Professional Documents

Culture Documents

Controlwave Integrated Pump Control (2007) PDF

Uploaded by

EnnSeeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Controlwave Integrated Pump Control (2007) PDF

Uploaded by

EnnSeeCopyright:

Available Formats

Product Data Document

420DS-12A

October 1, 2007 - Page 1

Integrated Pump Control

SCADA RTU

Pre-Engineered Water and Wastewater Benefits

Remote Pump Control Application Package Pre-programmed package eliminates the need

for custom programming

One package for one to three pumps provides

consistency for operators and technicians

Local Display/Keypad Operator Interface panel

for on-site system control

Alarm and historical data reporting for full

SCADA integration

Multiple pump scenarios allow flexibility to meet

a wide range of applications

Pump start/stop as well as VFD speed control

Easy-to-use web page station configuration and

setup

Single program offers performance and simplicity Easily interfaces to field devices and sensors

for monitoring and control of remote water and Security and water quality functions can be

wastewater applications easily added as needed

Well station

Plant managers will take maximum advantage of

Remote tank level control the flexibility and maintenance personnel will ap-

preciate the simplicity of the Bristol ControlWave

Reservoir Control pump control application. All remote water and

Duplex Lift or Booster station wastewater applications have the same require-

ments to automatically control one or more pumps

Triplex Lift or Booster station to maintain level, pressure and/or flow. Some sites

may also have the need to control chemical feed,

This standard pre-programmed application lever- measure rain level, and detect intrusion events. All

ages our decades of experience monitoring and of these are pre-programmed and available for use

controlling remote pumps in a wide variety of water to customize for the specific site.

and wastewater sites in North America and through-

out the world. The standard application can be When the application requires modifications or addi-

used with the appropriate Bristol ControlWave tions to the standard program, Bristol ControlWave

PLC/RTU, from Emerson Process Management to Designer allows unlimited customization by your

meet the I/O requirements at the various sites. The engineering staff or other integrators.

combined solution offers a cost effective system that

is ready to deploy without the typical programming

overhead.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Product Data Document Integrated Pump Control

420DS-12A

October 1, 2007 - Page 2 SCADA RTU

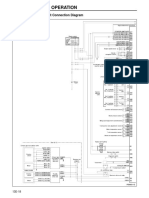

Specifications Analog outputs:

VFD speed control

Well or Reservoir Chemical feed pump

Digital inputs: Counter inputs:

Pump 1 status Station flow

Pump Remote/Local Rain gauge

Digital outputs:

Pump start Triplex Booster or Lift Station

Pump Stop Digital inputs:

Analog inputs: Pump 1, 2 & 3 status

Station flow Pump 1, 2 & 3 Remote/Local

Well drawdown 2 tank level DI

Outlet pressure ControlWave ExpressPAC Intrusion or Motion

SCADA Package

Chlorine residual Digital outputs:

Clearwell level or tank level Pump 1, 2 & 3 start

Analog outputs: Pump 1, 2 & 3 Stop

VFD speed control Analog inputs:

Chemical feed pump Station flow

Counter inputs: Inlet pressure

Outlet pressure ControlWave MIcro

Station flow PLC/RTU SCADA Package

Rain gauge Chlorine residual

Clearwell level or tank level

Duplex Booster or Lift Station Analog outputs:

Digital inputs: VFD speed control

Pump 1 & 2 status Chemical feed pump

Pump 1 & 2 Remote/Local Counter inputs:

2 tank level DI Station flow

Intrusion or Motion Rain gauge

Digital outputs:

Pump 1 & 2 start

Pump 1 & 2 Stop

Analog inputs:

Station flow

ControlWave MIcro

Inlet pressure PLC/RTU

Outlet pressure

Chlorine residual

Clearwell level or tank level

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Product Data Document Integrated Pump Control

420DS-12A

October 1, 2007 - Page 3 SCADA RTU

SCADA Packages Historical Archive

The Bristol ControlWave Micro and ControlWave Historical data is stored in three archive files in the

