Professional Documents

Culture Documents

ESPSS Brochure

Uploaded by

jakub_gramolCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ESPSS Brochure

Uploaded by

jakub_gramolCopyright:

Available Formats

What is EcosimPro?

Astrium

ESA-AOES Medialab

ESA (images by AOES Medialab)

EcosimPro is a software tool for modeling and simulating

multidisciplinary continuous and discrete systems. It

incorporates an object-oriented programming language, a

powerful DAE solver and a friendly Graphic User Interface.

EcosimPro and EA Internacional

Empresarios Agrupados Internacional SA (EAI) is an

ESA-AOES Medialab

architect-engineering organisation that was founded in 1971

and belongs to the following companies: Tcnicas Reunidas

SA, GHESA Ingeniera y Tecnologa SA, Iberdrola Ingeniera y

Construccin SAU, and SOCOIN Ingeniera y Construccin

SLU.

EA began developing EcosimPro in 1989 under a contract from

the ESA to simulate ECLSS in manned spacecraft. The

EcosimPro is designed so that components can be reused in many multidisciplinary nature of this type of simulation gave rise to

different systems without having to be reprogrammed. It the creation of generic modelling software for use in many

provides a highly intuitive environment that enables the user to other continually broadening areas.

easily display simulation schematic diagrams and carry out both EA Internacional is the official distributor of ESPSS libraries to

transient and steady state studies. external users.

EcosimPro is an open tool which allows using other existing code

ESPSS

ESA-C.Carreau

written in C, C++ or FORTRAN and, in turn, generating C++ code

with the final simulation model.

ESPSS Project Developers

Backed by the technical support of ESA, four companies

European Space Propulsion

participate in the development of ESPSS software, thus

guaranteeing a successful simulation tool:

System Simulation

ESA-S.Corvaja 09

Empresarios Agrupados, experts in the design and production

ESA Simulation libraries, based on EcosimPro,

of software simulation tools, coordinating partner of the

project and responsible for the ESPSS modelling for modelling spacecraft and launch vehicle propulsion systems

EADS Astrium Space Transportation, the main industrial EA Internacional S.A.

architect and stage integrator of Ariane launchers,

responsible for User Requirements and Validation cases

Magallanes, 3 Madrid

CENAERO, a company at the forefront of CFD and 28015 Spain

Optimization methods, responsible for the Advanced 1D E-mail: info@ecosimpro.com

algorithms, zooming with external CFD codes and system

optimization with Max code coupling URL: http://www.ecosimpro.com EMPRESARIOS AGRUPADOS

KOPOOS, a company with large experience in Satellite Phone: +34 91 309 81 42

Propulsion Systems of Chemical and Electrical types,

Fax: +34 91 591 26 55

responsible for the Priming and Tank filling validation cases

ESPSS SIMULATION PLATFORM FLUID_PROPERTIES LIBRARY

The Fluid_properties Library is a set of thermodynamic functions returning the properties of most of the fluids used for rocket applications. Fluids are

TURBO-MACHINERY LIBRARY

Two different types of turbo-machinery are available: one generic model if the off-design

supported in different categories depending on the type used: characteristics are unknown, and one specific model which can only be used with user defined

maps, for well-defined turbo-machinery

- Perfect gases properties according to CEA code, or interpolated in external temperature dependent properties files (user modifiable)

Turbine and compressor maps are very general because the parameters are scaling with the

- Simplified liquids interpolated in external temperature dependent properties files (user modifiable)

ESA/CNES/P.Baudon

The European Space Propulsion System Simulation (ESPSS) is an ESA

mean radius and the speed of sound. Therefore, given characteristics remain valid for

initiative that aims to create a European simulation platform for spacecraft and

- Real fluids properties directly interpolated in external 2D properties files (user modifiable), normally obtained running the REFPROP code (NIST) geometrically similar turbines/compressor, and for different fluids

launch vehicle propulsion systems. It consists of a set of libraries based on the

EcosimPro simulation environment. ESPSS provides a state-of-the-art tool for The homogeneous model calculates mixtures of a real fluid with a non-condensable gas (quality, void fraction, etc) in case of two phase two-fluid flow

