Professional Documents

Culture Documents

T30 R1

Uploaded by

Ram KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T30 R1

Uploaded by

Ram KumarCopyright:

Available Formats

Ingersoll Rand Industrial Technologies provides products, services and solutions to enhance the efficiency and

productivity of our commercial, industrial and process customers. Our innovative products include air compressors,

air systems components, tools, pumps, material and fluid handling systems and microturbines.

www.ingersollrand.com

Ingersoll Rand (India) Ltd. Ingersoll Rand compressors are not designed, intended or approved for breathing air applications.

Ingersoll Rand does not approve specialized equipment for breathing air applications and

21-30, GIDC Estate, Naroda, assumes no responsibility or liability for compressors used for breathing air service.

Ahmedabad - 382 330, India.

Phone : (079) 2282 0123, 2282 0323 Nothing contained on these pages is intended to extend any warranty or representation,

expressed or implied, regarding the product described herein. Any such warranties or other

Fax : (079) 2282 1003, 2282 1256

terms and conditions of sale of products shall be in accordance with Ingersoll Rands standard

11-2006 marg

E-mail : airsolutionsindia@irco.com terms and conditions of sale for such products, which are available upon request.

Product improvement is a continuing goal at Ingersoll Rand. Designs and specifications are

subject to change without notice or obligation.

2006 Ingersoll Rand Company

Ingersoll Rand - T30 A leader in its class since 1929

The Ingersoll Rand T30 has been the leader in its class since it

was introduced in 1929. Whether this is measured by reliability, Others may claim to handle heavy duty applications, but the T30

efficiency, rugged flexibility or maintainability, it has no equal. defines the concept. Run it in the most demanding intermediate duty

Designed for heavy industrial applications, the two stage application imaginable. It wont make any difference because this

reciprocating air compressors provide the quality and compressor performs with total dependability in the most demanding,

performance that exceed customer requirements. heavy-duty industrial applications. The T30 unique and ideal to meet

your demands of a compressor package in the 3-30 HP range.

After all, weve been doing this for over 100 years!

The Inside Story

A two-stage model (1) compresses air to an intermediate pressure in the first stage,

(2) removes heat of compression through an intercooler, and (3) compresses air to a final pressure

in a second compression stage. Two-stage compressors are more efficient and are generally used

for pressures above 100 PSI (maximum pressure to 175 PSI).

No other Reciprocating

Compressor offers these

efficient, cost-saving

features:

A durable cast iron pump

which provides 15,000+

hours of trouble-free

service

A 100% copper finned

intercooler lowers operating

temperatures and extends

pump life

An overhung crankshaft

and single-piece connecting

rod allow access to the

running gear for easy

maintenance

Individually cast cylinders

provide flexible, less

expensive maintenance on

just one cylinder at a time

rather than servicing the

entire pump

S T A T I O N A R Y

Electric-Driven Two Stage T30 Series

Designed for heavy shop or industrial use, Ingersoll Rand Two-Stage electric air compressors

provide the quality and performance that are ideal for most applications and users, including:

automotive service and body shops; fleet maintenance; machine shops; production and

manufacturing lines; construction; wood working shops; dry cleaners; car washes;

maintenance/repair shops and farms.

Value Packaged

Economically priced, Ingersoll Rand Two-Stage Value Packaged air compressors are perfect for

automotive, commercial or light industrial applications where a dependable air supply is required.

The value package includes the added features of a mounted and wired starter, automatic

start/stop pressure switch control with suitable size receiver tank.

Durable cast-iron, two-stage design offers extended pump life

for years of trouble-free service

175 PSI maximum operating pressure

100% continuous duty for tough applications

Automatic start/stop control/pressure switch operation

Includes motor starter, oil sight glass (10-15 HP only),

manual drain and ASME tank

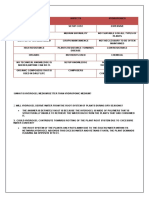

Motor HP Range Free Air Delivery m/hr (cfm)

Model At Working Pressure (Horizontal) Air Receiver m (lit.)