ExpressPAC integrated SCADA packages, from ControlWave PLC/RTU flash memory. This ensures

Emerson, are designed and built for out-of-the-box maximum data integrity even in the event of a

installation and startup. The assemblies are fully SCADA communication network failure. The his-

integrated units that combine the PLC/RTU with torical data archives may be collected periodically

a variety of options commonly required in SCADA on a scheduled or demand basis by the OpenBSI

applications. These include a NEMA 4X rated en- Harvester utility. This technique also minimizes

closure, power supply and battery backup options, communication bandwidth requirements significantly

termination options, display and operator input op- benefiting radio and cellular network architectures.

tions, and wireless communication options.

Daily Archive:

Stores 35 days of time-stamped minimums, maxi-

mums, averages and totals

Hourly Archive:

Stores hourly time-stamped minimums, maximums,

averages and totals

Trend Archive:

The Trend Archive stores instantaneous values at a

fixed period from one minute to sixty minutes.

ControlWave MIcro Setup and Configuration

PLC/RTU SCADA Package

As mentioned earlier, the ControlWave pump control

SCADA application is pre-programmed. The unit

The ControlWave SCADA packages with the pre- only needs site specific configuration through the

programmed pump controller application are ideal easy-to-use set of web pages supplied with the ap-

for integrating remote site measurement and control plication software. These configuration web pages

into the SCADA system. are accessible through the OpenBSI TechView

utility.

Station Control Strategies:

Level control

Pressure control

Time control

Pump lead/lag and pump alteration

Pump interlock and permissive conditions

Manual and PID VFD Control

TechView allows easy connection to any

ControlWave PLC/RTU through serial or Ethernet

ports. The utility is essentially a web page browser

that really simplifies menu navigation and PLC/RTU

configuration.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Product Data Document Integrated Pump Control

420DS-12A

October 1, 2007 - Page 4 SCADA RTU

The initial configuration setup is presented in a step-

by-step procedure using a question and answer for-

mat. Once familiar with the procedures, individual

configuration pages can easily be accessed rather

than using the Q & A format.

I/O Configuration

Q & A Configuration

Configuration Page Loop Control Page

The configuration pages allow you to set the com- A station overview display is also provided to show

munication address and parameters, select station pump run status, local/remote operation, and instan-

control mode parameters, enter setpoints and alarm taneous values of pressure, flow and level.

limits, modify zero and span for analog inputs, add

permissives and interlocks, and perform pump Setup and configuration may also be performed

startups. from the integral display/keypad on the ControlWave

PLC/RTU SCADA package or via the SCADA

system host HMI. All configuration parameters are

made available to OPC servers for compatibility with

our OpenEnterprise SCADA software as well as

third party SCADA software packages.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Product Data Document Integrated Pump Control

420DS-12A

October 1, 2007 - Page 5 SCADA RTU

KPSI Submersible Level Transducers

Tank and wet well level measurement

5 to 700 feet

.05% to 1 % full scale accuracy

Non-fouling diaphragm options for lift station

applications

4-20 mA or 0-5 V output

AquaSensors Water Quality Instruments

The AquaSensors DataStick provides a cost-ef-

fective plug and play analytical measurement sys-

tem for continuous use in industrial environments.

Software components DataStick communicates with ControlWave via a

preconfigured serial Modbus function block.

The ControlWave pump control application is

available pre-installed in a ControlWave Micro or Direct measurement of pH, reagent free residual

Express PLC/RTU. A modifiable version is avail- chlorine, dissolved oxygen, ORP or turbidity

able allowing program additions, but does not allow

modifications to the pump control program itself. 11 CPVC direct insertion probe

There is also a complete source version that allows 10-30 Vdc, <200 mW

unlimited modification of the pump control program.

