Professional Documents

Culture Documents

01 Refracto Meter 01

Uploaded by

ASHOK KUMAR LENKAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01 Refracto Meter 01

Uploaded by

ASHOK KUMAR LENKACopyright:

Available Formats

OASIS LABORATORIES PRIVATE LIMITED, DEHRADUN

SOP No.:

QUALITY CONTROL DEPARTMENT Page 1 of 3

QCG001

Supersedes : Effective date:

STANDARD OPERATING PROCEDURE

00 April 2010

Version No. : SOP FOR OPERATION AND CALIBRATION Review date:

01 OF REFRACTOMETER March 2013

1.0 OBJECTIVE:

To describe the procedure for the Operation and Calibration of

Refractometer.

2.0 SCOPE:

This SOP is applicable to Operation and Calibration of Refractometer at

M/s. Oasis Laboratories Private Limited, Dehradun.

3.0 RESPONSIBILITY:

Quality Control Department

4.0 ACCOUNTABILITY:

HOD QC

5.0 PROCEDURE :

5.1 Open the prism by unlocking the lever, place of few drops of the

liquid under study on the surface of the lower prism, which has a

matt and ground surface.

5.2 Lift the lower prism and lock it with the upper prism by the same

lever when the liquid will be formed into a very thin layer between

the two prisms.

5.3 Look through the telescope when a bright circular path of the light

partly coloured will be seen.

5.4 Focus the eyepiece on the index line and adjust the reflecting

mirror to get a maximum illumination through the telescope.

5.5 Rotate the milled drum in front till a coloured band of light

appears.

5.6 Rotate the milled drum till this sharp critical line of demarcation

coincides with the junction of the crossed graticulas index lines.

Designation Signature Date

Prepared by Chemist QC

Reviewed by Manager QC

Approved by Manager - QA

OASIS LABORATORIES PRIVATE LIMITED, DEHRADUN

SOP No.:

QUALITY CONTROL DEPARTMENT Page 2 of 3

QCG001

Supersedes : Effective date:

STANDARD OPERATING PROCEDURE

00 April 2010

Version No. : SOP FOR OPERATION AND CALIBRATION Review date:

01 OF REFRACTOMETER March 2013

5.7 Look though the left eye piece and focus the lens till the refractive

index scale and the graticulas index line are in clear focus, take

the reading of the scale, this gives the refractive index of the

sample.

5.8 Repeat the process to take a number of readings whose average

gives the refractive index of the liquid.

5.9 It the refractive index is to be determining at a fixed desired

temperature, water from a separate thermostatic bath be

circulated within the prism box using the inlet and outlet tubes and

check the temp. with thermometer.

5.10 Before putting in any new liquid, the surface of the prism must be

thoroughly cleaned with water or other organic solvent like

acetone to remove the solution previously us.

5.11 Before keeping the instrument in the wooden box, the prisms

must be thoroughly cleaned and dried.

6.0 CALIBRATION:

To achieve accuracy, the apparatus should be calibrated against distilled

water which has refractive index of 1.3325 at 25 or against the

reference liquids given are below:-

Reference liquid Refractive Index at 20

Carbon tetrachloride 1.4603

Toluene 1.4969

Frequency of calibration : Monthly

7.0 RECORDS:

Calibration Record of Refractometer (Annexure-1).

8.0 ANNEXURES:

Annexure-1: Format for Calibration Record of Refractometer.

9.0 ABBREVIATIONS & DEFINITIONS:

SOP : Standard Operating Procedure.

Dept. : Department.

Designation Signature Date

Prepared by Chemist QC

Reviewed by Manager QC

Approved by Manager - QA

OASIS LABORATORIES PRIVATE LIMITED, DEHRADUN

SOP No.:

QUALITY CONTROL DEPARTMENT Page 3 of 3

QCG001

Supersedes : Effective date:

STANDARD OPERATING PROCEDURE

00 April 2010

Version No. : SOP FOR OPERATION AND CALIBRATION Review date:

01 OF REFRACTOMETER March 2013

HOD : Head of the Department.

QC : Quality Control

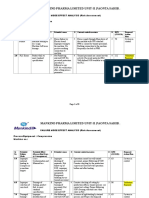

ANNEXURE: 1

SOP REF NO QCG001 QC-F-001-01

Name of Instruments : Refractometer Apparatus

Name of Manufacturer : Delhi India

Instrument ID Number : QC/INS/010

Frequency of calibration : Monthly

Instruments location : Q.C. LAB.

CALIBRATION PROCEDURE: To active accuracy of the instrument it calibrated against water which

has refractive index of 1.3325 at 250 C against following liquid.

