Professional Documents

Culture Documents

Sop Mesin Hidrolik

Uploaded by

Vevi Elvira SiicewetvirapoenyanyasiiEapOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sop Mesin Hidrolik

Uploaded by

Vevi Elvira SiicewetvirapoenyanyasiiEapCopyright:

Available Formats

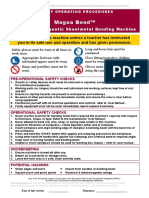

S T A N D A R D OP E R A TI N G PR OC ED UR E

Hydraulic Press

DO NOT use this machine unless you have been trained and assessed to a

competent level in its safe use and operation, and have been given

permission to use this equipment.

Safety glasses must be worn when Long and loose hair must be contained

operating this equipment. when operating this equipment.

Safety footwear must be worn when Close fitting/protective clothing must be

operating this equipment. worn when operating this equipment.

Rings and jewellery must not be worn

when operating this equipment.

PRE-OPERATIONAL SAFETY CHECKS

1. Ensure that risk assessment has been read. UQ risk assessment task ID #35690.

2. Ensure no slip/trip hazards are present in workspaces and walkways.

3. Check for hydraulic fluid leaks.

4. Check that all guards are in position if appropriate.

5. Faulty equipment must not be used. Immediately report suspect machinery.

OPERATIONAL SAFETY CHECKS

1. Move adjusting beam to correct height and secure pins.

2. Ensure column pins are fully engaged after adjusting height.

3. Safely position table plates to support and secure job.

4. Carefully align work under press for even force to be applied.

5. Position a suitable drift between arbor and object to be pressed.

6. Ensure job parts are aligned properly before and during the pressing process and clean to avoid

being squeezed out or ejected, be sure item or parts cant fly out under load or drop to the floor.

7. Utilise machine guards if available and when appropriate.

8. Keep head, hands & other body parts clear of both the job parts and machine while press is being

operated.

9. Close relief valve and engage contact with arbor or drift.

10. Do NOT apply excessive force.

11. Carefully operate pump handle using minimum force required to complete the press job.

12. Beware that high forces are being applied during the pressing process.

13. When press operation is complete open the relief valve to release pressure and remove items.

HOUSEKEEPING

1. Return all tooling and fixtures to the correct storage location.

2. Leave the machine in a safe, clean and tidy state.

3. Return surplus material to stock & dispose of waste material in an appropriate recycling or waste bin

POTENTIAL HAZARDS

Falling objects Manual handling objects

Crush and pinch points Eye injuries

FORBIDDEN

Distracting operator

This SOP does not necessarily cover all possible hazards associated with the machine and should be used in conjunction with other references

It is designed to be used as an adjunct to teaching Safety Procedures and to act as a reminder to users prior to machine use.

Document: SP-047-B Last reviewed: 06/06/13

You might also like

- SP-091-C CNC Router SOPDocument1 pageSP-091-C CNC Router SOPBorislav VulićNo ratings yet

- Sop - Bar BendingDocument1 pageSop - Bar BendingHARSHAD50% (2)

- Magna Bend SopDocument1 pageMagna Bend SopClarkKent Fabro Batucan0% (1)

- SOP Pines Tube Bender #1002123456789112345Document3 pagesSOP Pines Tube Bender #1002123456789112345saturnelNo ratings yet

- TIG Welder Safety ProcedureDocument2 pagesTIG Welder Safety ProcedureShahid RazaNo ratings yet

- Standard Operating Procedures: CNC RouterDocument3 pagesStandard Operating Procedures: CNC RouterBien LeNo ratings yet

- Form Inspeksi CompressorDocument1 pageForm Inspeksi CompressorekoimampNo ratings yet

- SOP Workshop Hy FinalDocument4 pagesSOP Workshop Hy FinalanbuNo ratings yet

- Bench GrinderDocument1 pageBench GrinderSreejith S NairNo ratings yet

- Chain Block InspectionDocument1 pageChain Block InspectionMochammad AriefNo ratings yet