These three offerings provide the flexibility to meet Censar Six-Cense multiparameter in-line sensor

the needs of wide range of users, technicians and measures in real time (pH, ORP, conductivity, dis-

engineers. solved oxygen, free chlorine, and temperature)

Products for expanded functionality Direct insertion into pressurized main 2 inches

to 72 inches in diameter

The pump control SCADA package can be com- Operates under working pressures up to 230 psi

bined with a variety of additional products that facili-

tate integration or provide even greater functionality. Reagent-free measurement of Chlorine

Measures Monochloramine for plans using

Process Measurement Transmitters chloramination

Bristol 2808 & 3808

Low maintenance, low cost sensor replacement

2808 analog pressure transmitter for tank level

measurement

Security Vision application package

3808 digital DP transmitter for flow

measurement Pre and post event video capture and replay

Adjustable ranges Pre-programmed function block provides all

video file/folder manipulation

High accuracy

OpenBSI Utility for collection and replay of

Two year warranty captured events

Local indicator option IP enabled network video camera with FTP

server

Facility entry access control and reporting

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Product Data Document Integrated Pump Control

420DS-12A

October 1, 2007 - Page 6 SCADA RTU

OpenEnterprise SCADA Host Related specification documents:

ControlWave Micro 420ds5k.pdf

The OpenEnterprise SCADA software provides a

turnkey SCADA solution from field equipment to ControlWave ExpressPAC - 420ds7c.pdf

Supervisory Control, Management Reporting and ControlWave Micro Enclosures 420ds0d.pdf

Enterprise wide data distribution. OpenEnterprise ControlWave Designer 420ds3d.pdf

is the tool that links Projects, Operations, Accounts

and Management, making SCADA a part of the Security Vision 454ds11b.pdf

business process. OpenEnterprise 450ds1b.pdf

Real-time Relational Object Oriented Database Water Quality and SCADA security on the

Included Historian with backfill capability www.ControlWave.com web site.

Advanced state of the art graphics builder Complete specifications are available on the

www.EmersonProcess.com/Remote web site.

Powerful reporting tools

Alarm and Event Manager

Open standards support for SQL, ODBC/ADO,

Java DBC, OPC OLE & HDA, DDE, VB

Thin client options for corporate and operational

users

OPC data access direct from database

Fault tolerant and distributed servers over WAN

or LAN

2007 Remote Automation Solutions, division of Emerson Process Management. All rights reserved.

Bristol, Inc., Bristol Babcock Ltd, Bristol Canada, BBI SA de CV and the Flow Computer Division , are wholly owned subsidiaries of Emerson Electric Co. doing business as Remote Auto-

mation Solutions (RAS), a division of Emerson Process Management. FloBoss, ROCLINK, Bristol, Bristol Babcock, ControlWave, TeleFlow and Helicoid are trademarks of RAS. AMS,

PlantWeb and the PlantWeb logo are marks of Emerson Electric Co. The Emerson logo is a trademark and service mark of the Emerson Electric Co. All other marks are property of their

respective owners.

The contents of this publication are presented for informational purposes only. While every effort has been made to ensure informational accuracy, they are not to be construed as war-

ranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. RAS reserves the right to modify or improve the designs or

specifications of such products at any time without notice. All sales are governed by RAS terms and conditions which are available upon request. RAS does not assume responsibility for

the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any RAS product remains solely with the purchaser and end-user.

Emerson Process Management

Remote Automation Solutions

Watertown, CT 06795 USA T 1 (860) 945-2200

Mississauga, ON 06795 Canada T 1 (905) 362-0880

Worcester WR3 8YB UK T 44 (1) 905-856950

Website: www.EmersonProcess.com/Remote

You might also like

- FCD Enterprise: Conn-Port RTU For Embedded Microcomputer Based SCADA SystemDocument24 pagesFCD Enterprise: Conn-Port RTU For Embedded Microcomputer Based SCADA SystemFCD EnterpriseNo ratings yet

- The PIC Microcontroller: Your Personal Introductory CourseFrom EverandThe PIC Microcontroller: Your Personal Introductory CourseRating: 1 out of 5 stars1/5 (2)

