Professional Documents

Culture Documents

Cemtec A1 Black PU

Uploaded by

Pageduesca RouelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cemtec A1 Black PU

Uploaded by

Pageduesca RouelCopyright:

Available Formats

CEMTEC A1 BLACK P.U.

LIQUID APPLIED WATERPROOFING

MEMBRANE

CEMTEC A1 BLACK P .U. is a one-component,

P.U. Priming - Prepare primer coat by mixing one (1)

liquid, cold applied waterproofing membrane base part Xylene to three (3) part CEMTEC A1 BLACK

on polyurethane resin. It is primarily designed to P.U. by volume. For horizontal or vertical surfaces,

give superior waterproofing and protection to virtually apply a thin coat of primer. Airless spraying

all substrate. It reacts with moisture in the equipments may also be used. Care should be taken

atmosphere and forms an impervious, rubberized that no excess liquid collect on the edges of the

membrane that resists water, oil, fuel and other wall converging on the floor. If this occurs, the liquid

common air pollutants. It is an advanced state-of- must be evenly spread out by brush. Allow to cure

art waterproofing system and offers tangible, cost- prior to the next coat (usually from 10-14 hours).

saving benefits over conventional sheet and bitumen Best results can be obtained by limiting the

based systems. thickness of the prime coat between 0.3-0.4 mm.

First And Succeeding Coats - After the prime

RECOMMENDED USES

coat has cured, apply a thin coat of CEMTEC A1

Recommended for use in water storage tanks, BLACK P .U. (without xylene) starting with the

P.U.

towers, pier, swimming pools and roofs. vertical surface. Ensure that the edges of the vertical

Recommended for use in undertile areas such as surface are evenly coated with P.U. and extends to

bathrooms, kitchens and other wet sections. the horizontal surface by 100 mm. Disperse liquid

ADVANT

ADVANT AGES

ANTAGES that may collect on the edges. Coating shall be

z Easy to apply, by brush, roller or spray. allowed to cure at least one (1) day prior to the

Eliminates the use of adhesives, sealing succeeding coats. Thickness should be limited to

tapes, blow torches, heating kettles 0.5 - 0.6mm per coat. Optimum performance can

commonly associated with sheet type or be obtained at a total membrane thickness of 1.0

bitumen based system. No need for highly mm including the prime coat.

skilled laborers. Caution - DO NOT APPLY CEMTEC A1 BLACK

z Does not create mess and objectionable odor P.U. ON WET OR UNPREPARED SURFACES.

like bitumen based materials. Provides a Smoking should be strictly prohibited during

seamless (no joint) waterproofing unlike sheet application.

type membranes whose application is In confined areas of application, breathing equipment

susceptible to water leak coming from the should be made available for operatives.

seams. No waste and cuttings. COVERAGE

z Resists deterioration from salts, acids, oil,

20 ltr will cover approx. 16 m2 at 1000 dry film micron

alkali solutions, gasoline and bacteria. thickness depending on surface profile.

z Adheres tenaciously to any substrate and

remains flexible under extremes of

temperature, will not crack or become brittle

PACKAGING

with age.

z Versatile, nonflammable and non-toxic. 20 ltr pails / 20kg pails

z Due to efficiency in application, labor cost is

LIMIT

LIMITAATIONS

reduced and results in shorter completion

z Not Recommended to be exposed to direct

time of construction.

sunlight

z Available in 20 ltr pail unlike bulky sheet type

z Open only the required amount of material

membranes.

that can be used. The material will harden/

z Maintenance free waterproofing system.

cure in the container if not used.

DIRECTIONS FOR USE z If R.H. is less that 50% contact CMCI

Surface Preparation - Remove all dirt, laitance, Technical Dept.

oil grease, wax and other loose materials from the z Solvents in CEMTEC A1 BLACK PU are

surface using a stiff nylon or steel bristled brush flammable. Keep away from heat, sparks,

followed by compressed air. Voids, crack, and open flame or lighted cigarettes. Use

irregular surface with at least 3 mm depth shall be explosion-proof application equipments.

filled or levelled with mortar screed and allowed to

cure at least forty eight (48) hours.

