Professional Documents

Culture Documents

API Vs ANSI Flanges

Uploaded by

AKSHAY BHATKAR0 ratings0% found this document useful (0 votes)

358 views1 pageAPI and ASME/ANSI flanges can have the same bolt circle dimensions but have different pressure rating systems. API flanges specify allowable materials and have a set pressure rating, while ASME rates pressure based on material and temperature. Though dimensions are the same, API flanges are rated for higher pressures and are used in refinery systems handling flammable fluids, while ASME flanges are more common for industrial water and gas systems.

Original Description:

Demo

Original Title

API vs ANSI Flanges

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAPI and ASME/ANSI flanges can have the same bolt circle dimensions but have different pressure rating systems. API flanges specify allowable materials and have a set pressure rating, while ASME rates pressure based on material and temperature. Though dimensions are the same, API flanges are rated for higher pressures and are used in refinery systems handling flammable fluids, while ASME flanges are more common for industrial water and gas systems.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

358 views1 pageAPI Vs ANSI Flanges

Uploaded by

AKSHAY BHATKARAPI and ASME/ANSI flanges can have the same bolt circle dimensions but have different pressure rating systems. API flanges specify allowable materials and have a set pressure rating, while ASME rates pressure based on material and temperature. Though dimensions are the same, API flanges are rated for higher pressures and are used in refinery systems handling flammable fluids, while ASME flanges are more common for industrial water and gas systems.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

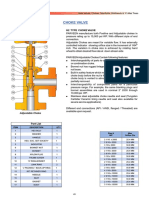

API vs ANSI/ASME Flanges

Although the dimensions of ASME and API flanges may sometimes be compatible for

bolting - using the same bolt circle and the same number of bolts - they do not share

the same pressure rating system.

ASME rates the pressure of a class based on the material of construction and

the design temperature

API specifies allowable materials and gives it a specific pressure rating

The difference between ASME/ANSI and API is the fabrication material and a higher

rated API operating pressure.

ASME/ANSI flanges are commonly used in industrial process systems handling

water, steam, air and gas. API flanges are manufactured for high strength operating

refinery systems with products such as oil and explosive gases.

The flange standards API 6A and ASME/ANSI B16.5 have the same dimensions - but

the API 6A flanges are rated for higher pressures as indicated below

API vs. ASME/ANSI Flanges with the same Dimensions

Nominal Size Range

Pressure Class Rating (psi)

(inches)

Flange

ASME/ANSI ASME/ANSI

API 6A API 6A1)

B16.5 B16.5

600 2000

Weld neck 900 3000 113/16 - 11

1500 5000

1/2 - 24

600 2000 113/16 - 211/4

Blind and

900 3000 113/16 - 203/4

Threaded

1500 5000 113/16 - 11

In the old API standard, flanges ranged from 1 1/2 to 10(20) inches.

You might also like

- Acme & Stub Acme LoadDocument4 pagesAcme & Stub Acme Loadraseen pNo ratings yet

- SC-90 Conventional Surface Wellhead System PDFDocument12 pagesSC-90 Conventional Surface Wellhead System PDFErcan YilmazNo ratings yet

- Choke ParveenDocument3 pagesChoke ParveenYM Edwin Gil BeltranNo ratings yet

- CT WKM Powrseal GateDocument28 pagesCT WKM Powrseal GatemoonanbuNo ratings yet

- 02 PCE Extracts PDFDocument4 pages02 PCE Extracts PDFebeNo ratings yet

- Bop1006 b73s33s-3r2l3l-35h-0Document1 pageBop1006 b73s33s-3r2l3l-35h-0api-513539506No ratings yet

- Uztel OrizontalDocument5 pagesUztel OrizontalDorin RaduNo ratings yet

- API 6A PSL Levels 1Document2 pagesAPI 6A PSL Levels 1lembe sergeNo ratings yet

- GE Gate Valve PDFDocument2 pagesGE Gate Valve PDFgacm98No ratings yet

- Tech Manual 1222B: Booster Cylinder Assembly EH34-BC03Document21 pagesTech Manual 1222B: Booster Cylinder Assembly EH34-BC03jose perozoNo ratings yet

- D392005428-MKT-001 6012 Bop PDFDocument2 pagesD392005428-MKT-001 6012 Bop PDFMitul PatelNo ratings yet

- Drill Pipe Basket Design for TransportDocument8 pagesDrill Pipe Basket Design for TransportmirraoNo ratings yet

- CS® Tubing Torque ChartDocument2 pagesCS® Tubing Torque Chartjesus infanteNo ratings yet

- Hydril Annular BOP1Document2 pagesHydril Annular BOP1Abde EsselamNo ratings yet

- Te ValveDocument30 pagesTe Valvecrni roko100% (2)

- Valveworks USA 7-1/16Document30 pagesValveworks USA 7-1/16LeandroNo ratings yet

- China Guanghan Petroleum 2 FZ 35-35 RAMSDocument1 pageChina Guanghan Petroleum 2 FZ 35-35 RAMSTiffany DacinoNo ratings yet

