Professional Documents

Culture Documents

Typical Systems Depiction For PIDs

Uploaded by

RaghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Typical Systems Depiction For PIDs

Uploaded by

RaghCopyright:

Available Formats

Typical Systems Depiction PS.05.03-04 Rev.

00

Kvaerner Powergas

for P&IDs Page 1 of 38

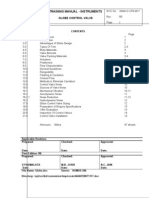

CONTENTS

1. INTRODUCTION.........................................................................................................................4

2. APPLICATION.............................................................................................................................4

3. GENERAL ....................................................................................................................................4

4. TYPES OF P&IDs .......................................................................................................................4

4.1 Process P&ID .........................................................................................................................5

4.2 Offsites and Utility Generation (O&U) P&ID: ......................................................................5

4.3 Utility Distribution P&ID:......................................................................................................5

5. LAYOUT OF THE P&IDs ..........................................................................................................6

5.1 EQUIPMENT .........................................................................................................................6

5.2 PIPING ...................................................................................................................................7

5.3 INSTRUMENTATION ..........................................................................................................8

5.4 ELECTRICAL........................................................................................................................9

6. TYPICAL ASSEMBLIES.............................................................................................................9

6.1 Typical control valve installation ...........................................................................................9

6.2 Steam trap assembly .............................................................................................................10

6.3 Battery limit conditions ........................................................................................................10

6.4 Cooling water header............................................................................................................11

6.5 Flare header ..........................................................................................................................11

6.6 Safety valve discharging to atmosphere ...............................................................................12

6.7 Thermal relief valve discharging to atmosphere ..................................................................13

6.8 Safety valve discharging to closed system ...........................................................................13

6.9 Desuperheater .......................................................................................................................14

6.10 Centrifugal pump installation ...............................................................................................14

6.11 Pump vent/drain....................................................................................................................15

6.12 Minimum flow bypass with restriction orifice/control valve ...............................................16

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 2 of 38

6.13 Typical positive displacement pump installation .................................................................16

6.14 Positive displacement pump capacity control ......................................................................18

6.15 Atmospheric storage tank venting arrangement ...................................................................18

6.16 Blanketed tanks ....................................................................................................................19

6.17 Tank heating arrangement ....................................................................................................19

6.18 Typical floating roof tank installation ..................................................................................20

6.19 Truck loading arm ................................................................................................................21

Figure 1: Typical control valve installation ......................................................................................22

Figure 2: Steam trap assembly ..........................................................................................................22

Figure 3: Battery limit installation.....................................................................................................23

Figure 4: Cooling water header..........................................................................................................24

Figure 5: Flare header ........................................................................................................................25

Figure 6: Safety valve discharging to atmosphere ............................................................................26

Figure 7: Thermal relief valve discharging to atmosphere ................................................................27

Figure 8Single PSV discharging to closed system ............................................................................27

Figure 9: PSV with spare discharging to closed system ....................................................................28

Figure 10: Desuperheater...................................................................................................................28

Figure 11: Typical centrifugal pump installation...............................................................................29

Figure 12: Pump vent/drain ...............................................................................................................29

Figure 13: Pump vent/drain (lights)...................................................................................................30

Figure 14: Minimum flow bypass with restriction orifice .................................................................31

Figure 15: Minimum flow bypass with control valve........................................................................32

Figure 16: Typical positive displacement pump installation .............................................................33

Figure 17: Positive displacement pump capacity control ..................................................................33

Figure 18: Atsmopheric storage tank venting arrangement...............................................................34

Figure 19: Blanketed tanks (pressure controller)...............................................................................34

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 3 of 38

Figure 20: Blanketed tanks (self actuated PCV)................................................................................35

Figure 21: Tank heating (manual control) .........................................................................................35

Figure 22: Tank heating (automatic control) .....................................................................................36

Figure 23: Typical floating roof tank installation ..............................................................................37

Figure 24: Truck loading arm ............................................................................................................38

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 4 of 38

1. INTRODUCTION

This Design Guide indicates the format and the basis to be used in the preparation of Piping and

Instrumentation Diagrams ( P&IDs). The basis provided in the document is to be followed, unless

clients comments or special process requirements dictate otherwise.

