Professional Documents

Culture Documents

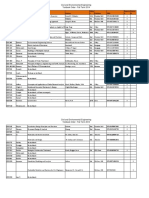

CI3907 Granosik

Uploaded by

deviationzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CI3907 Granosik

Uploaded by

deviationzCopyright:

Available Formats

Design of Reinforcement

for Pile Caps

Strut-and-tie models are illustrated for axial tension and bending loadings

by Tadeusz Granosik

D

eep foundations for pipe racks and open frame

structures used in the petrochemical industry are

often subjected to axial tension and bending. While

reinforcement design guidance is available for pile caps

subject to compressive or tensile loading,1, 2 many engineers

still use flexural design theory to determine the required pile

cap reinforcement for tensile loading, even when the clear span

to overall depth pile cap ratio is less than 2. This article will

help resolve this issue by providing some design examples.

Figure 1 shows a pile cap reinforcement scheme typically

found in structural drawings, with the top layer of bars

carrying the bending moment due to pile tension. A strut-and- Fig. 1: Typical pile cap reinforcement arrangement

tie model for a pile cap supported by two piles subjected to

compression is shown in Fig. 2. In this case, the compressive

load from the column is transmitted to the piles through

F

straight-line struts. At the bottom of the pile cap, the

horizontal components of the compressive struts are carried

by reinforcing bars acting as a tension tie. b

This article presents simplified strut-and-tie models for b/4 b/4

reinforcement of pile caps in the presence of tensile loads. For

the reinforcement design provided in this paper, a pile cap F/2 F/2

subjected to tension is loaded inversely to a pile cap subjected

to compression. This is demonstrated for pile caps supported

by two and four piles, which are the most common

d

h

configurations currently used.

T

Pile Caps Subjected to Axial Tension

ap

Supported by two piles

When the pile cap is subjected to tensile loading, the F/2 F/2

compressive struts are in equilibrium with the tensile tie

located at the top of the pile cap. For the pile cap supported

by two piles, it is assumed that the vertical column r

reinforcement is uniformly distributed along the column Fig. 2: Strut-and-tie model for a pile cap supported by two piles and

sides, perpendicular to the longitudinal axis of the pile cap. subjected to compression

www.concreteinternational.com | Ci | JULY 2017 37

r

F

F/2 F/2

T T

b

a a T1 b

T T

a a 1 T r 2 b 2+a 2

I I 2 2

ap

T1 T1 T

T

T T

T

h

T

d

F/2 r 2

F/2

F 2

b 2a 2

F/4 F/4 2

r

Fig. 3: Strut-and-tie model for a pile cap supported by two piles and

I vertical ties

subjected to tension

ap

T1 T1

h

d

Thus, the axial force F, as shown in Fig. 3, is distributed along

two vertical components. The tensile force T can be

determined geometrically as follows

F/4 F/4

(1) r 2

The required tension reinforcement area As is thus given by

Fig. 4: Strut-and-tie model for a pile cap supported by four piles and

subjected to tension

(2)

where fy is the specified yield strength of the reinforcement.

shown in Fig. 5. The force couple can be calculated using the

Supported by four piles following equation

For a pile cap supported by four piles, it can be assumed

that the vertical column reinforcement is concentrated at all (5)

four corners of the column. In this case, the axial force is

distributed along four vertical components, as shown in Fig. 4. Supported by two piles

For the geometrical relationships shown in Fig. 4, the diagonal In this case, the tensile force in a pile cap supported by two

tensile force, T1, is first calculated followed by the required piles can be determined by substituting FM in place of 0.5F in

tensile force, T. Eq. (1). This substitution gives

(3) (6)

(4) The reinforcement required to carry the tension tie force TM

can be calculated from Eq. (2).

With this tensile force known, the reinforcement to resist

the tension tie force, T, can be calculated from Eq. (2). Supported by four piles

To determine the tensile force when the pile cap is

Pile Caps Subjected to Bending Moment supported by four piles, one can substitute 0.5FM for 0.25F in

When the pile cap is subjected to a bending moment, the Eq. (3). This substitution gives

load can be resisted by a tension tie force couple, FM, which is

applied at the column reinforcement center of gravity, as (7)

38 JULY 2017 | Ci | www.concreteinternational.com

M Summary

This article presents simplified reinforcement designs

based on the strut-and-tie model for pile caps supported by two

FM FM and four pile configurations when subjected to axial tension

and bending. Apart from a horizontal reinforcement calculated

for tension forces T and TM, the vertical ties shown in Fig. 3

b

through 5 are proposed. These ties create a clear load path to

a a transfer the tensile force from the pile cap to piles via dowels.