Date Reference Liquid std R.I . Observed Tolerance Next Due Remark Performed Checked

at 200 c R.I. Date by by

Carbon Tetrachloride 1.4603 0.0001

Toluene 1.4969 0.0001

Designation Signature Date

Prepared by Chemist QC

Reviewed by Manager QC

Approved by Manager - QA

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Water System DrawingDocument1 pageWater System DrawingASHOK KUMAR LENKANo ratings yet

- DayQuil Cold & Flu Relief LiquiCaps ReviewDocument1 pageDayQuil Cold & Flu Relief LiquiCaps ReviewASHOK KUMAR LENKANo ratings yet

- Mankind Pharma Limited Unit-Ii, Paonta Sahib .: 1.0 PowerDocument9 pagesMankind Pharma Limited Unit-Ii, Paonta Sahib .: 1.0 PowerASHOK KUMAR LENKA100% (1)

- Usp 1116 Usp 36 NF31S1 PDFDocument11 pagesUsp 1116 Usp 36 NF31S1 PDFASHOK KUMAR LENKANo ratings yet

- Job Descriptions Roles and ResponsibilitiesDocument7 pagesJob Descriptions Roles and ResponsibilitiesASHOK KUMAR LENKANo ratings yet

- 03-09-2017 Sorbitol Soluction 70%Document1 page03-09-2017 Sorbitol Soluction 70%ASHOK KUMAR LENKANo ratings yet

- 2500Document4 pages2500ASHOK KUMAR LENKANo ratings yet

- Ajit Kumar Rout: Curriculam VitaeDocument3 pagesAjit Kumar Rout: Curriculam VitaeASHOK KUMAR LENKANo ratings yet

- 58 66 (Ajpr)Document9 pages58 66 (Ajpr)ASHOK KUMAR LENKANo ratings yet

- Vap1.7 MSDSDocument10 pagesVap1.7 MSDSASHOK KUMAR LENKANo ratings yet

- List of Instru - EquipDocument2 pagesList of Instru - EquipASHOK KUMAR LENKANo ratings yet

- AutoCAD Tutorial 002 PDFDocument54 pagesAutoCAD Tutorial 002 PDFskannanmecNo ratings yet

- PLAN Vs ACHIEVEMENT (26.12.16) : Department: MicrobiologyDocument1 pagePLAN Vs ACHIEVEMENT (26.12.16) : Department: MicrobiologyASHOK KUMAR LENKANo ratings yet

- XL Laboratories Purchases PVDC Film from ACG PharmapackDocument1 pageXL Laboratories Purchases PVDC Film from ACG PharmapackASHOK KUMAR LENKANo ratings yet

- A4c - NAM Registration GuidelineDocument92 pagesA4c - NAM Registration GuidelineASHOK KUMAR LENKANo ratings yet

- Communications Officer 61-11 - JDDocument15 pagesCommunications Officer 61-11 - JDASHOK KUMAR LENKANo ratings yet

- 26.12.16 Revised Embossing Letter RequirementDocument4 pages26.12.16 Revised Embossing Letter RequirementASHOK KUMAR LENKANo ratings yet

- Requirement of Embossing Letter Details For Blister Packing Change PartsDocument2 pagesRequirement of Embossing Letter Details For Blister Packing Change PartsASHOK KUMAR LENKANo ratings yet

- 14MA GarciaDocument10 pages14MA GarciaMusab Hashmi100% (1)

- List of Instru - Equip.Document2 pagesList of Instru - Equip.ASHOK KUMAR LENKANo ratings yet

- Amit ResumeDocument5 pagesAmit ResumeASHOK KUMAR LENKANo ratings yet

- XL - PC Report - 2,3,4,5,6 - Feb - 17Document84 pagesXL - PC Report - 2,3,4,5,6 - Feb - 17ASHOK KUMAR LENKANo ratings yet

- Stability: Basic CoarseDocument79 pagesStability: Basic CoarseASHOK KUMAR LENKANo ratings yet

- Suppliers ListDocument3 pagesSuppliers ListASHOK KUMAR LENKANo ratings yet

- Annexure 01 Job Responsbility FormDocument1 pageAnnexure 01 Job Responsbility FormASHOK KUMAR LENKANo ratings yet

- Job responsibility form templateDocument1 pageJob responsibility form templateASHOK KUMAR LENKANo ratings yet

- Procurement: Balance Capacity Least Count Type of Balance No. of Items Placement Digit of Display RequirementDocument2 pagesProcurement: Balance Capacity Least Count Type of Balance No. of Items Placement Digit of Display RequirementASHOK KUMAR LENKANo ratings yet

- Nicotinamide COADocument2 pagesNicotinamide COAASHOK KUMAR LENKANo ratings yet

- Polysorb 85 - 70 - 00 RM COADocument2 pagesPolysorb 85 - 70 - 00 RM COAASHOK KUMAR LENKANo ratings yet

