Professional Documents

Culture Documents

Shor Brace

Uploaded by

Muhammad ZuhayrCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shor Brace

Uploaded by

Muhammad ZuhayrCopyright:

Available Formats

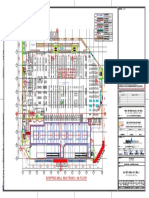

ALUMINIUM Symbol 1 ) All Dimensions are in millimeters (mm) unless otherwise mentioned:

BEAM SECTION

Legend 2 ) Bay sizes for Scaffolding not to exceed ________ , Unless otherwise mentioned:

TIMBER BEAM H 20 5.90m 3 ) Portions /Areas not covered by Scaffolding should be supported by the

FRAME

SHORBRACE TIMBER BEAM H 20 4.90m Universal jack Contractor as per site condition.

ELEVATION FRAME TIMBER BEAM H 20 3.90m

The Customer is responsible for ensuring that all structures are adequately braced

and/or tied to carry the load and ensure stability as indicated on the drawing. No braces

TIMBER BEAM H 20 3.60m Base jack or ties are to be removed with Manar concern

TIMBER BEAM H 20 3.30m Temporary working platforms for erection or Dismantling purpose will be designed,

CROSSBRACE

TIMBER BEAM H 20 2.9m Cantilever frame Supplied and fitted by customer. Customer is responsible to ensure that working

FRAME platform or means of access necessary for safe access are provided whether shown

TIMBER BEAM H 20 2.45m Shorbrace frame on this drawing or not

TELESCOPIC TIMBER BEAM H 20 1.90m

BRACING TUBE

FRAME Cross Bracing 0.9M a . Erection of Scaffolding should be as per the Drawing .

U HEAD b . Max distance ( Spacing ) Between Ledger to Ledger is 1.5m .

Cross Bracing 1.2M

c . Manar does not supply labours or technical supervision . The responsibility of

Customer includes the method ,control and suitability of all sequencing, the time

checking, loading , striking, movement , lifting and Stripping of the temporary work and the

Crossbrace 1.5m design , supply and erection of any temporary working platform for erection & dismantling.

750 7690 a . Back propping may be required . Back propping is the responsibility of the

Crossbrace 1.8m

MAX. 4500 mm

Customer..

550 MM

2000 4000 Crossbrace 2.1m

4500

4500

THICK. a . Loads on forms and falsework have been analyzed in accordance with the Guide for Formwork

A23 A25 and BS 5975 & 5973 , Code of practice for False Work :

2000

B40 +18.15

b . Loads are assumed as Uniformly Distributed.

c . Dead Load of structure has been considered in designing of Scaffolding, excluding of Finishing

loads.

1875

d . For Removing (dismantling /unfixing) of Scaffolding, the contractor must check for cube

strength. This is the responsibility of contractor.

3875

4000

e .This drawing is prepared based on the information Provided to us by the customer.

However, it is the responsibility of client to verify and check the requirements of loading

assumptions,details, dimensions, erection sequences etc. as as required.

2000

1. For Slabs & Beams

Density Of Concrete 25.00 KN/m^3

2020 2000 2000 Weight of Formwork

Live Load ( BS 5975 )

0.48 KN/m^2

_____ KN/m^2

2000 4000 Total Load

2. For Walls & Columns

_____ KN/m^2

1800

Max Allow Load For Walls _____ KN/m^2

B49

Max Allow Load For Columns _____ KN/m^2

500

Max Design Wind Pressure _____KN/m^2

+10.15

2 2 PC1 Raw-material properties used for fabrication of our Falsework are ,

1

I . Plywood

Thickness of plywood : 18 mm

6000

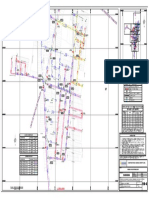

X13 SECTION A - A X11

Allowable Stresses :

1

Fb=1200 PSI= 8.27 N/mm2 , Fv= 53 PSI= 0.365 N/mm2

+18.15 Fc =1.200,000 PSI or 8273.76 N/mm2, L/ 360 ( As per ACI )

II . Manar Alluminium Beam

Allowable Bending Moment 8.75 N/Sqm

4000

4000

Allowable Shear Force 45.11 N/Sqm

Quality,Satisfaction, Economy and safety are our main objectives. Therefore, if any

inconvenient with our offered design , our highly qualified and experienced design team

will work with you to reach your target and goal .