7.03 kg/cmg 12.3 kg/cmg

2340 2-3 15.12 (8.90) 14.58 (8.60) 0.150 (150) - 0.225 (225)*

2475 5 24.34(14.32) 23.78(13.99) 0.225 (225) - 0.300 (300)*

2475 7.5 30.90(18.20) 30.84(17.80) 0.225 (225) - 0.300 (300)*

2545 7.5 - 12.5 60.30(35.50) 59.46(35.00) 0.300 (300) - 0.500 (500)

7100 12.5 - 20 80.16(47.20) 79.50(46.80) 0.300 (300) - 0.500 (500)

15T 15 - 30 133.50(79.40) 133.02(78.30) 0.500 (500)

* Above mentioned models available with vertical air receiver, capacity : 0.15m (150 litres), 0.25m (250 litres), 0.30m (300 litres)

Performance for above models available on request for higher working pressure upto 17.5 kg/cm g.

All performance details subject to tolerance as per IS-5456.

Conversion Details : 1 cfm = 0.02831 m/min 1 psi = 0.07031 kg/cm

1 m = 1000 litres 1 hp = 0.746 kW

S T A T I O N A R Y

Electric-Driven Single Stage & Two Stage Dry Type Vacuum Pumps

S T A T I O N A R Y

Electric-Driven Two Stage T30 Series High Pressure

Air Compressors

Ingersoll Rand multi-stage high pressure air compressors are designed for high pressure applications.

These compressors have extra heavy-duty components and are designed for minimum maintenance and

maximum performance. High pressure air compressors are widely used in power generation plant,

PET blow moulding industry, military, diving and component testing.

Durable cast-iron with two, three and four stage design

Intermediate duty applications

Vacuum is one of the most versatile of power sources. All of these requirements are met by the Ingersoll Rand Extended pump life for years of trouble-free service

It can lift, hold, compact, evacuate, move, dehydrate, T30 air cooled reciprocating single stage and two Stage

agitate, actuate, form, rotate, filter, clean and simulate vacuum pumps. Standard Scope of Supply

high altitude. (for receiver mounted air compressors)

These pumps achieve vacuum upto 737mm (29.0' Hg)

In printing, plastics, materials handling, food for single stage and upto 754.4mm (29.7" Hg) for two V - sheave (compressor pulley)

processing, packaging, health care and many other stage configuration, at sea level. Dry type intake filter

industries, vacuum is called upon to perform many

These dry type vacuum pumps are ideal for paper Air cooled inter-stage cooler with

essential functions.

handling, food processing, vacuum forming, liquid

condensate drain leg

Producing a vacuum for modern industrial applications transfer and many other applications.

requires a method of air removal that is simple,

Inter-stage pressure gauge

dependable and economical to operate and maintain. Inter-stage safety valve

Air-cooled after-cooler

Model Piston Displacement Vacuum (Hg) Motor

cfm inch HP

V235 21.60 29.00 1.5

V235T 10.80 29.60 1.5

V244 34.60 29.00 2.0

V244T 17.30 29.65 2.0

V255 60.00 29.00 5.0

V255T 30.00 29.70 5.0

7V 110.00 29.00 7.5 High Pressure Receiver Mounted Package

7VT 55.00 29.65 7.5 Free Air Delivery cfm

Model Motor HP At Working Pressure

15V 149.60 29.20 10.0

15VT 99.00 29.65 10.0 35.1 kg/cmg

251 Package 5 6.45

Note :

1. Suffix T denotes two stage. 7T2 Package 10-12.5 21.60

Free Air Delivery cfm

2. These vacuum pumps can be supplied bare or base - plate mounted.

3. Optional Items: Scrubber, Vacuum gauge and Low oil level switch. Model Motor HP At Working Pressure 15T2 Package 20 37.70

4. Performances indicated are at sea level. 35.1 kg / cmg 70.3 kg / cmg 15T2 Duplex Package 40 75.40

231 3 4.80

251 5 6.45 For high pressure operation, adequate care must be taken for

proper selection. Our distributors would be happy to assist

7T4 5 7.86 6.40 you in correct selection of model. Models are also available for

higher working pressures upto 351 kg/cm g. Details available

7T2 12.5 21.60 on request.