High Quality Construction Chemicals

CONSTRUCTION MATERIAL CHEMICAL INDUSTRIES P.O. Box 7137, Dammam 31462, Saudi Arabia

Tel: 00966-3-8471450; Fax: 00966-3-8471575; Email: tech@cmci-sa.com Web: www.cmci-sa.com

PHYSICAL PROPERTIES

PROPERTIES RESULTS

RESULTS TEST METHOD

Tensile Strength - 200% Modulus 200 p.s.i. ASTM D 412

Tensile Strength at break 435 p.s.i. ASTM D 412

Tensile set recovery % 95 ASTM D 412

Elongation% 440 ASTM D 412

Low temperature flexibility

Cracking None ASTM C-836

Adhesion to mortar, n/m 3325 ASTM D 413 TypeA

Water vapor permeability,

Metric perms 0.4 ASTM E-96 Method BW

Shore A hardness 45 ASTM D 2240

Tear resistance, KN/m 25.1 ASTM D-624 die C

Heat aging % weight loss 0.92 7 days at 82 C

In service temperature No cracking ----

20- hours @ 121 C No shrinkage and 435%

elongation

Chemical Resistance, % wt. change ASTM D 471

Water 3.5

10% NaCl 2.1

5% NaOH 2.3

5% H2SO4 3.3

Brittleness temperature C -42 ASTM D-746

Note: Ultimate tensile strength can be increased seven (7) times if reinforced with fabric mesh.

QUALITY STATEMENT

CMCI manufacture its products at their manufacturing

facility in Saudi Arabia as per the Quality Procedures

certified to conform with Quality Management System

described in ISO 9000 series

CMCI provides a comprehensive technical support system

for its full range of high performance construction products.

CMCI also offers full technical field support to consultants,

Architects, Contractors, applicators and End Users

The Technical Specification information and recommendation given are based on the current technical knowledge and the user

or his representative is recommended to check the suitability of the product. CMCI reserves the right to amend the technical

characteristic of the product as part of ongoing research and development. As the work execution is beyond the direct and

continuous control of CMCI no guaranty and or responsibility is assumed on the performance of work completion executed with

use of our products.

You might also like

- Technical Submittal: Product Name Nitoflor EPU100Document14 pagesTechnical Submittal: Product Name Nitoflor EPU100rayNo ratings yet

- Astm C920-11Document4 pagesAstm C920-11蔡豐任100% (1)

- TDS Nitocote EPU Saudi ArabiaDocument4 pagesTDS Nitocote EPU Saudi ArabiaShaikhRizwan100% (1)

- Kut Thioseal 227: Two Component Gun and Pouring Grade Polysulfide SealantDocument4 pagesKut Thioseal 227: Two Component Gun and Pouring Grade Polysulfide Sealanthafee83No ratings yet

- Cemtec AL PUDocument3 pagesCemtec AL PUPageduesca RouelNo ratings yet

- Astm C656Document3 pagesAstm C656alokjha_03No ratings yet

- TDS - Sonoshield ParkcoatDocument2 pagesTDS - Sonoshield ParkcoatVenkata RaoNo ratings yet

- Spec Booklet Complete PDFDocument276 pagesSpec Booklet Complete PDFresellana5893No ratings yet

- DR Fixit FastflexDocument3 pagesDR Fixit FastflexsubhaschandraNo ratings yet

- Non-Asbestos Fiber-Mat Reinforced Cement Substrate Sheets: Standard Specification ForDocument4 pagesNon-Asbestos Fiber-Mat Reinforced Cement Substrate Sheets: Standard Specification ForNicolas FernandezNo ratings yet

- Section 09260 Gypsum Board AssembliesDocument10 pagesSection 09260 Gypsum Board AssembliesMØhãmmed ØwięsNo ratings yet

- Basf Masterprotect 1815 TdsDocument3 pagesBasf Masterprotect 1815 TdsEngTamer100% (1)

- Masterflow 559: Versatile High Strength, Non Shrink Cementitious Construction GroutDocument3 pagesMasterflow 559: Versatile High Strength, Non Shrink Cementitious Construction GroutGavriel NgNo ratings yet

