Professional Documents

Culture Documents

EP60042 Engineering Design Process

Uploaded by

IndranilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EP60042 Engineering Design Process

Uploaded by

IndranilCopyright:

Available Formats

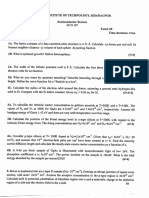

INDIAN INSTITUTE OF TECHNOLOGY, KHARAGPUR

Date: FN/AN, Time: 2 Hrs., Full Marks: 30, Deptt: Rajendra Mishra School of Engineering

Entrepreneurship, No. of Students: 130, Mid Spring Semester Examination, Sub. No. EP60042,

Sub Name: Engineering Design Process, __ Yr. B.Tech.(H) I B.Arch.(H) I M.Sc.1 M.Tech(Dual)

Instruction: Please write in brief and to the point.

1. a) "QFD is an important step in Engineering Design" - Explain.

b) Five possible {Technical Descriptors' are to be considered at secondary level - two in {material' sub-

head and three in 'process' sub-head under two primary level grouping, in developing a product chosen

by you. Description of four 'Customer Requirements' at the secondary level comprising two each under

two primary level groupings for the same are also to be considered based on a survey for the above

product in a standard QFD template. Numerical values as 6, 7, 4 and 8 in a scaie of 1 to 10, arranged

from top to bottom, as column vector, signifies importance of Customer Requirements. The

corresponding 'Scale-Up Factor' as 1.3, I, 1 and 1.3; and the' Sales Point' as 1.5,2, I, and 1 may also

be considered. Values as 9, 3 and 1 may be assigned for symbols for (Strong', 'Medium' and 'Weak'

respectively in the inter-relationship matrix, applicable according to your consideration. (i) Construct

the HoQ diagram including the inter-relationship among Technical Descriptors, assuming data as

required and (ii) determine the Relative Weights of the Technical Descriptors as row vector, showing

detailed computation for the first column.

c) Expound RPN in Design FMEA [Marks: 2+ (5+4)+2 = 13]

2. a) Illustrate the steps involved in Engineering Design Process.

b) Describe 'Alpha' and 'Beta' prototyping, with an example.

c) Exemplify 'Product Architecture' with reference to household electric fans [Marks: 2+2+2 = 6]

3. a) Elucidate the consideration of Process capability in engineering design. (b) Compute Cpm and Cpkm,

considering a design characteristic with target of 10011and upper and lower specifications limit of 10411and

9611.The process average (11)is 99.6 and the standard deviation is 1.02. [Marks: 1+2=31

4. The following is the description of an .engineering product, having three designed components P, Q and R

in series. P has a reliability value of 0.75 and cost as Rs.2000/-; Q has a reliability value of 0.92 and cost as

Rs.4000/- and R has a reliability value of 0.89 and cost as Rs.6000/-. The current selling price of the product is

Rs. 14000/-. A proposal of redesigning P as P' is under consideration to upgrade the reliability of the

component to 0.81 and the corresponding cost will be Rs 3000/-. P or P' as single component or in parallel

combinations can be configured in the design to improve product reliability. The packaging, however, does not

allow more than two of the same components or its variants. Therefore, besides P or P' singly, any of the

combinations, P and P; P and P'; P' and P' only can be designed. Recommend the most profitable design, if the

selling prices are Rs. 16000/-, Rs. 18000/- and Rs. 21000/- corresponding to the reliability value-ranges as

0.65-0.75, above 0.75- 0.78 and above 0.78. [Marks: 4]

5. Consider a product in engineering manufacturing, where (i) material, (ii) labour and manpower and (iii)

overhead costs are in the order of 60%, 10% and 20% respectively. The resultant profit is 10%. Design

improvement in product features helps to add a premium of 6% to the price. The sales volume also, due to

such improvement, goes up by 7%. Elucidate with a numerical example, (a) the impact of design improvement

on profit due to the above. Further, (b) show as to how the profit is impacted with a material cost reduction,

through value engineering in design, to the tune of 5%. [Marks: 3+1=4]

You might also like

- Complete PCB Design Using OrCAD Capture and PCB EditorFrom EverandComplete PCB Design Using OrCAD Capture and PCB EditorRating: 5 out of 5 stars5/5 (1)