15T2 20 / 25 37.70 36.96

You might also like

- Discrepancy in CAE Electricity Bill for Unit No. GGN-14-1102Document2 pagesDiscrepancy in CAE Electricity Bill for Unit No. GGN-14-1102Ram KumarNo ratings yet

- Power System Toolbox OverviewDocument63 pagesPower System Toolbox OverviewRam KumarNo ratings yet

- Power System Toolbox OverviewDocument63 pagesPower System Toolbox OverviewRam KumarNo ratings yet

- How Does A Piezo-Electric Accelerometer Work?Document19 pagesHow Does A Piezo-Electric Accelerometer Work?Sri SaiNo ratings yet

- PedDocument32 pagesPedPartha SarathyNo ratings yet

- An Open Source Power System Analysis Toolbox: 7% (%#/#,) "3 ? @AB A@C AD@Document56 pagesAn Open Source Power System Analysis Toolbox: 7% (%#/#,) "3 ? @AB A@C AD@Chandan KumarNo ratings yet

- How Does A Piezo Accel WorkDocument52 pagesHow Does A Piezo Accel WorkRam KumarNo ratings yet

- Instrum enDocument313 pagesInstrum enBobby WskNo ratings yet

- How Does A Piezo-Electric Accelerometer Work?Document19 pagesHow Does A Piezo-Electric Accelerometer Work?Sri SaiNo ratings yet

- Electric Machines Reference Frame TheoryDocument29 pagesElectric Machines Reference Frame TheoryRam KumarNo ratings yet

- Coram: Hon'Ble Mr. Justice P.B. Bajanthri: in The High Court of Punjab and Haryana at ChandigarhDocument1 pageCoram: Hon'Ble Mr. Justice P.B. Bajanthri: in The High Court of Punjab and Haryana at ChandigarhRam KumarNo ratings yet

- EES May 2015Document80 pagesEES May 2015Ram KumarNo ratings yet

- Discrete Control SystemDocument12 pagesDiscrete Control SystemRam KumarNo ratings yet

- Checklist for OEM terms and conditionsDocument1 pageChecklist for OEM terms and conditionsRam KumarNo ratings yet

- Modelling and Analysis of Electrical MachinesDocument1 pageModelling and Analysis of Electrical MachinesRam KumarNo ratings yet

- Employee Corner Screen Reader AccessDocument27 pagesEmployee Corner Screen Reader AccessRam KumarNo ratings yet

- Staff Service RulesDocument73 pagesStaff Service RulesRam KumarNo ratings yet

- End Termination NitDocument28 pagesEnd Termination NitRam KumarNo ratings yet

- CB Test Report-NJF - KNJDocument2 pagesCB Test Report-NJF - KNJRam KumarNo ratings yet

- Time-Domain Response of Linear Time-Invariant State EquationsDocument29 pagesTime-Domain Response of Linear Time-Invariant State EquationsRam KumarNo ratings yet

- Mws Gen Inp TXT SplineDocument12 pagesMws Gen Inp TXT SplineApuu Na Juak EhNo ratings yet

- T30 R1Document4 pagesT30 R1Ram KumarNo ratings yet

- Vapor Phase Dry OutDocument5 pagesVapor Phase Dry OutRam KumarNo ratings yet

- Chapter 14 TransformerDocument16 pagesChapter 14 TransformerRam KumarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Manual Saliran Mesra Alam (MSMADocument20 pagesManual Saliran Mesra Alam (MSMAkatakgoreng100% (2)

- Predicction of Cone Crusher Performance Considering Linear WearDocument70 pagesPredicction of Cone Crusher Performance Considering Linear WearHector100% (1)

