Professional Documents

Culture Documents

Prinzipschema Eng

Uploaded by

Luis AlbanesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prinzipschema Eng

Uploaded by

Luis AlbanesCopyright:

Available Formats

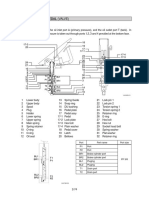

R/I - Drawing

Thermal oil heating plant

Regiomat guarantees a controllable flow through the heater. The thermal oil has the possibility to expand

over a non-turn-off pipeline between the heater and the expansion vessel. The nitrogen in the expansion

vessel guarantees the necessary pressure balance and protects the thermal oil from the oxygen in the air.

This is the reason why the thermal oil doesn't oxidize even when we have high temperatures. So you have a

system which works for more than 15 years without any problems.

The necessary safety installations are:

A flow controller to make sure that enough thermal oil flows.

A level switch to make sure that there is enough thermal oil in the system and that no gas can get into

the system. Because it is not allowed to run the pump in a dry condition.

A thermostat in the main pipeline to make sure that the temperature of the thermal oil can not get higher

as a defined maximum temperature.

A thermostat for the flue gas to make sure that the temperature of the flue gas is not higher than a

defined maximum temperature.

A pressostat to make sure that there is enough nitrogen pressure.

28 Main flow pipe

14 15 16 17

PI PZA- Consumer

21 TIC

5 25

20 TZA+

19 FIAZ-

LI

18

TZA+ 1

26 LI

2 4 27

N 24

Heater 13 LI

LZA-

23 TI

22 TOS-

7

12 12

PI M PI 8

6 Main return pipe

9 11 3 11 10 9

Legende:

1 Heater 11 Vibration absorber 21 Temperature controller

2 Burner 12 Manometer 22 Thermostat

3 Circulation pump 13 Nitrogen 23 Temperature gauge

4 Expansion vessel 14 Safety valve 24 Level switch

5 Nitrogen system 15 Vacuum breaker 25 Rupture disk

6 Gas collection bottle 16 Manometer 26 Level control

7 Autom. centralized air separator 17 Pressostat 27 Filling pump

8 Cock with cap 18 Thermostat flue gas 28 Safety valve

9 Shut-off valves 19 Flow control

10 Strainer 20 Thermostat main pipe

You might also like

- Electrical System Components Locations GuideDocument3 pagesElectrical System Components Locations GuideEliseo CenicerosNo ratings yet

- 7 96892 - A3 FoldoutsDocument54 pages7 96892 - A3 FoldoutsLuis Eduardo Corzo EnriquezNo ratings yet

- Section 4 Electrical SystemDocument3 pagesSection 4 Electrical SystemTaha RdmanNo ratings yet

- NL BKDX30 95Document4 pagesNL BKDX30 95Željko ĆavarNo ratings yet

- Transformer Components ExplainedDocument2 pagesTransformer Components ExplainedPanas JeNo ratings yet

- Standing Freezer Esploso - Ricambi - STA - HFC - 20190401Document1 pageStanding Freezer Esploso - Ricambi - STA - HFC - 20190401viewtrading878No ratings yet

- 4-1 Component locationDocument3 pages4-1 Component locationwilfredo escobar gutierrezNo ratings yet

- Steam to Turbine Flow ProcessDocument2 pagesSteam to Turbine Flow ProcessNur Ali SaidNo ratings yet

- 5-1. Steering SystemDocument58 pages5-1. Steering SystemSaidi JalelNo ratings yet

- TRO unit component part namesDocument1 pageTRO unit component part namesMark Dominic FedericoNo ratings yet

- Group 6 RCV Pedal: 1. StructureDocument6 pagesGroup 6 RCV Pedal: 1. StructureАлексейNo ratings yet

- H Series Above GroundDocument4 pagesH Series Above GroundLlanca BlasNo ratings yet

- Section 4 Electrical SystemDocument3 pagesSection 4 Electrical SystemDavidNo ratings yet

