Professional Documents

Culture Documents

APCO Silent Check PDF

Uploaded by

tanvir04169Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APCO Silent Check PDF

Uploaded by

tanvir04169Copyright:

Available Formats

2000

Millennium

Edition

6 4 0

N

I

T

E

L

L

U

B

SERIES 600

GLOBE STYLE

SIZES 3 THROUGH 42 INCHES

SILENT CHECK VALVES

Wafer and Globe Styles

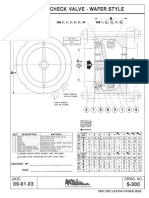

SERIES 300

WAFER STYLE

SIZE 1 THROUGH 10 INCHES

CHECK VALVES

VALVE & PRIMER CORPORATION

1420 S. WRIGHT BLVD. SCHAUMBURG, IL 60193-4599 Return to Previous Menu 11

847.524.9000 FAX:847.524.9007 800.323.6969

website: www.apcovalves.com e-mail: factory@apcovalves.com

. . . WHY MORE ENGINEERS ARE

Hydraulics engineers are concerned in increasing numbers with the problem of water hammer. At best it is a noise nui-

sance while in its most virulent form it can tear the finest pumping system apart.

What Causes Water Hammer?

The conditions responsible for this phenomenon are well Recognizing this, it becomes obvious that one secret to

known; they occur when a quantity of energy is suddenly preventing water hammer due to flow reversal in a system is

released in a confined space. Energy is a function of mass to provide a check valve which will close before this reversal

times velocity and relating this to practical hydraulics of flow can take place. APCO Silent Check Valves perform

engineering means that water hammer occurs when a excellently in these applications.

body of water in motion in a pipe is suddenly stopped.

The following briefly outlines the characteristics of various

One of the circumstances under which this phenomenon types of check valves:

most commonly occurs is when a pump is shut down and

the forward flow of water reverses under the influence of

gravity and commence to run the opposite way until stopped

by a check valve.

Swing Checks

The common Swing Check Valve is so designed that it This compromise is higher head loss than Swing Check type

often sees the reversal of flow before closing. This means valves. The attached graph shows the relative head losses for

that the body of water is already in motion and has to be three popular types of check valves. It can be clearly seen

stopped abruptly as the Swing Check Valve closes. that Silent Check Valves do not suffer badly in comparison,

especially when it is recognized the slightly higher head loss

Silent Check Valves in the Silent Check Valves means a little more electrical power

is used during pumping operation. When comparison is made

It was to meet this steadily growing problem that the Silent with prevailing rates for commercial power, this head loss

Check Valve evolved. In designing this valve all other charac- may become an academic rather than a practical concern.

teristics were subordinated to the principal need that it must

positively close before a reversal of flow takes place, silently. These facts show why more engineers are specifying APCO

Silent Check Valves for their customers protection.

The Silent Check Valve was designed to open at approxi-

mately 1/4 to 1/2 psi, which means that when a pump is shut

down, a Silent Check Valve will completely close while there Typical Silent Check Valve Installation

is still positive head on the inlet side of approximately 1/2 psi. On Vertical Turbine Pumps

In this simple manner reverse flow, which is a major cause

of water hammer, never gets a chance to start (in contrast

to the swing check).

Experienced engineers know that it is only possible to achieve

perfection in one characteristic in a design at the expense or

compromise with other characteristics. We feel that we would

be remiss if we did not draw the engineers attention to the

compromise that has been made in perfecting the silent

virtues of the Silent Check Valve and elaborate to some extent

on the significance of this compromise.

LOS ANGELES COUNTY SANITARY DISTRICT

12 Return

LOS to Previous

COYOTES PLANT Menu

2-16 125# CLASS SILENT CHECK VALVES

6 4 0

N

SPECIFYING SILENT CHECK VALVES.

I

T

E

Install SILENT CHECK VALVES on Discharge Side of the Pump!

L

STOPS REVERSE FLOW / STOPS WATER HAMMER before it Starts!