TANKS LIBRARY

analyzing different phenomena in propulsion systems validated successfully

Functions calculating real

with experiments entailing priming cases, two-phase tank filling processes The Tank_Bladder component models two different fluid cavities, one for the liquid and another for the

properties interpolate in 2D

and the Ariane 5 ESC-A upper stage. property tables. Two kind of gas mixture. It also calculates the bladder movement separating the liquid from the gas

interpolations are available:

ESPSS libraries are delivered along with the source code, thus allowing the 1D Tanks calculate the temperature variation along a vertical axis. The pressurization of the gas part

users to either modify or reuse any of the library components. As ESA holds the - Direct interpolation using the by boiling inside the liquid or by filling processes is included in the formulation. The heat and mass

proprietary rights to the ESPSS libraries, any entity interested in using them couples P-S, P-H, and returning transfer at the liquid/gas interface is also calculated

need prior approval from ESA. a property.

- Reverse interpolation using the

EcosimPro is a commercial simulation environment developed by Empresarios

couples T-S, H-S or Rho-U and

Agrupados Internacional S.A. (EAI) and is presently used in other areas such returning pressure.

T-S thermodynamic diagram Available real fluids

as environmental control and life support in manned spacecraft, power plant

systems, biological simulation, loop heat pipes, etc. EAI is the official

ESA/CNES/ARIANESPACE-P.Baudon

distributor of the ESPSS libraries.

ESPSS libraries provide palettes of components

which allows building graphically complex systems

ESPSS libraries: a summary:

A specific library providing a standard properties database for propellants,

pressurants and other fluids and materials Tank pressure, liquid height & temperature results

Model of a Pressurisation system

A general purpose library for two-phase fluid 1D models. Hydraulic or

pneumatic systems with coupled heat transfer networks and controllers can be COMB_CHAMBERS LIBRARY

easily represented Models with one or more chambers can be evaluated under quasi steady or transient conditions

(start-up and shutdown) where the valve sequences are decisive

Specific libraries for the simulation of 1D two-phase tanks and turbo

machinery components (pumps, turbines and compressors) Wall heat exchange, pressure drops,

cavity priming and vaporization

A specific library for the simulation of combustion chambers, nozzles and phenomena (progressive consumption

cooling systems of injected liquid) are taken into account

Some application domains are: . The Cooling Jackets components

ESPSS palettes of

Performances of a Cold Thruster Xenon cycle (BB actuation)

components completely model 3D geometries built

Modelling of spacecraft or ground pressurization systems including priming by means of several 3D walls around the

processes, tank behaviour, heat exchange, mechanical or electronic pressure channels (1D fluid component):

FLUID_FLOW_1D LIBRARY Cooling jacket channels Thermal nodes distribution

regulators

Hydraulic or pneumatic systems with coupled heat transfer networks and controllers can be easily represented with this library

Modelling of any kind of liquid rocket engine cycle with one or more Start up and shut down representation

Programming of the components is non-dependent on the working fluid: conservation equations are stated in a general way, the

combustion chambers including turbo machinery (pumps, compressor and

fluid phase and the quality being calculated by the properties functions

turbines) and two phase cooling systems

ESA-S.Corvaja 09

Priming phenomena (with or without a non-condensable gas travelling in a

liquid) can be calculated in pipes or other specific spacecraft subsystems.

ESPSS also permit analyzing in great detail transient aspects due to inertia

(water-hammer), heat exchange (radiators) or control processes

ESPSS allows the simulation of the

hydrodynamic cavitation with or without a

Interaction with other software is possible, especially in the following areas: non-condensable gas travelling in a liquid

Optimization for design and test fitting, coupling to external software (e.g. using real properties fluids:

CFD), etc. Staged engine model Chamber & Preburner temperature

Simplified model of a priming Pressure surge peaks Pressure surge peaks

You might also like

- Applications of MATLAB To Problems in Quantum Mechanics For Research and Education (1995) : Dirac Notation InterpreterDocument42 pagesApplications of MATLAB To Problems in Quantum Mechanics For Research and Education (1995) : Dirac Notation InterpreterSuleman AwanNo ratings yet

- ACT Prep Syllabus (Fall 2019)Document7 pagesACT Prep Syllabus (Fall 2019)Fallon HoweNo ratings yet

- Fundamentals of Biostatistics 7th Edition Chapter-1Document10 pagesFundamentals of Biostatistics 7th Edition Chapter-1diniindahlestari0% (2)

