Professional Documents

Culture Documents

Doc090 PDF

Uploaded by

Steve WilsonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Doc090 PDF

Uploaded by

Steve WilsonCopyright:

Available Formats

Large Construction Storm Water Politition Prevention Plan (VSWPPP.

)

University ofMississippi Medical Center Jackson, Mississippi

8.3 Spill Prevention and Response Procedures

The Spilt Prevention Control and Countermeasures (SPCC) Plan requirements of 40 CFR 112

are applicable. Limited amounts of oil and/or chemical products are anticipated to be stored

onsite during construction. UMMCs facility-wide SPCC plan will cover any response and

preventive measures to address storage of chemicals and oil products or spills thereof. This

CSWPPP will address some spill prevention and response issues. In the event of a spill,

employees are instructed to make every effort to contain the release, noti& the Incident

Commander (Safety Officer Jason Jones), and prevent any release from leaving the facility

site. It will be the Incident Commanders responsibility to detemilne if the spill needs to be

reported to the regulatory autdorities.

Additional preventative measures utilized by the site are: 1) proper storage and disposal of used

batteries 2) proper labeling of drums containing used oil and ensuring that stored drums are kept

inside buildings and away from potential accidental tippage situations 3) maintaining accurate

labels and inventory of chemical materials, solvents, paints, lubricants etc. and 4) storage of

solvents and flammable materials in a proper and safe manner.

8.3.1 Likely Releases and In-place Preventative Controls

Spills and releases are most likely to result from potential equipment failure or operator error.

This section summarizes potential causes of releases and associated in-place preventative

controls.

1. Operator error during loading/unloading or refueling operations. Potential errors include

overfiuing, not disconnecting lines prior to vehicle departure, drain valves left open, or

fill valves left open allowing precipitation to enter and cause tank overflow. Specific

procedures have been developed to minimize this potential and include regular periodic

inspections, locking valves when not in use, and on-the-job training in correct

procedures.

2. Piping, pressure fittings. tank ruptures, or other forms of equipment failure. The rate and

quantity of a release would depend on the location of the rupture. Release rate could be

assumed to be the total volume of the tank associated with the piping or fittings being

released in a 15-minute timeframe. The release to the environment would be at that rate

March 201) Page 15

You might also like

- Grand Gulf LetterDocument3 pagesGrand Gulf LetterSteve WilsonNo ratings yet

- 2018 ACT Junior YearDocument15 pages2018 ACT Junior YearSteve WilsonNo ratings yet

- Grand Gulf Power Statistics With Other ReactorsDocument150 pagesGrand Gulf Power Statistics With Other ReactorsSteve WilsonNo ratings yet

- MS Electricity RatesDocument2 pagesMS Electricity RatesSteve WilsonNo ratings yet

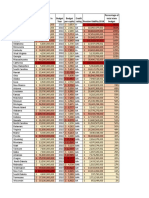

- Jackson Metro Sales Tax DisbursementsDocument1 pageJackson Metro Sales Tax DisbursementsSteve WilsonNo ratings yet

- Order Entergy Case 103118Document1 pageOrder Entergy Case 103118Steve WilsonNo ratings yet

- The State of Mississippi vs. Entergy MississippiDocument70 pagesThe State of Mississippi vs. Entergy MississippiSteve WilsonNo ratings yet

- MS Opportunity ZonesDocument4 pagesMS Opportunity ZonesSteve WilsonNo ratings yet

- Jackson-Greely Farm Inc. vs. USDocument55 pagesJackson-Greely Farm Inc. vs. USSteve WilsonNo ratings yet

- Failing SchoolsDocument7 pagesFailing SchoolsSteve WilsonNo ratings yet

- MDA Tourism Rebate ProgramDocument1 pageMDA Tourism Rebate ProgramSteve WilsonNo ratings yet

- Pension Liability by Percentage of State BudgetDocument1 pagePension Liability by Percentage of State BudgetSteve WilsonNo ratings yet

- District Maintenance 2014-2015Document26 pagesDistrict Maintenance 2014-2015Steve WilsonNo ratings yet

- District Maintenance 2014-2015Document26 pagesDistrict Maintenance 2014-2015Steve WilsonNo ratings yet

- MML 2017 Salary and Benefits SurveyDocument176 pagesMML 2017 Salary and Benefits SurveySteve WilsonNo ratings yet

- PERS Benefits Contributions 2008 To 2017Document1 pagePERS Benefits Contributions 2008 To 2017Steve WilsonNo ratings yet

- JPS Building Maintenance 2008 To 2018Document1 pageJPS Building Maintenance 2008 To 2018Steve WilsonNo ratings yet

- District Maintenance 2015-2016Document26 pagesDistrict Maintenance 2015-2016Steve WilsonNo ratings yet

- Complaint in Surveying CaseDocument10 pagesComplaint in Surveying CaseSteve WilsonNo ratings yet

- District Maintenance 2013-2014Document27 pagesDistrict Maintenance 2013-2014Steve WilsonNo ratings yet

- District Maintenance 2012-2013Document26 pagesDistrict Maintenance 2012-2013Steve WilsonNo ratings yet

- District Maintenance 2016-2017Document26 pagesDistrict Maintenance 2016-2017Steve WilsonNo ratings yet

- District Maintenance 2015-2016Document26 pagesDistrict Maintenance 2015-2016Steve WilsonNo ratings yet

- Sales Tax Disbursements To CitiesDocument10 pagesSales Tax Disbursements To CitiesSteve WilsonNo ratings yet

