Professional Documents

Culture Documents

Wall Thickness Calculation ASME B31!8!2007 Template

Uploaded by

zubair1951Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wall Thickness Calculation ASME B31!8!2007 Template

Uploaded by

zubair1951Copyright:

Available Formats

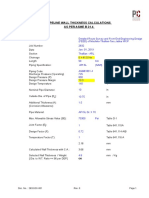

ATTACHMENT - X

Document No. X

Wall Thickness Calculation of 36in Gas Pipeline (Location Class-3, D.F.=0.5, Corr. Allow.=1.5mm)

1

2 DESIGN INPUT

3 Design Code ASME B31.8

4 Pipeline Size / Nominal O.D D 36 in 914 mm

5 Corrosion Allowance A 1.5 mm

6 Location Class 3

7 Design Factor F 0.5

8

o

9 Steel Coefficient of Expansion, 0.0000117 per deg C 6.50E-06 in/in/ C

10 Modulus of Elasticity E 2.07E+05 Mpa 3.05E+07 Psi

11

12 Pressure and Temperature Data

13 Design Pressure P 63.5 bar g 921.0 psi g

o o

14 Design Temperature (Underground) Td 65 C 149.0 F

o o

15 Installation (backfill) Temp Ti 13 C 55.4 F

16 Weld joint factor E 1

17 Temperature Derating Factor T 1

18

19 A. WALL THICKNESS

20 Grade X60

21 SMYS of Line Pipe S 60200 psi 415 MPa

22 Wall Thickness Calculated tmin 15.5 mm 0.610 inch

23 tmin = P x D / (2x Sx Fx E x T) + A

24 Next higher API wall thickness t 15.9 mm 0.626 inch

25 D/t Check ( Should be < 96) 58

26

27 B. EQUIVALENT STRESS CHECK FOR CORRODED PIPE CONDITION

28 Wall thickness (t) 14.4 mm

29 Hoop Stress = Sh = PD/2t 201.6 MPa

30

31 B.1 Restrained Pipe (Underground)

32 Thermal Stress = ST = a (Ti - Td) E -125.9 MPa

33 Longitudinal Stress due to pressure = SP = 0.3 Sh 60.5 MPa

34

35 Longitudinal Stress, SL

36 SL = SP + ST + SB + SX 0.9 x SMYS = 374 MPa

37

38 Without considering SB (Bending stress) and SX (Axial stress due to external loading):

39 SL = SP + ST -65.5 MPa

40 Longitudinal Stress check : SL 0.9 x SMYS hence OK

41

42 Equivalent Stress, SE

43 SE1 = | Sh - SL | SE1 267.1 MPa

44 SE2 = [ Sh2 + SL2 - Sh SL ]1/2 SE2 241.1 MPa

45 SE = Max (SE1, SE2) 0.9 x SMYS = 374 MPa SE 267.1 MPa

46 Equivalent Stress check : SE 0.9 x SMYS hence OK

47

48 B.2 Unrestrained Pipe (Aboveground)

49 Longitudinal Stress due to pressure = SP = 0.5 Sh 100.8 MPa

50

51 Longitudinal Stress, SL

52 SL = SP +SB + SX 0.75 x SMYS = 312 MPa

53 Without considering SB (Bending stress) and SX (Axial stress due to external loading):

54 SL = SP 100.8 MPa

55 Longitudinal Stress check : SL 0.75 x SMYS hence OK

56

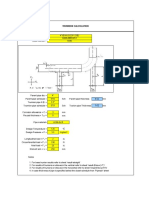

57 C. MINIMUM BENDING RADIUS

58 Minimum bending radius for underground section is calculated from maximum margin of bending stress,

59 based on Max (SE1, SE2) = 0.9 x SMYS. Hence, bending stress SB = -106.5 MPa

60 R (Minimum Bend Radius) = E D / (2 |Sb|) 889 m

61

62 D. CHECK ON THINNING DUE TO COLD BENDS: BEND RADIUS = 40 D

G

63 Inner bend radius divided by diameter, (n) 39.5

64 As per PD 8010-1:2004, % of Wall thinning = 50 / (n+1) 1.23 %

65 Pipe thk. before bending = cal thk/(1-thinning %) 15.7 mm

66 Available thickness for bending (= Selected thk) 15.9 mm

67 Adequacy Check (Pipe thk before bending < Available thk) OK

68

Page 1 of 1

You might also like

- Wall Thickness Calculation - ASME B31.8 2007 (Template)Document1 pageWall Thickness Calculation - ASME B31.8 2007 (Template)Hendra Yudistira100% (1)

- Wall THK Calculation Asme b31.4Document7 pagesWall THK Calculation Asme b31.4Luis Jose Duran100% (1)