L

U

Water Hammer can be both destructive and annoying. It is

caused when a pump is shut down and the forward flow of

B

water is allowed to reverse and is suddenly stopped by the

check valve.

By positioning a Silent Check Valve on the discharge side of the

pump, the reverse flow (which is the cause of Water Hammer)

never has a chance to start. This is because APCO Silent Check

Valves are designed to open at approximately 1/4 to 1/2 psi and

to completely close before the flow can reverse itself.

Short face-to-face dimensions of APCO Silent Check Valves also

contribute to compactness in equipment room piping.

Typical Silent Check Valve Installation

HEAD LOSS INCREASE

note: APCO Silent Check Valves can

be installed in any position.

SILENT CHECK VALVES

CHECK VALVES

COMPARISON

Wafer and Globe Styles

HEAD LOSS

CURVES

VELOCITY INCREASE

APCO PRESSURE-TEMPERATURE RATINGS

MAXIMUM NON-SHOCK SERVICE PRESSURE, P.S.I.

CAST IRON DUCTILE IRON BRONZE CARBON STEEL STAINLESS STEEL

TEMP. ASTM A126 GR.B ASTM A536 ASTM B62 ASTM A216 GR WCB ASTM A351 CF 8M

F

CLASS 125 CLASS 250 PRESSURE CLASS PRESSURE CLASS PRESSURE CLASS PRESSURE CLASS

1 - 12 14 - 24 30 - UP 1 - 12 14 - 24 30 - UP 150 300 150 300 150 300 400 600 150 300 400 600

CHECK VALVES

0 to 150 225 500

-20 to 100 250 640 285 740 990 1480 275 720 960 1440

-20 to 150 200 150 150 500 300 300 242 620 272 707 945 1415 257 670 892 1340

200 190 135 115 460 280 250 235 600 210 465 260 675 900 1350 240 620 825 1240

250 175 125 85 415 260 200 235 582 195 425 245 665 887 1332 227 590 785 1180

300 165 110 50 375 240 150 215 565 180 390 230 655 875 1315 215 560 745 1120

SEAT

TEST 200 150 150 500 300 300 275 720 300 1000 315 815 1090 1630 305 795 1060 1585

PSI

SHELL

TEST 300 230 230 750 450 450 400 975 450 1500 450 1125 1500 2225 425 1100 1450 2175

PSI

Return to Previous Menu 13

WAFE R STYLE

S E R I E S 3 0 0

Full flow area approximately 3% greater than Pipe Size

STANDARD CONSTRUCTION

Cast Iron Body

USE ONLY

Bronze Trim FLAT FACE FLANGE

AND

FULL FACE GASKET

Stainless Steel Spring

OPTIONAL CONSTRUCTION

Stainless Steel

Ductile Iron or SEAT RING

MATING

FLANGE

Cast Steel Body OD ID

with Bronze or

Stainless Steel Trim

Resilient Seating (Buna-N)

SEE FIGURE 1. (OPTIONAL)

NOTE:

ID OF MATING FLANGE (SEAT SIDE ONLY)

SHOULD NEVER BE GREATER THAN SEAT RING OD.

RESILIENT

SEAT DETAIL

FIGURE 1

optional for both

wafer or globe

250 LB. CLASS styles

125 lb. & 250 lb. A.S.A. Pressure Classes 300 LB. CLASS

BOLT CIRCLE

Model Valve Face to No. of Bolts Bolt Circle Bolt Size 125 LB. CLASS

No. Size Face 125# 250# 125# 250# 125# 250# 150 LB. CLASS

301 1 2116 4 4 318 312 2 x 4 4

1 1 5

8 x 412 BOLT CIRCLE

30114 114 2116 4 4 312 378 1

2 x 414 5

8 x 412 PRESSURE JOINT

30112 112 238 4 4 378 412 1

2 x 4 34 3

4 x 514

IS EFFECTED

302 2 258 4 4 434 5 5

8 x 5 14 5

8 x 5 12

AFTER

30212 212 278 4 4 512 578 5

8 x 5 34 3

4 x 612

303 3 318 4 4 6 658 5

8 x 614 3

4 x 7 INSTALLATION

304 4 4 8 8 712 778 5

8 x 7 3

4 x 8 APPLIES

* 305 5 458 8 8 812 914 3

4 x 7 34 3

4 x 9 TO BOTH

306 6 512 8 12 912 1058 3

4 x 8 34 3

4 x 10 WAFER

* 125 lb. A.S.A. Pressure Class AND

308 8 612 8 1134 3

4 x 10 GLOBE

* 310 10 814 12 1414 7

8 x 12 12 STYLES.