2. APPLICATION

This Design Guide is intended for use in basic, front-end projects. For detail engineering projects,

modifications or expansion of existing facilities, the philosophy followed by the licensor shall be

followed.

This guideline is to be used by process engineer during P&ID development.

3. GENERAL

The Design Guide must be read in conjunction with the following documents

PS.06.01-03 Piping Philosophy for P&IDs

PS.06.02-03 Instrumentation philosophy for P&IDs

P&ID Legend : Drg No.

Sample Connections : Drg No

Pump Seal Plans : Drg No.

4. TYPES OF P&IDs

A Piping and Instrumentation diagram is a schematic and symbolic representation that provides

detailed information of the piping and instrumentation as well as the special features.

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 5 of 38

This document is one of the most important documents and is the basis for detailed design and

engineering, construction and operation of the plant. The following types of P&ID are prepared for

any project

Process P&ID

Offsites and Utility Generation (O&U) P&ID

Utility distribution P&ID

4.1 Process P&ID

The process P&ID defines the process equipment, piping, process control and instrumentation of

the plant. This is developed for basic engineering projects and obtained from the process licensor

for detailed engineering projects.

4.2 Offsites and Utility Generation (O&U) P&ID:

The Utility generation P&IDs define the equipment, piping, process control and instrumentation

for generation of the utilities required by the process plant. Typically these will include Water

Systems (Raw water, Cooling water, Service water, DM water etc), Air Systems (Instrument, Plant

air), Inert gas systems (Nitrogen, Fuel gas), Steam systems, Effluent collection and treatment.

Offsites P&ID defines the equipment, piping, process control and instrumentation for the storage

and transfer facilities for feed, products, intermediates etc.

The O&U P&IDs are generally developed by the detail engineering contractor based on the

requirements of the process plant.

4.3 Utility Distribution P&ID:

This diagram shows the headers, subheaders, branches required for connectiong the utility system

from the supplier to the users within the plant. The layout of the diagram is based on the layout.

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 6 of 38

This P&ID is also referred to as a Utility Flow Diagram (UFD). This is developed by the Piping

group based on the layout and the line sizes are checked the process department.

5. LAYOUT OF THE P&IDs

The layout of the P&ID is very important. When too many equipment or information is shown in a

P&ID, the information can become unclear.

Each P&ID should not contain more than 4-6 pieces of equipment. The addition of notes,

instrument details, piping requirements during the course of engineering must be kept in mind while

laying out the drawing.

The engineer shall try, as far as possible, to maintain the relative elevation between equipment

especially while depicting gravity flows.

Equipment numbers and description shall be entered at the top of the drawing.

All notes shall be numbered sequentially and placed in the right hand side of the P&ID.

5.1 EQUIPMENT

1. All equipment including standby equipment shall be indicated. If it is required to repeat

equipment on another P&ID, the equipment should be shown as dotted on the subsequent

drawing.

2. The equipment tag number shall be placed as close to the vessel as possible. The tag number

along with the equipment description should be indicated at the top of the drawing.

3. The vendor supplied packages are indicated only as a dashed / dotted box with the vendor P&ID

drawing number referenced within the block.

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 7 of 38

4. The major internals of the equipment like demister pad, dip pipe, vortex breaker should be

indicated. For tray columns, the tray numbers at critical locations of feed, side draw off, pump

around, top and bottom tray should be indicated. The packed column must indicate the number

of packed sections and special internals like spray nozzles.

5. All nozzles on the equipment should be indicated including manhole/handholes, nozzles with

blind flanges. Nozzle size / rating to be shown only if different from connecting line size.

