation ColumnPutri SaidatinaNo ratings yet

- Safety Valve Technical DetailsDocument5 pagesSafety Valve Technical DetailsvineethvskkdNo ratings yet

- Hvac Q & ADocument26 pagesHvac Q & ArishimaranNo ratings yet

- CV of GTDocument5 pagesCV of GTMD ASIF ALINo ratings yet

- Hydraulic Power Pack: H P T H P TDocument5 pagesHydraulic Power Pack: H P T H P TDragan LazicNo ratings yet

- Hyd 246C KENR5117KENR5117-03 - SISDocument4 pagesHyd 246C KENR5117KENR5117-03 - SISmizaelNo ratings yet

- Vena SIF Piping CalculationDocument5 pagesVena SIF Piping CalculationPratap KollapaneniNo ratings yet

- Conval Clampseal Catalog 2019Document44 pagesConval Clampseal Catalog 2019Roger SeaverNo ratings yet

- Control ValvesDocument127 pagesControl ValvesMarcus Barber100% (1)

- BAC LD Butterfly Valves Lugged Type Carbon Steel/stainless Steel ANSI Class 150 and 300Document1 pageBAC LD Butterfly Valves Lugged Type Carbon Steel/stainless Steel ANSI Class 150 and 300ChristianNo ratings yet

- Motor PDFDocument81 pagesMotor PDFmaungNo ratings yet

- Base and Hanger Spring Data SheetsDocument4 pagesBase and Hanger Spring Data SheetsxkokarcaxNo ratings yet

- Proses Pembuatan LPG: Extraction Plant Dan Fractionation Plant PT. Perta Samtan GasDocument23 pagesProses Pembuatan LPG: Extraction Plant Dan Fractionation Plant PT. Perta Samtan GasBagas JuniarNo ratings yet

- Line Sizing ManualDocument17 pagesLine Sizing ManualAkshay bhuranNo ratings yet

- Shipham Valves: Mesc No. 772701.005.1 and Secured To Valve With ST - St. WireDocument1 pageShipham Valves: Mesc No. 772701.005.1 and Secured To Valve With ST - St. Wirepritam sarkarNo ratings yet

- Auto ClaveDocument464 pagesAuto ClavenokarajuNo ratings yet

- TSM - FHM - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: 9H-FHB - 03025 - 001Document2 pagesTSM - FHM - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: 9H-FHB - 03025 - 001özkanNeşeliNo ratings yet

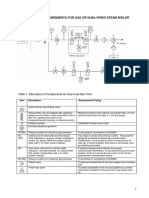

- Gas Train Requirements For Gas or Dual Fired Steam Boiler PDFDocument2 pagesGas Train Requirements For Gas or Dual Fired Steam Boiler PDFringo limNo ratings yet

- Flowmeter SelectionDocument1 pageFlowmeter Selectionnahuelcarballido100% (1)

- Blow Out Prevention SystemDocument10 pagesBlow Out Prevention SystemABDULBASIT ALINo ratings yet