I vertical ties References

1. Mitchell, D.; Collins, M.P.; Shrinivas, B.B.; and Rabbat, B.G.,

AASHTO LRFD Strut-and-Tie Model, Design Examples, EB 231,

ap

Portland Cement Association, Skokie, IL, 2004, 58 pp.

2. Widianto, and Bayrak, O., Example 11: Deep Pile Cap with

h

d Tension Piles, Further Examples for the Design of Structural Concrete

with Strut-and-Tie Models, SP-273, K.-H. Reineck and L.C. Novak, eds.,

American Concrete Institute, Farmington Hills, MI, 2010, pp. 11-1 to 11-23.

Selected for reader interest by the editors after independent expert

TM TM evaluation and recommendation.

r

Tadeusz Granosik is a retired Senior

Fig. 5: Strut-and-tie model for a pile cap supported by two piles and

Structural Engineer last employed by

subjected to a bending moment

WorleyParson, Calgary, AB, Canada. He

has been involved in the design of steel

The resulting reinforcement required to resist the tension tie and concrete structures, and foundations

for the pulp and paper, oil sands, and

force TM can now be calculated using Eq. (2). In the case of a

pharmaceutical industries. He received his

combined loading configuration that includes both tensile

MS from Lodz Technical University, d,

force and a bending moment, the required reinforcement is to Poland, and his PhD from Warsaw Technical

be calculated via superposition using the calculated values for University, Warsaw, Poland.

both T and TM.

VISIT THE

ACI Store

The ACI Store has over 400 standards, technical reports, special publications, and webinars,

many ready to download straight to your mobile device. Visit today at www.concrete.org.

+1.248.848.3700 www.concrete.org

www.concreteinternational.com | Ci | JULY 2017 39

You might also like

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- ArchBridgeBuckling PDFDocument31 pagesArchBridgeBuckling PDFjayaramanrathnamNo ratings yet

- Management of Fatigue Cracking West Gate Bridge, Melbourne PDFDocument9 pagesManagement of Fatigue Cracking West Gate Bridge, Melbourne PDFAVSSSNo ratings yet

- Bridge Manual PDF Complete v3.4Document374 pagesBridge Manual PDF Complete v3.4Anonymous YakppP3vAnNo ratings yet

- PLAXIS-UDSM-Masonry Model (V20Update1)Document22 pagesPLAXIS-UDSM-Masonry Model (V20Update1)NISHANT ROYNo ratings yet

- AREMA Estructuras ART. 2.30 Al 39Document18 pagesAREMA Estructuras ART. 2.30 Al 39pepegrillo891100% (1)

- Galvanized Structural Bridge Rope: ASTM A603Document1 pageGalvanized Structural Bridge Rope: ASTM A603Gilberto ChangNo ratings yet

- 2010-06-02 - Manual For Bulb Tee Girders PDFDocument29 pages2010-06-02 - Manual For Bulb Tee Girders PDFaapennsylvaniaNo ratings yet

- Large-Scale Testing of Steel Reinforced Concrete (SRC) Coupling BeamsDocument21 pagesLarge-Scale Testing of Steel Reinforced Concrete (SRC) Coupling BeamsMREFAATNo ratings yet

- MAGEBA Tensa Modular JointsDocument8 pagesMAGEBA Tensa Modular JointsbriankimbjNo ratings yet

- Horizontal Construction JointsDocument18 pagesHorizontal Construction JointsPremasiri KarunarathnaNo ratings yet

- Seismic Design of Bridges - Equivalent Cantilever MethodDocument14 pagesSeismic Design of Bridges - Equivalent Cantilever MethodJosue LewandowskiNo ratings yet

- Connections in Precast Concrete Structures - Effects of Restrained Creep and ShrinkageDocument20 pagesConnections in Precast Concrete Structures - Effects of Restrained Creep and Shrinkageunix0123No ratings yet

- Installation Guide: State-Of-The-Art Natural SealantsDocument16 pagesInstallation Guide: State-Of-The-Art Natural SealantsОксана ЛукашукNo ratings yet