- Beckhoff - Waster and Clean Water Process Solution r4Document32 pagesBeckhoff - Waster and Clean Water Process Solution r4Romi AntonNo ratings yet

- Practical Data Acquisition for Instrumentation and Control SystemsFrom EverandPractical Data Acquisition for Instrumentation and Control SystemsNo ratings yet

- Multi-Pump Control Applications For ABB ACQ 810 Industrial DriveDocument8 pagesMulti-Pump Control Applications For ABB ACQ 810 Industrial DriveJose Leonardo Simancas GarciaNo ratings yet

- Digital Power Electronics and ApplicationsFrom EverandDigital Power Electronics and ApplicationsRating: 3.5 out of 5 stars3.5/5 (3)

- 5B. - Steam Turbine Control - Petrotech PDFDocument4 pages5B. - Steam Turbine Control - Petrotech PDFJaviStg1100% (1)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- ADAC 4000 Boiler Book PDFDocument11 pagesADAC 4000 Boiler Book PDFfauzi endraNo ratings yet

- Vacon 100 Flow BrochureDocument12 pagesVacon 100 Flow BrochureZeh Garcia JuniorNo ratings yet

- Application of Scada For Water Treatment Plant: - by Shraddha Malve MT19ENV017Document34 pagesApplication of Scada For Water Treatment Plant: - by Shraddha Malve MT19ENV017Shraddha Malve100% (1)

- Streamlining Water Management Operations:: Moving Beyond Mechanical To Automated Electronic ControlDocument3 pagesStreamlining Water Management Operations:: Moving Beyond Mechanical To Automated Electronic ControlHuy VuNo ratings yet

- Automazione ENGDocument4 pagesAutomazione ENGChakchouk MED WALIDNo ratings yet

- Automated Urban Drinking Water Supply WithDocument5 pagesAutomated Urban Drinking Water Supply WithManjunath HSNo ratings yet

- Appcontroller: I-Vu Building Automation SystemDocument2 pagesAppcontroller: I-Vu Building Automation SystemPatricia MilanesiNo ratings yet

- Pocket Folder - Contents (PDF) - Added 4-3-20Document22 pagesPocket Folder - Contents (PDF) - Added 4-3-20Dereck SeckmanNo ratings yet

- Uc Open XP: I-Vu Building Automation SystemDocument2 pagesUc Open XP: I-Vu Building Automation SystemClaudio MerinoNo ratings yet

- DEH Control System TrainDocument14 pagesDEH Control System Trainkarthick.gNo ratings yet

- Iaetsd A Novel Approach Towards Automatic Water Conservation SystemDocument8 pagesIaetsd A Novel Approach Towards Automatic Water Conservation SystemiaetsdiaetsdNo ratings yet

- RVX Power: Speed GovernorDocument4 pagesRVX Power: Speed Governorgonzalo cruz garcia100% (1)

- Pipeline Scada SystemDocument64 pagesPipeline Scada SystemMayank VishnoiNo ratings yet

- Feedback 38-004Document15 pagesFeedback 38-004aditya narayan shuklaNo ratings yet

- Scada - Rtu InterfaceDocument59 pagesScada - Rtu Interfaceshivam.nagar100% (1)

- Pipeline SCADADocument11 pagesPipeline SCADAGiridhar Kumar NanduriNo ratings yet

- Sugar Mill ControlDocument12 pagesSugar Mill ControlZishan Tyagi100% (1)

- Eqs CWM S BulletinDocument2 pagesEqs CWM S BulletinDJ WALETNo ratings yet

- Honeywell Sugar PresentationDocument31 pagesHoneywell Sugar Presentationaharnisha100% (1)

- Flow Control Trainer: DescriptionDocument2 pagesFlow Control Trainer: DescriptionshubhamNo ratings yet

- Flygt APP 700 Monitoring and Control Units: Advanced Control For Pump Station ApplicationsDocument6 pagesFlygt APP 700 Monitoring and Control Units: Advanced Control For Pump Station ApplicationsRobiNo ratings yet