- Ed Thorp - A Mathematician On Wall Street - Statistical ArbitrageDocument33 pagesEd Thorp - A Mathematician On Wall Street - Statistical Arbitragenick ragoneNo ratings yet

- Electric Circuit Variables and ElementsDocument30 pagesElectric Circuit Variables and Elementsjessdoria100% (3)

- REXXDocument173 pagesREXXRamesh Krishnan RajaveluNo ratings yet

- Grade 9: Federal Democrati C Republi C OF Ethi OPI A MI NI Stry OF Educati ONDocument324 pagesGrade 9: Federal Democrati C Republi C OF Ethi OPI A MI NI Stry OF Educati ONየየጁ ልጅ እኔNo ratings yet

- Quality Maintenance TPMDocument42 pagesQuality Maintenance TPMSantosh SharmaNo ratings yet

- Aviacion - Aviones XDocument65 pagesAviacion - Aviones XsincobrarenfechaNo ratings yet

- Systems Architecture Modeling with the Arcadia Method: A Practical Guide to CapellaFrom EverandSystems Architecture Modeling with the Arcadia Method: A Practical Guide to CapellaRating: 5 out of 5 stars5/5 (1)

- AA Introduction To MATLAB Applications in Chemical Engineering, PDFDocument277 pagesAA Introduction To MATLAB Applications in Chemical Engineering, PDFMohammed GhanemNo ratings yet

- Aircraft Vehicle Systems Modelling and Simulation Under UncertaintyDocument64 pagesAircraft Vehicle Systems Modelling and Simulation Under Uncertaintyjakub_gramolNo ratings yet

- Modelica Tutorial PDFDocument191 pagesModelica Tutorial PDFjakub_gramol0% (1)

- 3.lecture - 2 Type of Areal PhotgraphDocument34 pages3.lecture - 2 Type of Areal PhotgraphFen Ta HunNo ratings yet

- Comprehensive Model-Based Engineering For Systems of Systems 2016Document4 pagesComprehensive Model-Based Engineering For Systems of Systems 2016Heng ZhangNo ratings yet

- ESP8266EXDocument16 pagesESP8266EXEmre BircanNo ratings yet

- EOS: Growing The Business of Additive Manufacturing (AM) : P-1160-E April 2017Document15 pagesEOS: Growing The Business of Additive Manufacturing (AM) : P-1160-E April 2017ycwbycwbNo ratings yet

- Ev3 Coding IntroductionDocument9 pagesEv3 Coding IntroductionhabrimaNo ratings yet

- Intership 2 PPT FinalDocument25 pagesIntership 2 PPT FinalRajdeep MallickNo ratings yet

- Mendes 2016 VehicleDocument8 pagesMendes 2016 VehicleThanachot GolazNo ratings yet

- Mechanical Engineer's Resume Highlights Skills and ExperienceDocument1 pageMechanical Engineer's Resume Highlights Skills and ExperienceMohammed RuissiNo ratings yet

- EAEEIE 2017 FinalDocument7 pagesEAEEIE 2017 FinalAnh vũNo ratings yet

- Simulation of Composite Manufacturing Processes - IntroDocument38 pagesSimulation of Composite Manufacturing Processes - IntrobobNo ratings yet

- Proj Paper 3Document5 pagesProj Paper 3Pallavi BhartiNo ratings yet

- Portfolio U Matter AppDocument9 pagesPortfolio U Matter AppMaissama TalhaNo ratings yet

- Eegsig Machine Learning-Based Toolbox For End-To-End Eeg Signal ProcessingDocument8 pagesEegsig Machine Learning-Based Toolbox For End-To-End Eeg Signal ProcessingIoana GuțăNo ratings yet

- Electronic Products - March 2011-TVDocument120 pagesElectronic Products - March 2011-TVVlad VladNo ratings yet

- Benefit To Students: Looking For Internship ?Document1 pageBenefit To Students: Looking For Internship ?Krupal PatelNo ratings yet

- Anisopter Onepager v01Document1 pageAnisopter Onepager v01Guillermo García GilaNo ratings yet

- Ecosim ProDocument51 pagesEcosim Proloiso2No ratings yet

- Official User ManualDocument11 pagesOfficial User Manualalfa robiNo ratings yet

- Simulation and Modelliing Manual - For MergeDocument18 pagesSimulation and Modelliing Manual - For MergeRitik TiwariNo ratings yet