- Section 5 Steering SystemDocument16 pagesSection 5 Steering SystemaimerNo ratings yet

- TEKNA Gravity PartsDocument2 pagesTEKNA Gravity PartsjohnNo ratings yet

- WelehDocument1 pageWelehRafaell SantaNo ratings yet

- GROUP 10 STEERING VALVE CONTROLDocument2 pagesGROUP 10 STEERING VALVE CONTROLTaha RdmanNo ratings yet

- Group 7 Brake Pedal (Valve)Document2 pagesGroup 7 Brake Pedal (Valve)hungNo ratings yet

- GROUP 10 STEERING VALVE COMPONENTSDocument2 pagesGROUP 10 STEERING VALVE COMPONENTSعمروصالح كليسNo ratings yet

- Group 7 Brake Pedal (Valve) : 1. StructureDocument2 pagesGroup 7 Brake Pedal (Valve) : 1. StructureĐạt VươngNo ratings yet

- PVG 32 Proportional Valve Group General Description: Technical InformationDocument1 pagePVG 32 Proportional Valve Group General Description: Technical InformationjonNo ratings yet

- Single Skid Lubrication and Hydraulic System 07Document23 pagesSingle Skid Lubrication and Hydraulic System 07masdikaNo ratings yet

- 2 10 PDFDocument2 pages2 10 PDFarmando vara chavezNo ratings yet

- Group 10 Steering Valve: 1. StructureDocument2 pagesGroup 10 Steering Valve: 1. StructureالمهندسوليدالطويلNo ratings yet

- 2 10 PDFDocument2 pages2 10 PDFالمهندسوليدالطويلNo ratings yet

- Section 5 Steering SystemDocument19 pagesSection 5 Steering SystemMarco OlivettoNo ratings yet

- Interface - Signal Locations: Interface Viewed From BelowDocument2 pagesInterface - Signal Locations: Interface Viewed From Belowmdelvallev100% (3)

- Group 10 Steering Valve: 1. StructureDocument2 pagesGroup 10 Steering Valve: 1. StructureĐạt VươngNo ratings yet

- Section 4 Electrical SystemDocument3 pagesSection 4 Electrical SystemWagner Hudson WaguinhoNo ratings yet

- QST30 GCS ConnectionsDocument5 pagesQST30 GCS ConnectionsOGNo ratings yet

- Hyundai R140W-9 Electrical SystemDocument56 pagesHyundai R140W-9 Electrical SystemHai Van100% (1)

- Group 7 Brake Pedal (Valve)Document2 pagesGroup 7 Brake Pedal (Valve)Quốc Phú ĐinhNo ratings yet

- 12248-Parts Illustrations Model JU4H-UF34Document17 pages12248-Parts Illustrations Model JU4H-UF34Kedabu tarulukNo ratings yet

- Group 7 Brake Pedal (Valve)Document2 pagesGroup 7 Brake Pedal (Valve)Taha RdmanNo ratings yet

- Dometic 2018 Price ListDocument132 pagesDometic 2018 Price ListNerdy100% (1)

- Magneti Marelli g5 g6 IntDocument4 pagesMagneti Marelli g5 g6 IntEdsonNo ratings yet

- Medium pressure blade hydraulic schematicDocument12 pagesMedium pressure blade hydraulic schematicPauk HseinNo ratings yet

- Group 10 Steering Valve: 1. StructureDocument2 pagesGroup 10 Steering Valve: 1. StructureANDREI26No ratings yet

- Electrical System Component LocationsDocument3 pagesElectrical System Component LocationsmarpsonNo ratings yet

- Absorption Refrigeration System (ARS)Document20 pagesAbsorption Refrigeration System (ARS)Samaid AbdullahNo ratings yet

- 4-1. Electrical System HindaiDocument60 pages4-1. Electrical System Hindaimiguel angelNo ratings yet

- Diesel Engine Diagram (For CD 15/18/20/25/30/35 P)Document2 pagesDiesel Engine Diagram (For CD 15/18/20/25/30/35 P)Helmax ForkliftNo ratings yet