6. Notes on critical elevation should be added as required.

7. Future requirement of equipment should be indicated only by means of a note.

5.2 PIPING

1. All process and utility lines should be indicated. All lines will have the same thickness.

2. Indicate arrows along the lines to show flow direction.

3. All process lines entering or leaving a drawing should terminate at the right or left hand side of

the drawing with a continuation arrow. Utility lines can be terminated at any convenient

location in the drawing.

4. The line entering or leaving a P&ID shall indicate

5. The continuation drawing number within the arrow

6. The origin or destination equipment item / line prefixed by TO or FROM as required.

7. The lines should be tagged as per the piping philosophy for the project. This should have line

size, service designation, line number, piping spec as a standard.

8. All special piping requirements E.g. slope, no pockets, minimum distance etc to be indicated.

9. All valves required for operation and maintenance including process vents and drains, utility

connections should be indicated.

10. If seal loops are present, the height should be indicated.

11. All piping spec breaks (change in piping class or material of construction) should be indicated.

Generally the line number should be changed after the spec break unless the project philosophy

indicates otherwise.

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 8 of 38

12. Utility required for pump, agitator seals should be indicated in a separate P&ID that gives

details of the seal plans. However the process engineer can indicate the seal details and utilities

in the process P&ID itself if there is no space constraint.

13. All special piping items should be tagged using prefix SM. Piping will assign tag numbrs during

detail engineering.

14. Tracing, jacketing for pipes shall be indicated.

15. Valve positions should be indicated where applicable NC, LO, LC. NC shall not be

used for vents, drains, control valve bypass.

16. Termination points in a package item shall be referenced within the dotted box indicating

package item.

5.3 INSTRUMENTATION

1. Instrumentation should be as per the simplified ISA procedure unless otherwise specified by

project philosophy. The signal converters (I/P), transmitters, sensing elements (FE, TE) shall

not be tagged.

2. All primary instruments, controllers, alarms, interlocks which are required for process control

and operation should be indicated

3. Control valves with block and bypass and failure positions shall be indicated.

4. Local control panels are not indicated for vendor packages.

5. Isolation valves for instrumentation shall be indicated. Typically these are as per the table below

unless there are special process requirements:

Type of Instrument Process connection, Block valve, mm

mm NB

1. Orifice flowmeter 15 (2 Nos) 15 (2 Nos)

2. Pressure instrument 20 20

3. Diaphragm seal Pressure Instrument 40 40

4. Level gauge 25 25

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 9 of 38

5. DP type level Instrument 25 25

6. Diaphragm seal level Instrument 50 50

7. Temperature Instrument 40 -

5.4 ELECTRICAL

1. Motors are not shown for pumps, compressors. Motors are shown for agitators, fans for air

cooler and cooling tower, motorised valves.

2. Local start / stop push buttons are not indicated in the P&IDs.

3. Push buttons and switches associated with DCS and Interlock systems should be indicated.

6. TYPICAL ASSEMBLIES

The following figures give the typical assemblies that should be followed during the preparation of

the P&IDs. The Notes provide explanation regarding the application and additional information to

help the process engineer in modifying the standard assembly to suit the project requirement.

6.1 Typical control valve installation

Refer to figure 1 for typical control valve assembly depictions. Following notes are to be read in

conjunction with figure 1.

1. Control valves to be provided with block valves to allow the control valve to be removed for

maintenance. For control valves above 200 NB, the requirement of block and bypass valve to be

decided on a case to case basis. The Block and bypass sizes to be as per Table 2.

2. The bypass line size to be the same as the bypass valve size.

3. The bypass valve to be globe valve (if globe valve is acceptable for the system) upto 200 NB

size and same as block valve type beyond 200 NB

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 10 of 38

4. All control valves to be provided with 20 NB drain valve with blind flange. Drain valves to be

provided upstream and downstream of fail close (FC) valves and upstream of fail open (FO)

valves.