- PSP330Document4 pagesPSP330Ali HadiNo ratings yet

- IAPP Boiler & SCADA PDFDocument7 pagesIAPP Boiler & SCADA PDFgeethuNo ratings yet

- DCS PresentationDocument22 pagesDCS PresentationMUHAMMAD TAUFEEQNo ratings yet

- Report - Pump Room AutomationDocument12 pagesReport - Pump Room AutomationtanujgateNo ratings yet

- 00 Industrial Automation - OverviewDocument38 pages00 Industrial Automation - OverviewRAJESH PANIGRAHINo ratings yet

- ePIC Rod Pump ContollerDocument8 pagesePIC Rod Pump ContollerjuandiegoangaritaNo ratings yet

- Controls and Instrumentation - CompressedDocument12 pagesControls and Instrumentation - CompressedCricri CriNo ratings yet

- 515 BF03 ApDocument4 pages515 BF03 Appcxhu1No ratings yet

- System For Water Level & Flow Regulation by PID: Products 2 Years GuaranteeDocument33 pagesSystem For Water Level & Flow Regulation by PID: Products 2 Years GuaranteeAugusto CamposNo ratings yet

- Solution For Water Wells and Tank Control System: December 2016Document7 pagesSolution For Water Wells and Tank Control System: December 2016Archiford NdhlovuNo ratings yet

- Lufkin Well Manager: Progressing Cavity Pump ControllerDocument2 pagesLufkin Well Manager: Progressing Cavity Pump ControllerjoshuaNo ratings yet

- Chiller Plant Manager - McguayDocument4 pagesChiller Plant Manager - McguaysuathayriNo ratings yet

- 505DR - Product SpecDocument5 pages505DR - Product SpecAmtNo ratings yet

- Hydro MPC-F 2 CR32-3 U2 D-B-G-ADocument8 pagesHydro MPC-F 2 CR32-3 U2 D-B-G-ADiana SubaricNo ratings yet

- PLC Vs Multismart ComparisonDocument8 pagesPLC Vs Multismart ComparisonViren SopariwalaNo ratings yet

- Lecture 3Document26 pagesLecture 3Anonymous 2vaaNbDvNo ratings yet

- Transformer Monitoring Systems - MRDocument4 pagesTransformer Monitoring Systems - MRKelly chatingNo ratings yet

- Rod Pump Controller 2Document8 pagesRod Pump Controller 2ezioNo ratings yet

- iQPump Micro Brochure PDFDocument20 pagesiQPump Micro Brochure PDFCARLOS FERNANDEZNo ratings yet

- Receiving Elements: Instrumentation & ControlDocument47 pagesReceiving Elements: Instrumentation & ControlSka dooshNo ratings yet

- Digital Master ControlDocument34 pagesDigital Master Controlcdurani2n100% (1)

- Variable Speed Benefits BROVFD-R1Document4 pagesVariable Speed Benefits BROVFD-R1momin momaniNo ratings yet

- ACQ810 Catalog 3AUA0000160101 EN RevADocument36 pagesACQ810 Catalog 3AUA0000160101 EN RevAkhaldoun samiNo ratings yet

- Pub021 001 00 - 0116Document20 pagesPub021 001 00 - 0116arefNo ratings yet

- STG820 - Steam Turbine Governor: ALSPA P320 System - Technical Data Sheet P-TP09-A49052Document3 pagesSTG820 - Steam Turbine Governor: ALSPA P320 System - Technical Data Sheet P-TP09-A49052hudson100% (2)

- DCS LectureDocument80 pagesDCS LectureShashankRajoria100% (3)

- SCADA PresentationDocument6 pagesSCADA PresentationGigih PramonoNo ratings yet

- Total Dust Collector Control Systems: Precision P2Document8 pagesTotal Dust Collector Control Systems: Precision P2Luis ZavalaNo ratings yet

- VACON 100 FLOW BrochureDocument12 pagesVACON 100 FLOW Brochurehunt huntNo ratings yet