* 250 lb. A.S.A. Pressure Class SCREW RETAINS

358 8 612 12 13 8 x 1114

7 SEAT DURING

360 10 814 16 1514 1 x 1334 HANDLING

AND

SHIPPING.

OPERATING PRESSURE TO 1500 LB. CLASS IS AVAILABLE

PLEASE CONTACT FACTORY FOR HIGHER PRESSURE CLASSES.

14 CHECK THESE 3 VITAL FEATURES THAT

Return MAKEMenu

to Previous

APCO SILENT CHECK VALVES YOUR BEST CHOICE

6 4 0

N

G LOB E STYLE

I

T

S E R I E S 6 0 0

E

Full flow area approximately 10% greater than Pipe Size

L

L

STANDARD CONSTRUCTION

U

Cast Iron Body

B

Bronze Trim

Stainless Steel Spring

OPTIONAL CONSTRUCTION

Stainless Steel

Ductile Iron or

Cast Steel Body

with Bronze or

Stainless Steel Trim

Resilient Seating (Buna-N)

COMPRESSION MOLDED (NOT GLUED OR CHEMICALLY

BONDED) ONTO THE SEAT ALLOWING METAL TO METAL

CONTACT WITH DROP TIGHT RESILIENT SHUT-OFF.

NOTE:

If special mating flanges are used,

SILENT CHECK VALVES

ID of mating flange (seat side only) should

USE ONLY

never be greater than seat ring OD.

FLAT FACE FLANGE

Wafer and Globe Styles

AND

FULL FACE GASKET

RESILIENT

SEAT DETAIL

125 lb. & 150 lb. 250 lb. & 300 lb.

A.S.A. Pressure Classes A.S.A. Pressure Classes

Face Bolt * Max. Face Bolt * Max.

Model Valve Flange to Circle Bolts No. of Mating Model Valve Flange to Circle Bolts No. of Mating

No. Size Diam. Face Diam. Size Bolts Flange ID No. Size Diam. Face Diam. Size Bolts Flange ID

603 3 712 6 6 5

8 4 338 653 3 814 6 658 3

4 8 338

604 4 9 714 712 58 8 434 654 4 10 714 778 3

4 8 434

* 605 5 10 812 812 34 8 512 655 5 11 812 914 3

4 8 512

* 606 6 11 9 912 34 8 612 656 6 1212 9 1058 3

4 12 612

* 608 8 1312 1018 1134 34 8 812 658 8 15 1018 13 7

8 12 812

* 610 10 16 12 1414 78 12 1034 660 10 1712 12 1514 1 16 1034

* 612 12 19 1414 17 78 12 1278 662 12 2012 1414 1734 118 16 1278

CHECK VALVES

* 614 14 21 1534 1834 1 12 1434 664 14 23 1534 2014 118 20 1434

616 16 2312 1758 2114 1 16 1612 666 16 2512 1758 2212 114 20 1612

618 18 25 1834 2234 118 16 1834 668 18 28 1834 2434 114 24 1834

* 620 20 2712 2058 25 118 20 2058 670 20 3012 2058 27 114 24 2058

624 24 32 24 2912 114 20 2434 674 24 36 24 32 112 24 2434

630 30 3834 2914 36 114 28 2912 680 30 43 2914 3914 134 28 2912

636 36 46 45 4234 112 32 36 686 36 50 45 46 218 32 36

642 42 53 50 4912 112 36 42 692 42 57 50 5234 214 36 42

OPERATING PRESSURE TO 1500 LB. CLASS IS AVAILABLE. PLEASE CONTACT FACTORY FOR HIGHER PRESSURE CLASSES.