5. Reducers/Expanders to be provided within the control valve assembly, immediately adjacent to

the valves when block valve sizes are below the line size.

6. Spec break if needed to be provided at the downstream of the 2nd block valve and bypass valve

of the control valve assembly.

7. Instrument air-fail position (FO, FC, FL) to be indicated below the control valve.

6.2 Steam trap assembly

Refer to figure 2 for typical steam trap assembly depictions. Following notes are to be read in

conjunction with figure 2.

1. Steam trap discharging to be provided with block valves and bypass globe valve. Strainer to be

provided if not integral with the trap.

2. Spec break, if required, is to be provided at the downstream of the trap and bypass valve of the

steam trap assembly.

3. Downstream block valve need not be provided for traps discharging to atmosphere if two

independent outlets are provided.

4. Line traps are provided at the point of entry of steam to equipment such as Vacuum ejectors,

heat exchangers. Traps for removal of condensate from steam headers and distribution systems

to be indicated by piping department.

6.3 Battery limit conditions

Refer to figure 3 for typical depictions of battery limit conditions. Following notes are to be read in

conjunction with figure 3.

1. Isolation valve type to be as per piping requirement.

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 11 of 38

2. Spectacle blind shall be provided at the battery limit so that operation and maintenance

requirements can be met.

3. Block valve in steam lines shall be provided with warm up bypass valve. The bypass valve shall

be a globe valve and shall be installed across the main isolation valve. The size of the warm up

bypass valve shall be as per Table 1

4. Two block valves with blind and bleed shall be provided in process services in which

contamination cannot be tolerated. Check valve shall be provided to prevent reverse flow in

process lines.

6.4 Cooling water header

Refer to figure 4 for typical depictions of cooling water headers. Following notes are to be read in

conjunction with figure 4.

1. Jumpover between cooling water supply and return headers to be provided at minimum distance

from dead end of headers to facilitate pre-commissioning and start-up activities. The connection

shall be one size smaller than the header size.

6.5 Flare header

Refer to figure 5 for typical depictions of flare headers. Following notes are to be read in

conjunction with figure 5.

1. The block valve when provided for flare line shall be Locked Open type and with the

following Note

Flare line isolation valve shall be installed in horizontal line with the stem in downward

position to avoid free fall of gate and blockage.

2. All dead ends of flare header (including sub-headers) to be capped (preferred to flanged ends to

prevent leakage) and provided with purge connection of fuel gas or nitrogen. A purge rate of

0.03 m/s (0.1 ft/s) in the header is to be ensured.

3. Following note to be included in P&ID for header

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 12 of 38

All tail pipes to be sloped towards header. All flare lines to join header from top or side of

header at 45 deg angle

4. Indicate slope of 1:500 in flare header upto flare KO pot.

5. If a low temperature relief is expected e.g. liquid LPG relief that can reduce the temperature

below ambient, a material spec break is to be provided. Low temp material to be provided at

least 6m downstream and upstream of the header at the point of joining.

6.6 Safety valve discharging to atmosphere

Refer to figure 6 for typical depictions of safety valve discharging to atmosphere. Following notes

are to be read in conjunction with figure 6.

1. Safety valves in non-hazardous, non-toxic and non-hydrocarbon service can discharge to

atmosphere

2. No upstream and downstream isolation is permitted for PSVs in IBR service.

3. Upstream isolation valves if provided shall be LO type and have a note Isolation valve to be

full-bore type or FB indicated against the valve.

4. (Ensure Abbreviation FB is included in the legend diagram)

5. 20NB venting valve shall be provided if isolation valves are provided.

6. Reducers, if required to be provided, based on pressure drop check as per API, shall be placed

immediately adjacent to the PSV. The isolation valves shall be line size.

7. The discharge line to have a note A 6 mm diameter weep hole for drainage to be provided at

low point

8. Piping spec breaks, if required, shall be provided at the PSV outlet.

9. The inlet line to the PSV shall have SLOPE indication in the direction of the equipment being

protected and also NO POCKETS indication

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 13 of 38

6.7 Thermal relief valve discharging to atmosphere

Refer to figure 7 for typical thermal relief valve (discharging to atmosphere) depictions. Following

notes are to be read in conjunction with figure 7.

