Professional Documents

Culture Documents

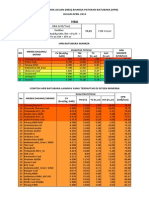

Mechanical Design Calculation of Pipe Rack Under Pass 1

Uploaded by

tobeeprassCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanical Design Calculation of Pipe Rack Under Pass 1

Uploaded by

tobeeprassCopyright:

Available Formats

Calculation of Pipe Rack Under Pass 1

Mechanical Design Calculation of Pipe Rack

Under Pass 1

0 For Approval 19.06.2015 TTP DI ABN

REV DESCRIPTION DATE PREPARED CHECKED APPROVED COMPANY

Calculation of Pipe Rack Under Pass 1

REVISION DATE DESCRIPTION

A 19-06-2015 For Approval

Calculation of Pipe Rack Under Pass 1

Chapter I

Introduction

1.1 Description

This document is a calculation report for a new installation pipe rack at under pass 1 PT. ABN,

the calculation scope is limited to analyze and design the steel structure of pipe rack using the

assumed and predicted loading which will be listed on the loading discussion. Location for pipe rack

under pass 1 can seen at figure 1, below:

Figure 1. Pipe Rack Underpass 1 Desain

This calculation report to give detail of loading information, structure modelling, structure

elements analysis of new pipe rack at under pass 1.

Calculation of Pipe Rack Under Pass 1

1.2 Codes & Standards

SNI 03 1727 1989 Pedoman perencanaan pembebanan untuk rumah dan gedung

AISC LRFD

The software used in the structure analysis for this design is SAP2000 ver 15.

1.3 References

In order to arrange this document refers to references documents as follow:

CSI Analysis Referece Manual For SAP 2000, Computer And Structures Inc.,Berkeley,

California, USA. January 2007.

Calculation of Pipe Rack Under Pass 1

Chapter II

Design Concept

2.1 Design Criteria

General design criteria of pipe rack can seen below.

2.2 Profile Property

Quality of steel which is used in this calculation can seen below:

Quality similar to steel with grade s375.

- Yield strength : 275 N/mm2

- Tensile strength : 410 N/mm2

Allowable maximum deflection for service condition.

Tabel 1. Allowable deflection due to SNI 03-1729-2002

2.3 Design Load

Loading of deck structure and support of beam assigned base on criteria as follow

2.3.1 Dead Load

Dead load covered all permanent or semi permanent structure, include self weight equipment,

as follow:

Steel Self weight

o Equal angle bar (50 x 50 x 6 mm) : 0,142 kN/ 3,75m

o Expanded material : 0,3 kN/ m2

o Railing : 0,25 kN

Pipe weight

o Crude oil pipe (6 ) : 1,038 kN/ 3,75m

o Gas pipe (3) : 0,423 kN/ 3,75m

2.3.2 Live Load

2.3.2.1 Q1 LL

Calculation of Pipe Rack Under Pass 1

Q1LL is live load from volume capacity of the each pipe which take on this case (pipe rack)

Crude oil pipe (6)

o Volume

= 2 = (3,14 x 0.0752) x 3,75 (meter)

= 0,066 (meter3/ 3,75m)

o Massa

= = 913 kg/ m3 x 0,066 m3

= 60,47 kg/ 3,75m

Q1LL pipe 6 = 0,604 kN/ 3,75m

gas pipe (3)

o Volume

= 2 = (3,14 x 0.03752) x 3,75 (meter)

= 0,016 (meter3/ 3,75m)

o Massa

= = 913 kg/ m3 x 0,066 m3

= 0,019 kg/ 3,75m

Q1LL pipe 3 = 0,0002 kN/ 3,75m

Total Q1LL: (0,604+0,0002)*1.25 (impact factor) = 0,75 kN/3,75

2.3.2.2 Q2 LL

Live load assigns to deck slab as uniform load. Uniform live load is taken as 250 kg/m, that

covers people load and his equipment during maintenance.

2.3.3 Wind Load

Determination of wind load base on ASCE 7-2010 analyze and design wind velocity is 40 m/sec.