- Sikaproof Membrane: Product Data SheetDocument2 pagesSikaproof Membrane: Product Data SheetKennethNo ratings yet

- Sikagard EPSDocument18 pagesSikagard EPSTheOne Yasir0% (1)

- Conmix PRODUCT REFERENCE GUIDE CCDDocument24 pagesConmix PRODUCT REFERENCE GUIDE CCDalbarajeel forwarding001No ratings yet

- Volume Ii: Specifications (Stamped Concrete) : Issue: FINAL, 14th FEB 2013Document8 pagesVolume Ii: Specifications (Stamped Concrete) : Issue: FINAL, 14th FEB 2013Ahmad Saadeldin100% (1)

- Molded Glass Fiber Reinforced Gypsum Parts: Standard Specification ForDocument2 pagesMolded Glass Fiber Reinforced Gypsum Parts: Standard Specification ForJesús Luis Arce Guillermo100% (1)

- Astm d2939Document7 pagesAstm d2939Ahmad KhreisatNo ratings yet

- 355 SaDocument2 pages355 Sakhalid764100% (1)

- Isobond: SBR Bonding AdmixtureDocument3 pagesIsobond: SBR Bonding AdmixtureHussain MarzooqNo ratings yet

- C836C836M 15.PDF (EngPedia - Ir)Document3 pagesC836C836M 15.PDF (EngPedia - Ir)Baba Mountain Gem ServicesNo ratings yet

- Astm e 1745Document2 pagesAstm e 1745Zahoor Ahmed Mohsan100% (1)

- 1003 - 1 Timber Shutter SpecificationsDocument16 pages1003 - 1 Timber Shutter SpecificationsP Ravi BabuNo ratings yet

- TDS Nitomortar TC2000 Saudi ArabiaDocument3 pagesTDS Nitomortar TC2000 Saudi ArabiaHarry BawingNo ratings yet

- High Solids Content, Cold Liquid-Applied Elastomeric Waterproofing Membrane For Use With Separate Wearing CourseDocument3 pagesHigh Solids Content, Cold Liquid-Applied Elastomeric Waterproofing Membrane For Use With Separate Wearing CourseSatya kaliprasad vangara100% (1)

- TDS - Rheofinish 288 FDDocument2 pagesTDS - Rheofinish 288 FDVenkata RaoNo ratings yet

- Cri 104 Standard For Installation of Commercial CarpetDocument48 pagesCri 104 Standard For Installation of Commercial Carpetbalan 16No ratings yet

- Astm C1491Document3 pagesAstm C1491BeymerBustamanteMejíaNo ratings yet

- Disclosure To Promote The Right To InformationDocument18 pagesDisclosure To Promote The Right To Informationsudhir5441No ratings yet

- FOSROC SPECS - HDPE - P STD + Proofex 3000VDocument15 pagesFOSROC SPECS - HDPE - P STD + Proofex 3000VAjin Sharma100% (1)

- Section 5.0 - Epoxy Coatin SystemsDocument36 pagesSection 5.0 - Epoxy Coatin SystemsgemotorresNo ratings yet

- Chemical Resistance GuideDocument11 pagesChemical Resistance GuideMohamed NouzerNo ratings yet

- Mar Resistance of Organic Coatings: Standard Test Method ForDocument3 pagesMar Resistance of Organic Coatings: Standard Test Method Formit uotNo ratings yet

- Saso Astm A615mDocument12 pagesSaso Astm A615mMohammed Imadullah Khan100% (1)

- Alkyd Topcoat Technical Data Sheet Jotun PaintDocument4 pagesAlkyd Topcoat Technical Data Sheet Jotun PaintGurdeep Sungh Arora0% (1)

- Astm D7682-10 PDFDocument4 pagesAstm D7682-10 PDFdang2172014No ratings yet

- Conmix Utg 2011Document2 pagesConmix Utg 2011Fredj Ben SalemNo ratings yet

- ASTM's C926, C897, C932, C631Document25 pagesASTM's C926, C897, C932, C631sarah magdyNo ratings yet