- CH 45 - Pumped Drainage - RevisedDocument27 pagesCH 45 - Pumped Drainage - RevisedK4No ratings yet

- Pump Station Design Guidelines 2nd EditionDocument34 pagesPump Station Design Guidelines 2nd Editionel_koptan00857693100% (1)

- CH 45 - Pumped Drainage - RevisedDocument27 pagesCH 45 - Pumped Drainage - RevisedK4No ratings yet

- Dampers CatalogDocument318 pagesDampers CatalogEnnSeeNo ratings yet

- 11 00248 RefCooling Manual - FINAL - Low Res PDFDocument52 pages11 00248 RefCooling Manual - FINAL - Low Res PDFEnnSeeNo ratings yet

- How To Size A Room Air Conditioner PDFDocument3 pagesHow To Size A Room Air Conditioner PDFKo PaukNo ratings yet

- 28 196 PDFDocument10 pages28 196 PDFEnnSeeNo ratings yet

- Automation Design V3 9 PDFDocument57 pagesAutomation Design V3 9 PDFmurugan1620No ratings yet

- Cosmoplast-Changing World 2012Document28 pagesCosmoplast-Changing World 2012EnnSeeNo ratings yet

- Automation Design V3 9 PDFDocument57 pagesAutomation Design V3 9 PDFmurugan1620No ratings yet

- Concrete CasingDocument10 pagesConcrete CasingPipeline EngineerNo ratings yet

- Out of The BlueDocument30 pagesOut of The BlueEnnSeeNo ratings yet

- A Corrosion Risk Assessment Model For Underground PipingDocument5 pagesA Corrosion Risk Assessment Model For Underground PipingEnnSee100% (1)

- CAD in Process Plant EngineeringDocument8 pagesCAD in Process Plant EngineeringImam Munadi AniesNo ratings yet

- Horizontal Directional Drilling With Ductile Iron PipeDocument8 pagesHorizontal Directional Drilling With Ductile Iron PipeEnnSeeNo ratings yet

- Burnay, Bushman & Laroi - 2019Document10 pagesBurnay, Bushman & Laroi - 2019TinyjurshNo ratings yet

- Engine Torque Settings and Spec's 3.0L V6 SCDocument4 pagesEngine Torque Settings and Spec's 3.0L V6 SCMario MaravillaNo ratings yet

- John Hopkins Evidence Table - Systematic ReviewDocument2 pagesJohn Hopkins Evidence Table - Systematic Reviewsandy ThylsNo ratings yet

- Bhaktavatsalam Memorial College For Women: Hand Book 2020 - 21Document37 pagesBhaktavatsalam Memorial College For Women: Hand Book 2020 - 21Anu RsNo ratings yet

- Focus On Teaching - Jim KnightDocument213 pagesFocus On Teaching - Jim KnightFernando TeixeiraNo ratings yet

- Fire Alarm SymbolsDocument6 pagesFire Alarm Symbolscarlos vasquezNo ratings yet

- IPE SakibBhaiMagicChothaDocument55 pagesIPE SakibBhaiMagicChothaTousif SadmanNo ratings yet

- Ut 621024Document14 pagesUt 621024DarleiDuarteNo ratings yet

- Review. Applications of Ecogeography and Geographic Information Systems in Conservation and Utilization of Plant Genetic ResourcesDocument11 pagesReview. Applications of Ecogeography and Geographic Information Systems in Conservation and Utilization of Plant Genetic ResourcesEmilio Patané SpataroNo ratings yet

- Generic StructureDocument6 pagesGeneric StructureAndre AlvarezNo ratings yet

- MiningDocument3 pagesMiningDherick RaleighNo ratings yet

- Ficha Tecnica Reflector 2000W Led Lluminacion de Campos de Futbol Estadios Goled Philips Osram Opalux LedDocument5 pagesFicha Tecnica Reflector 2000W Led Lluminacion de Campos de Futbol Estadios Goled Philips Osram Opalux Ledluis perdigonNo ratings yet

