Professional Documents

Culture Documents

DNV Os-E201 - 2012-12

Uploaded by

Muthu Kumar0 ratings0% found this document useful (0 votes)

145 views1 pageDNV Code

Original Title

DNV OS-E201_2012-12

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDNV Code

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

145 views1 pageDNV Os-E201 - 2012-12

Uploaded by

Muthu KumarDNV Code

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Offshore Standard DNV-OS-E201, December 2012

Ch.3 Sec.3 Page 66

203 Categorisation of piping components shall be according to Table B2.

Table B2 Categories for piping and components

Category

Component Application or rating or description

IA IB IC II

Flow metering- and instrumentation pipe- Including supports and attachments X

spools, pig receivers, pig launcher and

other special piping items 2)

Standard type X

Flanges and couplings 1) Non-standard type for high pressure, flammable or toxic

fluids X

Valves for Gas & Hydrocarbons

(DN 350 mm and P 100 bar) or X

Valves (DN 25 mm and P 500 bar)6)

(incl. Choke valves) Valves for fluids X

(DN 25 mm and P 500 bar6)

Non-standard valves X

ESD and blow down valves Including actuator and controls. 2) X

Safety valves and rupture discs 2), 3) X

Christmas tree valves, blocks, Surface trees only, unless subsea trees are covered by

X

connections etc. extended scope

Including pressure retaining instruments and special

Non-standard components X

piping parts. 4)

Expansion joints, bellows For flammable or toxic fluids X

Flexible hoses For flammable or toxic fluids X

Swivels and swivel stacks For flammable or toxic fluids X

General instruments Standard, well proven instruments, thermowells, X

pressure gauges, switches, control valves etc.

Flare and vent Booms, stack or ground flare, including structures X

Burners and flare tip X

Hydraulic and pneumatic control and 5)

shutdown panels X

1) The extent of witnessing tests for category IA piping components may be agreed with DNV for spools etc. containing non-

flammable, non-toxic fluids at low temperature (below 220C) and at low pressures (below 10 bar).

2) A reduced categorisation may be agreed with DNV for spools etc. containing non-flammable, non-toxic fluids at low temperature

(below 220C) and at low pressures (below 10 bar).

3) Design review of valve and bursting disc is not required. The extent of witnessing of leak-, calibration-, capacity- and

qualification- testing to be agreed with DNV based on manufacturers QA/QC system. DNV shall normally witness batch

qualification tests of bursting discs.

4) Categorisation and approval procedure to be agreed with DNV on a case by case basis, considering selection of materials, service

and complexity of design and fabrication method.

5) The approval procedure to be agreed with DNV on a case by case basis, depending on function and criticality. See also relevant

standards covering instrumentation and automation.

6) Otherwise category II, unless special or unconventional design which is considered category IB.

DET NORSKE VERITAS AS

You might also like

- Hydrant ValvesDocument4 pagesHydrant ValvesoscarninanNo ratings yet

- 01 Introduction To DunlopDocument33 pages01 Introduction To DunlopFikret YenenNo ratings yet

- API Specification 6D 24th Edition Errata 10 20210803Document1 pageAPI Specification 6D 24th Edition Errata 10 20210803ANANDNo ratings yet

- 10 Year Periodic Testing of LPG Spherical TankDocument1 page10 Year Periodic Testing of LPG Spherical TankBNH Gas TanksNo ratings yet

- Pfi Es-48Document7 pagesPfi Es-48Ecruz Cruz LNo ratings yet

- Ico3s Iom ManualDocument2 pagesIco3s Iom ManualAditya B. RyantoNo ratings yet

- EN 12277 enDocument1 pageEN 12277 enDean WilyNo ratings yet

- Written Schemes of Examinations Example Template - Course DownloadDocument9 pagesWritten Schemes of Examinations Example Template - Course Downloadgamil2No ratings yet

- Iso 91 2017Document22 pagesIso 91 2017anitagissellatapiaNo ratings yet

- UKOOA Hose Management Document Rev 3 FINALDocument59 pagesUKOOA Hose Management Document Rev 3 FINALIgor BastosNo ratings yet

- Astm D2420-23Document3 pagesAstm D2420-23saderfendeNo ratings yet

- D3230 19 PDFDocument7 pagesD3230 19 PDFalexanderNo ratings yet

- Tosaca Catalogue PDFDocument16 pagesTosaca Catalogue PDFgabNo ratings yet

- Welder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Document2 pagesWelder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Ali TalebiNo ratings yet