WORKS EQUALLY WELL IN ANY POSITION

SELF-CLEANING SPRING GUARANTEES NO STICKING Return to Previous Menu 15

CAREFULLY SELECTED STAINLESS STEEL SPRING ENSURES SMOOTH SILENT CLOSING

What makes the APCO Silent

Performance Guarantee

The graph below shows the comparative head loss through different manufacturers Silent Check Valves. The figures

used to construct this graph were obtained from certified independent laboratory tests for the APCO valves and com-

pared against other available published data.

The lower losses of APCO Silent Check Valve as indicated by this graph frequently gives rise to the question How does

APCO manage to keep its losses below those of the other valves examined?

Superior performance is never accidental and this question is best answered by the following details.

First, every APCO valve is designed with the initial premise that the minimum cross-sectional area shall exceed that of

the pipe it serves. In every APCO valve the full cross-sectional area of the most critical points, is greater than the cross-

sectional area of the pipe. This is clearly illustrated on the valve drawing of a 5 APCO Silent Check Valve on the adja-

cent page.

Secondly, APCO has designed many types of valves for hydraulic service for over sixty years and our engineers are espe-

cially conscious of the importance of good hydraulic flow lines. Again, an examination of the drawing on the next page

will show how very carefully the contours have been worked out to give the best possible hydraulic flow results.

Even small details such as streamlining the spokes have been given due consideration. This devotion to design detail

makes it readily obvious why the APCO Silent Check Valve can reasonably be expected to have the most favorable flow

characteristics of any Silent Check Valve.

PRESSURE LOSS CURVE COMPARISON BETWEEN APCO SILENT CHECK VALVES AND OTHER SIMILAR MAKES

(ACTUAL TESTS SHOWN FOR A PARTICULAR SIZE)

Construction

The superior performance characteristics of the APCO Silent

4

Check Valve are matched by its equally superior quality of RANGE OF MOST COMMON

( I N F E E T O F WAT E R )

construction as the following design details will show. OPERATING VELOCITY FLOWS

PRESSURE LOSS

PRESSURE LOSS

VALVE 3

The seat is held by stainless steel screws so that it can be M

( I N P. S. I . )

taken apart after years of service as easily as the day it was VALVE

W

made. VALVE 2

C

Electrolytic action is eliminated by having the shaft of the plug

ride in bushings made of the same material as the shaft itself. 1

APCO

VALVE

A simple loose guide bushing for the shaft is provided made

of the same material as the shaft. This bushing is held in place

by the spring, so that in the event it is considered necessary

to take the valve apart in the field, the bushings can be easily VELO CITY IN PIPE (F.P. S . )

removed by hand.

16 Return to Previous Menu

6 4 0

N

I

Check Valve so outstanding?

T

E

APCO Silent Check Valves have been thoroughly tested by Factory Mutual Research Corp. As a

L

result, the 300 Series and 600 Series Valves can be used on hazardous fire fighting equipment and

L

fire protection systems with assurance of performance. For such applications, insist on the Factory

Mutual Guarantee Label of Approval on your Silent Check Valve. Available on sizes as indicated.

U

B

Materials of Construction

All the materials used in APCO valves are clearly referred to by their appropriate ASTM numbers.

APCO offers Ductile Iron as an alternate to the conventional cast iron.

A brief technical explanation of the qualities is given below.

The Advantages of Ductile Iron

Ductile Iron, contrary to its name, is not really a cast iron at all but an alloy developed by the International Nickel Company.

Cast Iron has graphite present in lenticular flakes which causes it to be brittle and have a relatively low tensile strength.

The graphite in Ductile Iron is present in spheroidal shape making it ductile with a much higher tensile strength.

Various types of Ductile Iron are available and we use the one especially recommended for valves. This is

Type 65-45-12 Ductile Iron ASTM A536 strength of 65 to 80,000 psi and a yield strength of 45 to 60,000 psi,

equivalent to carbon steels, yet retaining the anti-corrosion properties of iron.