- Metal Bandsaw: Use and Operation and Has Given PermissionDocument2 pagesMetal Bandsaw: Use and Operation and Has Given PermissionPHH9834No ratings yet

- Maestronano Pro Spectrophotometer: Instruction ManualDocument40 pagesMaestronano Pro Spectrophotometer: Instruction ManualYuriAlexanderEspinozaPugaNo ratings yet

- Portable Eyewash Inspection ChecklistDocument1 pagePortable Eyewash Inspection Checklistarunjith r100% (1)

- Install Insulation SOPDocument5 pagesInstall Insulation SOPnida ahmad musyafa ptasrNo ratings yet

- SWP Welder Gas Metal Arc AS560Document2 pagesSWP Welder Gas Metal Arc AS560Kamal ShaariNo ratings yet

- 2.contoh Jsa Form 2003Document63 pages2.contoh Jsa Form 2003f_hunila100% (1)

- Job Hazard Analysis for Deep Well Drilling with HotworksDocument2 pagesJob Hazard Analysis for Deep Well Drilling with Hotworksjay RNo ratings yet

- Swamper DutiesDocument1 pageSwamper DutiesGoldwin Ricky AritonangNo ratings yet

- Sop Saw Power HacksawDocument1 pageSop Saw Power HacksawBorislav VulićNo ratings yet

- PROSEDUR PEMERIKSAAN ALAT DAN PERALATANDocument7 pagesPROSEDUR PEMERIKSAAN ALAT DAN PERALATANFendi AchmadNo ratings yet

- Operation of CNC Machine JSA PDFDocument2 pagesOperation of CNC Machine JSA PDFashok Kumar100% (1)

- Manual Milling ChecklistDocument17 pagesManual Milling ChecklistSasa MonicaNo ratings yet

- 1) SWP - Forklifts - 2Document4 pages1) SWP - Forklifts - 2John Rey PerlasNo ratings yet

- JSA For Washing and Air BlowingDocument3 pagesJSA For Washing and Air BlowingMohammed MinhajNo ratings yet

- SOP - Stick WeldingDocument1 pageSOP - Stick WeldingMALLADI PRADEEPNo ratings yet

- Mitre SawDocument1 pageMitre Sawapi-534238122No ratings yet

- Operation Control - Powered and Hand Tools Procedure: Pt. Eskimo WieraperdanaDocument7 pagesOperation Control - Powered and Hand Tools Procedure: Pt. Eskimo WieraperdanadennisjuntakNo ratings yet

- Part 3 ObservationsDocument7 pagesPart 3 ObservationsAmjadNo ratings yet

- Hiradc LiftingDocument2 pagesHiradc LiftingAsvini SegeranNo ratings yet

- Msds ArgonDocument8 pagesMsds ArgonsigitNo ratings yet

- Jsa For WeldingDocument2 pagesJsa For WeldingMohamed Samir50% (2)

- HSE work at height inspection checklistDocument6 pagesHSE work at height inspection checklistoka andrea0% (1)

- Scissor Lift ChecklistDocument1 pageScissor Lift ChecklistDIBNESH PANDITA100% (1)

- Risk Assessment For Cleaning ServicesDocument11 pagesRisk Assessment For Cleaning ServicesThandabantu MagengeleleNo ratings yet

- Sop of ScaffoldingDocument3 pagesSop of ScaffoldingSanjeet SinghNo ratings yet

- Boom Lift - Daily ChecklistDocument1 pageBoom Lift - Daily Checklistpawankumar100% (2)

- 54 FGD-JSA - Pickling & Passivation WorkDocument5 pages54 FGD-JSA - Pickling & Passivation WorkRamesh Babu Palnati100% (1)

- Sogetrap JSA Lifting Cabin by ForkliftDocument2 pagesSogetrap JSA Lifting Cabin by ForkliftTSP HSENo ratings yet