- Nitocote ET402: Constructive SolutionsDocument3 pagesNitocote ET402: Constructive SolutionsGavriel Ng100% (1)

- Hempel'S Vinyl Ester GF 35910: Description: Recommended UseDocument2 pagesHempel'S Vinyl Ester GF 35910: Description: Recommended UseEngTamerNo ratings yet

- 0079 - Asian Wall PuttyDocument5 pages0079 - Asian Wall Puttypravi3434No ratings yet

- Corrugated Pipe Single Wall Technical SpecificationDocument7 pagesCorrugated Pipe Single Wall Technical SpecificationbcsmurthyNo ratings yet

- Astm D4260-88 PDFDocument2 pagesAstm D4260-88 PDFdang2172014No ratings yet

- Estidama Compliance Handbook Opt Tcm8-12519Document11 pagesEstidama Compliance Handbook Opt Tcm8-12519Rawan Alwan ZarifNo ratings yet

- Ul 1709 (2022)Document34 pagesUl 1709 (2022)gaso99100% (1)

- GFRCDocument11 pagesGFRCMhmd AbdoNo ratings yet

- PDS Simacover Tar Epoxy 3404-00Document4 pagesPDS Simacover Tar Epoxy 3404-00Aulia RahmahNo ratings yet

- Astm c717 - SelantesDocument13 pagesAstm c717 - SelantesJavier VianaNo ratings yet

- Abuse-Resistant Nondecorated Interior Gypsum Panel Products and Fiber-Reinforced Cement PanelsDocument7 pagesAbuse-Resistant Nondecorated Interior Gypsum Panel Products and Fiber-Reinforced Cement PanelsAlejandroNo ratings yet

- Astm F 668Document6 pagesAstm F 668Ivan AlanizNo ratings yet

- (BS 4887-1-1986) - Mortar Admixtures. Specification For Air-Entraining (Plasticizing) AdmixturesDocument12 pages(BS 4887-1-1986) - Mortar Admixtures. Specification For Air-Entraining (Plasticizing) AdmixturesHung LeNo ratings yet

- D7530D7530M-10 Standard Specification For Self-Adhesive Glass Fiber Fabric Reinforced Polymer Modified Asphalt Steep Slope Roll Roofing Surfaced With Mineral GranulesDocument5 pagesD7530D7530M-10 Standard Specification For Self-Adhesive Glass Fiber Fabric Reinforced Polymer Modified Asphalt Steep Slope Roll Roofing Surfaced With Mineral GranulesSatya kaliprasad vangaraNo ratings yet

- Non Conformance Report: Refer Attached PhotographsDocument8 pagesNon Conformance Report: Refer Attached PhotographsJitender Tanwar100% (1)

- Cemtec A1 Black PUDocument2 pagesCemtec A1 Black PUAhmad ElghazolyNo ratings yet

- Technical Data Sheet: Lasteek Rwe500Document2 pagesTechnical Data Sheet: Lasteek Rwe500Engr KamalNo ratings yet

- iKOTE CM 40X (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 40X (TDS) 02-APRIL-2024nguyen hoang AnhNo ratings yet

- BitugardDocument2 pagesBitugardAhmad SamyNo ratings yet

- Polycoat RBE 1000: SBS Modified Bitumen Jellified EmulsionDocument2 pagesPolycoat RBE 1000: SBS Modified Bitumen Jellified Emulsionsoliman fathyNo ratings yet

- Brushbond Roofguard BFL3Document2 pagesBrushbond Roofguard BFL3peashNo ratings yet

- Computation of Income TaxDocument10 pagesComputation of Income TaxPageduesca RouelNo ratings yet

- Gen. Principles of TaxationDocument22 pagesGen. Principles of TaxationPageduesca RouelNo ratings yet

- Banta Ylan Sang AnDocument136 pagesBanta Ylan Sang AnPageduesca RouelNo ratings yet

- Computation of Income TaxDocument10 pagesComputation of Income TaxPageduesca RouelNo ratings yet

- Project Exec & Quality PlanDocument7 pagesProject Exec & Quality PlanGurumoorthy Chandran100% (1)

