Professional Documents

Culture Documents

Eutalloy 11496

Uploaded by

jorge_2012Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eutalloy 11496

Uploaded by

jorge_2012Copyright:

Available Formats

Nickel-Based Alloy Recommended for to Protect Against

Wear or Corrosion Control

Eutalloy 11496

Ideal for protective coating, joining and cladding applications

The deposit is easy to machine with standard cutting tools

Exceptionally heat resistant

Ideal for protection against metal-to-metal friction

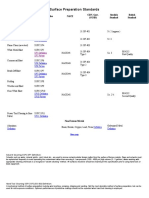

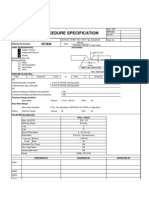

DESCRIPTION: PROCEDURE FOR USE:

Eutalloy 11496 is a multi-component nickel-base alloy Finishing Procedure:

powder used to produce hard, low friction overlay deposits Grinding Wheel Type: Green Silicon Carbide

for wear or corrosion control. Composition based on AMS Grit Size: 60 - 80

4775C and precise particle sizing ensures consistent Grade: H (soft)

deposition, fusing and hardness. It is a hot process powder Structure: 5

designed to be applied and fused using a puddle type Bond Type: Vitried

torch such as the Eutalloy or Ultrajet Eutalloy thermal spray Wheel Speed: Use Manufacturers Recommendation

processes. For applications on surfaces of steels, stainless Work Speed: 50 -65 surface feet per minute

steels, cast irons and nickel-base alloy that are subject to Traverse Speed

abrasion, metal to metal wear or in some cases corrosion. Roughing: 5-15 inches per minute

Finishing: 3-8 inches per minute

In-Feed

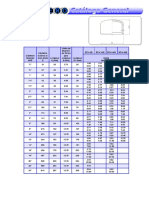

TECHNICAL DATA: Roughing: 0.001 inches per pass

Powder Properties Finishing: 0.0005 inches per pass or less

Nominal Composition: Nickel, Balance Chromium, 15.5% Coolant: Flood coolant with rust inhibitors in 2-5%

Boron, 3.2% Silicon, 3.8% Iron, 3.5% Carbon, 0.7% concentration

Magnetic Properties: This alloy contains enough

Chromium, Boron, and Silicon to make it Notes:

non-magnetic (ie Primarily Austenitic Structure). 1. Before grinding, all edges and ends of coating must be

Nominal Particle Size: -125 micron x down chamfer ground.

Hall Flow Rate: 15 seconds 2. Frequently dress the grinding wheel face to reduce

Bulk Density: 4.3 g/cc friction and heat.

Approximate Melting Range: Solidus: 1750F (955C)

Liquidus: 1950F (1065C) APPLICATIONS:

Powder Coverage: 50 inch2 per pound @ 1/16 thickness.

Cams Screws

Coating Properties Ceramic die cutters

Hardness: Rockwell C scale 59 Camshafts

Density: 7.6 g/cc Ball joints

Approximate Thermal Expansion: 200-1000 F 7.4 x 10-6/F Plug gauges

1000-1400F 7.2 x 10-6/F Molds Nozzles

Mandrels

1400-1800F 8.0 x 10-6/F

Tool rests

Electrical Conductivity: Should be similar to NiChrome (80/20)

alloy Valve seats

Tappets

HEALTH & SAFETY:

Observe normal spraying practices, respiratory protection and proper air ow pattern advised. For general spray practices,

see AWS Publications AWS C2. 1-73, Recommended Safe Practices for Thermal Spraying and AWS TSS-85, Thermal Spray-

ing, Practice, Theory and Application. Thermal spraying is a completely safe process when performed in accordance with

proper safety measures. Become familiar with local safety regulations before starting spray operations. DO NOT operate

your spraying equipment or use the spray material supplied, before you have thoroughly read the equipment instruction

manual.

Refer to the Eutectic web site for Material Safety Data Sheet (MSDS) information.

