Professional Documents

Culture Documents

Today

Uploaded by

pranav84in0 ratings0% found this document useful (0 votes)

17 views2 pagesIT is at the heart of successful enterprises worldwide, and manufacturing enterprises are no exception. The use of the computer has had a positive impact on manufacturing engineering in many ways. Computer Numerical Control machines (cnc) typically replace or work in conjunction with some existing manufacturing process.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIT is at the heart of successful enterprises worldwide, and manufacturing enterprises are no exception. The use of the computer has had a positive impact on manufacturing engineering in many ways. Computer Numerical Control machines (cnc) typically replace or work in conjunction with some existing manufacturing process.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views2 pagesToday

Uploaded by

pranav84inIT is at the heart of successful enterprises worldwide, and manufacturing enterprises are no exception. The use of the computer has had a positive impact on manufacturing engineering in many ways. Computer Numerical Control machines (cnc) typically replace or work in conjunction with some existing manufacturing process.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

Today's manufacturing enterprise, whether it produces

consumer goods or weapons systems, must often juggle a

range of conflicting demands. Smaller lot sizes, increased

product flexibility, higher product quality, decreased delivery

time, and smaller profit margins are typical of the ambitious

goals in many such organizations. Through it all, the

enterprise must consistently aim for the five R's-- produce

the right product, with the right quality, in the right

quantity, at the right price, and at the right time-- and it

must do more than satisfy its customers; it must delight

them. Correct and timely information is key to meeting

these goals, and information technology-- database

management systems, enterprise resource planning

systems, and simulation and computer-aided design tools--

has become indispensable to most manufacturing

enterprises. Although its role in manufacturing has been

more to support processes, IT is evolving to become a

catalyst for process and product change. In this case study,

an apparel manufacturer used a modeling framework

developed by Georgia Tech to implement multiple IT

solutions. It was then able to rapidly shift production

resources between two separate product lines. IT is at the

heart of successful enterprises worldwide, and

manufacturing enterprises are no exception. Terry

Manufacturing, the case study for this article, successfully

implemented its IT strategy, thereby enabling itself to effect

a significant transformation in operations and remain in

business as a viable and reliable model supplier to both the

defense and civilian markets.

The use of the computer has had a positive impact on manufacturing

engineering in many ways. Engineering is a term applied to the

profession in which a knowledge of the mathematical and natural

sciences, gained by study, experience and practice, is applied to the

efficient use of the materials and forces of nature. The term engineer

denotes a person who has received professional training in pure and

applied sciences.

The first and biggest positive impact on engineering has been the use

of Computer Numerical Control machines (CNC); computers were

first introduced to these controls in the early 1970’s. CNC machines

typically replace or work in conjunction with some existing

manufacturing process. For example before CNC machines a person

using a drill press to machine holes would have to do a lot of work for

themselves. They would have to place a drill in the drill chuck is

secured in the spindle of the drill press. They can then select the

desired speed for rotation, and activate the spindle. Then they

manually pull on the qu...

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- KAHOOT - Assignment 4.1 Lesson PlanDocument3 pagesKAHOOT - Assignment 4.1 Lesson PlanJan ZimmermannNo ratings yet

- Cat4 Test Practice For Year 11 Level GDocument6 pagesCat4 Test Practice For Year 11 Level GJoel OkohNo ratings yet

- ACCA Advanced Corporate Reporting 2005Document763 pagesACCA Advanced Corporate Reporting 2005Platonic100% (2)

- Policarpio Vs Manila Times - Unprotected Speech LibelDocument3 pagesPolicarpio Vs Manila Times - Unprotected Speech LibelStef BernardoNo ratings yet

- The Preparedness of The Data Center College of The Philippines To The Flexible Learning Amidst Covid-19 PandemicDocument16 pagesThe Preparedness of The Data Center College of The Philippines To The Flexible Learning Amidst Covid-19 PandemicInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Syllabus/Course Specifics - Fall 2009: TLT 480: Curricular Design and InnovationDocument12 pagesSyllabus/Course Specifics - Fall 2009: TLT 480: Curricular Design and InnovationJonel BarrugaNo ratings yet

- IBM System X UPS Guide v1.4.0Document71 pagesIBM System X UPS Guide v1.4.0Phil JonesNo ratings yet

- Barangay Sindalan v. CA G.R. No. 150640, March 22, 2007Document17 pagesBarangay Sindalan v. CA G.R. No. 150640, March 22, 2007FD BalitaNo ratings yet

- Butterfly Valve Info PDFDocument14 pagesButterfly Valve Info PDFCS100% (1)

- Final Presentation BANK OF BARODA 1Document8 pagesFinal Presentation BANK OF BARODA 1Pooja GoyalNo ratings yet

- Research Paper 701Document13 pagesResearch Paper 701api-655942045No ratings yet

- Proper AdjectivesDocument3 pagesProper AdjectivesRania Mohammed0% (2)

- STAFFINGDocument6 pagesSTAFFINGSaloni AgrawalNo ratings yet

- Druze ScriptureDocument15 pagesDruze ScriptureChristopher DeMott100% (2)

- A Quality Improvement Initiative To Engage Older Adults in The DiDocument128 pagesA Quality Improvement Initiative To Engage Older Adults in The Disara mohamedNo ratings yet

- Joshua 24 15Document1 pageJoshua 24 15api-313783690No ratings yet

- Approach To Vaginal Discharge in ChildrenDocument12 pagesApproach To Vaginal Discharge in ChildrensujataNo ratings yet

- Q&A JurisdictionDocument20 pagesQ&A JurisdictionlucasNo ratings yet

- What Is Folate WPS OfficeDocument4 pagesWhat Is Folate WPS OfficeMerly Grael LigligenNo ratings yet

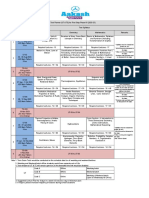

- UT & TE Planner - AY 2023-24 - Phase-01Document1 pageUT & TE Planner - AY 2023-24 - Phase-01Atharv KumarNo ratings yet

- Hercules Industries Inc. v. Secretary of Labor (1992)Document1 pageHercules Industries Inc. v. Secretary of Labor (1992)Vianca MiguelNo ratings yet

- Chpater 2 PDFDocument44 pagesChpater 2 PDFBilalNo ratings yet

- Producto Académico #2: Inglés Profesional 2Document2 pagesProducto Académico #2: Inglés Profesional 2fredy carpioNo ratings yet

- Long 1988Document4 pagesLong 1988Ovirus OviNo ratings yet

- Diploma Pendidikan Awal Kanak-Kanak: Diploma in Early Childhood EducationDocument8 pagesDiploma Pendidikan Awal Kanak-Kanak: Diploma in Early Childhood Educationsiti aisyahNo ratings yet

- In Mein KampfDocument3 pagesIn Mein KampfAnonymous t5XUqBNo ratings yet

- Java ReviewDocument68 pagesJava ReviewMyco BelvestreNo ratings yet

- Pentecostal HealingDocument28 pagesPentecostal Healinggodlvr100% (1)

- GN No. 444 24 June 2022 The Public Service Regulations, 2022Document87 pagesGN No. 444 24 June 2022 The Public Service Regulations, 2022Miriam B BennieNo ratings yet

- United States Court of Appeals, Third CircuitDocument1 pageUnited States Court of Appeals, Third CircuitScribd Government DocsNo ratings yet