- Numerical Analysis of Composite Steel-Concrete Columns of Arbitrary Cross SectionDocument10 pagesNumerical Analysis of Composite Steel-Concrete Columns of Arbitrary Cross SectionNasar KhanNo ratings yet

- Evaluation of Minimum Shear Reinforcement Requirements For Higher Strength ConcreteDocument9 pagesEvaluation of Minimum Shear Reinforcement Requirements For Higher Strength ConcreteHuda JawadNo ratings yet

- Pd6694-1 - Generic Vehicle Rev3Document141 pagesPd6694-1 - Generic Vehicle Rev3stavros_stergNo ratings yet

- Compressive Membrane ActionDocument19 pagesCompressive Membrane ActionFatima AhmedNo ratings yet

- OTEC (Kanawha River Bridge) S WilliamsonDocument59 pagesOTEC (Kanawha River Bridge) S Williamsonstevewv100% (1)

- Texas Bridge Railing ManualDocument79 pagesTexas Bridge Railing ManualBárbara CastroNo ratings yet

- Ba16 97Document83 pagesBa16 97yeezhexiang100% (1)

- Web 5133Document118 pagesWeb 5133bbblguNo ratings yet

- Temporary Strand Cutting Sequence: Single Span Prestressed Girder Construction SequenceDocument1 pageTemporary Strand Cutting Sequence: Single Span Prestressed Girder Construction SequenceJesús Rodríguez RodríguezNo ratings yet

- Chapter 5 Concrete StructuresDocument432 pagesChapter 5 Concrete StructuresrizwanNo ratings yet

- US-34 Over The Missouri River - Design Construction of A Haunched Steel Plate Girder W Substringer BridgeDocument10 pagesUS-34 Over The Missouri River - Design Construction of A Haunched Steel Plate Girder W Substringer BridgeaapennsylvaniaNo ratings yet

- Nisava River BridgeDocument17 pagesNisava River BridgeAlin ApoNo ratings yet

- Bridge Design in FinlandDocument10 pagesBridge Design in Finlandअरुण कुमार सोनीNo ratings yet

- Bridges With Multiple Cable-Stayed SpansDocument12 pagesBridges With Multiple Cable-Stayed SpanssergioNo ratings yet

- Carson Baker Creep Essay v8Document32 pagesCarson Baker Creep Essay v8api-251331545No ratings yet

- Shear in Inclined WebsDocument2 pagesShear in Inclined WebsjologscresenciaNo ratings yet

- Shear Strength of Reinforced Concrete Beams Under Uniformly Distributed LoadsDocument10 pagesShear Strength of Reinforced Concrete Beams Under Uniformly Distributed LoadsMoataz M. M. Rizk100% (1)

- Bridge Falsework: MAB1053 Principles of Bridge Engineering Universiti Teknologi MalaysiaDocument38 pagesBridge Falsework: MAB1053 Principles of Bridge Engineering Universiti Teknologi MalaysiaSAMNo ratings yet

- Concrete Rock InterfaceDocument7 pagesConcrete Rock Interfacedyc123No ratings yet

- 111 - The Design and Construction of Cliffsend UnderpassDocument4 pages111 - The Design and Construction of Cliffsend UnderpassYash SinghNo ratings yet

- Elementos de Sistemas de Prefabricados de PuentesDocument347 pagesElementos de Sistemas de Prefabricados de PuentesWaldo Enrique Quispe PalominoNo ratings yet

- Transverse Analysis of Full-Scale Precast Segmental Box Girder Segments WithDocument11 pagesTransverse Analysis of Full-Scale Precast Segmental Box Girder Segments WithbistsushantNo ratings yet

- Stonecutters BridgeDocument20 pagesStonecutters BridgeMarcos MorrisonNo ratings yet

- Buckling of MicropilesDocument4 pagesBuckling of MicropilesAnonymous qTP5oq7g100% (2)

- Biaxial Method CzerniakDocument10 pagesBiaxial Method CzerniakfermedinNo ratings yet

- Elastomeric Bridge Bearings-R1Document6 pagesElastomeric Bridge Bearings-R1Den BagusNo ratings yet

- Elastomeric Bearing - Full Details PDFDocument11 pagesElastomeric Bearing - Full Details PDFm.ispasNo ratings yet

