Professional Documents

Culture Documents

Electrotek 02 Papertools

Uploaded by

Jose PocomuchaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrotek 02 Papertools

Uploaded by

Jose PocomuchaCopyright:

Available Formats

Paper Tools

Richard P. Bingham

There are many different types of tools available for troubleshooting, auditing, and

evaluating the power quality compatibility and susceptibility of a facility. From handheld

DVMs to sophisticated power quality analyzers with mega-hertz sampling rates, each

tool has its own strengths and weaknesses for a given application. While there a lots of

useful standards and reference materials out there, a good, general purpose tool that

covers a wide variety of situations (and is very inexpensive) is the NFPA 70B Electrical

Equipment Maintenance publication.

The IEEE Power Engineering Society is responsible for the updating and development of

a number of valuable references, such as IEEE 519 and IEEE 1159, along with the

entire "color book" series. While these are well-written and useful publications, they are

written and reviewed, as the title applies, by primarily power engineers. Often these

documents have formulas and technical terms that some electrical contractors are not

familiar with, which makes the application of such more challenging.

The NFPA 70B approaches the material from a different perspective. The committee is

comprised of members from numerous backgrounds and responsibilities, including the

IBEW, NECA, NEMA, NETA, the Dept of State, OSHA, manufacturers of equipment, and

others. Angie Stoyas, of the US Army Corp of Engineers, provides vision and effective

leadership as the chairperson, and assisted by the knowledgable liason to the NFPA,

Joe Sheehan, who also works on the NEC committee. This diverse group of people

make sure that the resulting publication is accurate and highly applicable to its readers.

Any additions or changes are subject to public proposals and comments, and then must

be approved by the entire NFPA organization at its annual meeting.

As the title applies, the purpose of this publication "is to reduce hazards to life and

property that can result from failure or malfunction of industrial-type electrical systems

and equipment. The first three chapters of these recommendations for an effective

Electrical Preventive Maintenance (EPM) program have been prepared with the intent of

providing a better understanding of benefits, both direct and intangible, that can be

derived from a well-administered EPM program. This practice explains the function,

requirements, and economic considerations that can be used to establish such a

program."

Today, many companies are outsourcing their electrical equipment maintenance to

electrical contractors as a more economical way to maintain their equipment and

facilities. For companies that already have established EPM programs based on 70B,

the contractor is expected to continue to maintain the program at the same level. And

when the contractor is called upon to establish a new program for a facility, it provides

an excellent basis for such. Maintenance of motors, lighting, distribution panels,

transformers, breakers, fuses and motor control circuits are just some of the topics

covered in a step-by-step, concise manner.

Richard P. Bingham is the manager of technology and products for Dranetz-BMI.

copyright February 1998 Electrical Contractor Magazine

www.ecmag.com

The 1998 revision includes a greatly expanded chapter on power quality. Categories of

power quality phenomena covered include harmonics, sags, swells, voltage unbalance

and single phasing, transients, over/undervoltage, sustained interruptions, noise, and

interharmonics. Each category is broken down into sections on definitions, symptoms

and effects, causes, surveying and testing, and recommended solutions. There is also a

section on grounding and a list of additional references to consult with if you can't find

the answer in the document.

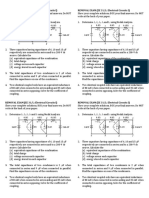

There are graphs of typical power quality phenomena, such as the classic voltage notch

and harmonic-laden current waveform of the 6 pole converter, as shown in Figure 1.

This waveform is often found in the front end of ASDs and other three phase devices

that rectified the AC into DC before converting it into other voltages levels and/or

frequencies. This current waveform contains the dominate harmonic pairs (5-7, 11-13,

17-19, 23-35...) that follow the rule: harmonic numbers = integer (1,2,3,..) multiplied by

the number of paths of conduction (3 phases * 2 for full wave rectifiers) plus and minus

one.

Figure 1

Figure 2 has another classic waveform, the negative transient followed by the ringing

voltage which can be 1.2 to 1.8 times the normal peak voltage, which usually occur

when the power factor capacitor is switched in. This typically occurs at a certain time in

the morning or at certain load levels. The uncharged capacitor "steals electrons" until it

is charged up, reducing the voltage waveform in the form of a negative transient. This

sudden current draw resonants with the system impedance to cause the ringing

waveform after it. Sometimes, the negative transient can be deep enough to cause zero

crossing errors. The ringing transients can cause tripping of overvoltage protection

circuits.

Richard P. Bingham is the manager of technology and products for Dranetz-BMI.

copyright February 1998 Electrical Contractor Magazine

www.ecmag.com

Figure 2.