- RPL Engg Drawing NSQF-6Document9 pagesRPL Engg Drawing NSQF-6Safvan KhansahebNo ratings yet

- CV Nataraj M 19Document4 pagesCV Nataraj M 19Nataraj ShettyNo ratings yet

- Rapid Technologies in Integrated Product Development B. Dyba A, E. Chlebus, T. BoratyñskiDocument4 pagesRapid Technologies in Integrated Product Development B. Dyba A, E. Chlebus, T. Boratyñskimohanmech2006886No ratings yet

- Shri G. S. Institute of Technology and ScienceDocument32 pagesShri G. S. Institute of Technology and Scienceabhaymvyas1144No ratings yet

- TQM - House of quality 1Document31 pagesTQM - House of quality 1an7l7aNo ratings yet

- CFD ProjectDocument4 pagesCFD ProjectkrukshNo ratings yet

- Software Project Management - Ci30130 - Set 1Document4 pagesSoftware Project Management - Ci30130 - Set 1Shashank VinitNo ratings yet

- Gujarat Technological University Master of Engineering Subject Code: 3722023 Subject Name: 2 SemesterDocument3 pagesGujarat Technological University Master of Engineering Subject Code: 3722023 Subject Name: 2 SemesterHardik JogranaNo ratings yet

- Guidelines-Facility Industrial DesignDocument3 pagesGuidelines-Facility Industrial Designkhanh123ctmNo ratings yet

- Ecm366 Oct23-Feb24Document8 pagesEcm366 Oct23-Feb24Nurhuda AlyaNo ratings yet

- IDT Report Format & Guildlines Sem 7Document10 pagesIDT Report Format & Guildlines Sem 7bolewNo ratings yet

- Value Engineering Value Management-1Document34 pagesValue Engineering Value Management-1gokultheking100% (3)

- IU BIM Execution Plan TemplateDocument15 pagesIU BIM Execution Plan TemplateAnonymous 9iK0i8h0dPNo ratings yet

- Unit 26 CNC Assignment m1Document6 pagesUnit 26 CNC Assignment m1Eslam Mohammed AhmedNo ratings yet

- Assignment 2Document6 pagesAssignment 2Zeeshan AmjadNo ratings yet

- CH 10Document7 pagesCH 10Witness Wii MujoroNo ratings yet

- PROJECT WORK - Ind VisitDocument11 pagesPROJECT WORK - Ind VisitSachi MensiNo ratings yet

- Computer Applications in ArchitectureDocument21 pagesComputer Applications in ArchitecturePramod M ChauguleNo ratings yet

- Quality Function Deployment (QFD) : Mohan Khond Mechanical Engineering Department College of Engineering, PuneDocument18 pagesQuality Function Deployment (QFD) : Mohan Khond Mechanical Engineering Department College of Engineering, Punesan_02No ratings yet

- Aarón Rodríguez CVDocument1 pageAarón Rodríguez CVAaron RNo ratings yet

- Revision Questions 2222Document13 pagesRevision Questions 2222abdullah 3mar abou reashaNo ratings yet

- Guidelines For B.Tech Project Report Preparation: Order of The ContentsDocument10 pagesGuidelines For B.Tech Project Report Preparation: Order of The ContentsbhushansoniNo ratings yet

- Eduqas A Computer Science Sams From 2015Document48 pagesEduqas A Computer Science Sams From 2015Mohsin Khubaib AhmedNo ratings yet

- Final Reprt of 8th Sem TrainingDocument15 pagesFinal Reprt of 8th Sem TrainingPrabhanshu RanjanNo ratings yet

- All Tasks Solved Immediate Download: Requirements For Business Intelligence Capstone ProjectDocument8 pagesAll Tasks Solved Immediate Download: Requirements For Business Intelligence Capstone ProjectShivaani AggarwalNo ratings yet

- Estimating, Costing and Contracting (ECC)Document5 pagesEstimating, Costing and Contracting (ECC)Bharath A100% (1)

- A Project Proposal On: Group MembersDocument14 pagesA Project Proposal On: Group MembersMerina AdhikariNo ratings yet