- Hydraulic System 817-18523Document2 pagesHydraulic System 817-18523a.ilchuk39No ratings yet

- Rahma - Presentation OJT BismillahDocument33 pagesRahma - Presentation OJT Bismillahrizki dermawanNo ratings yet

- Mobile Fuel Tank Volumetrical Calibration System: Electrical Wiring and DiagramDocument9 pagesMobile Fuel Tank Volumetrical Calibration System: Electrical Wiring and DiagramJohn peñaNo ratings yet

- Electric Motor Peripheral Water PumpDocument3 pagesElectric Motor Peripheral Water PumpzhelipumpNo ratings yet

- Electrical System Components and LocationsDocument3 pagesElectrical System Components and LocationsAlbert BhattiNo ratings yet

- Legend: Hydraulic/Hydrostatic Schematic 319 (S/N 563311001 AND ABOVE)Document2 pagesLegend: Hydraulic/Hydrostatic Schematic 319 (S/N 563311001 AND ABOVE)Леонид ЮртаевNo ratings yet

- Sampling Pump DatasheetDocument2 pagesSampling Pump DatasheetAkash100% (1)

- Proposed Engineering Needs and Budget for Special Forces Brigade 2019Document16 pagesProposed Engineering Needs and Budget for Special Forces Brigade 2019Mohamed SameerNo ratings yet

- GD Chigo Heating & Ventilation Equipment Co., LTD.: Technical Support Division 2016-7Document42 pagesGD Chigo Heating & Ventilation Equipment Co., LTD.: Technical Support Division 2016-7osama shamoutNo ratings yet

- 3 1 PDFDocument2 pages3 1 PDFjulio cesarNo ratings yet

- Section 4 Electrical SystemDocument3 pagesSection 4 Electrical SystemYamilaNo ratings yet

- Injectors, Pressure Pipes and Leak-Off Line TAMD71B AUX PDFDocument2 pagesInjectors, Pressure Pipes and Leak-Off Line TAMD71B AUX PDFKALIL100% (1)

- Control Valve NetralDocument2 pagesControl Valve NetralSyakurNo ratings yet

- Screw Service ManualDocument71 pagesScrew Service Manualteddy_shasha89% (18)

- S# Direction Packrack Hydrocarbon Service DiaDocument4 pagesS# Direction Packrack Hydrocarbon Service DiaMuhammad Moeed AlamNo ratings yet

- Building Ideas: An Architectural Guide to the University of ChicagoFrom EverandBuilding Ideas: An Architectural Guide to the University of ChicagoRating: 4.5 out of 5 stars4.5/5 (2)

- Piston Ring TribologyDocument108 pagesPiston Ring TribologyShrigopal Prajapat100% (2)

- G (B) Visual and Dye-Penetrant Examination ReportDocument1 pageG (B) Visual and Dye-Penetrant Examination ReportArnaldoNo ratings yet

- Pipe Fitters HandbookDocument306 pagesPipe Fitters HandbookAto Kwamina AndersenNo ratings yet

- SSC160 Plug-in/Plug-out TerminationDocument2 pagesSSC160 Plug-in/Plug-out TerminationLuis AlbanesNo ratings yet

- Nrel Cost ReportDocument106 pagesNrel Cost ReportRao PanidapuNo ratings yet

- GE-Fuel Cell 020216Document43 pagesGE-Fuel Cell 020216Luis AlbanesNo ratings yet

- GP Engineer Guide Eng 2016 V19 WebDocument134 pagesGP Engineer Guide Eng 2016 V19 WebLuis AlbanesNo ratings yet

- Wartsila o e W 46fDocument2 pagesWartsila o e W 46fLuis AlbanesNo ratings yet

- Wildland Fire-Related Codes and StandardsDocument38 pagesWildland Fire-Related Codes and StandardsLuis AlbanesNo ratings yet

