Professional Documents

Culture Documents

HB 5

Uploaded by

Ibrahim SahinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HB 5

Uploaded by

Ibrahim SahinCopyright:

Available Formats

KORODUR HB 5

mineral bonding compound

FOR THE PERMABOND COMPOUND OF CEMENTITIOUS

SCREEDS ON SET CONCRETE

A P P L I C AT I O N PROCESSING JOINTS

KORODUR HB 5 ready to use, Subbase: Existing joints from the subbase have

cementitious bonding compound The base concrete, min. C 25/30 grade, to be provided in the screed as well.

for the permabond compound of must be pre-treated by milling, shot

all grades of screeds including peening or high-pressure wash etc. PRODUCTION/CONTROL

KORODUR hard aggregate screeds For permabond compound the surface producer:

on set concrete. must be free from cracks ,even, free KORODUR Westphal Hartbeton

Specially suitable for the KORODUR from cement slurry, free from dust and GmbH & Co. KG, works Wattenscheid

KOROTAN industrial flooring system, loose particles, free from oils, greases Quality assurance acc. to DIN EN 13813

see technical data sheet. It is unaffected and other contaminations, rough and Certification: DIN EN ISO 9001:2000

by possible subgrade moisture. For open-pore. The surface strength has

indoor and outdoor use. to be min. 1,5 N/mm2. PACKAGING/SUPPLY

The base concrete is to be pre-wetted 25 kg special paper packaging

P R O P E RT I E S 1 day prior to the installation, avoiding

brown-coloured for visual control formation of puddles. STORAGE

water-resistant, suitable for Mixing: dry, like cement,

wet-rooms Add per 25 kg bag of KORODUR HB shelf-life approx. 6 months.

chloride-free 5 approx. 5,5 litres water and stir for

optimum compound approx. 3 minutes with slow speed HINTS

vapour-open stirrer until a plastic consistency is This product contains cement and has an alkaline

reaction with moisture/water. Therefore protect

achieved. Do not use over-moistened hands and eyes. In case of contact with eyes

CONSUMPTION material. consult a doctor. Our recommendations for ap-

approx. 2 kg/m2 - depending on the Afterwards the material is brushed plication techniques are based on our experiences.

It is recommended to adapt processing and ma-

surface structure and the absorptivity with hard street broom, approx.

terial quantities to the given local conditions and

of the subbase. 1 2 mm thick, on to the prepared we refer in this context to our general terms of

Processing temperature: > 5C subbase the surface of the pre- sale and delivery.

Surface temperature: > 5C wetted subbase must be matt-damp. Further literature, processing hints, tender texts

on the different KORODUR industrial flooring

Take care that no colour fading/over- systems, KORODUR floor hardeners, KORODUR

moisturing occurs. Then the screed is special products are available on request.

immediately applied onto the still fresh per: May 2008

bonding compound KORODUR HB 5

to prevent too early drying out of the

bonding compound.

KORODUR International GmbH www.korodur.de

Head Office: Bochum-Wattenscheid Works: Hirschau Works (AKW-Kick):

Wernher-von-Braun-Str. 4 Hohensteinstr. 19 Georg-Schiffer-Str. 70

92224 Amberg 44866 Bochum 92242 Hirschau

P.O. Box 1653 92206 Amberg P.O. Box 60 02 48 44842 Bochum Phone: +49 (0) 96 22 / 1 83 15

0508/30

Phone: +49 (0) 96 21 / 47 59-0 Phone: +49 (0) 23 27 / 94 57-0

Telefax: +49 (0) 96 21 / 3 23 41 Telefax: +49 (0) 23 27 / 32 10 84

info@korodur.de wattenscheid@korodur.de

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Searay 330 Sundancer-ReportDocument11 pagesSearay 330 Sundancer-ReportAshok KamathNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Screw Jack DesignDocument13 pagesScrew Jack DesignIbrahimovic Elsaied78% (9)

