Professional Documents

Culture Documents

5-1 13 3/8" Surface Casing Design

Uploaded by

eng20072007Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5-1 13 3/8" Surface Casing Design

Uploaded by

eng20072007Copyright:

Available Formats

5-1 13 3/8" Surface casing design:

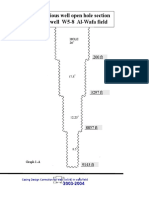

Surface casing 13 3/8 will be set at 3297 ft.

The following date will be used to design the casing.

Fracture gradient at 3297 ft 0.55 psi/ft 10.5 ppg.

Formation fluid density 0.451 psi/ft 8.67 ppg.

Mud weight when casing run 0.447 psi/ft 8.8 ppg.

Gas gradient expected 0.115 psi/ft.

Design factor DF Burst 1.1

Design factor 1.1

Design factor 1.95

MOP = Mix Over pull 100000 LB over pulls.

Casing availability: -

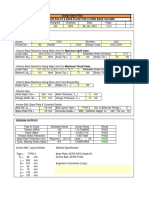

Wt Burst Collapse Tension 1000lb Body yield

Grade ID (in)

(lb/ft) (psi) (psi) (STC*1000) BTC 1000 lbs

K55 54.5 12.615 27.30 1130 547 1038 8.53

K55 61 12.515 3090 1540 595 962

N80 68 12.415 3450 2270 718 1.550

N80 72 12.347 5380 2670 1040 1693 1661

N80 98 11.937 6270 5910 2296 2144

C95 72 12.347 6390 2870 1204 1973

Table (5-1)

64 Casing Design Correction for Well (w5-8) in wafa field

2003-2004

5.1.1 Burst loading:

Injection pressure = FG/constant + DF L constant

Injection pressure =

Fracture gradient / 0.052 + 1 Depth 0.052

=(0.55/ 0.052 + 1) 3297 0.052 = 1985 psi

Surface pressure = 1985 (3297 0.115) = 1606 psi

Back up pressure at 3297 ft =

3297 0.052 8.67 = 1486 psi

5.1.1- Burst loads summary:

Internal Back-up

Depth Resultant Design loading

load loading

(ft) (lb) *1.1

(lb) (lb)

0 1606 0 1606 1767

3297 1985 1486 499 549

Table (5-2)

The design loading can now be plotted on a pressure depth

graph as shown in chart (5 - A).

5.1.2 - Collapse loading:

Collapse pressure originates from the column of mud used to drill

the hole, and acts on the out side of casing. It will be highest at

the bottom and zero at the top due to mud hydrostatic pressure

effect from out side, and the inside of casing will be empty.

Maximum hydrostatic load due to mud

= 0.052 8.6 3297 =1509 psi.

65 Casing Design Correction for Well (w5-8) in wafa field

2003-2004

Summary of collapse loads: -

External Back-up Resultant, Design

Depth, (ft)

loading, (lb) loading, (lb) (lb) loading *1.1

0 0 0 0 0

3297 1509 0 1509 1660

Table (5-3)

The design load can be also plotted on pressure depth graph as

shown in chart (5-B)

Choice of casing: -

Based on the design loading lines for both burst and collapse the

following string can be chosen.

Preliminary design

0 3297 ft N80 68 lb/ ft

NOTICE: The design should be kept as simple as possible.

66 Casing Design Correction for Well (w5-8) in wafa field

2003-2004

5.1.3 -Tension loading: -

W = 3297 * 68 = 224196 lb

Casing design has to be simple as possible

F=P*A

Where: -

P = 0.052 *8.8 * 3 297 = 1509 PSI

A = / 4 (13.375 ^ 2 12.415 ^ 2) = 19.445 in^2

F = 1509 *19.445 = 29342 Lb

Tensile loading at each depth can now be calculated drill string

design: -

Tension, Over pull 100000, Apply DF *1.95,

Casing, (lb/ft) Depth, (ft)

(lb) (lb) (LB)

0 194854 294854 379965

N 80 68 3297 - 29342 70658

Table (5-4)

This information can be plotted as a graph as shown in chart (5-C).

It can be seen that the pipe body yield strength of the chosen casings

exceeds the tension design lines .STC couplings will allow efficient

join strength.

Where: -

F = 29342, W F = 194854

67 Casing Design Correction for Well (w5-8) in wafa field

2003-2004

5.1.4 - Check axial Effects: -

Used the actual tension figures the reduction in collapse resistance should be calculate.