DISREGARDING THESE INSTRUCTIONS MAY BE HAZARDOUS TO YOUR HEALTH

YOUR RESOURCE FOR PROTECTION, REPAIR AND JOINING SOLUTIONS

Eutectic Corporation Eutectic Canada Eutectic Mexico

N94 W14355 Garwin Mace Drive 52 Hymus Blvd. Suite 220 KM 36.5 Autopista

Menomonee Falls, WI 53051 USA Pointe-Claire, Quebec H9R 1C9 Mexico-Quertaro

P 800-558-8524 F 262-255-5542 Phone: (800) 361-9439 54730 Cautitlan-Izcalli

Estado de Mexico, Mexico

Fax: (514) 695-8793

Phone: 011 (52) 55-5872-1111

www.eutectic-na.com e-mail: eutectic.mexico@eutectic.com.mx

Statement of Liability: Due to variations inherent in specic applications, the technical information contained herein, including any information as to suggested product applications or results, is presented without

representation or warranty, expressed or implied. Without limitation, there are no warranties of merchantability or of tness for a particular purpose. Each process and application must be fully evaluated by the user in

all respects, including suitability, compliance with applicable law and non-infringement of the rights of others, and Eutectic Corporation and its afliates shall have no liability in respect thereof.

11496 01-20-10 2008, Eutectic Corporation, Reg. T.M., Printed in the U.S.A.

You might also like

- AbraTec 6715Document2 pagesAbraTec 6715Luis MoriNo ratings yet

- EuTronic Arc Spray 595ASDocument2 pagesEuTronic Arc Spray 595ASEdwinNo ratings yet

- Colmonoy 5-S Data SheetDocument2 pagesColmonoy 5-S Data SheetLuis Hernandez0% (1)

- Xuper 6804 XHD: WeldingDocument2 pagesXuper 6804 XHD: WeldingAravind rajNo ratings yet

- Chromcarb N6006: WeldingDocument2 pagesChromcarb N6006: WeldingCasa de Adoración ConcepciónNo ratings yet

- Ceramite T: Bauxite and Silicon Carbide Based Trowellable RefractoryDocument2 pagesCeramite T: Bauxite and Silicon Carbide Based Trowellable RefractorySHRINIVASAN GTKNo ratings yet

- Metaceram 25010: Aluminum Oxide PowderDocument2 pagesMetaceram 25010: Aluminum Oxide PowderTob NisapakulNo ratings yet

- MetaCeram-25040.. Castollin EutecticDocument2 pagesMetaCeram-25040.. Castollin EutecticAndrés MolinaNo ratings yet

- ChromCarb N6006Document2 pagesChromCarb N6006mohamed AdelNo ratings yet

- StainTrode DDocument2 pagesStainTrode DGyanaranjan2011No ratings yet

- Cartech 321 Stainless: IdentificationDocument4 pagesCartech 321 Stainless: Identificationsaeedmahboob05No ratings yet

- Abratec 6710 XHD: WeldingDocument2 pagesAbratec 6710 XHD: WeldingAravind rajNo ratings yet

- Invar 36Document5 pagesInvar 36Yoni BenshaharNo ratings yet

- Chronifer M-4108Document3 pagesChronifer M-4108IltefatNo ratings yet

- Xuper 1665 XFCDocument2 pagesXuper 1665 XFCAntonio CardosoNo ratings yet

- Xuper 646 XHDDocument2 pagesXuper 646 XHDJuan LondonoNo ratings yet

- Data 9018 B3 LDocument2 pagesData 9018 B3 LAntonio Torres (Volcomtony)No ratings yet

- Machining GuidelinesDocument34 pagesMachining GuidelinesHamsini712No ratings yet

- Abratec 6710 XHD: Multi-Carbide Hardfacing ElectrodeDocument2 pagesAbratec 6710 XHD: Multi-Carbide Hardfacing ElectrodeCasa de Adoración ConcepciónNo ratings yet