- Instructions For Preparation of Practical Training ReportDocument7 pagesInstructions For Preparation of Practical Training ReportPankaj Kumar SharmaNo ratings yet

- Series B - Paper 2 QPDocument12 pagesSeries B - Paper 2 QPPatience MhakaNo ratings yet

- TITLE of Project: (On A Separate Title Page. List The Name of The "Project Leader" and The Member With TheirDocument1 pageTITLE of Project: (On A Separate Title Page. List The Name of The "Project Leader" and The Member With Theirjesus_vitangcolNo ratings yet

- Question Paper Code A12405 Software Engineering ExamDocument3 pagesQuestion Paper Code A12405 Software Engineering Exam4063pavan kalyan .sNo ratings yet

- M.Tech.: Computer Aided Design and ManufacturingDocument2 pagesM.Tech.: Computer Aided Design and ManufacturingbrarsidhuNo ratings yet

- Software Engineering Exam QuestionsDocument1 pageSoftware Engineering Exam QuestionsGomathi Computer ScienceNo ratings yet

- CWorkshop Parametric EstimateDocument3 pagesCWorkshop Parametric EstimateMARIO CELIS ACUNANo ratings yet

- University Mauritius Exam Software EngineeringDocument5 pagesUniversity Mauritius Exam Software Engineeringmy pcNo ratings yet

- Grade 12 IB DP Design Technology Internal Assessment - 2019/20Document6 pagesGrade 12 IB DP Design Technology Internal Assessment - 2019/20Harveen Kaur AnandNo ratings yet

- Semester IDocument17 pagesSemester IAnnantNo ratings yet

- CHEM ENG 3030 Design Project 2017Document12 pagesCHEM ENG 3030 Design Project 2017ThiênHiếuNo ratings yet

- GUIDELINES DraftDocument19 pagesGUIDELINES DraftRahul KumarNo ratings yet

- Expert Manufacturing Engineer Seeks New ChallengeDocument4 pagesExpert Manufacturing Engineer Seeks New ChallengeSudhir KulkarniNo ratings yet

- Plot No. 50, Sector 18 A, Nerul (W), Navi Mumbai Email: PhoneDocument2 pagesPlot No. 50, Sector 18 A, Nerul (W), Navi Mumbai Email: Phonepranal_mNo ratings yet

- Project FormatDocument11 pagesProject FormatPriyaNo ratings yet

- Skmm4513 Cad Project Sem 1 1516Document4 pagesSkmm4513 Cad Project Sem 1 1516Puvendran Balakrishnan100% (2)

- Winter - 18 Examination Subject Name: Estimating and Costing Model Answer Subject CodeDocument14 pagesWinter - 18 Examination Subject Name: Estimating and Costing Model Answer Subject CodenoorNo ratings yet

- ELEC3117-2010 Exam PaperDocument6 pagesELEC3117-2010 Exam PaperKris KrisNo ratings yet

- Coursework Assignment: LinksDocument7 pagesCoursework Assignment: LinksSalman KhanNo ratings yet

- NIT Rourkela Mid-Semester Exam for SPPQMDocument11 pagesNIT Rourkela Mid-Semester Exam for SPPQM36rajnee kantNo ratings yet

- QFD ChapterDocument23 pagesQFD Chapterarun paulNo ratings yet

- Building Proposal For ACME CollegeDocument4 pagesBuilding Proposal For ACME CollegeSiddhartha PokhrelNo ratings yet

- TECHNICAL DRAFTING COURSEDocument2 pagesTECHNICAL DRAFTING COURSEalbert corbillaNo ratings yet

- TQM-QFD Lect-Slides-Spring 2023Document39 pagesTQM-QFD Lect-Slides-Spring 2023Mubashar FareedNo ratings yet

- QB CT1 21-22 SenDocument2 pagesQB CT1 21-22 Senrohitmhaske0208No ratings yet

- Cad Cam NotesDocument122 pagesCad Cam NotesSUPRADEEP G100% (1)

- 1213sem2 Me5612Document5 pages1213sem2 Me5612Jeremy TohNo ratings yet

- Task Requirements SummaryDocument2 pagesTask Requirements Summarysomesh vanjaleNo ratings yet

- Project File Checkpoint 3Document7 pagesProject File Checkpoint 3مستر عبداللهNo ratings yet