5 APCO SERIES 600 SILENT CHECK VALVE WITH MINIMUM

SILENT CHECK VALVES

10% GREATER FLOW AREA.

Wafer and Globe Styles

COMPARE FLOW AREA OF PIPE BELOW WITH THOSE SHOWN AT DIFFERENT SECTIONS OF THE VALVE

Area of 5 Pipe = 20.1 Sq. In.

FLOW AREA OF

VALVE AT CROSS

SECTION LINES

SHOWN BELOW

E

27.1 SQ. IN.

Bronze Bushing

protects against

Electrolytic action

D

Smooth flow

29.1 SQ. IN.

Body Contour

guarantees

minimum loss

C

27.2 SQ. IN.

CHECK VALVES

B

22.1 SQ. IN.

STROKE Stainless

Steel Spring

(Also available

in Monel

for critical

A water condition)

23.1 SQ. IN.

ALL APCO

SILENT CHECK VALVES

100% HYDROSTATICALLY Stainless Steel Ball & Seat Retaining Screws.

TESTED TO ANSI STANDARDS Return to Previous Menu 17

SPECIFICATIONS

HEAD LOSS CHARACTERISTICS FOR

SILENT CHECK VALVES SERIES 300 (CHECK STYLE)

1 114 112 2 212 3 4 5 6 8

10

9

8

HEAD LOSS CHARACTERISTICS FOR

7

6

SILENT CHECK VALVES SERIES 600 (GLOBE STYLE)

5 100,000

9

4 8

HEAD LOSS IN FEET

7

3

6

2 50,000

4

3

1 42

.9

.8

36

.7 2

30

.6

FLOW IN GALLONS PER MINUTE

.5

.4

10,000 24

.3

9

8

.2 7 20

6

18

5,000

4 16

.1

2 3 4 5 6 7 8 9 10 2 3 4 5 6 7 8 9100 2 3 4 5 6 7 8 9 1,000 2 3 4 5 6 7 8 9 10,000 14

3

FLOW IN GALLONS PER MINUTE 12

2

10

For dynamic performance testing results

8

(the relationship of pressure rise to valve closure), please see Bulletin #769. 1,000

9

8

7

6

6

At left: 500

5

4

Typical Silent

Check Valve 3

4

application 2

on vertical 3

turbine

100

pumps (30). .1 .2 .3 .4 .5 .6 .7 .8 .9 1 2 3 4 5 6 7 8 9 10

Utah Valley HEAD LOSS IN FEET

Water

Treatment

Plant, Orem,

Utah.

S E R I E S 3 0 0 W A F E R S T Y L E S I L E N T C H E C K V A LV E

Wafer Style Silent Check Valves shall be designed with cast iron bodies, bronze seat, bronze plug and stainless steel

spring. The valve plug must be center guided at both ends with a through integral shaft and spring loaded for guar-

anteed silent shut-off operation.

The spring must be helical or conical. Seat and plug shall be hand replaceable in the field for ease of maintenance.

The flow area through the body shall be equal to or greater than the cross-section area of the equivalent pipe size.

Check Valve must be capable of silent operation when installed in vertical or horizontal position - flow up or down.

All materials of construction shall be certified in writing to conform to A.S.T.M. specifications as follows:

Body Cast iron ASTM A126 Gr.B

Plug & seat Bronze ASTM B584 C83600

Spring Stainless steel ASTM A276 T316

Exterior paint Universal Metal Primer FDA approved for potable water contact

Valve to be APCO Series 300 - 1 through 10 Silent Check Valve - Wafer Style, Factory Mutual Approved - sizes 4, 6, 8 and 10

(125 Lb. Class), sizes 4, 6, (250 Lb. Class), as manufactured by Valve and Primer Corporation, Schaumburg, Illinois, U.S.A.

S E R I E S 6 0 0 G L O B E S T Y L E S I L E N T C H E C K V A LV E

Globe Style Silent Check Valve shall be designed with semi-steel bodies, bronze seat, bronze plug and stainless

steel spring. The valve plug must be center guided at both ends with a through integral shaft and spring loaded for

guaranteed silent shut-off operation.