- API Spec 16C - Union Connections 20140103Document2 pagesAPI Spec 16C - Union Connections 20140103Deby PristantoNo ratings yet

- 25k Bop FlyerDocument1 page25k Bop FlyersyedainahmadNo ratings yet

- Mud Gate ValveDocument16 pagesMud Gate ValvesudhisnairNo ratings yet

- Gagemaker ProductsDocument50 pagesGagemaker ProductsMelquiades Hernández GonzálezNo ratings yet

- 13.625 10K Double Cameron U BOP PDFDocument2 pages13.625 10K Double Cameron U BOP PDFAndung Suwarto100% (1)

- Parker HTR ActuatorDocument22 pagesParker HTR ActuatorYorkistNo ratings yet

- DL Bop BrochureDocument4 pagesDL Bop BrochureIRWIN_DSOUZANo ratings yet

- Hammer Unions PDFDocument7 pagesHammer Unions PDFflasher_for_nokiaNo ratings yet

- BOP Pressure Test Report DetailsDocument1 pageBOP Pressure Test Report DetailssamNo ratings yet

- HMH KFDJ Diverters r1Document9 pagesHMH KFDJ Diverters r1budygmoodNo ratings yet

- Wellhead Equipment CatalogDocument29 pagesWellhead Equipment CatalogDewy PambayunNo ratings yet

- 21 2000 Shaffer Bolted Annular Bop Spec SheetDocument1 page21 2000 Shaffer Bolted Annular Bop Spec SheetJoel SNo ratings yet

- Fail Safe or TR RegulatorDocument2 pagesFail Safe or TR RegulatorYeit HauNo ratings yet

- Acme Thread 29 Formulas Depth 0.5/N+0.01Document6 pagesAcme Thread 29 Formulas Depth 0.5/N+0.01Dhanraj VasanthNo ratings yet

- 003 Casing & Tubing Hanger PDFDocument4 pages003 Casing & Tubing Hanger PDFalaliali88No ratings yet

- Bit ClassifierDocument104 pagesBit Classifiersaeed65No ratings yet

- 3-1/16" 10K Gate Valve Type FC, Api-6a, Petrotrim ServicesDocument1 page3-1/16" 10K Gate Valve Type FC, Api-6a, Petrotrim ServicesPetrotrim ServicesNo ratings yet

- Clamp Connections: Bearing Ring Load Ring Nut Washer DetailDocument2 pagesClamp Connections: Bearing Ring Load Ring Nut Washer DetailНикита ПромиснкийNo ratings yet

- Quick UnionsDocument1 pageQuick UnionsRefisal BonnetNo ratings yet

- Sara Sae - Manual TongDocument5 pagesSara Sae - Manual Tonganon_374733272No ratings yet

- GLV-Catalogue - Botil IndiaDocument18 pagesGLV-Catalogue - Botil IndiaHamza LamamraNo ratings yet

- Parveen Stabilizers Guide Drilling ToolsDocument2 pagesParveen Stabilizers Guide Drilling ToolsGonzalo Guzman Jaimes100% (1)

- Api 16A 3 Edition: Api 16A Chairman: John Busby Co-Chair: Jim MccabeDocument11 pagesApi 16A 3 Edition: Api 16A Chairman: John Busby Co-Chair: Jim Mccabesaeed65No ratings yet

- Casing HangerDocument2 pagesCasing Hangerandreinicusor1958-1No ratings yet

- Catálogo Cameron Bop Novo 2004-2005Document162 pagesCatálogo Cameron Bop Novo 2004-2005Edmo Virgens100% (1)

- NS Premium Joint Connection: Data SheetDocument1 pageNS Premium Joint Connection: Data SheetashadNo ratings yet

- Tech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopDocument34 pagesTech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopRiski KurniawanNo ratings yet

- Installation & Routine Maintenance Manual: FOR Type: 3" Mud Gate Valve (Model I)Document8 pagesInstallation & Routine Maintenance Manual: FOR Type: 3" Mud Gate Valve (Model I)Sergio Fabian VasicekNo ratings yet

- FKQ50-2 Use R ManualDocument56 pagesFKQ50-2 Use R ManualMuthia AstriNo ratings yet

- Field Test Procedures Chemical Injection ValveDocument2 pagesField Test Procedures Chemical Injection ValveHua Tien Dung100% (1)

- Oilfield Union Color Code GuideDocument5 pagesOilfield Union Color Code Guidelalberto96No ratings yet

- Bolt Load-Torque ChartDocument6 pagesBolt Load-Torque ChartIgor ScudellerNo ratings yet

- CamesaEMC Catalog 12-2013 7Document1 pageCamesaEMC Catalog 12-2013 7Gerardo LizardoNo ratings yet

- Cameron EB 555 D Rev U2 - VBR Engineering InfoDocument6 pagesCameron EB 555 D Rev U2 - VBR Engineering InfoCanrig Ramde100% (1)

- Satyakiran Engineers Private Limited: API 6A 20th Edition, Question Paper (Master) - RING JOINT GASKETDocument4 pagesSatyakiran Engineers Private Limited: API 6A 20th Edition, Question Paper (Master) - RING JOINT GASKETMayank GuptaNo ratings yet