- R07 Set No. 2Document7 pagesR07 Set No. 2nandusp1No ratings yet

- Please Note:: Physician (AFP) Costs $19,699, and There Are 80,601 Family Practitioners Who SubscribeDocument4 pagesPlease Note:: Physician (AFP) Costs $19,699, and There Are 80,601 Family Practitioners Who SubscribevaishNo ratings yet

- RF and Microwave EngineeringDocument3 pagesRF and Microwave EngineeringIndranilNo ratings yet

- Microcontroller and Embedded SystemsDocument2 pagesMicrocontroller and Embedded SystemsIndranilNo ratings yet

- 2014 Mid Spring EV20001Document1 page2014 Mid Spring EV20001IndranilNo ratings yet

- 2015 End Autumn EC31003Document3 pages2015 End Autumn EC31003IndranilNo ratings yet

- Microcontroller and Embedded SystemsDocument2 pagesMicrocontroller and Embedded SystemsIndranilNo ratings yet

- EP60042 Engineering Design ProcessDocument1 pageEP60042 Engineering Design ProcessIndranilNo ratings yet

- ALL The EIGHT Questions: Indian Ins-R:Itl:Jte of Technology, KharagpurDocument2 pagesALL The EIGHT Questions: Indian Ins-R:Itl:Jte of Technology, KharagpurIndranilNo ratings yet

- Mid Spring 2016 EC31006 PDFDocument2 pagesMid Spring 2016 EC31006 PDFIndranilNo ratings yet

- EC31 006 Microcontroller and Embedded SystemsDocument2 pagesEC31 006 Microcontroller and Embedded SystemsIndranilNo ratings yet

- 2012 End Spring EC21004Document2 pages2012 End Spring EC21004IndranilNo ratings yet

- 2014 Mid Spring BS20001Document6 pages2014 Mid Spring BS20001IndranilNo ratings yet

- CS, CH, MF,: Section-2Document2 pagesCS, CH, MF,: Section-2anirudtNo ratings yet

- EC31008 Digital Signal ProcessingDocument1 pageEC31008 Digital Signal ProcessingIndranilNo ratings yet

- Digital Signal ProcessingDocument2 pagesDigital Signal ProcessingIndranilNo ratings yet

- Microcontroller and Embedded SystemsDocument2 pagesMicrocontroller and Embedded SystemsIndranilNo ratings yet

- Mid Spring 2016 EC31006 PDFDocument2 pagesMid Spring 2016 EC31006 PDFIndranilNo ratings yet

- 2014 Mid Spring BS20001Document6 pages2014 Mid Spring BS20001IndranilNo ratings yet

- EC31008 Digital Signal ProcessingDocument1 pageEC31008 Digital Signal ProcessingIndranilNo ratings yet

- #Indian Institute of Technology, Kharagpur: Answer The QuestionsDocument1 page#Indian Institute of Technology, Kharagpur: Answer The QuestionsIndranilNo ratings yet

- EC31 006 Microcontroller and Embedded SystemsDocument2 pagesEC31 006 Microcontroller and Embedded SystemsIndranilNo ratings yet

- EC31 006 Microcontroller and Embedded SystemsDocument2 pagesEC31 006 Microcontroller and Embedded SystemsIndranilNo ratings yet

- Mid Spring 2016 EC31006 PDFDocument2 pagesMid Spring 2016 EC31006 PDFIndranilNo ratings yet

- Mid Spring 2016 EC31006 PDFDocument2 pagesMid Spring 2016 EC31006 PDFIndranilNo ratings yet

- EP60042 Engineering Design ProcessDocument1 pageEP60042 Engineering Design ProcessIndranilNo ratings yet

- Microcontroller and Embedded Systems - 1Document1 pageMicrocontroller and Embedded Systems - 1IndranilNo ratings yet

- 2011 End Autumn MA21007Document2 pages2011 End Autumn MA21007IndranilNo ratings yet

- EC31008 Digital Signal ProcessingDocument1 pageEC31008 Digital Signal ProcessingIndranilNo ratings yet

- 2012 Mid Autumn EC21107Document2 pages2012 Mid Autumn EC21107IndranilNo ratings yet