- Integrity Testing of Water Filtration Membrane Systems: Standard Practice ForDocument14 pagesIntegrity Testing of Water Filtration Membrane Systems: Standard Practice ForOh No PotatoNo ratings yet

- Mobile Offshore Drilling Units 2008: Rules For Building and ClassingDocument14 pagesMobile Offshore Drilling Units 2008: Rules For Building and ClassingmfazioliNo ratings yet

- NR 26 Safety SignallingDocument6 pagesNR 26 Safety SignallingMarcia Rezende AntonioNo ratings yet

- Simple Unfired Pressure Vessels Designed To Contain Air or NitrogenDocument88 pagesSimple Unfired Pressure Vessels Designed To Contain Air or NitrogenBenediktas Dervinis100% (1)

- Iso 1402 2021Document10 pagesIso 1402 2021Thejaswini100% (1)

- 12" Steel Model K12: Smith Meter CT Series PD Meter For Crude TransportationDocument4 pages12" Steel Model K12: Smith Meter CT Series PD Meter For Crude Transportationjuan carlosNo ratings yet

- R P RP O501 E W P S: Ecommended RacticeDocument43 pagesR P RP O501 E W P S: Ecommended RacticepaulortsNo ratings yet

- Norsok L-004-2016Document32 pagesNorsok L-004-2016nguyenmainamNo ratings yet

- M503 PDFDocument5 pagesM503 PDFLê Ngọc TàiNo ratings yet

- Astm C892Document5 pagesAstm C892deivisbtsNo ratings yet

- IMIOrton MV SeriesDocument4 pagesIMIOrton MV SeriesFelipe Gamboa GálvezNo ratings yet

- Material For Roll CastingDocument5 pagesMaterial For Roll CastingPankaj PandeyNo ratings yet

- Australian Standard: Steel Tanks For Flammable and Combustible LiquidsDocument7 pagesAustralian Standard: Steel Tanks For Flammable and Combustible Liquidswidhisaputrawijaya0% (2)

- EVS en ISO 16137 2006 en PreviewDocument11 pagesEVS en ISO 16137 2006 en PreviewMohamed MOUKHTARIANo ratings yet

- Pro HYdrant Test KItDocument1 pagePro HYdrant Test KItNos GoteNo ratings yet

- Can-Ulc-S601 StandardDocument10 pagesCan-Ulc-S601 StandardDymac IndiaNo ratings yet

- Understanding Ped For Asme VesselsDocument33 pagesUnderstanding Ped For Asme VesselsRamakrishnan SrinivasanNo ratings yet

- DBB CatalogueDocument28 pagesDBB CatalogueHeri SetyantoNo ratings yet

- LEEAOffshore Crane Inspection CourseDocument1 pageLEEAOffshore Crane Inspection CourseVignesh MadhavanNo ratings yet

- Is 6044 1-2013Document17 pagesIs 6044 1-2013tapas bera0% (1)

- SOLENOID VALVE ASCO LowPower - Gseries - R8 PDFDocument14 pagesSOLENOID VALVE ASCO LowPower - Gseries - R8 PDFNUR AFIFAHNo ratings yet

- BS en 14141 2013Document46 pagesBS en 14141 2013Ирина Михайлова100% (4)

- 6300Document2 pages6300Ali BaigNo ratings yet

- Iso 6605Document18 pagesIso 6605Fabio StuiNo ratings yet

- Astm A 521Document10 pagesAstm A 521Mohammad SahmoudNo ratings yet

- Water-Tube Boilers - Part 1: General Requirement: National Standard of The People'S Republic of ChinaDocument21 pagesWater-Tube Boilers - Part 1: General Requirement: National Standard of The People'S Republic of ChinaNATTHAPONG BUNSOMPOPNo ratings yet

- 6 MFL Tool Spec Rev 3.5Document1 page6 MFL Tool Spec Rev 3.5fadialkasrawiNo ratings yet

- Standard Metric Bolt Shank Dimensions PDFDocument2 pagesStandard Metric Bolt Shank Dimensions PDFbcvdocu100% (1)

- Gear Box No Load Run Test ReportDocument1 pageGear Box No Load Run Test ReportPRABHUDAYAL SHARMANo ratings yet

- Rd8100 Cable Pipe and RD Marker Brochure en v4Document12 pagesRd8100 Cable Pipe and RD Marker Brochure en v4mubarak khanNo ratings yet