Equal angle bar wind load

Calculation of Pipe Rack Under Pass 1

Area Calculations

Item Load

Section Profil Width Length Area

Description (kN/m)

Support WF

Support 150 mm 1,14 m 0,171 m2 239,96

WF 150x75

Vibration Load

Pressure Fluid Flow on crude oil pipe (6)

Pressure Fluid Flow on gas pipe (3)

Natural Frequency system (vibration)

You might also like

- Design Report - Pipe Support - R2 PDFDocument10 pagesDesign Report - Pipe Support - R2 PDFAkhilesh KajarekarNo ratings yet

- Pipe Material Strength CalculationDocument8 pagesPipe Material Strength CalculationnidhinNo ratings yet

- Maximum Span Between Pipe Supports For A Given Maximum Bending StressDocument76 pagesMaximum Span Between Pipe Supports For A Given Maximum Bending Stresserodrguez100% (1)

- Design Report For Water Works Roads and DrainageDocument6 pagesDesign Report For Water Works Roads and DrainageTayyabah ZafarNo ratings yet

- ChimneyDocument6 pagesChimneyMadhu GuptaNo ratings yet

- TG Foundation 316Document19 pagesTG Foundation 316Deepu PillaiNo ratings yet

- Calculation 240 (Rev02)Document15 pagesCalculation 240 (Rev02)KM YapNo ratings yet

- Calculation Reference PDFDocument116 pagesCalculation Reference PDFYuki GitaraNo ratings yet

- Wall FootingDocument7 pagesWall FootingKramyer100% (1)

- Appx-A Formula and CalculationDocument20 pagesAppx-A Formula and CalculationapiscobainNo ratings yet

- Inputs Required For FIV & AIV StudyDocument1 pageInputs Required For FIV & AIV StudyRonak MotaNo ratings yet

- Pipe Stress Analysis Training Complete CourseDocument24 pagesPipe Stress Analysis Training Complete CourseFábio GamaNo ratings yet

- Pipe Support Isolated FootingDocument11 pagesPipe Support Isolated Footingnazeer_mohdNo ratings yet

- Excel Fatigue AnalysisDocument11 pagesExcel Fatigue AnalysisAli GhNo ratings yet

- Apf Cal Pipe Bridge Rev 2Document36 pagesApf Cal Pipe Bridge Rev 2Edwin RachmanudinNo ratings yet

- Hen 0000 Me SP 0003 - B4Document16 pagesHen 0000 Me SP 0003 - B4shervinyNo ratings yet

- Design of Pipe Sleeper and Raised Pipe Sleeper On Steel FrameDocument22 pagesDesign of Pipe Sleeper and Raised Pipe Sleeper On Steel FrameAmmarNo ratings yet

- Case - 1: Foundation & Pedestal Design DocumentDocument10 pagesCase - 1: Foundation & Pedestal Design DocumentJayanti RahaNo ratings yet

- 63-A703-DC-008 Bund Wall Calculation PIT.ADocument5 pages63-A703-DC-008 Bund Wall Calculation PIT.ATu Tu DarNo ratings yet

- Lodhama-II Design CivilDocument68 pagesLodhama-II Design Civilnira365No ratings yet

- XX X XXXX XX XXXX 1rev XX Tank Farm Sleeper DesignDocument44 pagesXX X XXXX XX XXXX 1rev XX Tank Farm Sleeper Designg4gohar0% (1)

- Liquefaction AnalysisDocument75 pagesLiquefaction AnalysisRyanYuNo ratings yet

- Thrust Block Calculation For ф (90 DEGREE)Document5 pagesThrust Block Calculation For ф (90 DEGREE)albertooooooNo ratings yet

- Types of Damping 1. Viscous DampingDocument6 pagesTypes of Damping 1. Viscous DampingZandro GagoteNo ratings yet

- Maximum PressureDocument83 pagesMaximum Pressureanhhung80No ratings yet

- Steel Beam Flexural CapacityDocument6 pagesSteel Beam Flexural CapacitykstayroskNo ratings yet

- DGT 242 0 DG CW 001 C PDFDocument7 pagesDGT 242 0 DG CW 001 C PDFEng-Abdullah HishamNo ratings yet

- Anchor ForceDocument14 pagesAnchor ForceAdi Mulyadi100% (1)

- Septic Tank Design Program RAS2021 Updated 10.8.2009Document12 pagesSeptic Tank Design Program RAS2021 Updated 10.8.2009Sheikh Mizanur RahmanNo ratings yet

- Dead Load Only From The PipeDocument5 pagesDead Load Only From The PipeНемања Караклајић100% (1)

- Pip Ste03350 2008 PDFDocument33 pagesPip Ste03350 2008 PDFNagoya Taycho0% (1)

- Final WSS and New Tank Project ReportDocument43 pagesFinal WSS and New Tank Project Reportprachi_borkar100% (4)

- (WWW - Indowebster.com) - Microsoft Word - TUGAS AKHIR LIFTINGDocument36 pages(WWW - Indowebster.com) - Microsoft Word - TUGAS AKHIR LIFTINGsholehamikNo ratings yet

- Concrete Foundation DesignDocument3 pagesConcrete Foundation DesignPradeep Kumar SukumaranNo ratings yet