- Gate Valve Torque Cal - GuideDocument1 pageGate Valve Torque Cal - GuideTracy PatelNo ratings yet

- API Slide Rule (Flange & Hub)Document3 pagesAPI Slide Rule (Flange & Hub)didikhartadiNo ratings yet

- Wellhead Fittings & Valve Components - PGI-WFDocument28 pagesWellhead Fittings & Valve Components - PGI-WFIan KevinNo ratings yet

- 11"-5000psi Double Ram BOP ManualDocument64 pages11"-5000psi Double Ram BOP ManualDavid EskarousNo ratings yet

- Drill Collar SlipsDocument10 pagesDrill Collar SlipsAdrian CantaragiuNo ratings yet

- SB Darron Non-Magnetic Drill Collar CatalogDocument51 pagesSB Darron Non-Magnetic Drill Collar CatalogSiva GanaNo ratings yet

- Blast Joint/Flow Coupling: Document # RevisionDocument1 pageBlast Joint/Flow Coupling: Document # RevisionfelipeNo ratings yet

- Comparing API and ASME-ANSI Flanges Dimensions and Pressure RatingsDocument2 pagesComparing API and ASME-ANSI Flanges Dimensions and Pressure Ratingsjorge1952100% (1)

- Nozzle 1Document1 pageNozzle 1AKSHAY BHATKARNo ratings yet

- Part 6: Bottom Pipe To Tubesheet Joint Check (Detail D6)Document1 pagePart 6: Bottom Pipe To Tubesheet Joint Check (Detail D6)AKSHAY BHATKARNo ratings yet

- Spreader Beam (Planning)Document28 pagesSpreader Beam (Planning)AKSHAY BHATKARNo ratings yet

- Uw 27Document1 pageUw 27AKSHAY BHATKARNo ratings yet

- Equipment Nozzle Loading (Enl)Document1 pageEquipment Nozzle Loading (Enl)AKSHAY BHATKAR0% (1)

- Circular Panel With StiffenersDocument4 pagesCircular Panel With StiffenersAKSHAY BHATKARNo ratings yet

- Scan Sep 12, 2020Document8 pagesScan Sep 12, 2020AKSHAY BHATKARNo ratings yet

- Attachment - 1 (General Notes)Document1 pageAttachment - 1 (General Notes)AKSHAY BHATKARNo ratings yet

- Master List of Drawings and Documents-14.09.2020Document2 pagesMaster List of Drawings and Documents-14.09.2020AKSHAY BHATKARNo ratings yet

- Sample design calculation for skirt support of vertical columnDocument8 pagesSample design calculation for skirt support of vertical columnimrancenakk100% (2)

- External Pressure ToleranceDocument4 pagesExternal Pressure ToleranceAKSHAY BHATKAR100% (1)

- Interpretation For SA 105Document2 pagesInterpretation For SA 105AKSHAY BHATKARNo ratings yet

- Code Case 2695Document1 pageCode Case 2695AKSHAY BHATKARNo ratings yet

- Shell Dish Design Pressure VesselDocument26 pagesShell Dish Design Pressure VesselAKSHAY BHATKARNo ratings yet

- Spreader Beam AttachmentDocument28 pagesSpreader Beam AttachmentAKSHAY BHATKAR100% (1)

- Ticket 7113858447Document3 pagesTicket 7113858447AKSHAY BHATKARNo ratings yet

- Circular Panel With StiffenersDocument4 pagesCircular Panel With StiffenersAKSHAY BHATKARNo ratings yet

- Ticket 7116612898Document3 pagesTicket 7116612898AKSHAY BHATKARNo ratings yet

- Leg Support With Braces FinalDocument16 pagesLeg Support With Braces FinalAKSHAY BHATKAR100% (1)

- Calc Leg Check of Cross BracingDocument4 pagesCalc Leg Check of Cross Bracingdinesh_akabariNo ratings yet

- SD FtyDocument1 pageSD FtyAKSHAY BHATKARNo ratings yet

- Interview TipsDocument2 pagesInterview TipsAKSHAY BHATKARNo ratings yet

- To Upload1234Document1 pageTo Upload1234AKSHAY BHATKARNo ratings yet

- ASME Standards: A262 A276 A342/A342M A380 A484/A484M A493 A555/A555M A564/A564MDocument1 pageASME Standards: A262 A276 A342/A342M A380 A484/A484M A493 A555/A555M A564/A564MAKSHAY BHATKARNo ratings yet

- SRN Enquiry No. 4855Document51 pagesSRN Enquiry No. 4855AKSHAY BHATKARNo ratings yet

- Leg Support DesignDocument1 pageLeg Support DesignAKSHAY BHATKARNo ratings yet

- Anchor BTD DefgDocument14 pagesAnchor BTD DefgAKSHAY BHATKARNo ratings yet

- UHX STudyDocument12 pagesUHX STudyAKSHAY BHATKARNo ratings yet

- To Upload1234Document1 pageTo Upload1234AKSHAY BHATKARNo ratings yet

- To Upload1234Document1 pageTo Upload1234AKSHAY BHATKARNo ratings yet