- BS 5041.1-1987 Fire Hydrant Systems EquipmentDocument16 pagesBS 5041.1-1987 Fire Hydrant Systems EquipmentThái DươngNo ratings yet

- MS 01 168Document12 pagesMS 01 168Rawn BushNo ratings yet

- Report of Ultrasonic Flaw Detection Test of Weld JointDocument1 pageReport of Ultrasonic Flaw Detection Test of Weld Jointkevin desai100% (1)

- As IEC 61672 1 2004 Electroacoustics Sound Level Meters Specifications PDFDocument8 pagesAs IEC 61672 1 2004 Electroacoustics Sound Level Meters Specifications PDFhammerhead8318No ratings yet

- Asme Sec X 2017Document7 pagesAsme Sec X 2017SARSAN NDTNo ratings yet

- ASTM D6392-12 Det The Integrity of Nonreinforced Geomembrane Seams Using Thermo-Fusion MethodsDocument6 pagesASTM D6392-12 Det The Integrity of Nonreinforced Geomembrane Seams Using Thermo-Fusion MethodsMoeketsi KhubeluNo ratings yet

- Mud Plug InstallationDocument4 pagesMud Plug InstallationVahid TaghdiriNo ratings yet

- Sans2415 PDFDocument27 pagesSans2415 PDFCwenga CwestarNo ratings yet

- Fixed Offshore Platforms - Part 1: Life-Saving Appliances: Vietnam Standards TCVN 6767-1: 2000Document8 pagesFixed Offshore Platforms - Part 1: Life-Saving Appliances: Vietnam Standards TCVN 6767-1: 2000langtu2011No ratings yet

- Filtro Linha LFDocument7 pagesFiltro Linha LFWanderson GarroteNo ratings yet

- Receipe 80Document20 pagesReceipe 80hisaj4uNo ratings yet

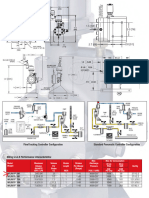

- Regulador FOLWGRIDDocument20 pagesRegulador FOLWGRIDDany GarciaNo ratings yet

- CAT LINE PP-H EN 10-2018 LRDocument234 pagesCAT LINE PP-H EN 10-2018 LRmiclodean4No ratings yet

- Inline Filter RFL Welded Version: Up To 15000 L/min, Up To 16 BarDocument4 pagesInline Filter RFL Welded Version: Up To 15000 L/min, Up To 16 Barrakhikishore143No ratings yet

- Float Tape Level Gauges 1 PDFDocument3 pagesFloat Tape Level Gauges 1 PDFpippalla aswiniNo ratings yet

- Float & Tape Level Gauges: FeaturesDocument3 pagesFloat & Tape Level Gauges: Featurespippalla aswiniNo ratings yet

- Wilroy6 Pager ReaderDocument4 pagesWilroy6 Pager ReaderMuthu KumarNo ratings yet

- Wilroy6 Pager ReaderDocument4 pagesWilroy6 Pager ReaderMuthu KumarNo ratings yet

- Uploads Products Technical Specs TECH Tech FFBDocument4 pagesUploads Products Technical Specs TECH Tech FFBMuthu KumarNo ratings yet

- SR en 10025-04Document8 pagesSR en 10025-04pukla100% (2)

- Equivalent ASTM MaterialDocument34 pagesEquivalent ASTM Materialgolf0910251891% (45)

- HEB Beams, European Standard Wide Flang..Document2 pagesHEB Beams, European Standard Wide Flang..Muthu KumarNo ratings yet

- PED GuideDocument25 pagesPED GuideqatarjourneyNo ratings yet

- Steel Grades For GB Standard JIS Standard ASTM Standard DIN Standard PDFDocument8 pagesSteel Grades For GB Standard JIS Standard ASTM Standard DIN Standard PDFsenthilkumar100% (1)

- Equivalent ASTM MaterialDocument34 pagesEquivalent ASTM Materialgolf0910251891% (45)

- PED GuideDocument25 pagesPED GuideqatarjourneyNo ratings yet

- Marine Boilers de 00 Whit GoogDocument482 pagesMarine Boilers de 00 Whit GoogMuthu KumarNo ratings yet

- 5183 Aluminum Welding WireDocument1 page5183 Aluminum Welding Wiresank79No ratings yet

- Dme Fastrack - Cie 1 - Oct 2021Document2 pagesDme Fastrack - Cie 1 - Oct 2021FOODIE USNo ratings yet