- Implementation of Eurocodes in SingaporeDocument18 pagesImplementation of Eurocodes in Singaporelimegreens100% (1)

- Durability of Concrete Exposed To Marine Environment-A Fresh LookDocument30 pagesDurability of Concrete Exposed To Marine Environment-A Fresh LookElizabeth CruzNo ratings yet

- Concrete Formwork For Tunnel LiningDocument58 pagesConcrete Formwork For Tunnel LiningAlejandro Castañón0% (1)

- Piping BasicsDocument10 pagesPiping Basicstulasirao.nammiNo ratings yet

- How To Perform Plate Load Test of Soil On SiteDocument21 pagesHow To Perform Plate Load Test of Soil On SitePaschal MazikuNo ratings yet

- Aluminium Ladders ChapterADocument41 pagesAluminium Ladders ChapterAIbrahim SahinNo ratings yet

- Asodur - D2: Schomburg SchomburgDocument2 pagesAsodur - D2: Schomburg SchomburgIbrahim SahinNo ratings yet

- Hot Dip GalvanizingDocument4 pagesHot Dip GalvanizingIbrahim SahinNo ratings yet

- T C D E G H I J K L A S D' R R' F P N M O B: Trafficable Fla Roof Trafficable Fla RoofDocument1 pageT C D E G H I J K L A S D' R R' F P N M O B: Trafficable Fla Roof Trafficable Fla RoofIbrahim SahinNo ratings yet

- Technical Description ChapterTBDocument8 pagesTechnical Description ChapterTBIbrahim SahinNo ratings yet

- Guiderails Vertical ChapterCDocument12 pagesGuiderails Vertical ChapterCIbrahim SahinNo ratings yet

- Baumit Facade Insulating Board EPS-F: ProductDocument6 pagesBaumit Facade Insulating Board EPS-F: ProductIbrahim SahinNo ratings yet

- 09 - PEX20 Screed & Concrete FloorDocument4 pages09 - PEX20 Screed & Concrete FloorIbrahim SahinNo ratings yet

- Fastening Sets: Nno Ech Arbeitsschutz GMBHDocument1 pageFastening Sets: Nno Ech Arbeitsschutz GMBHIbrahim SahinNo ratings yet

- Examples of ApplicationDocument12 pagesExamples of ApplicationIbrahim SahinNo ratings yet

- ABS Katalog EnglischDocument17 pagesABS Katalog EnglischIbrahim SahinNo ratings yet

- Safesite Corporate Brochure and O&M ManualDocument98 pagesSafesite Corporate Brochure and O&M ManualIbrahim SahinNo ratings yet

- ManSafe For Industry (UK)Document8 pagesManSafe For Industry (UK)Ibrahim SahinNo ratings yet

- ABS Katalog EnglischDocument17 pagesABS Katalog EnglischIbrahim SahinNo ratings yet

- Perma Track Details Sheet AllDocument16 pagesPerma Track Details Sheet AllIbrahim SahinNo ratings yet

- Roofing p17 18Document2 pagesRoofing p17 18Ibrahim SahinNo ratings yet

- Roofing p5 6Document2 pagesRoofing p5 6Ibrahim SahinNo ratings yet

- Roofing p29Document1 pageRoofing p29Ibrahim SahinNo ratings yet

- Reducing Our Impact With Every StepDocument6 pagesReducing Our Impact With Every StepIbrahim SahinNo ratings yet

- Roofing p28Document1 pageRoofing p28Ibrahim SahinNo ratings yet

- Koroplan DurDocument1 pageKoroplan DurIbrahim SahinNo ratings yet

- Esd Flooring Selection Chart: Carpet Tile Carpet Broadloom Vinyl Tile Vinyl Sheet Epoxy RubberDocument1 pageEsd Flooring Selection Chart: Carpet Tile Carpet Broadloom Vinyl Tile Vinyl Sheet Epoxy RubberIbrahim SahinNo ratings yet