- Product Guide o e w32Document254 pagesProduct Guide o e w32Luis AlbanesNo ratings yet

- Plan Fuel CellDocument122 pagesPlan Fuel CellLuis AlbanesNo ratings yet

- Spiral Cone UnfoldDocument12 pagesSpiral Cone UnfoldLuis AlbanesNo ratings yet

- Cladodes: A Source of Dietary FiberDocument7 pagesCladodes: A Source of Dietary FiberLuis AlbanesNo ratings yet

- AWS D1-1 PQR-WPS Yes Pre QualifiedDocument2 pagesAWS D1-1 PQR-WPS Yes Pre QualifiedJRodengineerNo ratings yet

- RF Fire Department Connection in Let Flow AssessmentDocument68 pagesRF Fire Department Connection in Let Flow AssessmentLuis AlbanesNo ratings yet

- Acrp RPT 141 Renewable EnergyDocument204 pagesAcrp RPT 141 Renewable EnergyLuis AlbanesNo ratings yet

- ASTM A27 Spec For General Steel CastingsDocument4 pagesASTM A27 Spec For General Steel CastingsKarthik Nagendra0% (1)

- Fire Protection Design Manual: Department of Veterans AffairsDocument71 pagesFire Protection Design Manual: Department of Veterans AffairsmitasyahuNo ratings yet

- APC - Grounding and The Use of The Signal Reference Grid in Data CenteresDocument9 pagesAPC - Grounding and The Use of The Signal Reference Grid in Data CentereswgetsubscribersNo ratings yet

- SchneiderDocument5 pagesSchneiderG_RanjithNo ratings yet

- Spirax Sarco - Compressed Air ManualDocument21 pagesSpirax Sarco - Compressed Air ManualCMEngineers100% (1)

- ASTM A47-A47M - Spec For Ferritic Malleable Iron Castings PDFDocument5 pagesASTM A47-A47M - Spec For Ferritic Malleable Iron Castings PDFLuis Albanes100% (3)

- Whole Building DesignDocument116 pagesWhole Building DesignLuis AlbanesNo ratings yet

- ASTM A 269 Standar Spec. For Seamless and Welded Autenitic SS TubingDocument6 pagesASTM A 269 Standar Spec. For Seamless and Welded Autenitic SS TubingJose TorresNo ratings yet

- Gard P I Club News179 A Fatal LPG Tanker AccidentDocument2 pagesGard P I Club News179 A Fatal LPG Tanker AccidentwojciechkoziolNo ratings yet

- ICLP Conference Calls for Withdrawal of Conflicting Lightning Protection StandardsDocument3 pagesICLP Conference Calls for Withdrawal of Conflicting Lightning Protection StandardsLuis AlbanesNo ratings yet

- ICLP Conference Calls for Withdrawal of Conflicting Lightning Protection StandardsDocument3 pagesICLP Conference Calls for Withdrawal of Conflicting Lightning Protection StandardsLuis AlbanesNo ratings yet

- Ana BchoachDocument2 pagesAna BchoachLuis AlbanesNo ratings yet

- Galvanized and Black Malleable Iron Pipe Fittings SpecificationsDocument24 pagesGalvanized and Black Malleable Iron Pipe Fittings SpecificationsdeniNo ratings yet

- Ayurveda Signs of LifeDocument15 pagesAyurveda Signs of LifeSanjeethNo ratings yet

- Soft Computing Techniques Assignment1 PDFDocument14 pagesSoft Computing Techniques Assignment1 PDFshadan alamNo ratings yet

- 10 ExtSpringsDocument27 pages10 ExtSpringsresh27No ratings yet

- A. evolve B. protect C. argue D. resist: Thời gian làm bài: 45 phút, không kể thời gian phát đềDocument5 pagesA. evolve B. protect C. argue D. resist: Thời gian làm bài: 45 phút, không kể thời gian phát đềPham Thuy HuyenNo ratings yet

- CM Group Marketing To Gen Z ReportDocument20 pagesCM Group Marketing To Gen Z Reportroni21No ratings yet