- Hif12003 EVALUAT SCOUR ON BRIDGES BEST PDFDocument340 pagesHif12003 EVALUAT SCOUR ON BRIDGES BEST PDFAnonymous VkzquW39No ratings yet

- Curved Prestressed BeamDocument5 pagesCurved Prestressed Beama96lhfNo ratings yet

- Allowable Tensile Stress For Webs of Prestressed Segmental Concrete BridgesDocument8 pagesAllowable Tensile Stress For Webs of Prestressed Segmental Concrete BridgesShikhar SinghNo ratings yet

- EC2 Strut and Tie DesignDocument69 pagesEC2 Strut and Tie DesignWai Hoong EngNo ratings yet

- Lateral Load Capacity of PilesDocument9 pagesLateral Load Capacity of Pileschutton681No ratings yet

- Aerodynamic Stability of Cable-Stayed-Suspension Hybrid BridgesDocument6 pagesAerodynamic Stability of Cable-Stayed-Suspension Hybrid Bridgesİlker Yılmaz TürkerNo ratings yet

- Field Performance of Full Depth Precast Concrete Panels in Bridge Deck ReconstructionDocument27 pagesField Performance of Full Depth Precast Concrete Panels in Bridge Deck Reconstructionunix0123No ratings yet

- Guideline On Design of Segmental Concrete BridgesDocument122 pagesGuideline On Design of Segmental Concrete BridgesChong Wee LinNo ratings yet

- 2011 Bridge SarkadyDocument17 pages2011 Bridge SarkadyTan Duy LeNo ratings yet

- A Critical Analysis of Castleford Footbridge, England: P. D. WilsonDocument10 pagesA Critical Analysis of Castleford Footbridge, England: P. D. WilsonAshdeep SinghNo ratings yet

- Moment Slab For Road BarriersDocument6 pagesMoment Slab For Road BarriersaminjolesNo ratings yet

- 正版AASHTOLRFDTUN 1 2017国外国际规范Document280 pages正版AASHTOLRFDTUN 1 2017国外国际规范赵晨No ratings yet

- RC 19Document8 pagesRC 19ianiroy13No ratings yet

- NZTA 2019359 Ahaura Bridge Replacement Contract Documents PDFDocument347 pagesNZTA 2019359 Ahaura Bridge Replacement Contract Documents PDFsab_veer2913No ratings yet

- Blass Gwu 0075M 11053Document97 pagesBlass Gwu 0075M 11053deviationzNo ratings yet

- ACI 318C Meeting Agenda - Spring 2019Document1 pageACI 318C Meeting Agenda - Spring 2019deviationzNo ratings yet

- Materials 13 05804 v2Document16 pagesMaterials 13 05804 v2deviationzNo ratings yet

- Aci Committee 318 - Structural Building Code: March 18, 2019Document2 pagesAci Committee 318 - Structural Building Code: March 18, 2019deviationzNo ratings yet

- Use and Care Manual, Installation Instructions: En-UsDocument40 pagesUse and Care Manual, Installation Instructions: En-UsdeviationzNo ratings yet

- A Practical Approach To The Leaning ColumnDocument9 pagesA Practical Approach To The Leaning ColumndeviationzNo ratings yet

- Unistrut: Medical Support Structure GuideDocument25 pagesUnistrut: Medical Support Structure Guidedeviationz100% (1)

- Mcpherson Design GROUP P.CDocument26 pagesMcpherson Design GROUP P.CdeviationzNo ratings yet

- Performance-Based Design of Buildings Subjected To Wind LoadsDocument5 pagesPerformance-Based Design of Buildings Subjected To Wind LoadsdeviationzNo ratings yet

- SP 152Document260 pagesSP 152deviationz100% (1)

- FL - Metal Pan StairsDocument17 pagesFL - Metal Pan StairsdeviationzNo ratings yet

- Spacing Example Secant Piles PDFDocument1 pageSpacing Example Secant Piles PDFdeviationzNo ratings yet

- Vol39No7 Full PDFDocument68 pagesVol39No7 Full PDFdeviationzNo ratings yet

- Ag 1115Document46 pagesAg 1115deviationz100% (1)

- Refrigerant Charging ProcedureDocument3 pagesRefrigerant Charging Procedurenagarajasarma78% (9)