- Wall THK Calculation Asme b31.4Document5 pagesWall THK Calculation Asme b31.4Dwi Hermawan100% (2)

- Elastic Bending Radius Calculation of PIPELINESDocument1 pageElastic Bending Radius Calculation of PIPELINESmailmaverick816777% (13)

- SPBG PLBG - Kalkulasi Tebal Pipa-ASME B31.3 - High PressureDocument1 pageSPBG PLBG - Kalkulasi Tebal Pipa-ASME B31.3 - High PressureAris KancilNo ratings yet

- Pipe Thickness Calculation PDFDocument1 pagePipe Thickness Calculation PDFHeny Martha67% (3)

- Permissible Elastic Bend Limit CalculationDocument4 pagesPermissible Elastic Bend Limit Calculationheldermanuel100No ratings yet

- ASME B31.3.4.8 Wall Thickness CalculatorDocument26 pagesASME B31.3.4.8 Wall Thickness Calculatoreko123100% (1)

- Sif B31 3Document10 pagesSif B31 3Sergio SmithNo ratings yet

- Wall Thickness CalDocument6 pagesWall Thickness CalNorazlan Shah MahadiNo ratings yet

- ASME B31.8 Riser CalcDocument23 pagesASME B31.8 Riser Calcisrar khan100% (2)

- 010-P-1-0233 Barred Tees Specification Rev 03Document20 pages010-P-1-0233 Barred Tees Specification Rev 03AdvisNo ratings yet

- Pipe Wall Thickness Calculation ASME B31.8Document16 pagesPipe Wall Thickness Calculation ASME B31.8DikaAnindyajati100% (2)

- Thickness CalcuationDocument6 pagesThickness CalcuationRanjan KumarNo ratings yet

- Thickness Analysis ReportDocument9 pagesThickness Analysis ReportEhtisham AndrAbiNo ratings yet

- 028120-SPL-003 Pipeline Material Rev. DDocument36 pages028120-SPL-003 Pipeline Material Rev. DRokan PipelineNo ratings yet

- Thickness Calculation For PipeDocument7 pagesThickness Calculation For PipeNAYEEM100% (5)

- Steel Pipe Design Calculation For SeamlessDocument4 pagesSteel Pipe Design Calculation For SeamlessA SubinNo ratings yet

- Flange Loading CheckDocument48 pagesFlange Loading CheckrefuzerNo ratings yet

- Calculation For Reinforced PadDocument4 pagesCalculation For Reinforced Padjsridhar_34750% (2)

- Design Data: 4" Weldolet CalculationDocument2 pagesDesign Data: 4" Weldolet Calculationgrabetty100% (2)

- Reinforcement CheckDocument2 pagesReinforcement Checkviv0102No ratings yet

- Welded Shoe CalculationDocument4 pagesWelded Shoe CalculationMichael RobinsonNo ratings yet

- Minimum Pipe Wall Thickness and MAWP SI Final ProtectedDocument11 pagesMinimum Pipe Wall Thickness and MAWP SI Final Protectedjsfscibd100% (1)

- Pipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Document9 pagesPipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Oswaldo GuerraNo ratings yet

- ASME B31.4 Riser CalcDocument14 pagesASME B31.4 Riser CalcCastorNoroñoNo ratings yet

- ASME B31.8 Riser CalcDocument12 pagesASME B31.8 Riser CalcSalz EngineeringNo ratings yet

- Hydrotest Full Details - and CalculationDocument6 pagesHydrotest Full Details - and CalculationDipak PatelNo ratings yet

- ASME B31.3 Wall Thickness CalculationDocument27 pagesASME B31.3 Wall Thickness CalculationJesus Magallanes SNo ratings yet

- Upheval Bukling CalculationDocument2 pagesUpheval Bukling Calculationbaghelrohit100% (7)

- Structural TrunnionDocument4 pagesStructural TrunnionecsalomNo ratings yet

- ASME Section VIII Pressure Vessel - Nozzle Load Application With Software AutomationDocument4 pagesASME Section VIII Pressure Vessel - Nozzle Load Application With Software AutomationRamuAlagappanNo ratings yet

- Alvaer DNV2.7-3 PDFDocument23 pagesAlvaer DNV2.7-3 PDFThanhdong Do100% (1)

- Crossing Calculation API Rp1102 TemplateDocument1 pageCrossing Calculation API Rp1102 TemplateBudi SantonyNo ratings yet

- Minimum Pipe Thickness - B31.1 - PG1Document10 pagesMinimum Pipe Thickness - B31.1 - PG1ravivarmadatla2011No ratings yet

- SU Blind Plate ThicknessDocument2 pagesSU Blind Plate Thicknessmanoj19801226100% (1)