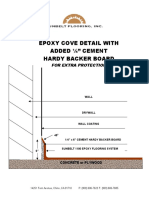

- Cove Base Detail With Hardy Backer Board.Document1 pageCove Base Detail With Hardy Backer Board.Ibrahim SahinNo ratings yet

- Standard Pigmented ColorsDocument1 pageStandard Pigmented ColorsIbrahim SahinNo ratings yet

- IKO Green BrochureDocument12 pagesIKO Green BrochureIbrahim SahinNo ratings yet

- Korodur Copetti Floor PDFDocument1 pageKorodur Copetti Floor PDFIbrahim SahinNo ratings yet

- Cove Base FRP Wall SystemDocument1 pageCove Base FRP Wall SystemIbrahim SahinNo ratings yet

- Daily Report 05 Sept 2022Document2 pagesDaily Report 05 Sept 2022t_i_f_anoNo ratings yet

- Asrafeege Calc Sheet PDFDocument8 pagesAsrafeege Calc Sheet PDFSaaidhNo ratings yet

- Change in Spaces: Adaptive Reuse From Residential To CommercialDocument33 pagesChange in Spaces: Adaptive Reuse From Residential To CommercialkeerthanaNo ratings yet

- Chardon Commercial Zoning CodeDocument10 pagesChardon Commercial Zoning CodeThe News-HeraldNo ratings yet

- Elmo 2bh1 Gas Ring Vacuum PumpsDocument11 pagesElmo 2bh1 Gas Ring Vacuum PumpsAlberto Costilla GarciaNo ratings yet

- NFP0011A - Ground Disturbance ProcedureDocument40 pagesNFP0011A - Ground Disturbance ProcedureWajdi MansourNo ratings yet

- Plant Underground Services DesignDocument27 pagesPlant Underground Services DesignbushraNo ratings yet

- 0-10V AHU DX Coil Interface (LC / VRF) Installation Manual: EnglishDocument36 pages0-10V AHU DX Coil Interface (LC / VRF) Installation Manual: EnglishAhmed Salah Abd EL-WahedNo ratings yet

- Shell Gadus S2 A320 2Document2 pagesShell Gadus S2 A320 2Raden ArdyNo ratings yet

- Lamberg Noora Seminaari 27102017 PDFDocument30 pagesLamberg Noora Seminaari 27102017 PDFThilluNo ratings yet

- Village Sanitation Profile-1Document5 pagesVillage Sanitation Profile-1sureshNo ratings yet

- Brochure Asset Doc Loc 5353646Document1 pageBrochure Asset Doc Loc 5353646Indra RahmadhaniNo ratings yet

- Operation and Maint Manual Swill Hydraulic PlateformDocument16 pagesOperation and Maint Manual Swill Hydraulic Plateformmicell dieselNo ratings yet

- Comparative Statement - Presidency UniversityRvsd - 14!01!15Document21 pagesComparative Statement - Presidency UniversityRvsd - 14!01!15yogesh100% (1)

- Water Ace R33SU Submersible PumpDocument16 pagesWater Ace R33SU Submersible PumpatereñoneNo ratings yet

- C-758 Power Cable Schdule R-0Document2 pagesC-758 Power Cable Schdule R-0HARSHAL KIRITBHAI PATELNo ratings yet

- StrengthDocument74 pagesStrengthAdrianKarlBonaNo ratings yet

- Bearing Pad "A" Bearing Pad "B": Bd-Id1EDocument11 pagesBearing Pad "A" Bearing Pad "B": Bd-Id1EJUAN RULFONo ratings yet

- Myron Braced TubeDocument7 pagesMyron Braced TubeAnass QawasmiNo ratings yet

- Chapter 8Document25 pagesChapter 8aung0024No ratings yet

- 3685 Mir 006 PDFDocument1 page3685 Mir 006 PDFashishpearlNo ratings yet

- Caterpillar Disassembly and Assembly Transmission 950g and 962g Wheel LoaderDocument20 pagesCaterpillar Disassembly and Assembly Transmission 950g and 962g Wheel Loaderpatrick100% (40)