- 2010 Mid Autumn EC21107Document2 pages2010 Mid Autumn EC21107IndranilNo ratings yet

- Saint Gb334 Final Exam (Questions)Document8 pagesSaint Gb334 Final Exam (Questions)teacher.theacestud0% (1)

- D10 CacDocument4 pagesD10 CacaskermanNo ratings yet

- HSC Business Studies Summary Notes by Nathan ReidyDocument35 pagesHSC Business Studies Summary Notes by Nathan ReidyDivesh Singh100% (3)

- Chapter 6 Financial StrategyDocument5 pagesChapter 6 Financial StrategySweta KumariNo ratings yet

- Chapter 3Document18 pagesChapter 3Abhirup SenguptaNo ratings yet

- Issues in Revised Schedule VI - Sushrut Chitale 15072012Document64 pagesIssues in Revised Schedule VI - Sushrut Chitale 15072012Anish NairNo ratings yet

- AltaRock Mid 2011 LetterDocument15 pagesAltaRock Mid 2011 LetterAnoop Kamlesh Davé100% (1)

- 223 JayakumarDocument33 pages223 JayakumarUniq ManjuNo ratings yet

- Kales TablesDocument61 pagesKales TablesmgajenNo ratings yet

- Financial Strategy: Retailing Management 8E © The Mcgraw-Hill Companies, All Rights ReservedDocument30 pagesFinancial Strategy: Retailing Management 8E © The Mcgraw-Hill Companies, All Rights ReservedYadav Krishna100% (2)

- Implementing TQ in The Construction Industry - A Practical GuideDocument279 pagesImplementing TQ in The Construction Industry - A Practical Guidechrispittman100% (1)

- Budgetary Control, Mar Cost c0st ST, Res AcDocument29 pagesBudgetary Control, Mar Cost c0st ST, Res AcYashasvi MohandasNo ratings yet

- Introduction To BusinessDocument7 pagesIntroduction To BusinessRishabh RankaNo ratings yet

- SAP Shortcut KeyDocument19 pagesSAP Shortcut KeyPhani PatibandlaNo ratings yet

- Profitability AnalysisDocument23 pagesProfitability AnalysisAmit PandiaNo ratings yet

- Internship Report (Finance Dept)Document31 pagesInternship Report (Finance Dept)Bilal Arshad86% (7)

- Village Farms AnalysisDocument26 pagesVillage Farms AnalysisAhmed Al-ownNo ratings yet

- Vol. 4 Issue 2 FullDocument90 pagesVol. 4 Issue 2 FullOmPrakashNo ratings yet

- VP Sales Marketing Food in Philadelphia PA Resume Steve ByruchDocument3 pagesVP Sales Marketing Food in Philadelphia PA Resume Steve ByruchSteve ByruchNo ratings yet

- Estée Lauder Expands GloballyDocument5 pagesEstée Lauder Expands GloballyMhegan ManarangNo ratings yet

- 2010 F2Document63 pages2010 F2Rehman MuzaffarNo ratings yet

- Practice Note PN 3.209 The Dangers of Fee CuttingDocument4 pagesPractice Note PN 3.209 The Dangers of Fee CuttingWarren NicholsonNo ratings yet

- Strategic ManagementDocument196 pagesStrategic ManagementSateesh Prem GuptaNo ratings yet

- CH 18Document51 pagesCH 18NghiaBuiQuang100% (4)

- IBM Planning Analytics Data SheetDocument8 pagesIBM Planning Analytics Data SheetSujit True BlueNo ratings yet

- Summary & Questions Quality Metal Service CenterDocument2 pagesSummary & Questions Quality Metal Service CenterRahul RathoreNo ratings yet

- 6.dia Represn in Biz StatisticsDocument6 pages6.dia Represn in Biz StatisticsBoobalan RNo ratings yet

- Business Environment NotesDocument88 pagesBusiness Environment NotesShaikh NazafNo ratings yet

- Strategic Management Example - Harta LegaDocument40 pagesStrategic Management Example - Harta Leganad78% (9)

- II Semester 2016-17 Course Handout BAV ECON F355Document19 pagesII Semester 2016-17 Course Handout BAV ECON F355Tushit ThakkarNo ratings yet