- Vizaline Filed Motion For Leave To File Third Party Complaint JX328692xC46BCDocument19 pagesVizaline Filed Motion For Leave To File Third Party Complaint JX328692xC46BCSteve WilsonNo ratings yet

- County Millage PropertyDocument2 pagesCounty Millage PropertySteve WilsonNo ratings yet

- 10 Main PDFDocument3 pages10 Main PDFSteve WilsonNo ratings yet

- City Millage MSDocument9 pagesCity Millage MSSteve WilsonNo ratings yet

- JPS Central Office SalariesDocument7 pagesJPS Central Office SalariesSteve WilsonNo ratings yet

- MS Tourism Tax ExtensionsDocument2 pagesMS Tourism Tax ExtensionsSteve WilsonNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Measuring Renilla Luciferase Luminescence in Living CellsDocument5 pagesMeasuring Renilla Luciferase Luminescence in Living CellsMoritz ListNo ratings yet

- Chicago Electric Inverter Plasma Cutter - 35A Model 45949Document12 pagesChicago Electric Inverter Plasma Cutter - 35A Model 45949trollforgeNo ratings yet

- Roadmap For Digitalization in The MMO Industry - For SHARINGDocument77 pagesRoadmap For Digitalization in The MMO Industry - For SHARINGBjarte Haugland100% (1)

- PharmacologyAnesthesiology RevalidaDocument166 pagesPharmacologyAnesthesiology RevalidaKENT DANIEL SEGUBIENSE100% (1)

- Injection Timing (5L) : InspectionDocument2 pagesInjection Timing (5L) : InspectionaliNo ratings yet

- Second Law of EntrophyDocument22 pagesSecond Law of EntrophyMia Betia BalmacedaNo ratings yet

- Guide to Fair Value Measurement under IFRS 13Document3 pagesGuide to Fair Value Measurement under IFRS 13Annie JuliaNo ratings yet

- Creatures Since Possible Tanks Regarding Dengue Transmission A Planned Out ReviewjnspeDocument1 pageCreatures Since Possible Tanks Regarding Dengue Transmission A Planned Out Reviewjnspeclientsunday82No ratings yet

- ROM Flashing Tutorial For MTK Chipset PhonesDocument5 pagesROM Flashing Tutorial For MTK Chipset PhonesAriel RodriguezNo ratings yet

- MSDS FluorouracilDocument3 pagesMSDS FluorouracilRita NascimentoNo ratings yet

- Antiquity: Middle AgesDocument6 pagesAntiquity: Middle AgesPABLO DIAZNo ratings yet

- CL 5313 17021-1 Requirements Matrix-1458-5Document6 pagesCL 5313 17021-1 Requirements Matrix-1458-5Ana AnaNo ratings yet

- NameDocument5 pagesNameMaine DagoyNo ratings yet

- Lanegan (Greg Prato)Document254 pagesLanegan (Greg Prato)Maria LuisaNo ratings yet

- NOTE CHAPTER 3 The Mole Concept, Chemical Formula and EquationDocument10 pagesNOTE CHAPTER 3 The Mole Concept, Chemical Formula and EquationNur AfiqahNo ratings yet

- Biomotor Development For Speed-Power Athletes: Mike Young, PHD Whitecaps FC - Vancouver, BC Athletic Lab - Cary, NCDocument125 pagesBiomotor Development For Speed-Power Athletes: Mike Young, PHD Whitecaps FC - Vancouver, BC Athletic Lab - Cary, NCAlpesh Jadhav100% (1)

- Test Bank For Core Concepts of Accounting Information Systems 14th by SimkinDocument36 pagesTest Bank For Core Concepts of Accounting Information Systems 14th by Simkinpufffalcated25x9ld100% (46)

- SOLVING LINEAR SYSTEMS OF EQUATIONS (40 CHARACTERSDocument3 pagesSOLVING LINEAR SYSTEMS OF EQUATIONS (40 CHARACTERSwaleedNo ratings yet

- Device Interface Device Type (Router, Switch, Host) IP Address Subnet Mask Default GatewayDocument2 pagesDevice Interface Device Type (Router, Switch, Host) IP Address Subnet Mask Default GatewayRohit Chouhan0% (1)

- Neuropathology of Epilepsy: Epilepsy-Related Deaths and SUDEPDocument11 pagesNeuropathology of Epilepsy: Epilepsy-Related Deaths and SUDEPTeuku AvicennaNo ratings yet

- Urodynamics Griffiths ICS 2014Document198 pagesUrodynamics Griffiths ICS 2014nadalNo ratings yet

- Laws of MotionDocument64 pagesLaws of MotionArnel A. JulatonNo ratings yet

- Emerson Park Master Plan 2015 DraftDocument93 pagesEmerson Park Master Plan 2015 DraftRyan DeffenbaughNo ratings yet

- Testbanks ch24Document12 pagesTestbanks ch24Hassan ArafatNo ratings yet

- Piping MaterialDocument45 pagesPiping MaterialLcm TnlNo ratings yet

- PCSE_WorkbookDocument70 pagesPCSE_WorkbookWilliam Ribeiro da SilvaNo ratings yet

- Ground Water Resources of Chennai DistrictDocument29 pagesGround Water Resources of Chennai Districtgireesh NivethanNo ratings yet

- Empowerment Technology Reviewer: First SemesterDocument5 pagesEmpowerment Technology Reviewer: First SemesterNinayD.MatubisNo ratings yet

- SEO Design ExamplesDocument10 pagesSEO Design ExamplesAnonymous YDwBCtsNo ratings yet

- Unit 1 - Introduction To BankingDocument17 pagesUnit 1 - Introduction To Bankingc08No ratings yet