- Assignment 1 ChitrakshiiDocument15 pagesAssignment 1 ChitrakshiichitrakshiNo ratings yet

- Technical - Manual El - Zinc MetalTech 2012Document158 pagesTechnical - Manual El - Zinc MetalTech 2012RICARDO GIERKENo ratings yet

- Guidelines For Pipe Bursting: U.S. Army Corps of Engineers Engineering Research and Development Center (ERDC)Document55 pagesGuidelines For Pipe Bursting: U.S. Army Corps of Engineers Engineering Research and Development Center (ERDC)Pilar MartínezNo ratings yet

- Fall 2014 Textbook Fall 2014Document2 pagesFall 2014 Textbook Fall 2014Tabish IslamNo ratings yet

- U Type Retaining WallDocument4 pagesU Type Retaining WallAshish G100% (1)

- Knauf GifafloorDocument4 pagesKnauf GifafloorRichard Aldeen VerzosaNo ratings yet

- 15MW材料表 1031Document2 pages15MW材料表 1031sontnieNo ratings yet

- AVK SVMC Pipe Joints BrochureDocument25 pagesAVK SVMC Pipe Joints BrochureImtiyaz KhanNo ratings yet

- CE3155-1-Introduction 2011Document47 pagesCE3155-1-Introduction 2011huiting loy100% (1)

- AN-P-CL 001 Recommendation For Civil Engineering and Construction of Chemical Plant Structures and InfrastructureDocument33 pagesAN-P-CL 001 Recommendation For Civil Engineering and Construction of Chemical Plant Structures and InfrastructureRanjit Koshy AlexanderNo ratings yet

- 40rr 2pDocument12 pages40rr 2pAlejandro Castillo100% (1)

- Reinforcement of Rock Slopes With Plane Wedge FailureDocument12 pagesReinforcement of Rock Slopes With Plane Wedge FailureJampani HymavathiNo ratings yet

- General 1.1. Scope: WWW - Uponor.caDocument6 pagesGeneral 1.1. Scope: WWW - Uponor.caalfredo_mqiNo ratings yet

- TID00018 Manual Cooler FLDDocument5 pagesTID00018 Manual Cooler FLDNatalia BeltránNo ratings yet

- Ajay Goyal - HSS Bridge Over Chenan BridgeDocument8 pagesAjay Goyal - HSS Bridge Over Chenan BridgemalevolentNo ratings yet

- Bridge Bearing Replacement Using Flat JacksDocument9 pagesBridge Bearing Replacement Using Flat JacksKamal AlkurdiNo ratings yet

- Answer Sheet LA023649 - Assn7 - Answer Sheet - CPCCBC4010B-UNGRADED - Ed1Document10 pagesAnswer Sheet LA023649 - Assn7 - Answer Sheet - CPCCBC4010B-UNGRADED - Ed1Leesa JaneNo ratings yet

- Computer Applications in Hydraulic Engineering - Gradually Varied FlowDocument6 pagesComputer Applications in Hydraulic Engineering - Gradually Varied FlowYohan Lim50% (2)

- Geotech Report 520Document27 pagesGeotech Report 520Ramakrishna RaoNo ratings yet

- Mini Chiller Daikin UALDocument34 pagesMini Chiller Daikin UALBismar wafiqNo ratings yet

- Front Page FluidDocument3 pagesFront Page FluidAkmal bin HasrolNo ratings yet

- Crystalline Waterproofing TechnologyDocument8 pagesCrystalline Waterproofing TechnologyKiran Kumar JhaNo ratings yet

- Sub: Price Structure For 80mm and 100mm Interlock PaversDocument1 pageSub: Price Structure For 80mm and 100mm Interlock PaversDeepNo ratings yet

- Overview Part 2Document59 pagesOverview Part 2Kim NamjoonNo ratings yet

- Flexible Pavment Design ReportDocument6 pagesFlexible Pavment Design Reportarvind sharmaNo ratings yet

- C014M PDFDocument4 pagesC014M PDFleo_pio_ochoaNo ratings yet

- Tencate GeotextileDocument12 pagesTencate GeotextileTamilchelvam MurogayahNo ratings yet

- Analysis Template - BWDB UpdatedDocument761 pagesAnalysis Template - BWDB UpdatedMohaiminul Karim100% (4)

- Ibs CalculationDocument2 pagesIbs CalculationMohd ZahinNo ratings yet