Casing, Depth, Tension, Pipe De-ratted

(lb/ft) (ft) (lb) yield, (lb) X Y collapse, psi

0 194854 1550000 0.125 0.925 2100

N80 68 3297 -29342 0.019 0.99 2270

Table (5-5)

X = axial load factor = Tension load / Body strength

X1= 194854 /1550000 = 0.125 Y = 0.925

X2= -29341/155000 = 0.0189 Y= 0.99

Where:-

X = axial load factor

Y =collapse strength rating factor

68 Casing Design Correction for Well (w5-8) in wafa field

2003-2004

5.2 9 5/8" Design of Intermediate Casing:

5.2.1 Burst Conditions: -

The worst case is where Kick occurs while drilling below the

intermediate casing shoe, filling the string with both gas and

mud.

There are three conditions to be considered for burst loading:-

Kick pressure from gas and mud.

Injection pressure at casing shoe.

Maximum surface pressure at top of casing.

These three pressures can be expressed mathematically in the

relation ship: -

Ps + X (GM) + Y (Gg) =IP

Where: -

Ps = maximum surface pressure (usually BOP rating) 5000 psi.

X = Length of mud column, (Ft).

GM = Mud gradient (heaviest mud used below shoe),(PPG ).

Y = Length of gas column, (Ft).

Gg = Gas gradient, (psi /ft)

IP = Injection pressure, (psi).

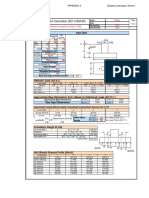

Casing availability:

Tension, 1000

WT Burst, Collapse Body yield

Grade ID, inch (STC LBS

(lb/ft) (psi) (psi) 1000 lbs

*1000) BTS

N 80 43.5 8.755 4350 3250 1074 776 691

N 80 43.5 8.755 6330 3810 1074 825 1005

N 80 47 8.681 6870 4760 1161 905 1080

C 95 53.5 8.535 9410 7330 1458 1220 1477

P110 43.5 8.755 8700 4430 1388 1106 1381

P110 47 8.681 9440 5310 1500 1213 1491

Table (5 -7)

69 Casing Design Correction for Well (w5-8) in wafa field

2003-2004

5.2.1 - Design will used the following data: -

9 5/8 casing setting depth 8857 ft.

Max- surface pressure BOP 5000 psi .

Facture gradient at shoe 0.702 psi/ft. 13.5 ppg.

Gas gradient expected 0.115 psi/ft. 2.2 ppg.

Formation fluid density 0.47 psi/ft. 9 ppg.

Mud weight when casing run 0.494 psi/ft. 9.5 ppg.

D.F Burst 1.1

D.F Collapse 1.1

D.F Tension 1.6 * 100000 LBS

Injection pressure = {(fracture gradient at shoe /0.052) + DF)}*

0.052 * casing setting depth.

I.P = {(0.702/0.052) + 1} * 0.052 *8857=6678 Psi

Back- up pressure due Formation fluid = 0.052 * 9 * 8857 = 4145

psi

Ps + (GM) x + (Gg) y = IP

Surface pressure + mud press pressure + gas pressure = pressure

at shoe

5000 + 0.494 x + 0. 115 y = 6678 1

X + y = 8857 2

Y = 8857 x

X = 1741 ft

0.494 x + 0.115 y = 1678

(0.494 * 1741) + 0.115 = 1678

860 + 0.115 y = 1678

0.115 y =818

Y = 7113 ft

X + y = 1741 + 7113 = 8854 ft

8854 *0.115 = 1018 psi

1678 1018 = 660 psi

660/0.45 = 1467 ft (mud column)

8854 1467 = 7387 ft (gas column)

The column he hydrostatic pressure due the gas column * gas

gradient.

The hydrostatic pressure due the gas=7387* 0.115 = 850 psi

70 Casing Design Correction for Well (w5-8) in wafa field

2003-2004

The hydrostatic pressure due the mud = 1467 * 0.494 = 725 PSI

TOTAL = 850 +725 =1575 PSI.