This drawing is the property of MANAR AL OMRAN. Any unauthorized use of this

1

4000

4000

drawing is considered illegal and subject to legal action by MANAR. This drawing is

NOT VALID UNLESS SIGNED AND STAMPED BY MANAR DESIGN DEPT.

1

2 2 DRAWING STATUS

FOR APPROVAL FOR CONSTRUCTION

AW LE

G

This Drawing is for This Drawing has been

2000 4000

+18.15AREA: 350.00 m Technical Discussion ,

issued for construction

DR MP

IN

450 MM +10.15

Pricing and Approval

by the Client. Unless

with acceptance of

2000 4000

B48

AREA: 350.00 m THICK. issued and signed in client with respect to

SA

Construction Status, design.

this drawing forms

B48

By______________

SECTION B - B

B48

no part of Agreement.

DATE ____________

By ______________

B40 B-B B1 B2 B3 B4 B5 B6 B7 B8 B9 B10 B11 B12 B13 B14 B15

DATE ____________

Y7 Y9 Y10

MAO

Y11

Y8

PC1 Y12

100

X2

2000

4600

B9 6000 6000

2000 2000

4000

3005 4000

0

2000 200

400

12170 4000

2000

2000

5500 3500 00

0 20

0

00

2000

2000 20

B71

200

B49

6000

2000

B44

PC1

4000 450 MM

4000

PC2

THICK. 00

20

2625

2625

2620

550 0 2000

2000 2000

0 200

4600 200 Y13

X3

00

2000 2000

1540 3460

0 20 1310

RB 1250X900

4000

200

WITH RAMP

B48

AREA: R10 R10

20002000 200

0 B60

1

2000

2000 2000

0

400

400

2000 4000

2000 4825 2000

6330

400

4000

0

4000

400 MM

0

2285 2285

2000

THICK. B47 B16

X4

2000

B62

B62

3890

4500 5540 TYPE "4" TYPE "2" 1825

B44

PC5

9000

B71

B56

B83

R17 R17

2000 2000

2000

B21

4000

X5

2000

3675

3675

FOR RAMP LEVELS REFER

4000

B61

TO ARCH. DRAWINGS 2000

B61

3375

4000 TYPE "2"

9000

B55

B74

R17 R17

4000 1375

4000 4000

1275 STEEL FLOOR B60

20002000

PC1

300

X6

1690

B21

750 7690

B78

750 MM

B55

B24

MAX. 4500 mm

R19 R19

THICK.

X6'

550 MM

2000 4000 4000 2000

4500

4500

4500

4500

4500

4500

4500

4500

4500

1275 TYPE "2" TYPE "2" THICK.

2000 2000

2000

2000

300 MM PC1 B21 B40

300

THICK.

X7

1875

1875

1875

1875

1875

1875

RAMP B17

3875

3875

3875

3875

4000

4000

550 MM

R19 R19 THICK. 3000 2000 2000 20002000 20002000

B77

4000 2000

B55

B2

B50

B40

20002000 2020 20002000

B47 2000 2000 20002000 2400 20002000 2000 2000

4500

2000 4000 4000 2000

2500

400 MM

4825

2000 2000

2000 2000

2000 2000

2000 2000

1800

1800

PC1

THICK.

B49

B49

500

X8

+18.15

R3

2 2 PC1

T.O.S

1

1

2000 4625 4250

3 4000 2000 550 MM 6000 2000 20002000 2000 2000

9000

1

B54

B2

THICK. 2000 4000

B76

3600 4000 2000 2000

4000

4000

4000

4000

4000

B47

20002000

2000 2000

2000

2190 1960

B56

4760

X9

2000

4000

4000

4000

4000

2000

B1

1

B75 950 MM 20002000 2 2

9000

2000

B18

B21

THICK.