- Adler 2006Document19 pagesAdler 2006Santiago MorenoNo ratings yet

- Intra-System Reliability of SICS: Video-Tracking System (Digital - Stadium®) For Performance Analysis in FootballDocument7 pagesIntra-System Reliability of SICS: Video-Tracking System (Digital - Stadium®) For Performance Analysis in FootballOlaf MounNo ratings yet

- Corporate Visual Identity ManualDocument173 pagesCorporate Visual Identity ManualGau MonNo ratings yet

- Jpro-Technologies JUGSaxonyDocument50 pagesJpro-Technologies JUGSaxonyjzarateaNo ratings yet

- Brosura Programill OneDocument24 pagesBrosura Programill OnemiauNo ratings yet

- Technical Datasheet - ANSYS SPEOS - Optical Sensor Test PDFDocument5 pagesTechnical Datasheet - ANSYS SPEOS - Optical Sensor Test PDFCarlos García ÁvilaNo ratings yet

- (Ccres Tools) Sesamme (Overview and Download Link)Document1 page(Ccres Tools) Sesamme (Overview and Download Link)creep_pigNo ratings yet

- Online Version ImplantSwissDocument8 pagesOnline Version ImplantSwissALi AHmEdNo ratings yet

- 19 Is 000003 BRO Symmetry Cracking Furnace Feb 2020Document5 pages19 Is 000003 BRO Symmetry Cracking Furnace Feb 2020ab_bn_1No ratings yet

- ESAComp Training 20190205Document219 pagesESAComp Training 20190205khurramNo ratings yet

- Man-pr-Intr0010-001-Igep SDK Software User ManualDocument22 pagesMan-pr-Intr0010-001-Igep SDK Software User ManualimmortalNo ratings yet

- A Tool-Supported Approach For Concurrent Execution of Heterogeneous ModelsDocument11 pagesA Tool-Supported Approach For Concurrent Execution of Heterogeneous ModelsSoltan AmelNo ratings yet

- Technical Datasheet - ANSYS SPEOS - Optical Part Design PDFDocument5 pagesTechnical Datasheet - ANSYS SPEOS - Optical Part Design PDFCarlos García ÁvilaNo ratings yet

- Advanced Imaging editorial mission delivers core tech solutionsDocument12 pagesAdvanced Imaging editorial mission delivers core tech solutionsAndi RusdiantoNo ratings yet

- PolymorphismDocument68 pagesPolymorphismBitcoinNo ratings yet

- OneFormer: One Transformer To Rule Universal Image SegmentationDocument18 pagesOneFormer: One Transformer To Rule Universal Image SegmentationYann SkiderNo ratings yet

- Corporate 2020 8 2Document20 pagesCorporate 2020 8 2DJSTEPHEN ILLUSTRISIMONo ratings yet

- Coatings & Construction Applications: Epotec Epoxy SystemsDocument4 pagesCoatings & Construction Applications: Epotec Epoxy SystemsAditya ShrivastavaNo ratings yet

- AscoGraph A User Interface for Sequencing and Score FollowingDocument5 pagesAscoGraph A User Interface for Sequencing and Score FollowingnchjhgjhjNo ratings yet

- Mansingh 2021Document3 pagesMansingh 2021Chirag SaraswatNo ratings yet

- One FormerDocument19 pagesOne FormerYi-Chen ChenNo ratings yet

- Red Hat System Administration I (rh124) PDFDocument12 pagesRed Hat System Administration I (rh124) PDFMustafa AladdinNo ratings yet

- Estress Success Story Letter WebDocument4 pagesEstress Success Story Letter WebADITYA DEVOLNo ratings yet

- Cocos Eds: Engine Diagnostics System, Off-Line VersionDocument2 pagesCocos Eds: Engine Diagnostics System, Off-Line VersionJolly CalibjoNo ratings yet

- ESP Safety Provides Affordable Industrial Safety SolutionsDocument1 pageESP Safety Provides Affordable Industrial Safety SolutionsNhung HoangNo ratings yet

- IASO TENSILE ESTRUCTURES - EngDocument46 pagesIASO TENSILE ESTRUCTURES - EngAbed GenaimNo ratings yet

- 18 Sound Product Overview 2011Document2 pages18 Sound Product Overview 2011sasiNo ratings yet