- Saddle Calc PD5500Document4 pagesSaddle Calc PD5500rsubramaniNo ratings yet

- Asme b31g Level 2 A1Document27 pagesAsme b31g Level 2 A1finiteinjustice75% (8)

- Bb.g-Vsp-Pve-Ed-20-Me-Das-001 - 0Document24 pagesBb.g-Vsp-Pve-Ed-20-Me-Das-001 - 0Luong AnhNo ratings yet

- Pipe Reinforcement Calculation (ASME-B31.3)Document3 pagesPipe Reinforcement Calculation (ASME-B31.3)jenshid100% (2)

- PIPECALC ASME B31.4 - Rev 2Document24 pagesPIPECALC ASME B31.4 - Rev 2Mohsin RazaNo ratings yet

- Pipeline Wall Thickness Calculation SheetDocument4 pagesPipeline Wall Thickness Calculation SheetthehraoNo ratings yet

- 2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Document20 pages2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Sridhar Vijayan100% (3)

- Trunnion Calcualtion SheetDocument22 pagesTrunnion Calcualtion SheetAbhijit50% (2)

- Pipe Wall Thickness Calculation According ASME B31 3Document93 pagesPipe Wall Thickness Calculation According ASME B31 3linhcdt3100% (1)

- Pipe Lowering CalculationDocument8 pagesPipe Lowering CalculationMochamad Safarudin50% (4)

- ASME PipingOffice - Piping CalculatorsDocument5 pagesASME PipingOffice - Piping CalculatorsJohn PaulNo ratings yet

- Hydrotest Pressure CalculationDocument26 pagesHydrotest Pressure CalculationChetan B Kapadia100% (13)

- Wall Thickness Calculation ASME B31!8!2007Document1 pageWall Thickness Calculation ASME B31!8!2007shafeeqm3086No ratings yet

- Wall-Thickness-Calculation-ASME B31.8-2016-API5LGRBDocument1 pageWall-Thickness-Calculation-ASME B31.8-2016-API5LGRBtitir bagchiNo ratings yet

- Pipe Bend Againts Coating 3LPE AnalisisDocument25 pagesPipe Bend Againts Coating 3LPE Analisisraditia2205100% (1)

- YoussefDocument1 pageYoussefhhgjdfNo ratings yet

- Pipe SupportDocument11 pagesPipe SupportAditya Bagus M100% (3)

- Solucionario Cap. 4 Mecánica de Materiales ChapraDocument12 pagesSolucionario Cap. 4 Mecánica de Materiales ChapraXavier Pacheco PaulinoNo ratings yet

- K-4b Perhitungan PipaDocument51 pagesK-4b Perhitungan PipaIndra MaulanaNo ratings yet

- BEAM DesignDocument45 pagesBEAM DesignJoseph Cloyd L. LamberteNo ratings yet

- Coupling Calculations and Ug-32 Unstayed Head CalculationsDocument9 pagesCoupling Calculations and Ug-32 Unstayed Head CalculationsLcm TnlNo ratings yet

- Skid Lifting Lug DesignDocument3 pagesSkid Lifting Lug Designmahhor82_635643838No ratings yet

- Pipeline Highway Crossing Design SpreadsheetDocument11 pagesPipeline Highway Crossing Design SpreadsheetBeljun FloresNo ratings yet

- 02 03ChapGereDocument16 pages02 03ChapGereXavier Pacheco PaulinoNo ratings yet

- CADWorx P&ID Lesson GuideLesson GuideDocument124 pagesCADWorx P&ID Lesson GuideLesson GuideLU1228100% (2)

- Process Flow Diagram of Gas Recovery Unit-ModelDocument1 pageProcess Flow Diagram of Gas Recovery Unit-ModelLU1228No ratings yet

- I-020-G-LO-001 Rev.0 Plot Plan Area Avgas PDFDocument1 pageI-020-G-LO-001 Rev.0 Plot Plan Area Avgas PDFLU1228No ratings yet

- Peb / Sto Hoja de Datos Filtro SeparadorDocument3 pagesPeb / Sto Hoja de Datos Filtro SeparadorLU1228No ratings yet

- DBM - Margarita Pipeline Rev # 2 FINAL June 30thDocument31 pagesDBM - Margarita Pipeline Rev # 2 FINAL June 30thLU1228No ratings yet

- 3 PL A01 1B 10013 1 1011Document1 page3 PL A01 1B 10013 1 1011LU1228No ratings yet

- F HD 190 BDocument16 pagesF HD 190 BLU1228No ratings yet

- DMV Wire Mesh PadsDocument4 pagesDMV Wire Mesh PadsLU1228No ratings yet

- F HD 197 BDocument8 pagesF HD 197 BLU1228No ratings yet

- F HD 192 BDocument7 pagesF HD 192 BLU1228No ratings yet

- DMV Wire Mesh PadsDocument4 pagesDMV Wire Mesh PadsLU1228No ratings yet

- Blast Machine ProcedureDocument8 pagesBlast Machine ProcedureLU1228No ratings yet