The spring must be helical or conical. The seat and plug shall be hand replaceable in the field for ease of maintenance.

The flow area through the body shall be equal to or greater than the cross-sectional are of the equivalent pipe size.

All materials of construction shall be certified in writing to conform to A.S.T.M. specifications as follows:

Body Cast iron ASTM A126 Gr.B

Plug & seat Bronze ASTM B584 C83600

Spring Stainless steel ASTM A276 T316

Exterior paint Universal Metal Primer FDA approved for potable water contact

Valve to be APCO Series 600 - 3 through 42 Silent Check Valves - Factory Mutual Approved - sizes 4, 6, 8, 10, 12 and

18, as manufactured by Valve & Primer Corporation, Schaumburg, Illinois, U.S.A.

VALVE & PRIMER CORPORATION

18 1420 S. WRIGHT BLVD. SCHAUMBURG, IL 60193-4599 Return

&

to Previous Menu

VALVE PRIMER CORPORATION HEREBY RESERVES THE RIGHT TO CHANGE ANY

847.524.9000 FAX:847.524.9007 800.323.6969 COMPONENT PARTS WHICH, IN THE OPINION OF ITS ENGINEERING DEPARTMENT,

website: www.apcovalves.com e-mail: factory@apcovalves.com WILL IMPROVE THE PRODUCT OR INCREASE ITS SERVICEABILITY.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PPE Sample QuestionDocument3 pagesPPE Sample Questiontanvir04169No ratings yet

- Factors That Affect Rusting - Lab Report..Document4 pagesFactors That Affect Rusting - Lab Report..rosaNo ratings yet

- Forged Brass Spring Loaded Check & Lever Operated Gate ValvesDocument1 pageForged Brass Spring Loaded Check & Lever Operated Gate Valvestanvir04169No ratings yet

- ASCO 40 Pressure SensorDocument3 pagesASCO 40 Pressure Sensortanvir04169100% (1)

- Apollo 32-100 Series Regular Port Threaded Bronze Ball ValveDocument1 pageApollo 32-100 Series Regular Port Threaded Bronze Ball Valvetanvir04169No ratings yet

- Silent Check Silent Check Silent Check Silent Check Silent Check V V V V VAL AL AL AL Alve - VE-VE - VE - Ve - W W W W Wafer Style Afer Style Afer Style Afer Style Afer StyleDocument2 pagesSilent Check Silent Check Silent Check Silent Check Silent Check V V V V VAL AL AL AL Alve - VE-VE - VE - Ve - W W W W Wafer Style Afer Style Afer Style Afer Style Afer Styletanvir04169No ratings yet

- Instructions For Installing Series LF23B, LF123LP, LFN250 and LFN250BDocument2 pagesInstructions For Installing Series LF23B, LF123LP, LFN250 and LFN250Btanvir04169No ratings yet

- Latih Tubi 4 AkasiaDocument24 pagesLatih Tubi 4 Akasiatumirah86No ratings yet

- Cambridge International Examinations Cambridge International General Certificate of Secondary EducationDocument16 pagesCambridge International Examinations Cambridge International General Certificate of Secondary EducationJoshua IbrahimNo ratings yet

- TACO Hardware E-CatalogueDocument15 pagesTACO Hardware E-Catalogueiqbal abdul azizNo ratings yet

- Production of Manual Metal Arc Welding Electrodes With Local Raw MaterialsDocument5 pagesProduction of Manual Metal Arc Welding Electrodes With Local Raw MaterialsShubham YadavNo ratings yet

- Chemical Composition of Meat and Nut Water of Major Coconut in PakistanDocument7 pagesChemical Composition of Meat and Nut Water of Major Coconut in PakistanSkyle VoNo ratings yet

- Cambridge International General Certificate of Secondary EducationDocument484 pagesCambridge International General Certificate of Secondary EducationolaNo ratings yet