Surface pressure = 6678 (8857 *0.115) =5659 psi

Back-up pressure due to formation = 1467 * 9 * 0.052= 687 psi

8857 * 9 * 0.052 = 4145 psi

3000 * 9 * 0.052 = 1404 psi

8857 40 = 8817 psi

8817 1467 7350 ft

3000 1467 = 1533 ft

1467 * 905 * 0.052 = 725 psi

7350 *0.115 = 176 psi

901 + 5000 = 5901 psi

5000 + 725 = 5725 psi

5725 + 845 = 6570 psi

Back-up

Internal Resultant, Design

Depth, (ft) External,

load, (psi) (psi) loading * 1.1

(psi)

0 5000 0 5000 5500

3000 5901 1404 4497 4947

8857 6570 4145 2425 2668

Table (5-8)

Burst loading plotted as shown in the chart (5 -D)

71 Casing Design Correction for Well (w5-8) in wafa field

2003-2004

5.2.2 Collapse loading: -

Cement weight (lead = 12.5 ppg) (tail = 15.8 ppg)

8875 500 = 8357 ft

8357 * 12.5 * 0.052 = 5432 psi

500 8 15.8 8 0.052 = 411 psi

External pressure due to the cement = 5432 + 411= 5843 psi

Back - up pressure due to mud=8357*9.5* 0.052 = 4128 psi

8857*9.5*0.052= 4375 psi

External Design

Back _ up Resultant ,

Depth, Ft pressure, loading 1.1,

Internal, psi psi

psi psi

0 0 0 0 0

8357 5432 4128 1304 1434

8857 5843 4375 1468 1615

Table (5 9 )

Collapse loading plotted as shown in the chart (5 -E).

From the plots and calculation for burst and collapse and available

casing the following combination was selected: -

Preliminary design:

0 3000 N80 43.5 lb/ft

3000 8857 N80 47 lb/ft

72 Casing Design Correction for Well (w5-8) in wafa field

2003-2004

73 Casing Design Correction for Well (w5-8) in wafa field

2003-2004

You might also like

- 5.2.3 Tension Loading:: Casing Depth, (FT) Tension, (LB) Over Pull 100000, (LB) Apply-DF 1.6 (LB)Document6 pages5.2.3 Tension Loading:: Casing Depth, (FT) Tension, (LB) Over Pull 100000, (LB) Apply-DF 1.6 (LB)eng20072007No ratings yet

- Example3 Design of Mat2016Document13 pagesExample3 Design of Mat2016awetgirmay41No ratings yet

- Steel DesignDocument36 pagesSteel DesignthetsoeNo ratings yet

- GTC1068CM1 102 92 C004Document71 pagesGTC1068CM1 102 92 C004anoginNo ratings yet

- FOOTING DESIGNDocument9 pagesFOOTING DESIGNMitra RampersadNo ratings yet

- TH 3 Ib UpliftDocument5 pagesTH 3 Ib UpliftswatiNo ratings yet

- Casing Design Graphical MethodDocument25 pagesCasing Design Graphical MethodSarbast TaqanaNo ratings yet

- A2-Pile Calculation - BH M1Document90 pagesA2-Pile Calculation - BH M1Priya GopalNo ratings yet

- Design CasingDocument10 pagesDesign CasingSelly ErlytasariNo ratings yet

- Abutment Worked ExampleDocument9 pagesAbutment Worked ExampleKenaia Adeleye100% (2)

- Load TestDocument16 pagesLoad TestMI ChoudharyNo ratings yet

- Pad Footing Report1Document4 pagesPad Footing Report1อมรฤทธิ์ พ่วงสมบัติNo ratings yet

- Pad Footing Report2Document4 pagesPad Footing Report2อมรฤทธิ์ พ่วงสมบัติNo ratings yet

- Pveng: Pressure Vessel Engineering LTDDocument5 pagesPveng: Pressure Vessel Engineering LTDBruno TrujilloNo ratings yet

- Test 2 DrilllingDocument7 pagesTest 2 DrilllingHaziq YussofNo ratings yet

- Footing Design F 1Document8 pagesFooting Design F 1prabhuNo ratings yet

- Load TestDocument16 pagesLoad TestTaimoor AhmadNo ratings yet

- RIV ACI 2-Pile CapDocument12 pagesRIV ACI 2-Pile CapMitra RampersadNo ratings yet

- Structural Steel Design Project: Calculation SheetDocument18 pagesStructural Steel Design Project: Calculation Sheetrameshbabu_1979No ratings yet

- Tank 620 US 0002 API 620 Calculation ReportDocument39 pagesTank 620 US 0002 API 620 Calculation ReportPhượng NguyễnNo ratings yet

- Design of ConcreteDocument36 pagesDesign of ConcreteDenden Dermawan100% (3)

- Combined FDN ColumnDocument21 pagesCombined FDN ColumnGautam SharmaNo ratings yet

