Professional Documents

Culture Documents

RW H - 0t

Uploaded by

Tanu RdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RW H - 0t

Uploaded by

Tanu RdCopyright:

Available Formats

ROCKWELL HARDNESS TEST

AIM:

To determine the Hardness of the given Specimen using Rockwell hardness test..

APPARATUS:

1. Rockwell hardness testing machine.

2. Black diamond cone indenter,

3. Testing specimens.

Rockwell hardness test equipment

SPECIFICATIONS:

Various scales on Rockwell hardness testing machine.

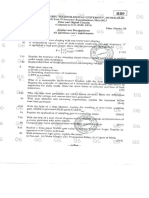

SCAL Indentor Intial load Major load Pointer Kind of material

E type position on

dial

A Cone, 1200 10 50 0 Much harder such as

cemented steels, carburized

steel

B Ball 10 90 30 Soft steels, Cu,Al, Brass,

1.588mm grey CI.

C Cone, 1200 10 140 0 Hard steels, Ti,W, Va

THEORY:

The hardness of a material is resistance to penetration under a localized pressure or

resistance to abrasion. Hardness tests provide an accurate, rapid and economical way of

determining the resistance of materials to deformation. There are three general types of hardness

measurements depending upon the manner in which the test is conducted:

a. Scratch hardness measurement,

b. Rebound hardness measurement

c. Indention hardness measurement

In scratch hardness method the material are rated on their ability to scratch one another

and it is usually used by mineralogists only. In rebound hardness measurement, a standard body

is usually dropped on to the material surface and the hardness is measured in terms of the height

of its rebound .The general means of judging the hardness is measuring the resistance of a

material to indentation. The indenters usually a ball cone or pyramid of a material much harder

than that being used. Hardened steel, sintered tungsten carbide or diamond indenters are

generally used in indentation tests; a load is applied by pressing the indenter at right angles to the

surface being tested. The hardness of the material depends on the resistance which it exerts

during a small amount of yielding or plastic. The resistance depends on friction, elasticity,

viscosity and the intensity and distribution of plastic strain produced by a given tool during

indentation.

PROCEDURE:-

1. Clean the surface of the specimen with an emery sheet.

2. Place the specimen on the testing platform.

3. Raise the platform until the longer needle comes to rest

4. Release the load.

5. Apply the load and maintain until the longer needle comes to rest

6. After releasing the load, note down the dial reading.

7. The dial reading gives the Rockwell hardness number of the specimen.

8. Repeat the same procedure three times with specimen.

9. Find the average. This gives the Rockwell hardness number of the given specimen.

PRECAUTION:-

1. Thickness of the specimen should not be less than 8 times the depth of

indentation to avoid the deformation to be extended to the opposite surface of a

specimen.

2. Indentation should not be made nearer to the edge of a specimen to avoid

unnecessary concentration of stresses. In such case distance from the edge to

the center of indentation should be greater than 2.5 times diameter of

indentation.

3. Rapid rate of applying load should be avoided. Load applied on the ball may rise

a little because of its sudden action. Also rapidly applied load will restrict plastic

flow of a material, which produces effect on size of indentation.

OBESERVATION TABLE:-

Rockwell hardness Rockwell

S.No Material Scale Load (kgf) Number hardness

Used Number

1 2 3 (Mean)

RESULT:

Rockwell hardness number of the given material is _________

You might also like

- Steps in Making Castings: Page 1 of 14Document14 pagesSteps in Making Castings: Page 1 of 14Tanu RdNo ratings yet

- Year: Iv - I Mech: Unconventional Machining ProcessesDocument26 pagesYear: Iv - I Mech: Unconventional Machining ProcessesTanu RdNo ratings yet

- Gautama Buddha and Development of BuddhismDocument9 pagesGautama Buddha and Development of BuddhismTanu RdNo ratings yet

- Brief History of Telangana State Movement (1948-2014Document5 pagesBrief History of Telangana State Movement (1948-2014Tanu RdNo ratings yet