2000 2000 2000

2000 4000

2000 2375 450 MM +18.15

B56 B51 B53 B52

B48

WITH

B48

THICK.

CLIENT:

RAMP

23501650

B71 T.O.S

B40 B-B

4000

X10

MAO

2200

2200

4000

2500

7600

B21 (MAX.) TYPE "4"

TYPE "1" TYPE "4"

2020

20002000 2000 2000 X10'

B25

(MAX.) 2000 2000 20002000 2000 4000

2375 2000 2000 20002000

2000 2000

4000

3675

3675

3675

3675

STEEL FLOOR

DHABI CONTRACTING

2800

2125

1675

1675

1675

1675

B60

TYPE "3"

X11

4000

4500

4825

4825

B28

B19

5200

TYPE "1"

(MAX.)

4255

4000

A-A

2000

3800

2000

A-A

B59

B22

X12

2000

17500 950 MM

MAO

(MAX.) THICK.

2000 2000 2000 4000

2000 2375 B20

CONSULTANT :

4825

4825

4500

4000

4000

MAO

TYPE "1" TYPE "1" TYPE "4"

2000

B71 X13

1875

3675

3675

3675

3675

3675

3675

3675

3675

3675

4000

4000

4000

4000

950 MM

B21

B25

2750 950 MM 2000 2000 20002000 2050 1950

2000 2000 2000 2000 2000 2000 2000 2000 2000 4000 4000

5800

2000 2000 2000 2000

THICK. B21

750 MM

THICK. THICK.

X14

2800

2625

1935 2065 20002000 2000 2000 2000 6750 4000 2000 2000 2000 2000 2000 2000 4000 4000 2000 20002000 2000 2000

4200 9000 3400

2000

2000 2000 2000 2000

B22

4605

4605

4605

4605

4605

4605

4505

B1 B2 B2 B2 B2 B2 B6 B46 B65 B1 B2 B4 B5 B2

4000

B3

X15

2750

B23

SUPPLIER:

B24 MANAR AL OMRAN

Salim Bin Hendi Al Harbi Est.

4825

4500

B25

FOR CONTINUTION REFER TO DWG FORMWORKS & SCAFFOLDING

B26

D14099-0100D-H-TD-SC-1-0101

B27

B28

B29

B30

PROJECT TITLE:

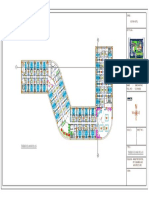

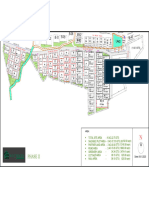

SHOPPING MALL @ JUMEIRAH

3675

3675

3675

B31

4000

B32

B33

DRAWING TITLE: SAMPLE PART DWG

SHORBRACE FOR SLAB

A1 A2 A3 A4 A5 A6 A7 A8 A9 A10 A11 A12 A13 A14 A15 A16 A17 A18 A19 A20 A21 A22 A23 A25 A26 A27

SCALE TECHNICAL

A24

DRAWN DESIGNED DATE

MANAGER

2000 2000 2000 4000 4000 2000 2000 PARTIAL AREA FOR

KEY PLAN - PARTIAL FIRST FLOOR PART 4 OF 4 SAMPLE DESIGN

ENG'R.EMERSON 23/10/2016 AS SHOWN ENG'R.SHAHID

AREA: 572.00 m DRAWING NUMBER REV. A

You might also like

- Side Shell: Oro Jackson Shell ExpansionDocument1 pageSide Shell: Oro Jackson Shell ExpansionAdly AlandaNo ratings yet

- ElectricalDocument1 pageElectricalisotect.contractsNo ratings yet

- Thrusters Fresh Cooling Water SystemDocument1 pageThrusters Fresh Cooling Water SystemAndreas SofianidisNo ratings yet

- Portfolio - Celestino, RhineDocument8 pagesPortfolio - Celestino, RhineAnonymous 9I5RViWz8UNo ratings yet