- Bridge DesignDocument220 pagesBridge Designrochelleandgello100% (1)

- Skirt Support TrialDocument11 pagesSkirt Support TrialAbhishek Nag0% (1)

- Strip Footing Design CalculationsDocument13 pagesStrip Footing Design CalculationsSha Mas ShaNo ratings yet

- ACI Pad Foundation ExampleDocument7 pagesACI Pad Foundation ExampleEm MarNo ratings yet

- Transmission Tower Foundation DesignDocument26 pagesTransmission Tower Foundation Design14pcash100% (1)

- Design of Box CulvertDocument21 pagesDesign of Box CulvertAnirbanBhattacharjeeNo ratings yet

- Design of anchor bolts and base plate for a fixed base columnDocument4 pagesDesign of anchor bolts and base plate for a fixed base columnSuryaSinghNo ratings yet

- Calculation Sheet Mat - FDNDocument14 pagesCalculation Sheet Mat - FDNDavid Sinambela0% (1)

- Chequered PlateDocument23 pagesChequered Platesaravanan428680% (10)

- Footing Pressure CheckDocument1 pageFooting Pressure CheckVaishak KrishnanNo ratings yet

- BOX Culvert Load DetailsDocument7 pagesBOX Culvert Load Detailsragalwar100% (1)

- Two-Storey School Building Structural Analysis and DesignDocument57 pagesTwo-Storey School Building Structural Analysis and DesignMark Angelo PoliciosNo ratings yet

- Design Calculations of Chiller FoundationDocument15 pagesDesign Calculations of Chiller FoundationStressDyn Consultants100% (1)

- Single FootingDocument1 pageSingle FootingCivilNo ratings yet

- Prepared BY Dr. Mohammed Kadhum FekheraldinDocument55 pagesPrepared BY Dr. Mohammed Kadhum Fekheraldinhemantkle2uNo ratings yet

- Design of One Way Simply Supported SlabDocument2 pagesDesign of One Way Simply Supported SlabSUDHIR GAYAKENo ratings yet

- Strength Calculation For PlatformDocument2 pagesStrength Calculation For PlatformRaghNo ratings yet

- Pile CapDocument8 pagesPile CapMdShahbazAhmedNo ratings yet

- FND BoltDocument1 pageFND BoltArunkumar RackanNo ratings yet

- Curved Steel I-Girder Bridge LFD Guide Specifications: (With 2003 Edition)Document69 pagesCurved Steel I-Girder Bridge LFD Guide Specifications: (With 2003 Edition)ephremNo ratings yet

- Column Skirt Support Design CalculationDocument5 pagesColumn Skirt Support Design CalculationRitesh VishambhariNo ratings yet

- Kentledge Design SpreadsheetDocument4 pagesKentledge Design SpreadsheetUtaya Kumar Veelmurugan100% (1)

- Isolated Footing DesignDocument7 pagesIsolated Footing DesignChristopher Joshua MartinezNo ratings yet

- Isolated FootingDocument14 pagesIsolated FootingchakrapanithotaNo ratings yet

- Basering calculations and weld sizes for operating caseDocument6 pagesBasering calculations and weld sizes for operating caseevrim77No ratings yet

- Teres House Calculation ReportDocument51 pagesTeres House Calculation ReportTom YeeNo ratings yet

- Crane Foundation DesignDocument14 pagesCrane Foundation Designway2saleem100% (2)

- Analysis: Tedds Calculation Version 1.0.23Document10 pagesAnalysis: Tedds Calculation Version 1.0.23Sachin AgarwalNo ratings yet

- Pveng: Pressure Vessel Engineering LTDDocument10 pagesPveng: Pressure Vessel Engineering LTDseshuNo ratings yet

- BS ABUTMENT DESIGNDocument17 pagesBS ABUTMENT DESIGNEng Venance Masanja100% (1)

- Chequered-Plate CALCULATIONDocument19 pagesChequered-Plate CALCULATIONRamuAlagappan100% (2)

- Example 1.4 - Perpendicular To FlightDocument14 pagesExample 1.4 - Perpendicular To FlightHawaiiChongNo ratings yet

- CSG DesignDocument97 pagesCSG DesignAndi Priyo Jatmiko100% (1)

- Slab Raft Foundation PresentationDocument25 pagesSlab Raft Foundation PresentationOsarieme Osakue100% (1)

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- Water Treatment PidDocument1 pageWater Treatment Pideng20072007No ratings yet