- Valve Sizing Selection 1231875721684103 3Document15 pagesValve Sizing Selection 1231875721684103 3Ursula BologaNo ratings yet

- Slug Catcher Finger TypeDocument1 pageSlug Catcher Finger TypeLU1228No ratings yet

- Peco Filter General Products BrochureDocument16 pagesPeco Filter General Products BrochureAiman Hilmi Aiman HilmiNo ratings yet

- Horizontal CoalescerDocument1 pageHorizontal CoalescerLU1228No ratings yet

- PSS Report206Document90 pagesPSS Report206Abhishek TiwariNo ratings yet

- Airbus A380-800Document3 pagesAirbus A380-800Usman MushtaqNo ratings yet

- Munday CH 5.3-5.3.1 Skopos TheoryDocument11 pagesMunday CH 5.3-5.3.1 Skopos TheoryEvelina Tutlyte100% (1)

- ModelsGuidelines v5Document37 pagesModelsGuidelines v5Martin NolanNo ratings yet

- FEE Lab Manual FinalDocument86 pagesFEE Lab Manual FinalbalasubadraNo ratings yet

- TD62382APG, TD62382AFG: 8Ch Low Input Active Sink DriverDocument11 pagesTD62382APG, TD62382AFG: 8Ch Low Input Active Sink DriverDiego GrisalesNo ratings yet

- Reading Passage 1: You Should Spend About 20 Minutes On Questions 1-12 Which Are Based On Reading Passage 1Document2 pagesReading Passage 1: You Should Spend About 20 Minutes On Questions 1-12 Which Are Based On Reading Passage 1Melisa CardozoNo ratings yet

- Bio GasDocument4 pagesBio GasRajko DakicNo ratings yet

- Execution Without ExcusesDocument16 pagesExecution Without ExcusesVishnu Menon100% (1)

- Educational Design Research: Introduction and Illustrative CasesDocument24 pagesEducational Design Research: Introduction and Illustrative Casespatterson nji mbakwaNo ratings yet

- Unit 2Document3 pagesUnit 2lewlking123No ratings yet

- Installation Manual For PV PanelDocument23 pagesInstallation Manual For PV PanelVăn ST QuangNo ratings yet

- Angoca Db2 Cheat Sheet For DevelopmentDocument3 pagesAngoca Db2 Cheat Sheet For DevelopmentTanveer AhmedNo ratings yet

- PDFDocument2 pagesPDFSalim AshorNo ratings yet

- Electoral ListDocument189 pagesElectoral ListAhmadShazebAzharNo ratings yet

- New Text DocumentDocument246 pagesNew Text DocumentMustafa Al-RawiNo ratings yet

- GSB (Coarse Graded) Summary Sheet: Physical PropertiesDocument10 pagesGSB (Coarse Graded) Summary Sheet: Physical PropertiesjitendraNo ratings yet

- OxyGEN Router User's GuideDocument83 pagesOxyGEN Router User's Guidemakro100% (1)

- Power PhrasesDocument23 pagesPower Phrasesname isNo ratings yet

- 6.3. Example of Transmission Ratio Assessment 6.3.1. Power-Split Hydro-Mechanical TransmissionDocument2 pages6.3. Example of Transmission Ratio Assessment 6.3.1. Power-Split Hydro-Mechanical TransmissionNita SebastianNo ratings yet

- Logic SelectivityDocument6 pagesLogic SelectivitymoosuhaibNo ratings yet

- Convention On Cybercrime BudafestDocument26 pagesConvention On Cybercrime BudafestWinardiNo ratings yet

- Evoque Owners Club Manual PDFDocument258 pagesEvoque Owners Club Manual PDFmihai12moveNo ratings yet

- Tubewell Energy Audit PDFDocument172 pagesTubewell Energy Audit PDFshaheerdurrani100% (1)

- Selfdrive Autopilot CarsDocument20 pagesSelfdrive Autopilot CarsPavan L ShettyNo ratings yet

- MotRadar System PrinciplesDocument26 pagesMotRadar System PrinciplesReadmotNo ratings yet

- Industrial Visit Report OnDocument41 pagesIndustrial Visit Report OnLalit SharmaNo ratings yet

- Xiaopan OS InstallationDocument6 pagesXiaopan OS InstallationMuhammad SyafiqNo ratings yet

- 07-GB Column BasesDocument14 pages07-GB Column BasesAUNGPSNo ratings yet

- Tabla 1-1 (W Shapes)Document17 pagesTabla 1-1 (W Shapes)Leonardo ZambranoNo ratings yet