- VH Ad 2 VHHH Aoc 4 (Typec)Document1 pageVH Ad 2 VHHH Aoc 4 (Typec)Loïc GIROUDNo ratings yet

- Notes:: Drop 50 MM Drop 50 MM Drop 50 MMDocument1 pageNotes:: Drop 50 MM Drop 50 MM Drop 50 MMassis alihNo ratings yet

- Direction Flow: SheetDocument1 pageDirection Flow: SheetTusarkanta BiswalNo ratings yet

- GR An Ite As /ap PR Ov Al: DC - 4 DC - 5 DC - 6Document1 pageGR An Ite As /ap PR Ov Al: DC - 4 DC - 5 DC - 6AVINASHNo ratings yet

- Huawei P30 Pro SchematicDocument77 pagesHuawei P30 Pro Schematicmaciej.gugolNo ratings yet

- Struct. Metallique Du HangarDocument1 pageStruct. Metallique Du HangarNourreddine HabibNo ratings yet

- Jamundi Project F24S New Proposal Level 2Document1 pageJamundi Project F24S New Proposal Level 2mariconsuelo rosa melanoNo ratings yet

- CBE Approved ROB-55 Launching 8.06.21Document1 pageCBE Approved ROB-55 Launching 8.06.21Ravikant YadavNo ratings yet

- Detail Layout Plan of Proposed Fuel Filling Station at Lhs of NH 146 at Vidisha Sagar Road On Undivided Carriage Way (SCALE1 IN 500)Document1 pageDetail Layout Plan of Proposed Fuel Filling Station at Lhs of NH 146 at Vidisha Sagar Road On Undivided Carriage Way (SCALE1 IN 500)abhijeet sahu0% (1)

- 9m Ev Electrical LV SchematicDocument1 page9m Ev Electrical LV SchematicShankar NaiduNo ratings yet

- Mayfair LOTS 4 & 10 Buildings 4-6: Building 6 Slab Edge PlanDocument1 pageMayfair LOTS 4 & 10 Buildings 4-6: Building 6 Slab Edge PlanEric WilsonNo ratings yet

- Wisdom Double Manhattan52 PDFDocument1 pageWisdom Double Manhattan52 PDFGigiNo ratings yet

- Hwy 49 Roadwork2Document1 pageHwy 49 Roadwork2The UnionNo ratings yet

- Third Floor Plan Third Floor Plan: NorthDocument1 pageThird Floor Plan Third Floor Plan: NorthKavya ChithavaduthaNo ratings yet

- Ewan Engineering Consultancy: Extr. 4 CM Heat InsulationDocument1 pageEwan Engineering Consultancy: Extr. 4 CM Heat InsulationAbid AyubNo ratings yet

- EQc5 - Osnova 2-7.sprata - VT1 - VT3Document1 pageEQc5 - Osnova 2-7.sprata - VT1 - VT3iklem79No ratings yet

- UMEX 2022 Floor PlanDocument1 pageUMEX 2022 Floor PlanYq SongNo ratings yet

- 9035 Erction DWG (Demirsan)Document1 page9035 Erction DWG (Demirsan)ghulamNo ratings yet

- LS Fence 1Document1 pageLS Fence 1jimNo ratings yet

- Refined Products System MapDocument1 pageRefined Products System MapRanderall TagahassellhoffNo ratings yet

- Wh-1088pe DrawingDocument1 pageWh-1088pe Drawingom sai quality developmentNo ratings yet

- Trazado Y Lotizacion: Nicolas Aurelio Quiroz PerezDocument1 pageTrazado Y Lotizacion: Nicolas Aurelio Quiroz PerezElmer Iván Llanos PortalNo ratings yet

- 1 Ins Sanit Mara-Is-05 Is Drenaje PluvialDocument1 page1 Ins Sanit Mara-Is-05 Is Drenaje PluvialjoseNo ratings yet

- A.108-1St Floor PDFDocument1 pageA.108-1St Floor PDFdothi aiuyenNo ratings yet

- NAS-6-RA04-EE030-0004-SD-01-01-R02-Code BDocument1 pageNAS-6-RA04-EE030-0004-SD-01-01-R02-Code BVijayan Thekke VeeduNo ratings yet

