Professional Documents

Culture Documents

GE 7FA Flex Seal Upgrade US

Uploaded by

Peter_Phee_341Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GE 7FA Flex Seal Upgrade US

Uploaded by

Peter_Phee_341Copyright:

Available Formats

Fabric Expansion Joint Technology

OEM Approved Flex-Seal Upgrade

for GE 7FA Turbine Owners

Expansion Joint Evaluation & Inspection_seals

Flex-Seal Upgrade for GE 7FA Turbine Ownersners

ID: 03.02.10.rev.0/02.12US

ID: 20.03.004A.11-13.US

Advantages of an EagleBurgmann

Flex-Seal Upgrade include:

Reliability from proven technology

Improved sealing capability

Cost effetive solution

Protects adjacent equipment from damaging

heat and gases

Improved safety

OEM approved upgrade

A qualified GE supplier

Supplied as a complete packaged kit

Complete turnkey installation

GE 7FA Flex-Seal Upgrade

As with most power plant equipment that experience dete-

rioration from continuous operation, the Flex-Seal plates lose

their sealing capabilities and flexibility over time. As a result,

excessive emissions of hot gases into the atmosphere and/or

the undesirable admission of cold air threaten to reduce the

thermal performance of the gas turbine.

Extensive research, development and testing onsite and at our

Vejen, Denmark facility have resulted in the only OEM ap-

proved upgrade solution that provides a gas tight seal over

the existing metal Flex-Seal on the GE 7FA turbine. With over

1,000 gas turbine installations worldwide, EagleBurgmann

collaborates with the turbine manufacturers and users to de-

velop cost-effective and reliable solutions for turbine owners.

Installing a Flex-Seal solution provides a gas tight seal over the existing metal Flex-Seal

EagleBurgmann KE, Inc. Tel: +1 (888) 645 7494

2100 Conner Road Ste 200 +1 (859) 746 0091 [E] KEinfo@us.eagleburgmann.com

Hebron KY 41048 USA Fax: +1 (859) 746 0094 www.eagleburgmann.com

GE 7FA Flex Seal Upgrade Solution

Upgrading the Flex Seal

The Flex-Seal is located under the lagging at the end

of the turbine manifold. An indicator of a failing Flex-

Seal is discoloration and corrosion of the outer metal

shroud.

With our complete turnkey services, we provide every-

thing from inspections of the existing Flex-Seal, trou-

bleshooting, supervision and training to total installa-

tion support of your upgrade.

Corrosion and discoloration of the metal shroud is a key indicator of a failing Flex Seal

Qualified Supplier

Before Upgrade After Flex-Seal Upgrade

For 50 years, EagleBurgmann Expansion Joint Solu-

tions has been working with equipment manufactur-

ers and end users worldwide to develop reliable and

safe solutions that meet the challenges of todays

environmental, productivity and quality expectations.

As part of the EagleBurgmann international organi-

zation, more than 5,000 employees contribute their

ideas, solutions, and commitment to ensure our cus-

tomers can rely on our products and services.

Contact one of our product specialists to discuss how

we can support your Flex-Seal upgrade.

The complete packaged

Flex-Seal kit includes:

(1) Combine-X Type HF belt

(2) Superwool Insulation

(3) Pre-Bolster

(4) Stud and Washer

(5) Cold-Side Flange

(6) Cold-Side Backup Bars

(7) Hot-Side Flange

(8) Hot Side Backup Bars

EagleBurgmann KE, Inc. Tel: +1 (888) 645 7494

2100 Conner Road Ste 200 +1 (859) 746 0091 [E] KEinfo@us.eagleburgmann.com

Hebron KY 41048 USA Fax: +1 (859) 746 0094 www.eagleburgmann.com

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Til 1755-R3 Lci Water - Cooled Bus LeaksDocument8 pagesTil 1755-R3 Lci Water - Cooled Bus LeaksMichael SanchezNo ratings yet

- Nissan Note E-Power 2022 Quick Guide ENDocument57 pagesNissan Note E-Power 2022 Quick Guide ENSarita EmmanuelNo ratings yet

- GEK101944Document8 pagesGEK101944Nouman Saeed100% (1)