- Peanut Oil COA AnalysisDocument2 pagesPeanut Oil COA AnalysisASHOK KUMAR LENKANo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Generation of Optical Chirality by The Tightly Focused Higher-Order PoincaréDocument7 pagesGeneration of Optical Chirality by The Tightly Focused Higher-Order PoincaréYounouss KEITANo ratings yet

- 准直镜Document9 pages准直镜陈森淼No ratings yet

- Bohr Model of Hydrogen AtomDocument26 pagesBohr Model of Hydrogen AtomDERICK YINDANo ratings yet

- (Ebook - Science.physic - Eng) .Wevers - Physics FormularyDocument108 pages(Ebook - Science.physic - Eng) .Wevers - Physics FormularyKostas LiapisNo ratings yet

- 5054 w17 QP 11Document20 pages5054 w17 QP 11Saad ArsalanNo ratings yet

- Modulator ManualDocument25 pagesModulator ManualRishi MaitiNo ratings yet

- Thermal Scanning ReportDocument26 pagesThermal Scanning ReportBer Salazar JrNo ratings yet

- Optical MEMS: MECH 466 Microelectromechanical SystemsDocument19 pagesOptical MEMS: MECH 466 Microelectromechanical SystemsDeePak AJayNo ratings yet

- Engineer Info Report 9199-8910 MW MOD PDocument23 pagesEngineer Info Report 9199-8910 MW MOD PNomaan MalikNo ratings yet

- Physics 72.1 Peer ReviewDocument12 pagesPhysics 72.1 Peer Reviewviviene24No ratings yet

- Reverse EngineeringDocument81 pagesReverse EngineeringkajalNo ratings yet

- Question: Why Light Is Bend While Passing From One Medium To Another Medium? Answer: When Light Passes From One Medium To Another, The Moving Direction of Light Changes. TheDocument2 pagesQuestion: Why Light Is Bend While Passing From One Medium To Another Medium? Answer: When Light Passes From One Medium To Another, The Moving Direction of Light Changes. Theshouvik100% (1)

- Archive Test Series JEE (Main) 2024 - Version 2.0Document2 pagesArchive Test Series JEE (Main) 2024 - Version 2.0mishraanuj3011No ratings yet

- ATOMIC ABSORPTION SPECTROSCOPYDocument18 pagesATOMIC ABSORPTION SPECTROSCOPYSoumya MitraNo ratings yet

- 100+ Creative Photography IdeasDocument108 pages100+ Creative Photography IdeasSaurabh0% (1)

- Bcva. LogmarDocument4 pagesBcva. LogmarDita MintardiNo ratings yet

- LightingDocument26 pagesLightingCollenne Kaye-Lie Garcia UyNo ratings yet

- E2297 22942 PDFDocument5 pagesE2297 22942 PDFvelu100% (1)

- LightDocument11 pagesLightamp1279No ratings yet

- A Model of Low Grazing Angle Sea Clutter For Coherent Radar Performance AnalysysDocument45 pagesA Model of Low Grazing Angle Sea Clutter For Coherent Radar Performance AnalysysPavel Schukin100% (1)

- Battle of The Brains Olathe East 2020Document4 pagesBattle of The Brains Olathe East 2020Aaditya PoreNo ratings yet

- Unesco - Eolss Sample Chapters: Solar Radiation Energy (Fundamentals)Document10 pagesUnesco - Eolss Sample Chapters: Solar Radiation Energy (Fundamentals)Petrescu VasileNo ratings yet

- Single-Mode Fibre, E9 - 125 - 250, OS2 - G.652.D PDFDocument1 pageSingle-Mode Fibre, E9 - 125 - 250, OS2 - G.652.D PDFDrago AndrijevicNo ratings yet

- Chapter-41 Electromagnetic WavesDocument17 pagesChapter-41 Electromagnetic Wavesökkeş kurtNo ratings yet

- Optics Mirrors and LensesDocument43 pagesOptics Mirrors and LensesKwenzie FortalezaNo ratings yet

- Chapter 06Document53 pagesChapter 06Sigmund PohanNo ratings yet

- Galaxy Lighting 2021-2022 灯饰目录Document240 pagesGalaxy Lighting 2021-2022 灯饰目录qq1691492197No ratings yet

- Nanoscribe Training - QiangDocument9 pagesNanoscribe Training - QiangHiba AljayuousiNo ratings yet

- A Guide To Experiments in Quantum Optics, Second Edition (2004)Document433 pagesA Guide To Experiments in Quantum Optics, Second Edition (2004)Pradeep Elangovan100% (1)

- Ficha Tecnica Del Cable de Fibra ADSS SJ RP LSZHDocument9 pagesFicha Tecnica Del Cable de Fibra ADSS SJ RP LSZHGersson ColmenaresNo ratings yet