- PWMDocument5 pagesPWMDaniel Uculmana LemaNo ratings yet

- Masterpoint Ultimate and Ultimate Cut: SpecificationDocument1 pageMasterpoint Ultimate and Ultimate Cut: SpecificationAdil Shahzad QaziNo ratings yet

- Eutalloy Thermal Spray Alloys: Alloys For Use With The Superjet-S EutalloyDocument8 pagesEutalloy Thermal Spray Alloys: Alloys For Use With The Superjet-S EutalloyLuis NarvaezNo ratings yet

- cc1105 DsDocument3 pagescc1105 DsJerry Mar LucenaNo ratings yet

- Ramax Hh-Eng P 1604 E6Document8 pagesRamax Hh-Eng P 1604 E6venkithankamNo ratings yet

- 1.9.1.2-75B - BondArc WireDocument6 pages1.9.1.2-75B - BondArc WireGiovanni Cervera FerriolNo ratings yet

- Brochure HEFDocument12 pagesBrochure HEFsreedhar srinivasanNo ratings yet

- Hand Solder Training PDFDocument52 pagesHand Solder Training PDFFatema ChoudhuryNo ratings yet

- Solder Hand Solder Training PDFDocument52 pagesSolder Hand Solder Training PDFftafedeNo ratings yet

- Eutectic 29029Document2 pagesEutectic 29029Imam SitumeangNo ratings yet

- 03 Vi Power IndustriesDocument9 pages03 Vi Power Industriesraj patelNo ratings yet

- Alpha SLS 65CDocument6 pagesAlpha SLS 65CJosé Antonio CuberoNo ratings yet

- Hpalloy X: High Performance Nickel Base Temp AlloyDocument4 pagesHpalloy X: High Performance Nickel Base Temp AlloycandraNo ratings yet

- Indium5.5LT Solder Paste: Product Data SheetDocument2 pagesIndium5.5LT Solder Paste: Product Data SheetluismcmcNo ratings yet

- Hoist Chains: For Manual and Motor-Driven HoistsDocument12 pagesHoist Chains: For Manual and Motor-Driven HoistsjoosuasinagaNo ratings yet

- Wall-Colmonoy Wallex-1 ENG January2021Document3 pagesWall-Colmonoy Wallex-1 ENG January2021pranav kariaNo ratings yet

- Silicon Bronze 655: Herculoy®, High-Silicon Bronze A, UNS C65500, H06 (50%) Temper RodDocument2 pagesSilicon Bronze 655: Herculoy®, High-Silicon Bronze A, UNS C65500, H06 (50%) Temper RodJay PNo ratings yet

- Thermaline 400: Selection & Specification DataDocument3 pagesThermaline 400: Selection & Specification DataJalaluddinNo ratings yet

- Arne English 991008Document7 pagesArne English 991008Mas Ist AsNo ratings yet

- Metal Seated Ball ValveDocument24 pagesMetal Seated Ball Valvehiep nguyenNo ratings yet

- Durafuse LT Lowtemperature Indium10.8hf 99797 A4 r6Document2 pagesDurafuse LT Lowtemperature Indium10.8hf 99797 A4 r6Karthik ManiNo ratings yet

- Espey WD200: Carbon Floating Ring Seals - Shaft SealsDocument5 pagesEspey WD200: Carbon Floating Ring Seals - Shaft SealsJose Vega VelascoNo ratings yet

- Cartech L-605 Alloy: IdentificationDocument5 pagesCartech L-605 Alloy: IdentificationYoni BenshaharNo ratings yet

- HP Alloy 718Document4 pagesHP Alloy 718Rajesh RadeNo ratings yet

- Introduction To Coring and Core Analysis - Feb - 05Document77 pagesIntroduction To Coring and Core Analysis - Feb - 05Ayman Shokry50% (2)