- TIL 1819 ImplementationDocument4 pagesTIL 1819 ImplementationManuel L LombarderoNo ratings yet

- Technical Information Letter: Thermal Engineering Product Service TIL 1108-R1Document7 pagesTechnical Information Letter: Thermal Engineering Product Service TIL 1108-R1Heryanto SyamNo ratings yet

- Nic 13.05Document14 pagesNic 13.05BouazzaNo ratings yet

- Generator VOL 8ADocument18 pagesGenerator VOL 8AEmadAlhosien AlhosienNo ratings yet

- DLN-1 Heavy Duty Gas Turbines: Improved Secondary Flame Detector SystemDocument8 pagesDLN-1 Heavy Duty Gas Turbines: Improved Secondary Flame Detector SystemManuel L LombarderoNo ratings yet

- TIL 1547 2 - Gas Turbine Flex Hose RecommendationDocument4 pagesTIL 1547 2 - Gas Turbine Flex Hose RecommendationHernan GirautNo ratings yet

- Finding Targets PDFDocument9 pagesFinding Targets PDFSteve TangNo ratings yet

- Til 1236-R2Document5 pagesTil 1236-R2makarov.olegNo ratings yet

- Igv 7eaDocument2 pagesIgv 7eaSamir BenabdallahNo ratings yet

- CDM PDFDocument3 pagesCDM PDFferas_elnggarNo ratings yet

- Til 1539Document13 pagesTil 1539Michael JordanNo ratings yet

- GEK116771Document12 pagesGEK116771Korneev MaximNo ratings yet

- Psib 20130524aDocument1 pagePsib 20130524aLéandre Ettekri NdriNo ratings yet

- TIL 1237-1: Potential Flexible Hose Installation Errors: Technical BulletinDocument6 pagesTIL 1237-1: Potential Flexible Hose Installation Errors: Technical BulletinAkramNo ratings yet

- Til 1886 Inspection of Low Pressure Rotor Wheel Dovetails On Steam Turbines With Fossil Fueled Drum Boilers PDFDocument6 pagesTil 1886 Inspection of Low Pressure Rotor Wheel Dovetails On Steam Turbines With Fossil Fueled Drum Boilers PDFManuel L LombarderoNo ratings yet

- EX2100e Excitation System TroubleshootingDocument120 pagesEX2100e Excitation System TroubleshootingOm EliasNo ratings yet

- GT Mtc. PracticesDocument59 pagesGT Mtc. PracticesAbhishek Prakash SrivastavaNo ratings yet

- T 2119Document3 pagesT 2119bruno devinck100% (1)

- 1420-2R1 Lube Oil Logic Enhancement PDFDocument4 pages1420-2R1 Lube Oil Logic Enhancement PDFManuel L LombarderoNo ratings yet

- Gea32081a LM6000 - Pa - Us - R1 - LRDocument1 pageGea32081a LM6000 - Pa - Us - R1 - LRErik Van GroningenNo ratings yet

- 4Q2005 7EA UsersGrpDocument19 pages4Q2005 7EA UsersGrpaxl1No ratings yet

- APA DOC No. 2014 PDFDocument67 pagesAPA DOC No. 2014 PDFThanapaet RittirutNo ratings yet

- 26, Til 1621 Prevention of Water Accumulation Inside The Atomizing Air SystemDocument5 pages26, Til 1621 Prevention of Water Accumulation Inside The Atomizing Air Systemankarao69No ratings yet

- GEK103623 DDocument18 pagesGEK103623 DNouman Saeed100% (1)

- TIL 1420-2r1 Lube Oil Logic EnhancementDocument4 pagesTIL 1420-2r1 Lube Oil Logic EnhancementManuel L LombarderoNo ratings yet

- Til 1323-3R1Document2 pagesTil 1323-3R1Hernan GirautNo ratings yet

- Cable Trays RequirementDocument1 pageCable Trays RequirementSulaiman JafferyNo ratings yet

- GER3620L Nov 3 09b 1Document60 pagesGER3620L Nov 3 09b 1rafieeNo ratings yet

- PDF 83885 Mark IV Operator Manual DLDocument46 pagesPDF 83885 Mark IV Operator Manual DLkareema92No ratings yet