- EX1200-Electrical Circuit Diagram (Cummins Engine Specification)Document1 pageEX1200-Electrical Circuit Diagram (Cummins Engine Specification)Norman CoetzeeNo ratings yet

- 3 2 PDFDocument2 pages3 2 PDFhernando ramosNo ratings yet

- NotesDocument1 pageNotesassis alihNo ratings yet

- A61 Q FDN Va 046778 001 Pile Cap DetailsDocument1 pageA61 Q FDN Va 046778 001 Pile Cap DetailsadnanNo ratings yet

- Detailed Plan of St-01: Esteban Y. Tan & AssociatesDocument1 pageDetailed Plan of St-01: Esteban Y. Tan & AssociatesRnln Sagales AmataNo ratings yet

- Section B B Note - : Column Number Column SizeDocument1 pageSection B B Note - : Column Number Column SizeRHUTI NAIKNo ratings yet

- Amodi1 2Document1 pageAmodi1 2Tusarkanta BiswalNo ratings yet

- City Place Dania - Linear Interior Walls (Inside Units Only)Document7 pagesCity Place Dania - Linear Interior Walls (Inside Units Only)James RecañaNo ratings yet

- Construction Details - Seating Element: Section Aa' Section BB'Document1 pageConstruction Details - Seating Element: Section Aa' Section BB'Vaishnavi MhatreNo ratings yet

- Power Distribution Schematic Diagram (09-01-2020)Document5 pagesPower Distribution Schematic Diagram (09-01-2020)Design RhineNo ratings yet

- Wakad New D.P PDFDocument1 pageWakad New D.P PDFsamarosNo ratings yet

- SSWP - Notch Area Working Sequence For Perimeter FormDocument2 pagesSSWP - Notch Area Working Sequence For Perimeter Formpolaris projectNo ratings yet

- Notes: Electrical KeyDocument1 pageNotes: Electrical KeyanzaniNo ratings yet

- PANEL 8X4 Fashion HubDocument1 pagePANEL 8X4 Fashion HubAnonymous wTVJ4cIYNo ratings yet

- 2nd FloorDocument1 page2nd FloorNavdeep GopamwarNo ratings yet

- Site Tanjung Uban Revisi 14 01 2021Document3 pagesSite Tanjung Uban Revisi 14 01 2021Abal AbalNo ratings yet

- Mlolongo Project Architectural PDFDocument1 pageMlolongo Project Architectural PDFNewtonNo ratings yet

- Mlolongo Project ArchitecturalDocument1 pageMlolongo Project ArchitecturalNewtonNo ratings yet

- P300 CockpitDocument1 pageP300 Cockpitjc8c6w5skvNo ratings yet

- Detalles Constructivos para La Red de Agua PotableDocument4 pagesDetalles Constructivos para La Red de Agua PotableRoberto Cabrera MillerNo ratings yet

- Site Development Plan Auxiliary: General Notes: Legends & SymbolsDocument16 pagesSite Development Plan Auxiliary: General Notes: Legends & SymbolsIan de GaliciaNo ratings yet

- Offshore Supply Vessel: ProfileDocument1 pageOffshore Supply Vessel: ProfileAswin Sathian100% (1)

- Limite de Frentes de TrabajosDocument1 pageLimite de Frentes de TrabajosJohann Nick Flores AparicioNo ratings yet

- Sta CC 14034 23 L02 120Document1 pageSta CC 14034 23 L02 120wcdrg59chcNo ratings yet

- Drawing 4.Document1 pageDrawing 4.tiyaniNo ratings yet

- PB02-HRH-001 Hot Reheat Steam SystemDocument1 pagePB02-HRH-001 Hot Reheat Steam SystemzhangNo ratings yet

- mcc2 PDFDocument1 pagemcc2 PDFSravyaSree100% (2)

- Kshethra Farms - Westwoods Phase - 2 - Plots Layout With Areas and Dim - Dated 015.12.2023-ModelDocument1 pageKshethra Farms - Westwoods Phase - 2 - Plots Layout With Areas and Dim - Dated 015.12.2023-Modelmanan.maheshwari298No ratings yet