- Cera Board 100Document2 pagesCera Board 100Javier TrujillanoNo ratings yet

- Morflo 170Document2 pagesMorflo 170baselNo ratings yet

- X17CrNi16 2Document2 pagesX17CrNi16 2madodandembeNo ratings yet

- Xuper 680 CGS: WeldingDocument2 pagesXuper 680 CGS: WeldingSharad ShahNo ratings yet

- Metallic Sample Preparation For EBSD by Mechanical Method and Argon Ion Beam MillingDocument5 pagesMetallic Sample Preparation For EBSD by Mechanical Method and Argon Ion Beam MillingGee AbrahamNo ratings yet

- 720 Pipette Puller ManualDocument22 pages720 Pipette Puller ManualPaulo CamargoNo ratings yet

- HVOF PowderDocument2 pagesHVOF PowderLogeshNo ratings yet

- Bronze Putty: Technical Data SheetDocument2 pagesBronze Putty: Technical Data SheetSharad ShahNo ratings yet

- Tech Uddeholm Ramax HH ENDocument8 pagesTech Uddeholm Ramax HH ENwrh9rqr22vNo ratings yet

- Cartridge Heaters Metric FIRERODDocument10 pagesCartridge Heaters Metric FIRERODEliasNo ratings yet

- Cartridge Heaters FIRERODDocument34 pagesCartridge Heaters FIRERODEliasNo ratings yet

- Prepared By: PESB Technical Service Department (2019)Document60 pagesPrepared By: PESB Technical Service Department (2019)ASY178100% (4)

- Ac-700 SpecificationDocument10 pagesAc-700 SpecificationTarek Abuzene100% (1)

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- Catalogo - General 340Document1 pageCatalogo - General 340jorge_2012No ratings yet

- General 142Document1 pageGeneral 142jorge_2012No ratings yet

- Reducciones Concéntricas y Excéntricas.: ANSI B-16.9 MSS-SP 43Document1 pageReducciones Concéntricas y Excéntricas.: ANSI B-16.9 MSS-SP 43jorge_2012No ratings yet

- Reducciones Concéntricas y Excéntricas.: ANSI B-16.9 MSS-SP 43Document1 pageReducciones Concéntricas y Excéntricas.: ANSI B-16.9 MSS-SP 43jorge_2012No ratings yet

- General 137Document1 pageGeneral 137jorge_2012No ratings yet

- Reducciones Concéntricas y Excéntricas.: ANSI B-16.9 MSS-SP 43Document1 pageReducciones Concéntricas y Excéntricas.: ANSI B-16.9 MSS-SP 43jorge_2012No ratings yet

- SettingDocument2 pagesSettingjorge_2012No ratings yet

- Seamless Medium-Carbon Steel Boiler and Superheater Tubes: Standard Specification ForDocument3 pagesSeamless Medium-Carbon Steel Boiler and Superheater Tubes: Standard Specification ForJuan Pablo BautistaNo ratings yet

- Blastal Coating Services Inc - Surface Preparation StandardsDocument5 pagesBlastal Coating Services Inc - Surface Preparation Standardsjorge_2012No ratings yet

- White Paper Series: Part 1 - How To Read A Pump Performance CurveDocument1 pageWhite Paper Series: Part 1 - How To Read A Pump Performance Curvediegorf22No ratings yet

- Endmemo: Kilogram-Force/square Meter PsiDocument3 pagesEndmemo: Kilogram-Force/square Meter Psijorge_2012No ratings yet

- Wheatley Series 822 Check Valves FlyerDocument2 pagesWheatley Series 822 Check Valves FlyerLorena DávilaNo ratings yet

- C07-08 - Developing A Framework For Sources of New Product IdeasDocument13 pagesC07-08 - Developing A Framework For Sources of New Product IdeasHeril GosarNo ratings yet

- Sandia - Pipeline Integrity ManagementDocument20 pagesSandia - Pipeline Integrity ManagementSubrata PaulNo ratings yet