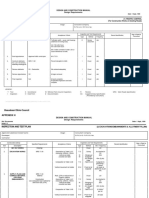

- PI - Template - 06A Water ITPDocument8 pagesPI - Template - 06A Water ITPPageduesca RouelNo ratings yet

- Excavation Checklist PDFDocument4 pagesExcavation Checklist PDFPageduesca RouelNo ratings yet

- Quality-Plan in Manufacturing Og Pre-Eng'Ng StructuresDocument23 pagesQuality-Plan in Manufacturing Og Pre-Eng'Ng StructuresPageduesca Rouel100% (1)

- Appendix H: Design and Construction Manual Design RequirementsDocument17 pagesAppendix H: Design and Construction Manual Design RequirementsPageduesca RouelNo ratings yet

- Project Execution ProcedureDocument4 pagesProject Execution Procedurecyno2167% (3)

- Project Quality Plan.Document27 pagesProject Quality Plan.Adeel RazzaqNo ratings yet

- Project Quality PlanDocument43 pagesProject Quality PlanPageduesca RouelNo ratings yet

- 5A-QA-PL-02Rev00 - Project Execution and Quality PlanDocument34 pages5A-QA-PL-02Rev00 - Project Execution and Quality Planirzaldy100% (8)

- Quality Management PlanDocument32 pagesQuality Management PlanPageduesca Rouel100% (2)

- Typical Project Quality Plan & ITP CPCDocument14 pagesTypical Project Quality Plan & ITP CPCPadmanabhan Venkatesh100% (1)

- Project Exec & Quality PlanDocument7 pagesProject Exec & Quality PlanGurumoorthy Chandran100% (1)

- Typical Project Quality Plan & ITP CPCDocument14 pagesTypical Project Quality Plan & ITP CPCPadmanabhan Venkatesh100% (1)

- Engineering Development Quality Inspection Test Plan ITPDocument13 pagesEngineering Development Quality Inspection Test Plan ITPPageduesca RouelNo ratings yet

- Project Execution ProcedureDocument4 pagesProject Execution Procedurecyno2167% (3)

- Engineering Development Quality Inspection Test Plan ITPDocument13 pagesEngineering Development Quality Inspection Test Plan ITPPageduesca RouelNo ratings yet

- Earthwork Excavation Method StatementDocument4 pagesEarthwork Excavation Method StatementPageduesca RouelNo ratings yet

- PI - Template - 06A Water ITPDocument8 pagesPI - Template - 06A Water ITPPageduesca RouelNo ratings yet

- Excavation Checklist PDFDocument4 pagesExcavation Checklist PDFPageduesca RouelNo ratings yet

- Excavation SafetyDocument31 pagesExcavation SafetyPageduesca RouelNo ratings yet

- Deep Excavation Techniques Deep Excavation Techniques: Presented byDocument31 pagesDeep Excavation Techniques Deep Excavation Techniques: Presented byRizwan Khurram100% (1)

- Excavations 2Document31 pagesExcavations 2sumitdel9136No ratings yet

- Floor Finishes and CoveringDocument69 pagesFloor Finishes and CoveringPageduesca RouelNo ratings yet

- Excavation Safety: Texas Department of InsuranceDocument12 pagesExcavation Safety: Texas Department of InsurancePageduesca RouelNo ratings yet

- Excavation SafetyDocument31 pagesExcavation SafetyPageduesca RouelNo ratings yet

- Underwater ConcretingDocument21 pagesUnderwater ConcretingPageduesca Rouel100% (2)

- Thermal Isolation of AccelerometersDocument4 pagesThermal Isolation of AccelerometersLake HouseNo ratings yet

- Out of The Fiery Furnace The Impact of Metals On The History ofDocument296 pagesOut of The Fiery Furnace The Impact of Metals On The History ofLeland Stanford0% (1)

- Sassafras Oils As Precursors For The Production of Synthetic Drugs: Profiling Via MEKC-UVD - By: C. Huhn, M. Pütz, R. Dahlenburg, U. PyellDocument11 pagesSassafras Oils As Precursors For The Production of Synthetic Drugs: Profiling Via MEKC-UVD - By: C. Huhn, M. Pütz, R. Dahlenburg, U. PyellyunusNo ratings yet