- Tender227 VOL II PDFDocument945 pagesTender227 VOL II PDFrasnowmah2012No ratings yet

- Design of Pinned Base Plate:-: Max Axial Case Max Uplift CaseDocument3 pagesDesign of Pinned Base Plate:-: Max Axial Case Max Uplift CaseYELLAMANDA SANKATINo ratings yet

- Final Report RC Group 12 Sec 1 - CompressedDocument187 pagesFinal Report RC Group 12 Sec 1 - CompressedAnas Akmal Bin AzharNo ratings yet

- Seismic Design Calculation p1 To p9Document9 pagesSeismic Design Calculation p1 To p9Ivan RocoNo ratings yet

- ASME Horizontal Vessel AnalysisDocument10 pagesASME Horizontal Vessel AnalysisSyedZainAliNo ratings yet

- PENSTOCK Optimization ResearchDocument3 pagesPENSTOCK Optimization ResearchAnjan SigdelNo ratings yet

- Qap-15-23 - rg1700 01 Rev-5 Design Criteria For Concrete Foundations and StructuresDocument23 pagesQap-15-23 - rg1700 01 Rev-5 Design Criteria For Concrete Foundations and StructuresAnonymous uLAATWpfNo ratings yet

- Suction TankDocument15 pagesSuction TankNorazmiMohdNorNo ratings yet

- Mathcad - 1000 KL Tank1Document23 pagesMathcad - 1000 KL Tank1Zulfikar N JoelNo ratings yet

- Axial Load Capacity For Deep Foundations Piles: Sand Input ResultsDocument8 pagesAxial Load Capacity For Deep Foundations Piles: Sand Input ResultsbalaNo ratings yet

- Virtual Anchor Length - KBRDocument22 pagesVirtual Anchor Length - KBRSammar Adhikari100% (2)

- Analysis Report Tensile Canopy - HOCKEY STADIUM - R0 - ADocument23 pagesAnalysis Report Tensile Canopy - HOCKEY STADIUM - R0 - ANeeraj KumarNo ratings yet

- Report BR No 80 R0 01 10 2023Document30 pagesReport BR No 80 R0 01 10 2023Saurabh PandeyNo ratings yet

- 10ab (Gallery 1)Document76 pages10ab (Gallery 1)vrajan1988No ratings yet

- Proposed 3-Storey Residence With Lower GroundDocument93 pagesProposed 3-Storey Residence With Lower Groundfrancis sebastian lagamayoNo ratings yet

- Drilling Platform DesignDocument10 pagesDrilling Platform Designbart porquiadoNo ratings yet

- DBR Cvs AuditoriumDocument9 pagesDBR Cvs AuditoriumJohn JacksonNo ratings yet

- DBR - Shell Component ShopDocument17 pagesDBR - Shell Component Shopvikas WaghmareNo ratings yet

- MainBridge - Design ReportDocument18 pagesMainBridge - Design ReportWan100% (1)

- Pier Coping Falsework Design - HframeDocument8 pagesPier Coping Falsework Design - Hframebart porquiado100% (1)

- Project: Lot8 at Macau: SUBJECT: Calculation For The WindowDocument50 pagesProject: Lot8 at Macau: SUBJECT: Calculation For The WindowHelen ChoiNo ratings yet

- SankhaDocument19 pagesSankhaSabeen budhathokiNo ratings yet

- SR Design Report BhelDocument12 pagesSR Design Report BhelSripara KrishnaNo ratings yet

- Proposed 3-Storey Residence With Lower GroundDocument92 pagesProposed 3-Storey Residence With Lower Groundfrancis sebastian lagamayoNo ratings yet

- Scaffolding Formwork Design CalculationsDocument17 pagesScaffolding Formwork Design Calculationsbhadrakmishra100% (3)

- Discrete Element Modelling - Trouble-Shooting and Optimisation TooDocument28 pagesDiscrete Element Modelling - Trouble-Shooting and Optimisation TooPaula ValenzuelaNo ratings yet

- Skid GensetDocument1 pageSkid GensettobeeprassNo ratings yet

- GA StockpileDocument1 pageGA StockpiletobeeprassNo ratings yet

- BC 01 DeflectorDocument1 pageBC 01 DeflectortobeeprassNo ratings yet

- BC 1Document1 pageBC 1tobeeprassNo ratings yet

- System InstalasiDocument2 pagesSystem InstalasitobeeprassNo ratings yet

- Am 16 Chios SunriseDocument9 pagesAm 16 Chios SunrisetobeeprassNo ratings yet

- DDR 1Document1 pageDDR 1tobeeprassNo ratings yet

- Harga Batubara Acuan (Hba) &harga Patokan Batubara (HPB) April 2014Document5 pagesHarga Batubara Acuan (Hba) &harga Patokan Batubara (HPB) April 2014Titin KustiniNo ratings yet

