Professional Documents

Culture Documents

Tir 001 FCD

Uploaded by

Joseph PerezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tir 001 FCD

Uploaded by

Joseph PerezCopyright:

Available Formats

TECHNICAL INSPECTION REPORT

Project Title: Flare Closed Drain Project (FCD-Main) Client: Black Cat / WP-QPH

Project No.: P-810108 Contractor: Petrol & Gas Const. Co. WLL (PGCC)

Document Title: RSLJ INSTALLATION FAILURE INSPECTION & CORRECTIVE ACTION PROPOSAL

Document No.: PGCC-TIR-001-BCEC Rev.: 0 Date: 29-May-17

Case Description:

Installation Failure of rubber seal lock joint

During the installation phase of the last rubber seal lock joint (RSLJ) at the AOC Drain line, a problem occurred.

The Bell portion has been observed stuck when it reached the last O-ring of the Spigot. It appears that the

O-Ring has firmly tightened inside the pipe, restricting the movement of the Bell to be pulled further.

Several attempts has been made to pull the Bell pipe but with no success. It has been decided to pull out the

pipe and conduct an internal surface inspection to point out the cause of the problem.

However, the Bell pipe appears to be completely stucked by the O-ring, as the pipe is doesn't come out when

it is attempted to be pulled out. The team only manage to pull out the pipe until a portion of the O-ring is

exposed. After several unsuccessful tries to pull it out, the team receded. It is agreed that the Bell pipe shall

be pulled in again, with additional lubricants applied onto the surface. In spite of the additional lubricants,

the team only manage to pull the Bell pipe up to the same O-ring where the problem has originall occurred.

Case Analysis:

Technical evaluation

An assessment has been made based on the actual events that took place during the RSLJ installation. It has

been concluded that the cause of the failure is due to dimensional difference between the Bell pipe's inner

diamater and the Spigot's outer diameter together with the O-ring itself with the following possibility:

A. The depth of the groove is shallow, thus, when the O-ring is placed, it protrudes outwards, occupying the

entire wall of the Bell Pipe. As the Bell pipe is pulled in, the protruding O-ring creates a vacuum seal that

resist the movement inside.

B. The Internal wall diameter of the Bell pipe does not match the Spigot's diameter with the O-ring on it. The

wall thickness on the affected portion may be thicker, causing a difference that narrows the space insufficient

for the O-ring to pass through.

Corrective Measure(s):

Proposed rectification of the case

In consideration to the points mentioned on the technical evaluation, a proposal has been made to manage

and serve as corrective action for it.

Proposed Action: The bell section of the pipe (300mm) shall be removed by cutting, creating a plain end. The

same method shall be applied on the spigot section, making it 2 plain ends to be joined by lamination.

The entire length required from the plain end of the elbow up to the edge of the pipe flushed on the wall of

the manhole shall be measured. Should there be any shortage of length due to the removal of the RSLJ sections,

it shall be amended by adding an extra spool piece between each ends, making it 2 lamination joints on both

side.

Prepared: Reviewed & Approved: Reviewed & Approved:

Position PGCC Representative PGCC Operations Head Client (BCEC)

Signature

Name

PGCC-TIR-000-(CLIENT) Prepared by: JECP

TECHNICAL INSPECTION REPORT

Project Title: Flare Closed Drain Project (FCD-Main) Client: Black Cat / WP-QPH

Project No.: P-810108 Contractor: Petrol & Gas Const. Co. WLL (PGCC)

Document Title: RSLJ INSTALLATION FAILURE INSPECTION & CORRECTIVE ACTION PROPOSAL

Document No.: PGCC-TIR-001-BCEC Rev.: 0 Date: 29-May-17

Date

Reference Image(s):

Figure 1

Figure 2

PGCC-TIR-000-(CLIENT) Prepared by: JECP

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- YAMAHA Blaster (Parts) PDFDocument65 pagesYAMAHA Blaster (Parts) PDFAlberto VegaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Denr Administrative Order (Dao) 2013-22: (Chapters 6 & 8)Document24 pagesDenr Administrative Order (Dao) 2013-22: (Chapters 6 & 8)Karen Feyt Mallari100% (1)