- An Introduction To Chemical ScienceDocument176 pagesAn Introduction To Chemical ScienceMakarand PatilNo ratings yet

- Rec ZN 4Document22 pagesRec ZN 4edwin quintanillaNo ratings yet

- Powder Metallurgy Science CH 1-CH 2Document32 pagesPowder Metallurgy Science CH 1-CH 2Adnan MaqboolNo ratings yet

- 10 Social Science Geography Revision Notes Ch6Document8 pages10 Social Science Geography Revision Notes Ch6Vishrut ShahiNo ratings yet

- Steel Coding SystemDocument5 pagesSteel Coding SystemWell LojuminNo ratings yet

- Resistance Wire: Properties of Major AlloysDocument2 pagesResistance Wire: Properties of Major Alloysyasir127No ratings yet

- AAMRADocument50 pagesAAMRARona Khairol Pratama100% (1)

- 3"-48" Ductile Iron Mechanical Joint Fittings Class 350Document11 pages3"-48" Ductile Iron Mechanical Joint Fittings Class 350MIGUEL MIGUEL RIVAS SALCEDONo ratings yet

- Metallurgy Notes 2 PDFDocument5 pagesMetallurgy Notes 2 PDFBOSS BOSSNo ratings yet

- Metalic Elements Practical Report Group 1Document12 pagesMetalic Elements Practical Report Group 1Mya VoNo ratings yet

- AIRCRAFT STRUCTURE MATERIAL METAL Pictures OnlyDocument27 pagesAIRCRAFT STRUCTURE MATERIAL METAL Pictures OnlyYasser ZubaidiNo ratings yet

- Karnataka Icse Schools Association: SECTION A (40 Marks)Document6 pagesKarnataka Icse Schools Association: SECTION A (40 Marks)Arebal100% (1)

- Understanding The Microstructure of Overheated Carbon Steel: ConstituentsDocument6 pagesUnderstanding The Microstructure of Overheated Carbon Steel: ConstituentsHOSSIENNo ratings yet

- Reed'S General Engineering Knowledge FOR Marine Engineers: Leslie JacksonDocument265 pagesReed'S General Engineering Knowledge FOR Marine Engineers: Leslie JacksonJose RamonNo ratings yet

- Conservation - of - Matter Test From Problem AtticDocument12 pagesConservation - of - Matter Test From Problem AtticMystNo ratings yet

- Blast Furnace Presentation Ver1Document39 pagesBlast Furnace Presentation Ver1abhijit kumarNo ratings yet

- Development and Use of Mill Scale Briquettes in BOF: Ironmaking & SteelmakingDocument7 pagesDevelopment and Use of Mill Scale Briquettes in BOF: Ironmaking & SteelmakingSrikanth SrikantiNo ratings yet

- Blow in Essar 15.2.10Document18 pagesBlow in Essar 15.2.10TheleapInoblivionNo ratings yet

- A532A532M-10 (2014) Standard Specification For Abrasion-Resistant Cast IronsDocument4 pagesA532A532M-10 (2014) Standard Specification For Abrasion-Resistant Cast Ironsalexander zuritaNo ratings yet

- Chapter - 3: Metals and Non MetalsDocument25 pagesChapter - 3: Metals and Non MetalsKiran PatilNo ratings yet

- Baptist Lui Ming Choi Secondary School First Term Examination (2012-2013) Form 3 ChemistryDocument12 pagesBaptist Lui Ming Choi Secondary School First Term Examination (2012-2013) Form 3 ChemistryyuNo ratings yet

- Lyapko Applicators - Your Health Is in Your Hands! - Methodological Recommendations PDFDocument49 pagesLyapko Applicators - Your Health Is in Your Hands! - Methodological Recommendations PDFYuldashNo ratings yet

- Synthesis, Purification, and Characterization W of A - (1,3-Propanedithiolato) - HexacarbonyldiironDocument3 pagesSynthesis, Purification, and Characterization W of A - (1,3-Propanedithiolato) - HexacarbonyldiironJacqueline Agatha FerreiraNo ratings yet