- Adding PID Controllers in Aspen HYSYS: Dynamic Simulation Course 2017Document1 pageAdding PID Controllers in Aspen HYSYS: Dynamic Simulation Course 2017eng20072007No ratings yet

- City Director of Public Works Organizational ChartDocument2 pagesCity Director of Public Works Organizational Charteng20072007No ratings yet

- Oklahoma Corporation Commission: Packer Setting ReportDocument2 pagesOklahoma Corporation Commission: Packer Setting Reporteng20072007No ratings yet

- Reliability and Risk Assessment: Ace 4 ApDocument1 pageReliability and Risk Assessment: Ace 4 Apeng20072007No ratings yet

- City Director of Public Works Organizational ChartDocument2 pagesCity Director of Public Works Organizational Charteng20072007No ratings yet

- Factory PidDocument1 pageFactory Pideng20072007No ratings yet

- Envelope Envelope-11Document1 pageEnvelope Envelope-11eng20072007No ratings yet

- Factory PidDocument1 pageFactory Pideng20072007No ratings yet

- BlocksDrilling Line Rev-Peview PDFDocument11 pagesBlocksDrilling Line Rev-Peview PDFLa Ode Hadi AugustmanNo ratings yet

- 1.3 Reliability Terminology: An Introduction To Reliability and Risk Assessment 3Document1 page1.3 Reliability Terminology: An Introduction To Reliability and Risk Assessment 3eng20072007No ratings yet

- El Sayed Amer Last UpdatedDocument3 pagesEl Sayed Amer Last Updatedeng20072007No ratings yet

- Gad SeparatorDocument3 pagesGad Separatoreng20072007No ratings yet

- DareDocument11 pagesDareeng20072007No ratings yet

- Ngdiploma EnglishDocument2 pagesNgdiploma Englisheng20072007No ratings yet

- 1007-Disq-0-L-ss-39154 Rev 2 Supplementary Purchasing Requirements For ValvesDocument14 pages1007-Disq-0-L-ss-39154 Rev 2 Supplementary Purchasing Requirements For Valveseng20072007No ratings yet

- Block ProposalDocument11 pagesBlock Proposaleng20072007No ratings yet

- Warna Three: What Is Marketing?Document11 pagesWarna Three: What Is Marketing?eng20072007No ratings yet

- 1007 DISQ 0 M SS 42005 Air Cooled Heat Exchangers SpecificationDocument18 pages1007 DISQ 0 M SS 42005 Air Cooled Heat Exchangers Specificationeng20072007No ratings yet

- Duplicate Cleaner LogDocument1 pageDuplicate Cleaner LogMuhammad Hafizuddin Bin JumadinNo ratings yet

- 0 - Cources IntroductionDocument5 pages0 - Cources Introductioneng20072007No ratings yet

- SuperbizDocument11 pagesSuperbizeng20072007No ratings yet

- Previous Well Open Hole Section For Well W5-8 Al-Wafa FieldDocument4 pagesPrevious Well Open Hole Section For Well W5-8 Al-Wafa Fieldeng20072007No ratings yet

- 1007 DISQ 0 J SS 33030 Control Valve SpecificationDocument18 pages1007 DISQ 0 J SS 33030 Control Valve Specificationeng20072007No ratings yet

- احدث CVDocument4 pagesاحدث CVeng20072007No ratings yet

- 1007-Disq-0-L-ss-39151 Rev 2 Spec For Chemical Cleaning of PipingDocument10 pages1007-Disq-0-L-ss-39151 Rev 2 Spec For Chemical Cleaning of Pipingeng20072007No ratings yet

- 1007-DISQ-0-M-SS-42026-Rev.3 ValvesDocument13 pages1007-DISQ-0-M-SS-42026-Rev.3 Valveseng20072007No ratings yet

- 1007 Disq 0 G Ae 30033 Rev 5 Equipment ListDocument22 pages1007 Disq 0 G Ae 30033 Rev 5 Equipment Listeng20072007100% (1)

- Exploring Novel Isocractic HPLC Method For Quantitative Determination of Cinnarizine and Piracetam in Their Capsule Preparations 1920 4159 1000225Document5 pagesExploring Novel Isocractic HPLC Method For Quantitative Determination of Cinnarizine and Piracetam in Their Capsule Preparations 1920 4159 1000225Adolfo OlmosNo ratings yet

- Bending Moment Due To Live Load:: A) IRC Class 70R Load (Tracked Vehicle)Document9 pagesBending Moment Due To Live Load:: A) IRC Class 70R Load (Tracked Vehicle)Tashi TamangNo ratings yet