- lbm0 9Document6 pageslbm0 9Tanu RdNo ratings yet

- English Tense TableDocument1 pageEnglish Tense TableTanu RdNo ratings yet

- Miscellaneous QuestionsDocument16 pagesMiscellaneous QuestionsTanu RdNo ratings yet

- Indian History PicturesDocument36 pagesIndian History PicturesTanu RdNo ratings yet

- History of India: For Custom/ Business Map Quote +91 8750051915Document26 pagesHistory of India: For Custom/ Business Map Quote +91 8750051915Tanu RdNo ratings yet

- Rock paintings of prehistoric IndiaDocument43 pagesRock paintings of prehistoric IndiaTanu RdNo ratings yet

- 100 Questions On Science TechnologyDocument15 pages100 Questions On Science TechnologyvgasNo ratings yet

- Later Vedic Period and SocietyDocument13 pagesLater Vedic Period and SocietyTanu Rd0% (1)

- Seemandhra - Co.in - Strength of Materials-II (1) 0Document1 pageSeemandhra - Co.in - Strength of Materials-II (1) 0Tanu RdNo ratings yet

- Material Name Composition Properties Applications: Ferrous MetalsDocument8 pagesMaterial Name Composition Properties Applications: Ferrous MetalsTanu RdNo ratings yet

- 4A. Electron Beam Machining (EBM)Document3 pages4A. Electron Beam Machining (EBM)Tanu RdNo ratings yet

- lbm0 9Document6 pageslbm0 9Tanu RdNo ratings yet

- AEE GS EnglishDocument15 pagesAEE GS EnglishTanu RdNo ratings yet

- Seemandhra - Co.in - Machine Drawing-2 0Document1 pageSeemandhra - Co.in - Machine Drawing-2 0Tanu RdNo ratings yet

- Ecm App 78Document15 pagesEcm App 78Tanu RdNo ratings yet

- Ecg 123Document5 pagesEcg 123Tanu RdNo ratings yet

- Active and Passive Voice Tenses ChartDocument9 pagesActive and Passive Voice Tenses ChartTanu RdNo ratings yet

- Nontraditional Machining Processes LectureDocument35 pagesNontraditional Machining Processes LectureTanu RdNo ratings yet

- G1Document11 pagesG1Tanu RdNo ratings yet

- Passivevoicechart 130622150953 Phpapp01Document2 pagesPassivevoicechart 130622150953 Phpapp01Tanu RdNo ratings yet

- Current Affairs 2017 Telugu Bit Bank Download 4Document4 pagesCurrent Affairs 2017 Telugu Bit Bank Download 4Tanu RdNo ratings yet

- Active and Passive Voice Exercise: AnswersDocument11 pagesActive and Passive Voice Exercise: AnswersFxwireless100% (1)

- Verb Tenses Tutorial ExercisesDocument14 pagesVerb Tenses Tutorial ExercisesYenTranNo ratings yet

- Current Affairs 2017 Telugu Bit Bank Download 3Document5 pagesCurrent Affairs 2017 Telugu Bit Bank Download 3Tanu RdNo ratings yet

- Indian GeographyDocument190 pagesIndian GeographyV Anil Kumar100% (1)

- Modal Verbs WithkeyDocument3 pagesModal Verbs WithkeyAnonymous zqdKPKoX100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CAE The Most Comprehensive and Easy-To-Use Ultrasound SimulatorDocument2 pagesCAE The Most Comprehensive and Easy-To-Use Ultrasound Simulatorjfrías_2No ratings yet

- Lesson 2 Socio Anthropological View of The SelfDocument12 pagesLesson 2 Socio Anthropological View of The SelfAilyn RamosNo ratings yet

- SECTION 303-06 Starting SystemDocument8 pagesSECTION 303-06 Starting SystemTuan TranNo ratings yet

- Sri Radhakrishna SwamijiDocument43 pagesSri Radhakrishna SwamijiNarayana IyengarNo ratings yet

- Proposal Anguria Pasta NewDocument24 pagesProposal Anguria Pasta NewNOOR IRDINA HAFIZAH BT TAUPISNo ratings yet