- A1 Coorporation DrawingDocument1 pageA1 Coorporation DrawingSujay KhadeNo ratings yet

- Special and Different: The Autistic Traveler: Judgment, Redemption, & VictoryFrom EverandSpecial and Different: The Autistic Traveler: Judgment, Redemption, & VictoryNo ratings yet

- Calculation Sheet Cuplock - ContainerDocument9 pagesCalculation Sheet Cuplock - ContainerMuhammad ZuhayrNo ratings yet

- Access Scaffolding - Leader FortDocument8 pagesAccess Scaffolding - Leader FortMuhammad ZuhayrNo ratings yet

- Calculation Sheet for Profex Panels at Al Rahmaniya MallDocument9 pagesCalculation Sheet for Profex Panels at Al Rahmaniya MallMuhammad ZuhayrNo ratings yet

- Qr00989-r0-Hire-first Floor SlabDocument1 pageQr00989-r0-Hire-first Floor SlabMuhammad ZuhayrNo ratings yet

- A Short Guide To Metric Nuts and BoltsDocument10 pagesA Short Guide To Metric Nuts and BoltsSandra FerrellNo ratings yet

- 2-Side Wall Water Tank & Pump RoomDocument1 page2-Side Wall Water Tank & Pump RoomMuhammad ZuhayrNo ratings yet

- VIP Platform Temp Venue Section View With MeasurementsDocument1 pageVIP Platform Temp Venue Section View With MeasurementsMuhammad ZuhayrNo ratings yet

- A Short Guide To Metric Nuts and BoltsDocument10 pagesA Short Guide To Metric Nuts and BoltsSandra FerrellNo ratings yet

- Area CalculationsDocument1 pageArea CalculationsMuhammad ZuhayrNo ratings yet

- Tabale de ParafusoDocument54 pagesTabale de ParafusoSilas MendesNo ratings yet

- Wedge AnchorDocument8 pagesWedge AnchorMuhammad ZuhayrNo ratings yet

- Eurocode Superceded ListDocument5 pagesEurocode Superceded ListLaughlikesiao HeheNo ratings yet

- Epayments Jntuh AcDocument1 pageEpayments Jntuh AcMuhammad ZuhayrNo ratings yet

- Guide To Design Criteria For Bolts and Riveted JointsDocument352 pagesGuide To Design Criteria For Bolts and Riveted JointsHomero Silva96% (24)

- tw14.030 en pt1 Issued July14 PDFDocument24 pagestw14.030 en pt1 Issued July14 PDFMuhammad ZuhayrNo ratings yet

- Reshoring Aci 3472R - 05 PDFDocument22 pagesReshoring Aci 3472R - 05 PDFEdwin Ramos Policarpio100% (1)

- Scaffolding PDFDocument80 pagesScaffolding PDFLeo Richmond75% (4)

- Shor BraceDocument1 pageShor BraceMuhammad ZuhayrNo ratings yet

- Cement Concrete Technology PDFDocument155 pagesCement Concrete Technology PDFArun VyasNo ratings yet

- Metriform System First FloorDocument1 pageMetriform System First FloorMuhammad ZuhayrNo ratings yet

- 06 Eurocodes Steel Workshop WALDDocument136 pages06 Eurocodes Steel Workshop WALDIonut SavaNo ratings yet

- The Attached Excerpted Resource Materials Have Been Made Available For Use Within ACI UniversityDocument11 pagesThe Attached Excerpted Resource Materials Have Been Made Available For Use Within ACI Universityguillemir100% (2)

- BS5950 Load CasesDocument46 pagesBS5950 Load CasesthespecifierNo ratings yet

- Bs5950!1!1990 Structural Steel Hot RolledDocument126 pagesBs5950!1!1990 Structural Steel Hot RolledMuhammad ZuhayrNo ratings yet

- Reshoring Aci 3472R - 05 PDFDocument22 pagesReshoring Aci 3472R - 05 PDFEdwin Ramos Policarpio100% (1)