- Bench GrinderDocument6 pagesBench GrinderGaurav KhamkarNo ratings yet

- Ppe When Working at HeightDocument2 pagesPpe When Working at Heightekoimamp100% (2)

- Form Cheklist Inspection APARDocument1 pageForm Cheklist Inspection APARqhse 3dihajiNo ratings yet

- 14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneDocument1 page14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneSHAH NAWAZ SAEEDNo ratings yet

- SOP Gas Cutting and Heating .Document1 pageSOP Gas Cutting and Heating .aarunsnairNo ratings yet

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsDocument2 pagesJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- Golden Rules SafetyDocument5 pagesGolden Rules SafetyWimboro Galasakti PrabowoNo ratings yet

- Sop For Operation of EotDocument2 pagesSop For Operation of Eotsaji kumarNo ratings yet

- SOP - Milling MachineDocument1 pageSOP - Milling MachineBagan PolaNo ratings yet

- Shaping MachineDocument1 pageShaping MachineUmashankar DebBarmaNo ratings yet

- Jsa Loading UnloadingDocument8 pagesJsa Loading Unloadinghilmi hilmiNo ratings yet

- No Telp Penting Cikarang - BekasiDocument7 pagesNo Telp Penting Cikarang - BekasifafarifaNo ratings yet

- Topic For TBMDocument19 pagesTopic For TBMdauxomNo ratings yet

- Hand Tools SOPDocument3 pagesHand Tools SOPAchmad Faisal FaputriNo ratings yet

- Occupational Safety and Health Industry Code of Practice for Road TransportDocument21 pagesOccupational Safety and Health Industry Code of Practice for Road TransportSaravanan RasayaNo ratings yet

- HSE Plan PT Techno Prefab IndonesiaDocument16 pagesHSE Plan PT Techno Prefab IndonesiaAyu Wulan SariNo ratings yet

- JAPL-F-HE-002-Weekly Excavator Inspection ChecklistDocument2 pagesJAPL-F-HE-002-Weekly Excavator Inspection ChecklistAli Hassan100% (2)

- Jsa n2 Purging PDF FreeDocument1 pageJsa n2 Purging PDF FreeSKH CultureNo ratings yet

- M S D S - Polymer CationicDocument3 pagesM S D S - Polymer CationicHeru PrasetyoNo ratings yet

- SP-020-B Electrically Powered Hand Tools SOPDocument1 pageSP-020-B Electrically Powered Hand Tools SOPDeon Pillay100% (1)

- Hydraulic Press: Use and Operation and Has Given PermissionDocument1 pageHydraulic Press: Use and Operation and Has Given PermissionAVIJIT SENNo ratings yet

- Manual Bending Rolls Safe Work ProcedureDocument2 pagesManual Bending Rolls Safe Work Procedurejason cepadaNo ratings yet

- Aseptomag Valve Technology - Order Code: Aseptic Double Chamber Bottom-Seat Valve DKBSDocument4 pagesAseptomag Valve Technology - Order Code: Aseptic Double Chamber Bottom-Seat Valve DKBSMahendra WedastamaNo ratings yet

- Procedures for Operating the Chandler Static Gel Strength AnalyzerDocument5 pagesProcedures for Operating the Chandler Static Gel Strength AnalyzeremiljuchiacNo ratings yet

- EGB-29P 58P Product SpecDocument4 pagesEGB-29P 58P Product SpecFathima ReginNo ratings yet

- Gladiator Inflatable Boats - User's Manual: Page 1 of 16Document16 pagesGladiator Inflatable Boats - User's Manual: Page 1 of 16Mihai AlexandruNo ratings yet

- New CV Fase ServiceDocument5 pagesNew CV Fase ServicemiodragNo ratings yet

- Study Control ValvesDocument1 pageStudy Control ValvesCarlos LoboNo ratings yet