- Application Bright Ideas Education Grant Program For TeachersDocument6 pagesApplication Bright Ideas Education Grant Program For Teachersapi-320983699No ratings yet

- (English (Auto-Generated) ) Intraday Trading On Nifty (2nd September, 2021) 8 Lakhs Profit Shreyas Bandi Trade Ideas Live (DownSub - Com)Document41 pages(English (Auto-Generated) ) Intraday Trading On Nifty (2nd September, 2021) 8 Lakhs Profit Shreyas Bandi Trade Ideas Live (DownSub - Com)YaaroNo ratings yet

- Jimma UniversityDocument99 pagesJimma UniversityBekan NegesaNo ratings yet

- Structure and Operation: 3. Electronic Control Unit Connection DiagramDocument16 pagesStructure and Operation: 3. Electronic Control Unit Connection DiagramAung Hlaing Min MyanmarNo ratings yet

- Service ManualDocument582 pagesService ManualBogdan Popescu100% (5)

- TCS3400 DS000411 4-00Document34 pagesTCS3400 DS000411 4-00Miguel_Angel92No ratings yet

- Communicative English Lab Manual 1643268175Document24 pagesCommunicative English Lab Manual 1643268175Dimple BhatiNo ratings yet

- Passmore Et Al (2019) Workplace CoachingDocument47 pagesPassmore Et Al (2019) Workplace CoachingMalarvilie KrishnasamyNo ratings yet

- Data Migration Good DocumentDocument16 pagesData Migration Good Documentsambit76No ratings yet

- History of Computer ReviewerDocument10 pagesHistory of Computer ReviewerNeil Andrew Aliazas78% (9)

- Iit JeeDocument8 pagesIit JeeRNo ratings yet

- ENGG 3150 Engineering Biomechanics Lab Guide 2006: University of Guelph School of EngineeringDocument13 pagesENGG 3150 Engineering Biomechanics Lab Guide 2006: University of Guelph School of Engineeringالقداري القداريNo ratings yet

- Compressor-Less: Historical ApplicationsDocument70 pagesCompressor-Less: Historical Applicationssuryakantshrotriya100% (1)

- Makaut Grade Card Collection Notice 2018-19Document1 pageMakaut Grade Card Collection Notice 2018-19Sourav PandaNo ratings yet

- Kick-Ass Customer Service-Part 1Document3 pagesKick-Ass Customer Service-Part 1Mahfuzul Haque SujanNo ratings yet

- Evs ManualDocument24 pagesEvs ManualJoseph TuckerNo ratings yet

- FDocument102 pagesFTop channelNo ratings yet

- Digital Signal Processing Lab ManualDocument61 pagesDigital Signal Processing Lab ManualOmer Sheikh100% (6)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialFrom EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialRating: 3.5 out of 5 stars3.5/5 (3)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 4.5 out of 5 stars4.5/5 (9)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosFrom EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosRating: 5 out of 5 stars5/5 (1)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesFrom EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesRating: 5 out of 5 stars5/5 (1)

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Analog Design and Simulation Using OrCAD Capture and PSpiceFrom EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNo ratings yet

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonFrom EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonRating: 5 out of 5 stars5/5 (2)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesFrom EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesRating: 5 out of 5 stars5/5 (1)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsFrom EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsRating: 3.5 out of 5 stars3.5/5 (2)

- ARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)From EverandARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)No ratings yet

- Practical Electronics for Inventors, Fourth EditionFrom EverandPractical Electronics for Inventors, Fourth EditionRating: 4 out of 5 stars4/5 (3)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)From EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Rating: 4.5 out of 5 stars4.5/5 (2)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (543)

- Current Interruption Transients CalculationFrom EverandCurrent Interruption Transients CalculationRating: 4 out of 5 stars4/5 (1)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- Wearable Sensors: Fundamentals, Implementation and ApplicationsFrom EverandWearable Sensors: Fundamentals, Implementation and ApplicationsEdward SazonovNo ratings yet

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)