- T 1566Document5 pagesT 1566Erwin Mauricio Alarcon PradenasNo ratings yet

- Variable Inlet Guide Vane System: GE Power SystemsDocument4 pagesVariable Inlet Guide Vane System: GE Power Systemsanggita gigih wahyu iriawan100% (1)

- Dual Hydrogen Control Panel (DHCP) : Installation and Operation ManualDocument51 pagesDual Hydrogen Control Panel (DHCP) : Installation and Operation ManualSupol100% (1)

- Psib 20160603aDocument3 pagesPsib 20160603aLéandre Ettekri Ndri100% (1)

- Alstom Gas-Turbines-Technical-Performance PDFDocument2 pagesAlstom Gas-Turbines-Technical-Performance PDFPoull SteeadyNo ratings yet

- Technical Information Letter: Thermal Engineering Product Service TIL 1881Document11 pagesTechnical Information Letter: Thermal Engineering Product Service TIL 1881Ignacio Moratinos Castañeda100% (1)

- Gt13e2 Gas Turbine PosterDocument1 pageGt13e2 Gas Turbine PosterHeri SetyantoNo ratings yet

- Til 1213 R1Document6 pagesTil 1213 R1Hernan GirautNo ratings yet

- Alstom GT KA-26 Overview PDFDocument35 pagesAlstom GT KA-26 Overview PDFCyrix.One100% (1)

- MOU (06std) - HDGT Auxiliary Systems LDocument80 pagesMOU (06std) - HDGT Auxiliary Systems Lalaeddine chahdane100% (1)

- Speedtronic Mark VI Turbine Control System: GE Power SystemsDocument22 pagesSpeedtronic Mark VI Turbine Control System: GE Power SystemsAli AlhukkeyNo ratings yet

- DLN1+ Combustion Upgrade Solution: Fact SheetDocument1 pageDLN1+ Combustion Upgrade Solution: Fact SheetAhmad Riaz KhanNo ratings yet

- Technical Information Letter: Dangers of Bearing RefurbishmentDocument7 pagesTechnical Information Letter: Dangers of Bearing RefurbishmentJJNo ratings yet

- T 1918Document4 pagesT 1918esutjiadiNo ratings yet

- Gas Turbine Compressor IssuesDocument9 pagesGas Turbine Compressor IssuesJJNo ratings yet

- Technical Information Letter: Ge Power TIL 2445 Product ServiceDocument4 pagesTechnical Information Letter: Ge Power TIL 2445 Product ServiceMinhajur Rahman100% (1)

- Gek 116689Document32 pagesGek 116689HANo ratings yet

- C80-35 Engineer PDFDocument151 pagesC80-35 Engineer PDFteutashNo ratings yet

- Stage 1 Shroud For FS7001BDocument1 pageStage 1 Shroud For FS7001Bteedee1No ratings yet

- 9fa ProbsDocument12 pages9fa ProbsMarbz Al MonteNo ratings yet

- NIC - 07-37 - Rev-01 Technical Updates Web Portal GEDocument47 pagesNIC - 07-37 - Rev-01 Technical Updates Web Portal GEManuel L LombarderoNo ratings yet

- NIC 12.02 - Rev.01 Axial Displacement Inspection Procedure For Axial Andcentrifugal Compressors PDFDocument29 pagesNIC 12.02 - Rev.01 Axial Displacement Inspection Procedure For Axial Andcentrifugal Compressors PDFDjaber ElhaicharNo ratings yet

- Temperature Control at 19MW On MS5001Document4 pagesTemperature Control at 19MW On MS5001chdi100% (1)

- 06 UCH GT 9001E - Inlet Filter & Duct SystemsDocument113 pages06 UCH GT 9001E - Inlet Filter & Duct SystemsHassan Mahmood100% (1)

- Eagleburgmann Ke Pte LTD Fabric Expansion Joint Flex Seal For Ge Gt2015 08-27-09 47Document1 pageEagleburgmann Ke Pte LTD Fabric Expansion Joint Flex Seal For Ge Gt2015 08-27-09 47Peter_Phee_341No ratings yet

- Fabric EJDocument20 pagesFabric EJOctama RizkyNo ratings yet

- Proactive and Reactive Sealing Solutions That Save You Time and MoneyDocument8 pagesProactive and Reactive Sealing Solutions That Save You Time and MoneyDaniel DuongNo ratings yet