- Statistics Interview QuestionsDocument5 pagesStatistics Interview QuestionsARCHANA R100% (1)

- PC 4 Product List 2019 - Pc4Document28 pagesPC 4 Product List 2019 - Pc4ShNo ratings yet

- As Biology Revision L3 Cells Microscopes and IAM PPQ 2Document7 pagesAs Biology Revision L3 Cells Microscopes and IAM PPQ 2Anonymous fFKqcYNo ratings yet

- Bashir Ahmad NewDocument3 pagesBashir Ahmad NewBashir AhmadNo ratings yet

- A6V12050595 - Valve Actuator DIL-Switch Characteristic Overview - deDocument42 pagesA6V12050595 - Valve Actuator DIL-Switch Characteristic Overview - depolo poloNo ratings yet

- Dayal Bagh: Spircon 2013: Book of AbstractsDocument202 pagesDayal Bagh: Spircon 2013: Book of AbstractsSant Mat100% (2)

- Advances in X-Ray Analysis - Volume 33 - 1989Document685 pagesAdvances in X-Ray Analysis - Volume 33 - 1989CVNo ratings yet

- PLTW: Digital Electronics Syllabus For Mrs. Yusufi: Unit 1: Fundamentals of Analog and DigitalDocument5 pagesPLTW: Digital Electronics Syllabus For Mrs. Yusufi: Unit 1: Fundamentals of Analog and DigitalTriston DurbinNo ratings yet

- Explosive Ordnance DisposalDocument13 pagesExplosive Ordnance DisposalZelwisNo ratings yet

- Sensor Guide: Standard Triaxial Geophones Specialty Triaxial Geophones Standard Overpressure MicrophonesDocument1 pageSensor Guide: Standard Triaxial Geophones Specialty Triaxial Geophones Standard Overpressure MicrophonesDennis Elias TaipeNo ratings yet

- Kerala University 2013 Admission ProspectusDocument50 pagesKerala University 2013 Admission ProspectusMuneer SainulabdeenNo ratings yet

- Sist-En-6101-2016 .Document9 pagesSist-En-6101-2016 .lokelooksNo ratings yet

- Forensic Pharmacy: Dr. Zirwa AsimDocument35 pagesForensic Pharmacy: Dr. Zirwa AsimZirwa AsimNo ratings yet

- Introducing The Phenomenon To Be Discussed: Stating Your OpinionDocument8 pagesIntroducing The Phenomenon To Be Discussed: Stating Your OpinionRam RaghuwanshiNo ratings yet

- DLP IN ICT 9 1st MeetingDocument2 pagesDLP IN ICT 9 1st MeetingHEDDA FULONo ratings yet

- Ucc 900 Sor em Wpi 0001 - B01Document73 pagesUcc 900 Sor em Wpi 0001 - B01JonesNo ratings yet

- Graffiti Model Lesson PlanDocument9 pagesGraffiti Model Lesson Planapi-286619177100% (1)

- World MultipleDocument271 pagesWorld MultipleatrkpoleNo ratings yet

- Final Paper - PARTIALDocument64 pagesFinal Paper - PARTIALDeanna GicaleNo ratings yet

- Verb-Particle Constructions in Romance. A Lexical-Syntactic AccountDocument29 pagesVerb-Particle Constructions in Romance. A Lexical-Syntactic AccountWagaJabalNo ratings yet

- An Introduction to Heisenberg Groups in Analysis and GeometryDocument7 pagesAn Introduction to Heisenberg Groups in Analysis and Geometrynitrosc16703No ratings yet

- CS 704 Socio-Emotional and Moral Development in Middle ChildhoodDocument25 pagesCS 704 Socio-Emotional and Moral Development in Middle ChildhoodPatricia PamintuanNo ratings yet

- Aw MD700 Manual G10 150706Document73 pagesAw MD700 Manual G10 150706Heraldo Ulguim Luis OliveiraNo ratings yet