The NFPA 70B should be a "paper tool" included in every contractor's tool box. Copies

can be inexpensively obtained from the National Fire Protection Association, 1

Batterymarch Park, Quincy, MA, over the Internet at www.nfpa.org, or by calling them at

617-770-3000.

Richard P. Bingham is the manager of technology and products for Dranetz-BMI.

copyright February 1998 Electrical Contractor Magazine

www.ecmag.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Feasibility Study of LED Bulbs FactoryDocument2 pagesFeasibility Study of LED Bulbs FactoryAmjad AtiqueNo ratings yet

- MODULE in Consumer ElectronicsDocument129 pagesMODULE in Consumer ElectronicsNyepni NelmiNo ratings yet

- Removal Exam 1Document1 pageRemoval Exam 1Miko F. RodriguezNo ratings yet

- L-s1 Led t8 Uspma - MPT 130513Document6 pagesL-s1 Led t8 Uspma - MPT 130513Evon ChayNo ratings yet

- 060105-UK Water DescalerDocument1 page060105-UK Water DescalerOvidiu FratuNo ratings yet

- HYUNDAI MV y LV BreakersDocument15 pagesHYUNDAI MV y LV BreakersLuisa Fernanda Buitrago ArroyaveNo ratings yet

- BLDC - BLDC Motor Control V1Document28 pagesBLDC - BLDC Motor Control V1উত্তরজীবী সাকিবNo ratings yet

- FD535 (Datasheet)Document3 pagesFD535 (Datasheet)BlAdE 12No ratings yet

- Avago ACPL-339J Driving and Protecting IGBTs Article - v4 (Final)Document4 pagesAvago ACPL-339J Driving and Protecting IGBTs Article - v4 (Final)Arvind NangareNo ratings yet

- Kabel MetalDocument2 pagesKabel Metalsri haryadiNo ratings yet

- 2A - Electrical and IgnitionDocument12 pages2A - Electrical and IgnitionDenis RoscaNo ratings yet

- DR GE MPACT - Emax 2 - Declaration of ConformityDocument4 pagesDR GE MPACT - Emax 2 - Declaration of ConformityIBRAHIM AL-SURAIHINo ratings yet

- Wound Rotor Repair Tips: Testing, Application and Failure AnalysisDocument14 pagesWound Rotor Repair Tips: Testing, Application and Failure Analysishino_kaguNo ratings yet

- AY140 Remote Controls EnglishDocument2 pagesAY140 Remote Controls EnglishTaher MassahNo ratings yet

- Ricky EtapDocument5 pagesRicky EtapAnonymous 6z6ibgdAlENo ratings yet

- Ni Jay VeeDocument46 pagesNi Jay Veejayvee banaagNo ratings yet

- SX310 WTE Diode PDFDocument4 pagesSX310 WTE Diode PDFHưng HQNo ratings yet

- PT 980410 Fundamental and Installation TR - W PDFDocument63 pagesPT 980410 Fundamental and Installation TR - W PDFMet PichborameyNo ratings yet

- Electrical SystemDocument57 pagesElectrical SystemAlly Mtz AlvaradoNo ratings yet

- Dcs800 ManualDocument4 pagesDcs800 ManualMohd AkhirNo ratings yet

- Is 1885 38 1993 PDFDocument20 pagesIs 1885 38 1993 PDFSubhasish PaulNo ratings yet

- Stamford S6L1D-G4 DatasheetDocument9 pagesStamford S6L1D-G4 DatasheetTrieu HuynhNo ratings yet

- BLDC Motor Ø8 MM: ECX SPEED 8 M BrushlessDocument1 pageBLDC Motor Ø8 MM: ECX SPEED 8 M BrushlessVinsen Teubun LetsoinNo ratings yet

- (DATASHEET) - Proximity Schneider PDFDocument174 pages(DATASHEET) - Proximity Schneider PDFPhreakerNo ratings yet

- 4 Power Transformer Protection Devices Explained in DetailsDocument8 pages4 Power Transformer Protection Devices Explained in DetailsmherbakNo ratings yet

- Iecex PTB 13.0003Document8 pagesIecex PTB 13.0003Francesco_CNo ratings yet

- MUR1520 MURB1520 MURB1520-1: Ultrafast RectifierDocument8 pagesMUR1520 MURB1520 MURB1520-1: Ultrafast RectifierMarianny MolinaNo ratings yet

- EDC Question BankDocument12 pagesEDC Question BankSam SureshNo ratings yet

- Auto ElectricianDocument16 pagesAuto ElectricianneoNo ratings yet

- Exercise Problems On DC GeneratorsDocument2 pagesExercise Problems On DC GeneratorsSyed Arif Ahmed0% (1)