- Table Formwork - New PDFDocument31 pagesTable Formwork - New PDFMuhammad Zuhayr100% (2)

- Aluprofilsystem en 0Document481 pagesAluprofilsystem en 0Vasile TomoiagaNo ratings yet

- Indczech NewDocument4 pagesIndczech NewmasilamaniNo ratings yet

- MRB & MRB-S: Plate Roll BendingDocument13 pagesMRB & MRB-S: Plate Roll BendingJohan SneiderNo ratings yet

- Lubriplate 630Document1 pageLubriplate 630Diego Fernando Pedroza UribeNo ratings yet

- Mechanical Properties of SteelDocument1 pageMechanical Properties of SteelrianrureNo ratings yet

- Groundwater Aeration Towers, Degasifiers, Air Strippers: Advanced Odor Removal SystemsDocument1 pageGroundwater Aeration Towers, Degasifiers, Air Strippers: Advanced Odor Removal SystemsherikNo ratings yet

- JHA ConcretingDocument3 pagesJHA Concretingfatimah beluhi75% (4)

- Aggregate Impact ValueDocument8 pagesAggregate Impact ValueAnis Nurfarahanim Abdul HalimNo ratings yet

- Nitrogen and Accumulator ChargingDocument3 pagesNitrogen and Accumulator ChargingKarthikeyanNo ratings yet

- C1361 PDFDocument5 pagesC1361 PDFLucas CamposNo ratings yet

- SikaWrap Dry Application 2016 Technical Information Manual UKDocument15 pagesSikaWrap Dry Application 2016 Technical Information Manual UKIbrahim SahinNo ratings yet

- 8942V 00 CN 16 12 007 1 SDocument23 pages8942V 00 CN 16 12 007 1 SAshwin SevariaNo ratings yet

- Soplador de Aire ZL 500Document24 pagesSoplador de Aire ZL 500miguel torbellinoNo ratings yet

- 04 PDFDocument146 pages04 PDFEli RochaNo ratings yet

- Piese CizmaDocument56 pagesPiese CizmaVictor AdamitaNo ratings yet

- James SchnaitmanDocument2 pagesJames Schnaitmanapi-78642001No ratings yet

- Pressure Test CertificateDocument1 pagePressure Test CertificateSopi LabuNo ratings yet

- Mah22Pr: Save Up TO 60%Document2 pagesMah22Pr: Save Up TO 60%mantenimientoNo ratings yet

- FULLY-AUTOMATIC MICROHARDNESS TESTING SYSTEMDocument8 pagesFULLY-AUTOMATIC MICROHARDNESS TESTING SYSTEMJohn HavaianoNo ratings yet

- Manual Mantenance ButterworthDocument41 pagesManual Mantenance Butterworthsarmidi sarmidiNo ratings yet

- Saudi Aramco RiggerDocument11 pagesSaudi Aramco RiggerShabbir Hussain85% (13)

- Intelligent BuildingDocument42 pagesIntelligent BuildingLuis Alonso SA100% (1)

- Industrial Engineering ProjectsDocument316 pagesIndustrial Engineering ProjectsbonostoreNo ratings yet

- Jit and Lean OperationsDocument8 pagesJit and Lean OperationsIvyJoyce100% (1)

- Micromachining of Engineering MaterialsDocument408 pagesMicromachining of Engineering Materialssam048No ratings yet

- Strap FootingDocument32 pagesStrap FootingChris Paulo100% (1)

- SY335C8I2K液压挖掘机零部件图册Document370 pagesSY335C8I2K液压挖掘机零部件图册Edgar Martinez Carmona100% (5)

- TM 9-2320-328-13P-1 Hewatt M1158 Part 1Document211 pagesTM 9-2320-328-13P-1 Hewatt M1158 Part 1Advocate0% (3)

- Zone Control Waterflow Switch VSRDocument4 pagesZone Control Waterflow Switch VSRasimnaqvi2008No ratings yet

- Vaghodia Compressor STNDocument41 pagesVaghodia Compressor STNAyaanNo ratings yet