- Adel Resume.Document4 pagesAdel Resume.adelsamhanNo ratings yet

- SAP2000 Base Isolation PDFDocument34 pagesSAP2000 Base Isolation PDFoscavier100% (2)

- PV System Load Estimation WorksheetDocument13 pagesPV System Load Estimation WorksheetRyan BurnsNo ratings yet

- Knuckle JointDocument32 pagesKnuckle JointThirumalaimuthukumaranMohanNo ratings yet

- Power Swing BlockingDocument1 pagePower Swing BlockingAbdul RahmanNo ratings yet

- UG-12 Boom PlacerDocument42 pagesUG-12 Boom PlacerPraful E. PawarNo ratings yet

- OTC 5886 Field Experience and Design Evolution of The Diverless Lay-Away Flowline Subsea TreeDocument6 pagesOTC 5886 Field Experience and Design Evolution of The Diverless Lay-Away Flowline Subsea TreeKevin GarciaNo ratings yet

- Catalogue - New QPF PDFDocument32 pagesCatalogue - New QPF PDFShaiju EbrahimNo ratings yet

- Shanty2Chic DIY Murphy Desk PDFDocument6 pagesShanty2Chic DIY Murphy Desk PDFsusana perezNo ratings yet

- Internship ReportDocument40 pagesInternship ReportMohammad Shafiq AliNo ratings yet

- Underground Coal Gasification (UCG)Document10 pagesUnderground Coal Gasification (UCG)partha das sharmaNo ratings yet

- Wheel Loader: Inspection Parameter ChecklistDocument4 pagesWheel Loader: Inspection Parameter ChecklistSonofwill Auger OdagledNo ratings yet

- Solar Thermal PowerDocument30 pagesSolar Thermal Powerveerakumars0% (1)

- FDocument23 pagesFFadhly Hidaya PutraNo ratings yet

- Fiat's Concrete Solutions for Environmental SustainabilityDocument42 pagesFiat's Concrete Solutions for Environmental SustainabilitySov BeNo ratings yet

- Standard Abbreviation List by Siemens 36Document1 pageStandard Abbreviation List by Siemens 36Pendl PendlNo ratings yet

- New Microsoft Office Word DocumentDocument3 pagesNew Microsoft Office Word DocumentRameshLoganathanNo ratings yet

- E 106Document1 pageE 106Bith SMGNo ratings yet

- Stainless Steel Hand Pallet: Material Handling and LiftingDocument1 pageStainless Steel Hand Pallet: Material Handling and LiftingAULIANo ratings yet

- Effects of Commercial Kitchen Pressure On Exhaust System PerformanceDocument8 pagesEffects of Commercial Kitchen Pressure On Exhaust System Performanceakumachi2009No ratings yet

- Minh Viet HR - ProfileDocument23 pagesMinh Viet HR - ProfileAriesNhaNo ratings yet

- Manual TG1Document19 pagesManual TG1Jose Manuel Pereira LópezNo ratings yet

- Hospital Wastewater Treatment Plant ComponentsDocument2 pagesHospital Wastewater Treatment Plant ComponentsRina D RakhmaNo ratings yet

- Foam Core PVC PipeDocument9 pagesFoam Core PVC Pipe7140220No ratings yet

- Architects in Bangalore House Residential Architects in Bangalore at Architects4DesignDocument28 pagesArchitects in Bangalore House Residential Architects in Bangalore at Architects4DesignNaveen BansalNo ratings yet

- Manual Guidelines Mine Haul Road Design Haul Trucks Roads Planning Alignment Sections Surface Construction EconomicsDocument95 pagesManual Guidelines Mine Haul Road Design Haul Trucks Roads Planning Alignment Sections Surface Construction EconomicsKRUSHNA CHANDRA GUJIRINo ratings yet

- Harmony Xb7 Xb7nd33Document6 pagesHarmony Xb7 Xb7nd33elborniNo ratings yet

- Astm D1599 PDFDocument3 pagesAstm D1599 PDFChemical Engineer100% (3)