- Lamborghini Diablo Engine Parts ManualDocument40 pagesLamborghini Diablo Engine Parts ManualAndrei Huţanu100% (1)

- SSR Up6 40 PDFDocument208 pagesSSR Up6 40 PDFDavid GarciaNo ratings yet

- SP-2154 - 2015valves Technical SpecificationDocument23 pagesSP-2154 - 2015valves Technical Specificationarjunprasannan7No ratings yet

- Series 1500/2500 Safety Relief ValvesDocument12 pagesSeries 1500/2500 Safety Relief ValvesSandro ChiliquingaNo ratings yet

- Contoh Itp Mechanical PltuDocument2 pagesContoh Itp Mechanical PltuyusufNo ratings yet

- BURNER MANAGEMENT SYSTEMS GUIDEDocument7 pagesBURNER MANAGEMENT SYSTEMS GUIDECalNo ratings yet

- MODEL 4500 Hydraulic Tubing Tong Operations and Service ManualDocument39 pagesMODEL 4500 Hydraulic Tubing Tong Operations and Service ManualDano CustodioNo ratings yet

- Dozing Equipment Hydraulic System D180 Power Steering: Section 6Document54 pagesDozing Equipment Hydraulic System D180 Power Steering: Section 6veljkoNo ratings yet

- Flush Bottom Valve Installation-Maintenance-Manual PDFDocument12 pagesFlush Bottom Valve Installation-Maintenance-Manual PDFtuscan23No ratings yet

- Ejercicios y Soluciones de Electroneumatica 15Document33 pagesEjercicios y Soluciones de Electroneumatica 15Alexander PenadoNo ratings yet

- Treadle ValveDocument8 pagesTreadle ValveBOB100% (1)

- Manual de Instalacion, Operacion y Mantenimiento de Bomba Gorman Rupp Serie vg3c3Document30 pagesManual de Instalacion, Operacion y Mantenimiento de Bomba Gorman Rupp Serie vg3c3muahdib100% (1)

- Applicable Standards - Ball & Plug Valves: Spec. 6A Spec. 6D Spec. RP6F Spec. 6FA Std. 598 Std. 605 Std. 607 ISO 9001Document2 pagesApplicable Standards - Ball & Plug Valves: Spec. 6A Spec. 6D Spec. RP6F Spec. 6FA Std. 598 Std. 605 Std. 607 ISO 9001Ercan YilmazNo ratings yet

- Repair Manual D2866LE enDocument156 pagesRepair Manual D2866LE enNazik94% (17)

- KinetrolDocument8 pagesKinetrolimbasdNo ratings yet

- Sigma 3 Servo Motor Er20 50 Pre 2003Document51 pagesSigma 3 Servo Motor Er20 50 Pre 2003Nishanth KallingentavidaNo ratings yet

- Manual PELTON PDFDocument14 pagesManual PELTON PDFsyahirabdullahNo ratings yet

- Challenger enDocument2 pagesChallenger enluis miguel escobar rondinelNo ratings yet

- 34 Samss 611Document8 pages34 Samss 611naruto256No ratings yet

- Valve - Manual Override PDFDocument2 pagesValve - Manual Override PDFGeorge_Wabag_2014No ratings yet

- FLEA 2010 REVIEW - SANITARY AND PLUMBING SYSTEMSDocument105 pagesFLEA 2010 REVIEW - SANITARY AND PLUMBING SYSTEMSCams JordanNo ratings yet

- Bomba Hidraulica Sauer Sustran Serie 90Document88 pagesBomba Hidraulica Sauer Sustran Serie 90mantenedor01100% (1)

- Westbay Mechanial SpecsDocument174 pagesWestbay Mechanial SpecsHARISH ROHANNo ratings yet

- Architectural Correlations: A History of Plumbing Design and StandardsDocument35 pagesArchitectural Correlations: A History of Plumbing Design and StandardsCes Dela CruzNo ratings yet