- Cengiz Can Resume 202109Document2 pagesCengiz Can Resume 202109ismenhickime sNo ratings yet

- Semplot Paper PDFDocument12 pagesSemplot Paper PDFDian SidikNo ratings yet

- Oracle Java Micro Edition Software Development Kit 8 (Oracle Java Me SDK 8)Document3 pagesOracle Java Micro Edition Software Development Kit 8 (Oracle Java Me SDK 8)masaangcakepNo ratings yet

- Cobot Introductory Brochure en LRDocument2 pagesCobot Introductory Brochure en LRNguyễn Anh TuấnNo ratings yet

- Handwriting Specialist Software Converts Typing to User's HandwritingDocument5 pagesHandwriting Specialist Software Converts Typing to User's HandwritingAvdhesh GuptaNo ratings yet

- AMOR El Masri: Education SkillsDocument1 pageAMOR El Masri: Education SkillsOmar Al MasriNo ratings yet

- Technology Adoption of Medical Faculty IDocument246 pagesTechnology Adoption of Medical Faculty IRändy BärracNo ratings yet

- TR csm469Document57 pagesTR csm469José PulgarNo ratings yet

- Reboan 8 MarDocument1 pageReboan 8 Marad1gamerNo ratings yet

- Evolvement of CASE Tools User ExperienceDocument7 pagesEvolvement of CASE Tools User ExperienceAnfelNo ratings yet

- Uses and Abuses of EIDORS - An Extensible Software Base For EITDocument21 pagesUses and Abuses of EIDORS - An Extensible Software Base For EITsastrakusumawijayaNo ratings yet

- Aerospace e DefenseDocument62 pagesAerospace e Defenseneto512No ratings yet

- A History of Aerospace Problems, Their Solutions, Their LessonsDocument250 pagesA History of Aerospace Problems, Their Solutions, Their Lessonsjakub_gramolNo ratings yet

- The ESA Lunar Lander MissionDocument8 pagesThe ESA Lunar Lander Missionjakub_gramolNo ratings yet

- Extensions To The Time Lag Models For Practical Application To Rocket Engine Stability DesignDocument306 pagesExtensions To The Time Lag Models For Practical Application To Rocket Engine Stability Designjakub_gramolNo ratings yet

- Lunar Lander and Return Propulsion System Trade StudyDocument322 pagesLunar Lander and Return Propulsion System Trade Studyjakub_gramolNo ratings yet

- Adaptation of The ESPSS Platform For The Design and Analysis of Liquid Propellant Rocket EnginesDocument10 pagesAdaptation of The ESPSS Platform For The Design and Analysis of Liquid Propellant Rocket Enginesjakub_gramolNo ratings yet

- ESA Lunar Lander PresentationDocument21 pagesESA Lunar Lander Presentationjakub_gramolNo ratings yet

- Direct Simulation Monte Carlo of Thruster Plumes-Satellite Base Region InteractionDocument11 pagesDirect Simulation Monte Carlo of Thruster Plumes-Satellite Base Region Interactionjakub_gramolNo ratings yet

- Open Model I Cause Rs GuideDocument215 pagesOpen Model I Cause Rs Guidejakub_gramolNo ratings yet

- The R InfernoDocument126 pagesThe R InfernoBenoit JottreauNo ratings yet

- Block Hadamard ProductDocument11 pagesBlock Hadamard Productjakub_gramolNo ratings yet

- OpenModelicaUsersGuide PDFDocument215 pagesOpenModelicaUsersGuide PDFjakub_gramolNo ratings yet

- MCMC BriefDocument69 pagesMCMC Briefjakub_gramolNo ratings yet

- Structuring PHD ThesisDocument20 pagesStructuring PHD Thesisjakub_gramolNo ratings yet

- Gentle Introduction To MCMCDocument85 pagesGentle Introduction To MCMCjakub_gramolNo ratings yet

- Thin Airfoil TheoryDocument17 pagesThin Airfoil Theoryjakub_gramolNo ratings yet

- Gaussian RegressionDocument207 pagesGaussian RegressionAnonymous qSEwMRyNo ratings yet