- The Apu Trilogy - Robin Wood PDFDocument48 pagesThe Apu Trilogy - Robin Wood PDFSamkush100% (1)

- Fake News Poems by Martin Ott Book PreviewDocument21 pagesFake News Poems by Martin Ott Book PreviewBlazeVOX [books]No ratings yet

- Concept Page - Using Vagrant On Your Personal Computer - Holberton Intranet PDFDocument7 pagesConcept Page - Using Vagrant On Your Personal Computer - Holberton Intranet PDFJeffery James DoeNo ratings yet

- O2 Orthodontic Lab Catalog PDFDocument20 pagesO2 Orthodontic Lab Catalog PDFplayer osamaNo ratings yet

- Analysis and Calculations of The Ground Plane Inductance Associated With A Printed Circuit BoardDocument46 pagesAnalysis and Calculations of The Ground Plane Inductance Associated With A Printed Circuit BoardAbdel-Rahman SaifedinNo ratings yet

- CG Module 1 NotesDocument64 pagesCG Module 1 Notesmanjot singhNo ratings yet

- Ancient MesopotamiaDocument69 pagesAncient MesopotamiaAlma CayapNo ratings yet

- Aortic Stenosis, Mitral Regurgitation, Pulmonary Stenosis, and Tricuspid Regurgitation: Causes, Symptoms, Signs, and TreatmentDocument7 pagesAortic Stenosis, Mitral Regurgitation, Pulmonary Stenosis, and Tricuspid Regurgitation: Causes, Symptoms, Signs, and TreatmentChuu Suen TayNo ratings yet

- Liquid Out, Temperature 25.5 °C Tube: M/gs P / WDocument7 pagesLiquid Out, Temperature 25.5 °C Tube: M/gs P / WGianra RadityaNo ratings yet

- 3GPP TS 36.306Document131 pages3GPP TS 36.306Tuan DaoNo ratings yet

- Space DynamicsDocument37 pagesSpace Dynamicspurushottam KashyapNo ratings yet

- ML AiDocument2 pagesML AiSUYASH SHARTHINo ratings yet

- Essentials For Professionals: Road Surveys Using SmartphonesDocument25 pagesEssentials For Professionals: Road Surveys Using SmartphonesDoly ManurungNo ratings yet

- Naukri LalitaSharma (3y 4m)Document2 pagesNaukri LalitaSharma (3y 4m)rashika asraniNo ratings yet

- Air Wellness QRSDocument2 pagesAir Wellness QRSapi-3743459No ratings yet

- BCP-8000 User's ManualDocument36 pagesBCP-8000 User's ManualAsad PatelNo ratings yet

- LKC CS Assignment2Document18 pagesLKC CS Assignment2Jackie LeongNo ratings yet

- Qualitative Research EssayDocument9 pagesQualitative Research EssayMichael FoleyNo ratings yet

- 2 Scour VentDocument8 pages2 Scour VentPrachi TaoriNo ratings yet

- The Templist Scroll by :dr. Lawiy-Zodok (C) (R) TMDocument144 pagesThe Templist Scroll by :dr. Lawiy-Zodok (C) (R) TM:Lawiy-Zodok:Shamu:-El100% (5)

- Elevator Traction Machine CatalogDocument24 pagesElevator Traction Machine CatalogRafif100% (1)

- GLOBAL Hydro Turbine Folder enDocument4 pagesGLOBAL Hydro Turbine Folder enGogyNo ratings yet

- The Impact of Employees' Commitment Towards Food Safety at Ayana Resort, BaliDocument58 pagesThe Impact of Employees' Commitment Towards Food Safety at Ayana Resort, Balirachelle agathaNo ratings yet

- KAC-8102D/8152D KAC-9102D/9152D: Service ManualDocument18 pagesKAC-8102D/8152D KAC-9102D/9152D: Service ManualGamerAnddsNo ratings yet

- Swami Rama's demonstration of voluntary control over autonomic functionsDocument17 pagesSwami Rama's demonstration of voluntary control over autonomic functionsyunjana100% (1)