- Cesp 105 - Foundation Engineering and Retaining Wall Design Lesson 11. Structural Design of Spread FootingDocument7 pagesCesp 105 - Foundation Engineering and Retaining Wall Design Lesson 11. Structural Design of Spread FootingJadeNo ratings yet

- Repair and Rehabilitation of Structures Two Mark Questions With AnswerDocument13 pagesRepair and Rehabilitation of Structures Two Mark Questions With AnswerSony Sundar33% (3)

- Thermal Performance Analysis On Staggered Finned Absorber Solar Air HeaterDocument12 pagesThermal Performance Analysis On Staggered Finned Absorber Solar Air HeaterTJPRC PublicationsNo ratings yet

- Choice of Rail WheelsDocument4 pagesChoice of Rail WheelsMahmut KarataşNo ratings yet

- Bio FiberDocument2 pagesBio FiberGelina HernandezNo ratings yet

- Grayloc CatalogDocument32 pagesGrayloc CatalogRamonNo ratings yet

- Outershield 71E-H: Mild Steel Rutile Cored WireDocument2 pagesOutershield 71E-H: Mild Steel Rutile Cored WireLuis DuarteNo ratings yet

- Thermal and Concentration Boundary LayersDocument5 pagesThermal and Concentration Boundary LayersRosalyne Artho-PhanNo ratings yet

- Corrosion Resistant Enclosures HOFFMANDocument231 pagesCorrosion Resistant Enclosures HOFFMANMario GuzmanNo ratings yet

- Steel Metal Product Supplier Provider All Product Grade ListDocument20 pagesSteel Metal Product Supplier Provider All Product Grade ListPRAVINNo ratings yet

- Substation Bus ConductorsDocument26 pagesSubstation Bus ConductorsherrtammNo ratings yet

- Electrical Spec.'S Wiring Devices & Methods of Installation 16130-1Document9 pagesElectrical Spec.'S Wiring Devices & Methods of Installation 16130-1Waleed Abd El-HamiedNo ratings yet

- Press Release - ANSI AMCA 500-D-18Document1 pagePress Release - ANSI AMCA 500-D-18sajjadNo ratings yet

- Caleffi Manifold DistributionDocument44 pagesCaleffi Manifold Distributione-ComfortUSANo ratings yet

- Prying Action Analysis Per AISC 9th Edition (ASD)Document5 pagesPrying Action Analysis Per AISC 9th Edition (ASD)Anonymous w5SJiLsNo ratings yet

- Pressure Relief Valves Operating Instructions: Supplemental ProtectionDocument2 pagesPressure Relief Valves Operating Instructions: Supplemental ProtectionlorenzoNo ratings yet

- General Data: Applications Maximum Operating Pressure and Liquid TemperatureDocument4 pagesGeneral Data: Applications Maximum Operating Pressure and Liquid TemperatureYabuki ShingoNo ratings yet

- Amaia Skies AvenidaDocument5 pagesAmaia Skies AvenidaJohn Paul SorianoNo ratings yet

- E-01 Electrical SymbolsDocument10 pagesE-01 Electrical SymbolsPham Hoang TuanNo ratings yet

- DME-I Model Paper-3 2Document3 pagesDME-I Model Paper-3 2Srinivas KosuriNo ratings yet

- 9-RCC Arches & LentilsDocument19 pages9-RCC Arches & LentilsNaman Jain100% (1)

- 86 °C FROILABO 340 L Vertical Deep Freezer, Models: BM Essential and EvolutionDocument1 page86 °C FROILABO 340 L Vertical Deep Freezer, Models: BM Essential and EvolutionElena SarbuNo ratings yet

- Cable Splicing Procedure 002Document1 pageCable Splicing Procedure 002RenzNo ratings yet

- 17-Retaining Wall DesignDocument24 pages17-Retaining Wall DesignPuti Mayesti100% (6)

- Types of Cement PDFDocument41 pagesTypes of Cement PDFyash karaleNo ratings yet

- Ultrasonic Testing of Austenitic Stainless Steel WeldsDocument15 pagesUltrasonic Testing of Austenitic Stainless Steel Weldssmartz inspection100% (1)

- Pile Bearing Capacity Prediction by Means of Static Penetrometer CPTDocument8 pagesPile Bearing Capacity Prediction by Means of Static Penetrometer CPTJohn STCNo ratings yet

- RAPID-P006A-SCS-PIP-LST-3200-0002 - 0 Line ListDocument49 pagesRAPID-P006A-SCS-PIP-LST-3200-0002 - 0 Line ListTĩnh Hồ Trung0% (1)