- Cyclic BNDocument12 pagesCyclic BNjakub_gramolNo ratings yet

- Nasa SP2010576Document128 pagesNasa SP2010576Michael LoupisNo ratings yet

- A Response To Orzack and SoberDocument10 pagesA Response To Orzack and Soberjakub_gramolNo ratings yet

- Vehicle Size, Weight, Injury RiskDocument84 pagesVehicle Size, Weight, Injury Riskjakub_gramolNo ratings yet

- Overview of Polynomial Chaos Methods For UQDocument27 pagesOverview of Polynomial Chaos Methods For UQjakub_gramolNo ratings yet

- Beam PDFDocument8 pagesBeam PDFjakub_gramolNo ratings yet

- Beyond Probability - A Pragmatic Approach To Uncertainty Quantification in EngineeringDocument88 pagesBeyond Probability - A Pragmatic Approach To Uncertainty Quantification in Engineeringjakub_gramolNo ratings yet

- Chapter 10Document30 pagesChapter 10Fernando Alcala Dela CruzNo ratings yet

- Data StratificationDocument19 pagesData StratificationVaibhav C GandhiNo ratings yet

- Lesson Tasks: Lesson Plan: Addition and Subtraction To 20Document2 pagesLesson Tasks: Lesson Plan: Addition and Subtraction To 20Марина СтанојевићNo ratings yet

- 2011 BDMS 4E Prelims 2 AM Paper 2Document25 pages2011 BDMS 4E Prelims 2 AM Paper 2Hui XiuNo ratings yet

- 2016 CodeUGM Usingn Code Design Life For Fatigue of WeldsDocument32 pages2016 CodeUGM Usingn Code Design Life For Fatigue of WeldsdddNo ratings yet

- Aqa Comp1 W MS Jun10Document29 pagesAqa Comp1 W MS Jun10Arsalan FotovatNo ratings yet

- Fla Unit 4 and 5Document198 pagesFla Unit 4 and 5lard BaringNo ratings yet

- 1/ The Authors Are Grateful To Willem Buiter, Jonathan Eaton, JacobDocument42 pages1/ The Authors Are Grateful To Willem Buiter, Jonathan Eaton, JacobAgni BanerjeeNo ratings yet

- Solar Still Research PaperDocument8 pagesSolar Still Research PaperGopakumar NairNo ratings yet

- Class 12 - Deleted Topics - MathsDocument5 pagesClass 12 - Deleted Topics - Mathsasharafarifs3No ratings yet

- Tutorial 1 STA416Document3 pagesTutorial 1 STA416Apis ZizanNo ratings yet

- Applied Sciences: Speech Enhancement For Hearing Aids With Deep Learning On Environmental NoisesDocument10 pagesApplied Sciences: Speech Enhancement For Hearing Aids With Deep Learning On Environmental NoisesDr. Rizwan UllahNo ratings yet

- Fundamentals of Computer Programming: Array and String FundamentalsDocument40 pagesFundamentals of Computer Programming: Array and String FundamentalsFares BelaynehNo ratings yet

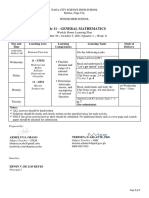

- General Mathematics - Module #3Document7 pagesGeneral Mathematics - Module #3Archie Artemis NoblezaNo ratings yet

- Quantitative 1H NMR SpectrosDocument22 pagesQuantitative 1H NMR Spectrossantosh0912830% (1)

- Regression Modelling and Least-Squares: GSA Short Course: Session 1 RegressionDocument6 pagesRegression Modelling and Least-Squares: GSA Short Course: Session 1 Regressioncarles1972mmNo ratings yet

- Normal Subgroup: You Can Enter A Subtitle Here If You Need ItDocument20 pagesNormal Subgroup: You Can Enter A Subtitle Here If You Need ItBujur KetarenNo ratings yet

- Analytic Geometry: The Conic SectionsDocument52 pagesAnalytic Geometry: The Conic SectionsMae MateoNo ratings yet

- Resume Cit PDFDocument1 pageResume Cit PDFJUNE CARLO ENCABONo ratings yet

- Lecture On Stochastic ProcessDocument2 pagesLecture On Stochastic ProcessMauro MLRNo ratings yet

- Exam in SF2862 and SF2863 Systems Engineering Monday June 3, 2013Document4 pagesExam in SF2862 and SF2863 Systems Engineering Monday June 3, 2013tswiftxoxoNo ratings yet