1. Thermal relief valves in non-hazardous, non-toxic and non-hydrocarbon service can discharge

to atmosphere.

2. The relief valve outlet shall be led to grade for discharge of liquid.

3. For cooling water service the PSV size shall be X 1.

6.8 Safety valve discharging to closed system

SINGLE PSV

Refer to figure 8 for typical safety valve discharging to closed system (single PSV) assembly

depictions. Following notes are to be read in conjunction with figure 8.

1. Safety valves in hazardous, toxic or hydrocarbon service to discharge to a closed system (either

flare or another equipment)

2. Isolation valves, if provided, to be LO type and have following note:

3. Isolation valve to be full-bore type. Valve to be oriented such that valve stem is horizontal.

4. 20NB depressurising valve to be provided between the isolation valve and the PSV.

5. Reducers, if required to be provided, based on pressure drop check as per API, to be placed

immediately adjacent to the PSV. The isolation valves to be line size.

6. The inlet line to the PSV to have SLOPE indication in the direction of the equipment being

protected and also NO POCKETS indication.

7. The discharge line from PSV to have SLOPE indication in the direction of draining and also

NO POCKETS indication.

8. The Piping spec breaks, if required, to be provided at the PSV discharge

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 14 of 38

PSV WITH SPARE

Refer to figure 9 for typical safety valve discharging to closed system (PSV with spare) assembly

depictions.

All above notes are applicable. In addition

1. If key type interlock is required for the inlet/ discharge isolation valves, this is to be denoted by

a dashed line connecting the valves with INTERLOCK written along the line.

6.9 Desuperheater

Figure 10 depicts desuperheater assembly. Diagram is self-explanatory and is to be used as such.

6.10 Centrifugal pump installation

Refer to figure 11 for typical depictions of centrifugal pump installation. Following notes are to be

read in conjunction with figure 11.

1. Isolation valve type to be as per piping requirement

2. Spectacle blind need not be provided if the fluid handled is non-toxic and non-hazardous.

3. Strainers to be provided at pump suction.

- Y type upto 40NB

- T type from 50NB to 300 NB

- Basket type beyond 300 NB.

4. Blinded vent and drain to be provided for Basket type strainer.

5. Reducers if provided in slurry service pumps must include the following note in P&ID

Eccentric reducer to be installed with flat side at bottom.

If expander is to be provided in pump suction then a straight length of 10D (where D is pump

inlet size) shall be provided downstream of the expander. This shall be indicated in the P&ID.

6. Motor is not indicated for pumps.

Motor run indication in DCS is shown as XA.

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 15 of 38

Any start/stop indication from DCS is to be indicated as HS with STOP or START on top

of instrument box.

Local start-stop push buttons are not shown.

Any interlock to pump trip to be indicated.

7. Pressure gauge to be provided at pump discharge. Requirement of diaphragm seal to be decided

based on the fluid properties.

8. Check valve to be provided with 20NB globe valve bypass valve when

- Design temperature exceeds 230oC

- Process fluid is congealing and solidifies at room temperature

- Process fluid is C4 or lighter (to avoid vaporisation)

6.11 Pump vent/drain

Refer to figures 12 and 13 for typical pump vent/drain assembly depictions. Figure 12 is for

general system, while figure 13 is specifically for lights. Following notes are to be read in

conjunction with figure 12 and 13.

1. Provide casing drain valve with blind flange for non-hazardous/ non-toxic service.

2. For other fluids, the drain is to be hooked up to a closed drain system. In this case the drain line

is provided with double block and spectacle blind.