- Kubernetes SecurityDocument34 pagesKubernetes SecurityAmit SharmaNo ratings yet

- Leader MLV Test-03 30 Oct QPDocument60 pagesLeader MLV Test-03 30 Oct QPInsane insaanNo ratings yet

- Copia de JOISTDocument44 pagesCopia de JOISTOscar SanabriaNo ratings yet

- Quantitative Corpus BasedDocument6 pagesQuantitative Corpus Basedahmn67No ratings yet

- SKF Single Plane Graphical Balancing Tutorial ENDocument13 pagesSKF Single Plane Graphical Balancing Tutorial ENVili KamenovaNo ratings yet

- CBSE Ryan International School Assessment-2Document5 pagesCBSE Ryan International School Assessment-2itztonyNo ratings yet

- STO Configuration in ERP SAP ECC 6Document4 pagesSTO Configuration in ERP SAP ECC 6balashowryraju100% (18)

- HPLC: A GUIDE TO HIGH PERFORMANCE LIQUID CHROMATOGRAPHYDocument90 pagesHPLC: A GUIDE TO HIGH PERFORMANCE LIQUID CHROMATOGRAPHYRakesh Kotta100% (1)

- IIT Madras Electrical Machines II Course NotesDocument12 pagesIIT Madras Electrical Machines II Course NotesJagabandhu KarNo ratings yet

- Flotrac Algorithm White PaperDocument4 pagesFlotrac Algorithm White PaperAnestesia 2017 UDECNo ratings yet

- Description of The Courses - Transportation Eng - 2013 v2 PDFDocument5 pagesDescription of The Courses - Transportation Eng - 2013 v2 PDFVinoth KumarNo ratings yet

- 800 Range Sensor 120ohms Strain GaugeDocument21 pages800 Range Sensor 120ohms Strain GaugeBigheti100% (1)

- Service Manual Service Manual Service Manual Service Manual: Epson GT-10000Document83 pagesService Manual Service Manual Service Manual Service Manual: Epson GT-10000chamaidisvNo ratings yet

- Sweater Consumption CostingDocument2 pagesSweater Consumption Costingapi-214283679No ratings yet

- Tutorial 3 AnswersDocument2 pagesTutorial 3 AnswersM Arif SiddiquiNo ratings yet

- Construcion Material CalibraitonDocument14 pagesConstrucion Material CalibraitonDoulat RamNo ratings yet

- IUPAC Naming by Aravind AroraDocument30 pagesIUPAC Naming by Aravind Aroratanish gehlotNo ratings yet

- Primo Theory Volume 5 Secured - Unlocked PDFDocument60 pagesPrimo Theory Volume 5 Secured - Unlocked PDFmsmali100% (1)

- 01-An Approach To Improved CNC Machining Using Vision-Based SystemDocument11 pages01-An Approach To Improved CNC Machining Using Vision-Based SystemCătălina StahurschiNo ratings yet

- Building Technology 4 Week 4Document42 pagesBuilding Technology 4 Week 4Xette FajardoNo ratings yet

- lATTICE BOLTZMANN METHODDocument15 pageslATTICE BOLTZMANN METHODKrunal GangawaneNo ratings yet

- Atlantis Rising Magazine #19Document73 pagesAtlantis Rising Magazine #19Robert DeBovis100% (4)

- 180.5Mbps-8Gbps DLL-based Clock and Data Recovery Circuit With Low Jitter PerformanceDocument4 pages180.5Mbps-8Gbps DLL-based Clock and Data Recovery Circuit With Low Jitter PerformanceMinh KhangNo ratings yet

- D IV SMT III - Kecakapan Bahari Sesi 1 - Anchor ArrangementsDocument17 pagesD IV SMT III - Kecakapan Bahari Sesi 1 - Anchor ArrangementsWeslyNo ratings yet

- Lab Report Experiment - 4Document16 pagesLab Report Experiment - 4Debjit SarkarNo ratings yet

- Bash CheatsheetDocument6 pagesBash CheatsheetDick GoNo ratings yet

- Functions Modeling Change: A Precalculus CourseDocument239 pagesFunctions Modeling Change: A Precalculus CourseDeniell Joyce MarquezNo ratings yet

- Discretization Methods of Fractional Parallel PIDDocument4 pagesDiscretization Methods of Fractional Parallel PIDBaherNo ratings yet