- Inspection report-GRVE BlankDocument2 pagesInspection report-GRVE BlankJoseph Perez100% (1)

- JSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedDocument13 pagesJSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedJoseph PerezNo ratings yet

- Example Quality PlanDocument11 pagesExample Quality PlanzafeerNo ratings yet

- Dissolved Gas Analysis of Transformer Oil: Mrs. Harsha Shah Insulation DivisionDocument38 pagesDissolved Gas Analysis of Transformer Oil: Mrs. Harsha Shah Insulation Divisionsjavre9390100% (1)

- Centaour 50 Solar TurbineDocument2 pagesCentaour 50 Solar TurbineTifano KhristiyantoNo ratings yet

- Anu Tandon Resignation As DirectorDocument3 pagesAnu Tandon Resignation As DirectorjaychandonkakhulasaNo ratings yet

- Inspection Report-Hdpec BlankDocument2 pagesInspection Report-Hdpec BlankJoseph Perez100% (1)

- Technology A Way of RevealingDocument24 pagesTechnology A Way of RevealingSheena jhane Magana100% (1)

- A Tracer Study On Btte GraduatesDocument15 pagesA Tracer Study On Btte GraduatesOzalleAngryBertNo ratings yet

- Sample Manpower ListDocument2 pagesSample Manpower ListJoseph Perez100% (2)

- Quotation 5324Document2 pagesQuotation 5324Joseph PerezNo ratings yet

- Forecast Request Form - PGCCDocument3 pagesForecast Request Form - PGCCJoseph PerezNo ratings yet

- Lifegoals - Ptr. Bong Saquing 250720201Document2 pagesLifegoals - Ptr. Bong Saquing 250720201Joseph PerezNo ratings yet

- Purchase Order Form (Sample)Document3 pagesPurchase Order Form (Sample)Joseph PerezNo ratings yet

- Material Inventory - PVC QSGTLDocument2 pagesMaterial Inventory - PVC QSGTLJoseph PerezNo ratings yet

- WarsDocument724 pagesWarsJoseph PerezNo ratings yet

- JHA SampleDocument1 pageJHA SampleJoseph PerezNo ratings yet

- Hardness Test Report BlankDocument2 pagesHardness Test Report BlankJoseph PerezNo ratings yet

- s03 - UNIFIED PERMIT TO WORKDocument2 pagess03 - UNIFIED PERMIT TO WORKJoseph PerezNo ratings yet

- s04 - VEHICLE MOVEMNETDocument2 pagess04 - VEHICLE MOVEMNETJoseph PerezNo ratings yet

- (Sample Checklist 001) : Toilet Cleaning Daily ChecklistDocument1 page(Sample Checklist 001) : Toilet Cleaning Daily ChecklistJoseph PerezNo ratings yet

- s02 - TOOL BOX MEETINGDocument1 pages02 - TOOL BOX MEETINGJoseph PerezNo ratings yet

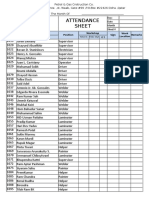

- Attendance Sheet: Emp. Employee Position Workshop Sign Remarks No. Name Work LocationDocument3 pagesAttendance Sheet: Emp. Employee Position Workshop Sign Remarks No. Name Work LocationJoseph PerezNo ratings yet

- E-Math: Circulating AreasDocument1 pageE-Math: Circulating AreasJoseph PerezNo ratings yet

- Item Description Size Material Grade: Tee Equal " CPVC 1" CPVC 1 " CPVCDocument2 pagesItem Description Size Material Grade: Tee Equal " CPVC 1" CPVC 1 " CPVCJoseph PerezNo ratings yet

- Shapes and Rods-2019Document18 pagesShapes and Rods-2019Joseph PerezNo ratings yet

- Relative Humidity TableDocument1 pageRelative Humidity TableJoseph PerezNo ratings yet