- 571-3212 Trifecta Lit 3-18Document2 pages571-3212 Trifecta Lit 3-18Joel MejiaNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- SGT800Document6 pagesSGT800Thanapaet RittirutNo ratings yet

- Thai DPM Prajin Underscores Targets in New PDP: Daily NewsDocument5 pagesThai DPM Prajin Underscores Targets in New PDP: Daily NewsPeter_Phee_341No ratings yet

- SINAMICS S120 Cabinet Modules Liquid Cooled en-USDocument412 pagesSINAMICS S120 Cabinet Modules Liquid Cooled en-USPeter_Phee_341No ratings yet

- MSD Servo Drive Software With Safety PLC Function: Error DescriptionDocument38 pagesMSD Servo Drive Software With Safety PLC Function: Error DescriptionPeter_Phee_341No ratings yet

- Abstract SGT800 TuesPM Meeting Todays Market Needs SiemensDocument1 pageAbstract SGT800 TuesPM Meeting Todays Market Needs SiemensPeter_Phee_341No ratings yet

- GE GeneratorDocument19 pagesGE GeneratorPeter_Phee_341No ratings yet

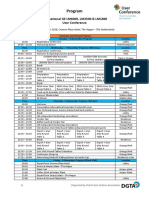

- Program: International GE LM6000, LM2500 & LM1600 User ConferenceDocument8 pagesProgram: International GE LM6000, LM2500 & LM1600 User ConferencePeter_Phee_341No ratings yet

- Turbine EngDocument1 pageTurbine EngPeter_Phee_341No ratings yet

- Turbine Oil Family CaltexDocument8 pagesTurbine Oil Family CaltexPeter_Phee_341No ratings yet

- Ger3809 - Generator Rotor Thermal SensitivityDocument22 pagesGer3809 - Generator Rotor Thermal SensitivityGalihSuciptoNo ratings yet

- Specification For Oil Approval Railway enDocument3 pagesSpecification For Oil Approval Railway enPeter_Phee_341No ratings yet

- Mobil DTE 800 Series: Maximum Protection and Performance For Gas and Steam TurbinesDocument2 pagesMobil DTE 800 Series: Maximum Protection and Performance For Gas and Steam TurbinesPeter_Phee_341No ratings yet

- Registration Form: As Part of Asia Power WeekDocument1 pageRegistration Form: As Part of Asia Power WeekPeter_Phee_341No ratings yet

- Eurovent - 4 - 22 - 2015 PDFDocument8 pagesEurovent - 4 - 22 - 2015 PDFPeter_Phee_341No ratings yet

- Revised GT SmartdoorDocument2 pagesRevised GT SmartdoorPeter_Phee_341No ratings yet

- F9fa 2019 Conference Program v6Document4 pagesF9fa 2019 Conference Program v6Peter_Phee_341No ratings yet

- Eagleburgmann Ke Pte LTD Fabric Expansion Joint Flex Seal For Ge Gt2015 08-27-09 47Document1 pageEagleburgmann Ke Pte LTD Fabric Expansion Joint Flex Seal For Ge Gt2015 08-27-09 47Peter_Phee_341No ratings yet

- After Market Brochure V 15Document11 pagesAfter Market Brochure V 15Peter_Phee_341No ratings yet

- Clean Air Solutions: Capability BrochureDocument11 pagesClean Air Solutions: Capability BrochurePeter_Phee_341No ratings yet

- APW17 Exhibitor ProspectusDocument6 pagesAPW17 Exhibitor ProspectusPeter_Phee_341No ratings yet

- Registration Form: As Part of Asia Power WeekDocument1 pageRegistration Form: As Part of Asia Power WeekPeter_Phee_341No ratings yet

- 9FA Enhancement Brochure - GEA17570Document8 pages9FA Enhancement Brochure - GEA17570Peter_Phee_341No ratings yet

- Hypothesis Testing Random MotorsDocument8 pagesHypothesis Testing Random MotorsLinn ArshadNo ratings yet

- Learning Plans in The Context of The 21 ST CenturyDocument29 pagesLearning Plans in The Context of The 21 ST CenturyHaidee F. PatalinghugNo ratings yet