- Reduction of Mill Scale by Carbon PDFDocument5 pagesReduction of Mill Scale by Carbon PDFDeni Shidqi KhaerudiniNo ratings yet

- Megha Engineering & Infrastructures Limited. Greenko Ap01 Irep Private LimitedDocument2 pagesMegha Engineering & Infrastructures Limited. Greenko Ap01 Irep Private LimitedABINASH SINGHNo ratings yet

- Bs4872 Visual ApprovalDocument1 pageBs4872 Visual Approvalkjmcbain100% (1)

- JSW Steel AR 21-22 - 2607Document472 pagesJSW Steel AR 21-22 - 2607the crazy laughersNo ratings yet

- Spring SteelDocument2 pagesSpring Steelvaishu1502No ratings yet

- WPS GTAW Stainless SteelDocument2 pagesWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- Welded Joints - Symbolic Representation On Drawings (To Bs en 22553) 1. Elementary SymbolsDocument8 pagesWelded Joints - Symbolic Representation On Drawings (To Bs en 22553) 1. Elementary SymbolsandreaNo ratings yet

- ASTM A536 Ductile Iron Grades PDFDocument1 pageASTM A536 Ductile Iron Grades PDFIksan MustofaNo ratings yet

- Marley Air Cooled Heat ExchangersDocument6 pagesMarley Air Cooled Heat ExchangershaosfNo ratings yet

- Main Features of MMSM Furnace: ObjectiveDocument4 pagesMain Features of MMSM Furnace: Objectivezamindar129No ratings yet

- En10028 2Document12 pagesEn10028 2Patilea Daniela100% (1)

- Welding MetallurgyDocument102 pagesWelding Metallurgyjefry100% (3)

- Updated Helical Torsion Springs NoteDocument21 pagesUpdated Helical Torsion Springs Note223399No ratings yet

- Rodrigo L. Solomon: Address: San Marcos, Camaligan, Camarines Sur Contact Number: 09489259111Document2 pagesRodrigo L. Solomon: Address: San Marcos, Camaligan, Camarines Sur Contact Number: 09489259111Ally CanaveralNo ratings yet

- Housed Units CatalogDocument591 pagesHoused Units CatalogropmachadoNo ratings yet

- Ad 432Document1 pageAd 432Victor OmotoriogunNo ratings yet

- 337 Product Data SheetDocument2 pages337 Product Data SheetRedzuanNo ratings yet

- Duraloy Technologies, Inc.: 120 Bridge Street Scottdale, PA 15683 USA Tel: 724-887-5100 Fax: 724-887-5224Document16 pagesDuraloy Technologies, Inc.: 120 Bridge Street Scottdale, PA 15683 USA Tel: 724-887-5100 Fax: 724-887-5224gmurdzhevNo ratings yet

- Types of Stainless SteelDocument5 pagesTypes of Stainless SteelAnonymous 6ZWS6IG2J9No ratings yet

- Brickwork BQ For BasementDocument19 pagesBrickwork BQ For BasementKhairul Hazwan100% (1)

- Anexo D - V201310Document25 pagesAnexo D - V201310DOM. COCHAMONo ratings yet

- CV - 2022 12 06 072621Document2 pagesCV - 2022 12 06 072621Delima Acedilla Van JacobNo ratings yet

- ACO Access Cover Brochure PDFDocument44 pagesACO Access Cover Brochure PDFSopheareak ChhanNo ratings yet

- Class: 6: Paper Code: UN479Document20 pagesClass: 6: Paper Code: UN479virajNo ratings yet

- 2010 Agenda Package - MMDocument255 pages2010 Agenda Package - MMCarlos SYNo ratings yet

- Corrosion MonitorDocument79 pagesCorrosion Monitorantony nirmalaNo ratings yet

- 06 Fire Water Piping Welding ProcedureDocument10 pages06 Fire Water Piping Welding ProcedureAkhilesh Kumar100% (1)