- North Shiploader's Chute PDFDocument2 pagesNorth Shiploader's Chute PDFtobeeprassNo ratings yet

- Mail MergeDocument1 pageMail MergeIqbal FaridNo ratings yet

- GA1Document1 pageGA1tobeeprassNo ratings yet

- Personal Statement For PHD in Mechanical EngineeringDocument3 pagesPersonal Statement For PHD in Mechanical EngineeringSylvester JemigbeyiNo ratings yet

- Ev 15l PDFDocument2 pagesEv 15l PDFJocelynNo ratings yet

- WATO EX-55,65 Service Manual - English - 20131025Document380 pagesWATO EX-55,65 Service Manual - English - 20131025travieso1120% (2)

- 0901d19680090e01 SKF Bushings Thrust Washers and Strips 1 EN - TCM - 12 582374Document48 pages0901d19680090e01 SKF Bushings Thrust Washers and Strips 1 EN - TCM - 12 582374zbhp zNo ratings yet

- Metro Standard StructDwgs 080613Document41 pagesMetro Standard StructDwgs 080613rpazbNo ratings yet

- Neps and Trash IndicatorDocument8 pagesNeps and Trash IndicatorShoaib ArifNo ratings yet

- List of GMP EquipmentDocument2 pagesList of GMP EquipmentBella ReadNo ratings yet

- Electrode Selection Excel SheetDocument1 pageElectrode Selection Excel Sheetchandrakit047No ratings yet

- Hardox 500 Sheet: General Product DescriptionDocument2 pagesHardox 500 Sheet: General Product DescriptionDylkanWingsNo ratings yet

- Solar Powered Water Pumping Systems: January 2005Document6 pagesSolar Powered Water Pumping Systems: January 2005Shabin MuhammedNo ratings yet

- Test Procedure For Determining of Aggregate Abrasion Value: Purpose of Testing: Table No: 1Document2 pagesTest Procedure For Determining of Aggregate Abrasion Value: Purpose of Testing: Table No: 1Pankaj shahNo ratings yet

- LHH CatalogueDocument32 pagesLHH CataloguelovelyirisNo ratings yet

- Pds Luxol 5000 VocDocument2 pagesPds Luxol 5000 VocmuthukumarNo ratings yet

- TLP Solutions: Our ActivitiesDocument16 pagesTLP Solutions: Our ActivitiesFrank DrennanNo ratings yet

- 1655-Equip- با با هوتکDocument8 pages1655-Equip- با با هوتکSayed WafiNo ratings yet

- Plane Normal ChecklistDocument1 pagePlane Normal Checklistkarlbeckham2002No ratings yet

- What Is MEMS TechnologyDocument6 pagesWhat Is MEMS TechnologyMAHDILEE100% (2)

- Project Report Rajuri Steel JalnaDocument40 pagesProject Report Rajuri Steel JalnaSingh GurpreetNo ratings yet

- Composite Steel Wire Rope ArtDocument10 pagesComposite Steel Wire Rope ArtsijuaNo ratings yet

- Cis 209Document4 pagesCis 209jerimiah_manzonNo ratings yet

- Vehicle Operating CostDocument15 pagesVehicle Operating CostAbdulkareem Adeyinka100% (1)

- Textile Today Emagazine August 2018 Issue PDFDocument100 pagesTextile Today Emagazine August 2018 Issue PDFadobe777No ratings yet

- m35 Site Specs 1C4751Document26 pagesm35 Site Specs 1C4751merakhaNo ratings yet

- TS of Travelling TripperDocument10 pagesTS of Travelling TripperShashank HegdeNo ratings yet

- Op JindalDocument12 pagesOp JindalPrateek JhaNo ratings yet

- Annotated Drawings of Britten Pears ArchiveDocument5 pagesAnnotated Drawings of Britten Pears ArchiveDavid CaetanoNo ratings yet

- Design, Cad Modeling & Fabrication of Geneva Operated Roller ConveyorDocument5 pagesDesign, Cad Modeling & Fabrication of Geneva Operated Roller ConveyorMohamed muzamilNo ratings yet

- Evaluation of Iron and Steel in Historic BridgesDocument8 pagesEvaluation of Iron and Steel in Historic BridgesjayaramanrathnamNo ratings yet

- Strengthening Fatigue-Cracked Steel Bridge DecksDocument10 pagesStrengthening Fatigue-Cracked Steel Bridge DecksJNo ratings yet