- 0 - Relative Atomic MassDocument7 pages0 - Relative Atomic MassMohamedNo ratings yet

- Protein MetabolismDocument18 pagesProtein MetabolismAbdul RehmanNo ratings yet

- Fermentation ManualDocument38 pagesFermentation ManualMuthu KumarNo ratings yet

- Lec4-CEM&G Session 4 Mats Props Stress StrainDocument64 pagesLec4-CEM&G Session 4 Mats Props Stress StrainSarah HaiderNo ratings yet

- CarbohydratesDocument116 pagesCarbohydratesMaisie LeeNo ratings yet

- Second Law of ThermodynamicsDocument3 pagesSecond Law of ThermodynamicsthienNo ratings yet

- Truss Problem 6.1 Johnston and Beer Book-Static 1-1Document15 pagesTruss Problem 6.1 Johnston and Beer Book-Static 1-1mahfuzul_haqueNo ratings yet

- Joint Universities Preliminary Examinations Board 2015 Examinations Chemistry: Sci-J153 Multiple Choice Questions: Answer All QuestionsDocument11 pagesJoint Universities Preliminary Examinations Board 2015 Examinations Chemistry: Sci-J153 Multiple Choice Questions: Answer All QuestionsDeborahNo ratings yet

- Water Chemistry - Mark Benjamin - 2nd EdDocument935 pagesWater Chemistry - Mark Benjamin - 2nd EdPedro Casa Grande Rosa95% (19)

- RSE 220-01-576 - Instruction Manual and Parts List - Ed. 596Document169 pagesRSE 220-01-576 - Instruction Manual and Parts List - Ed. 596Centrifugal Separator100% (3)

- 04 Script Examples Solid Liquid ExtractionDocument11 pages04 Script Examples Solid Liquid ExtractionLei YinNo ratings yet

- Types of Chemical ReactionsDocument35 pagesTypes of Chemical ReactionsJemina R. B. EspedillonNo ratings yet

- ANSYS Mechanical APDL Fracture Analysis GuideDocument134 pagesANSYS Mechanical APDL Fracture Analysis Guidearulrajasi0% (1)

- Analysis of Abietic Acid & Dehydroabietic Acid by LC-MSDocument6 pagesAnalysis of Abietic Acid & Dehydroabietic Acid by LC-MStplee_hbNo ratings yet

- Chapter 7. ReportDocument22 pagesChapter 7. ReportDivine CostalesNo ratings yet

- Tyfo UGDocument2 pagesTyfo UGdediodedNo ratings yet

- PDFDocument24 pagesPDFousmaneNo ratings yet

- ME106 - Casting (2015)Document64 pagesME106 - Casting (2015)just randomNo ratings yet

- Liquid Ring Vacuum Pump: LPH 55312, LPH 55316, LPH 55320Document12 pagesLiquid Ring Vacuum Pump: LPH 55312, LPH 55316, LPH 55320Edu CordonNo ratings yet

- Essential Variables API 1104Document4 pagesEssential Variables API 1104Madidj_2014No ratings yet

- Lecture 1. Physics of DiodesDocument4 pagesLecture 1. Physics of DiodesSmiley Grace GooNo ratings yet

- Common Methods For Heating Value CalculationDocument44 pagesCommon Methods For Heating Value Calculationmcdale100% (1)

- Chemistry Primer ANSWERSDocument81 pagesChemistry Primer ANSWERSYazdan KelawalaNo ratings yet

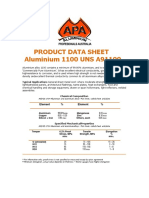

- 1100-Data Sheets PDFDocument3 pages1100-Data Sheets PDFPaturu VijayNo ratings yet

- Msds Colateric Msc-NaDocument2 pagesMsds Colateric Msc-NamndmattNo ratings yet

- Science Focus 4 CBDocument343 pagesScience Focus 4 CBmusic_stefan98100% (2)

- Sabic mLLDPE 8115 Series: PolymersDocument2 pagesSabic mLLDPE 8115 Series: PolymerslinhnguyenNo ratings yet