- Electronic Valve Testing (EVT) : Onsite Machining & Pipeline Services AustraliaDocument2 pagesElectronic Valve Testing (EVT) : Onsite Machining & Pipeline Services AustraliaJoseph PerezNo ratings yet

- Valve List TC# 2 - (578 Valves) Common Vendor - 25june15 (1) JASSIMDocument88 pagesValve List TC# 2 - (578 Valves) Common Vendor - 25june15 (1) JASSIMJoseph Perez0% (1)

- Document Transmittal To Black Cat - Dn80Document2 pagesDocument Transmittal To Black Cat - Dn80Joseph PerezNo ratings yet

- List of RecipeDocument1 pageList of RecipeJoseph PerezNo ratings yet

- d3 Mansoor Resume1Document4 pagesd3 Mansoor Resume1Joseph PerezNo ratings yet

- Book2 ATTENDANCE (02-10-2016 TO 6-10-2016) ADocument29 pagesBook2 ATTENDANCE (02-10-2016 TO 6-10-2016) AJoseph PerezNo ratings yet

- Relative Humidity TableDocument2 pagesRelative Humidity TableJoseph PerezNo ratings yet

- Applsci 12 02711 v2Document31 pagesApplsci 12 02711 v2Chandra MouliNo ratings yet

- Compact FlashDocument9 pagesCompact Flashenpr87reddyNo ratings yet

- Customers at SurveyDocument10 pagesCustomers at Surveynaren000No ratings yet

- Vibration Isolaton SelectionDocument24 pagesVibration Isolaton SelectionvelmuruganNo ratings yet

- Risk Solver Platform ReferenceDocument247 pagesRisk Solver Platform Referencemj_davis04No ratings yet

- 12556/gorakhdham Exp Third Ac (3A)Document2 pages12556/gorakhdham Exp Third Ac (3A)Lovkesh GoyalNo ratings yet

- AGC IPC Slash Sheet ReferenceDocument4 pagesAGC IPC Slash Sheet ReferenceSelvakumar NatarajanNo ratings yet

- ACC Flow Chart (Whole Plan) - Rev00Document20 pagesACC Flow Chart (Whole Plan) - Rev00amandeep12345No ratings yet

- GTGDocument4 pagesGTGSANDEEP SRIVASTAVANo ratings yet

- Volvo InstructionsDocument4 pagesVolvo InstructionsRonaldo Adriano WojcikiNo ratings yet

- Broadcast Tools Site Sentinel 4 Install Op Manual v2 12-01-2009Document41 pagesBroadcast Tools Site Sentinel 4 Install Op Manual v2 12-01-2009testeemailNo ratings yet

- Colebrook EquationDocument3 pagesColebrook EquationMuhammad Ghufran KhanNo ratings yet

- Fandek Evaporative Cooling System: F F F F Fan An An An Andek Dek Dek Dek DekDocument2 pagesFandek Evaporative Cooling System: F F F F Fan An An An Andek Dek Dek Dek DekCH1253No ratings yet

- Transformer HandbookDocument116 pagesTransformer HandbookAnder H. CaulfieldNo ratings yet

- HR Report ON Moser BaerDocument77 pagesHR Report ON Moser BaerKomal DhaliwalNo ratings yet

- Week 11b ViewsDocument26 pagesWeek 11b ViewsKenanNo ratings yet

- CadDocument20 pagesCadVivek DesaleNo ratings yet

- MF 3854 WDDocument96 pagesMF 3854 WDRizwanAli100% (1)

- Data0305 KX18DCDocument3 pagesData0305 KX18DCAbdelhamid SammoudiNo ratings yet

- Pioneer PDP-501MX Plasma DisplayDocument96 pagesPioneer PDP-501MX Plasma DisplayJavier RodriguezNo ratings yet

- Trumpf TruSystem 7500 Service ManualDocument424 pagesTrumpf TruSystem 7500 Service ManualVitor FilipeNo ratings yet

- EAC Software SetupDocument19 pagesEAC Software SetupBinh Minh NguyenNo ratings yet