- KARAKTERISTIK GEOTERMAL SUMUR EKSPLORASI AT-1, LAPANGAN PANAS BUMI ATADEI, KABUPATEN LEMBATA NTT. Kastiman Sitorus Dan Arif Munandar SUBDIT PANAS BUMIDocument7 pagesKARAKTERISTIK GEOTERMAL SUMUR EKSPLORASI AT-1, LAPANGAN PANAS BUMI ATADEI, KABUPATEN LEMBATA NTT. Kastiman Sitorus Dan Arif Munandar SUBDIT PANAS BUMIItTo MakinoNo ratings yet

- Why We Need A Flying Amphibious Car 1. CarsDocument20 pagesWhy We Need A Flying Amphibious Car 1. CarsAsim AhmedNo ratings yet

- 2011 Frequency AllocationsDocument1 page2011 Frequency Allocationsculeros1No ratings yet

- Medrano, Rene LynnDocument2 pagesMedrano, Rene LynnRene Lynn Labing-isa Malik-MedranoNo ratings yet

- 8051 Programs Using Kit: Exp No: Date: Arithmetic Operations Using 8051Document16 pages8051 Programs Using Kit: Exp No: Date: Arithmetic Operations Using 8051Gajalakshmi AshokNo ratings yet

- Lennox IcomfortTouch ManualDocument39 pagesLennox IcomfortTouch ManualMuhammid Zahid AttariNo ratings yet

- CadburyDocument21 pagesCadburyramyarayeeNo ratings yet

- Slup 230Document24 pagesSlup 230Jelena TodorovicNo ratings yet

- SIMPLE PlaybookDocument12 pagesSIMPLE PlaybookMatt LylesNo ratings yet

- Turbine Start-Up SOPDocument17 pagesTurbine Start-Up SOPCo-gen ManagerNo ratings yet

- Electro TechniquesDocument2 pagesElectro TechniquesPinkk DaisyfieldNo ratings yet

- Aectp 300 3Document284 pagesAectp 300 3AlexNo ratings yet

- CE-23113-SP-902-R01-00 Asset SpecificationDocument14 pagesCE-23113-SP-902-R01-00 Asset SpecificationСветлана ФайберNo ratings yet

- Biosynthesis and Characterization of Silica Nanoparticles From RiceDocument10 pagesBiosynthesis and Characterization of Silica Nanoparticles From Riceanon_432216275No ratings yet

- Kowalkowskietal 2023 Digital Service Innovationin B2 BDocument48 pagesKowalkowskietal 2023 Digital Service Innovationin B2 BAdolf DasslerNo ratings yet

- Kat-A 4102 Rotovalve Edition3!12!02-2013 enDocument4 pagesKat-A 4102 Rotovalve Edition3!12!02-2013 enWalter PiracocaNo ratings yet

- CoolonDocument2 pagesCoolonAnySikaNo ratings yet

- Norberto Elias: Graduation of Teach Portuguese Language With Ability in EnglishDocument14 pagesNorberto Elias: Graduation of Teach Portuguese Language With Ability in EnglishGildo Joaquim FranciscoNo ratings yet

- SQL and Hand BookDocument4 pagesSQL and Hand BookNaveen VuppalaNo ratings yet

- Hume 100 ReviewerDocument7 pagesHume 100 ReviewerShai GaviñoNo ratings yet

- Shift Registers NotesDocument146 pagesShift Registers NotesRajat KumarNo ratings yet

- MGNM801 Ca2Document19 pagesMGNM801 Ca2Atul KumarNo ratings yet

- The Data Driven AuditDocument34 pagesThe Data Driven AuditMon compte Mon compteNo ratings yet

- Progressive Muscle Relaxation ExerciseDocument2 pagesProgressive Muscle Relaxation Exerciseraghu2362704100% (1)

- CHASE SSE-EHD 1900-RLS LockedDocument2 pagesCHASE SSE-EHD 1900-RLS LockedMarcos RochaNo ratings yet

- Cambridge IGCSE ™: Combined ScienceDocument11 pagesCambridge IGCSE ™: Combined ScienceAhmed Jomaa Salem0% (1)