3. The closed drain system can be

- Closed Blowdown (CBD) for hydrocarbon and sour (containing H2S) service

- Chemical sewer for chemicals like caustic

4. For C4 and lighter fluids the casing drain is hooked up to the flare. In this case the block valves

to be minimum 600mm apart to be able to operate the upstream block valve in case the

downstream valve is frozen.

5. Provide a pump vent valve with blind flange for non-hazardous/ non-toxic service. In case the

pump is self-venting, the valve is not provided at the pump but the valved vent is provided in

the discharge line.

6. The vent line is hooked up to a closed system as for the casing drain. (refer Note 3)

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 16 of 38

7. When the suction vessel operates at vacuum conditions, the vent line shall be hooked up to the

suction vessel. This will allow positive filling of the pump with liquid before start up.

6.12 Minimum flow bypass with restriction orifice/control valve

Refer to figure 14 for typical depictions of minimum flow bypass achieved using restriction orifice,

while figure 15 represents control valve case. Following notes are to be read in conjunction with

figures 14 and 15.

1. Minimum flow bypass is required when the forward pump flow is not always higher than the

required minimum flow of selected pump. The RO is sized to provide continuous minimum

flow for the pump.

2. For economic reasons a combined flow orifice in the common discharge line of the pump and

spare pump can be considered. The disadvantage is the pumps are not protected against the

inadvertent closure of the discharge valve.

3. Minimum flow control using an automatic control valve is preferred for high capacity and high

pressure systems. The control valve is FO type so that the pump is protected in case of

Instrument air failure.

4. For economic reasons a combined flow control valve in the common discharge line of the pump

and spare pump can be considered. The disadvantage is the pumps are not protected against the

inadvertent closure of the individual pump isolation valve.

6.13 Typical positive displacement pump installation

Refer to figure 16 for typical depictions of positive displacement pump installations. Following

notes are to be read in conjunction with figure 16.

1. Isolation valve type to be as per piping requirement

2. Spectacle blind need not be provided if the fluid handled is non-toxic and non-hazardous.

3. Strainers to be provided at pump suction.

- Y type upto 40NB

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 17 of 38

- T type from 50NB to 300NB

- Basket type beyond 300 NB .

4. Blinded vent and drain to be provided for Basket type strainer.

5. Suction pulsation bottle or dampener is supplied by the pump vendor. The pump vendor also

decides the requirement of the dampeners. The dampener is tagged (F) to indicate that it is

vendor furnished. Dampeners shall be provided with vent and drain connections

6. Discharge pulsation bottle or dampener is supplied by the pump vendor. The pump vendor also

decides the requirement of the dampeners. The dampener is tagged (F) to indicate that it is

vendor furnished. Dampeners shall be provided with vent and drain connections

7. Motor is not indicated for pumps.

Motor run indication in DCS is shown as XA.

Any start/stop indication from DCS is to be indicated as HS with STOP or START on top

of instrument box.

Local start-stop push buttons are not shown.

Any interlock to pump trip to be indicated.

8. Pressure gauge to be provided at pump discharge. Since the pump discharge flow is pulsating,

the PI should be provided with a dampener.

9. The pump suction and discharge line shall be provided with a drain valve. The drain connection

in the pulsation bottles can be blinded if complete drainage via the pump line drains is possible.

10. In case of hazardous or toxic service the drains shall be hooked up to a closed drain system. In

this case the drain line is provided with double block and spectacle blind.

11. The closed drain system can be

- Closed Blowdown (CBD) for hydrocarbon and sour (containing H2S) service

- Chemical sewer for chemicals like caustic

12. A safety valve shall be installed at the pump discharge. Even if the pump vendor supplies an in-

built safety valve, an external safety valve must be provided because of the reliability of the in-

built safety valve. The safety valve is normally connected to the pump suction line. If it is

recommended to connect the safety valve to the suction vessel, a Locked Open valve shall be

provided.

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 18 of 38

13. Normally check valve is not provided in the pump discharge because of the pump configuration.

14. If the PD pump is to be used for metering, a calibration pot shall be provided at the pump

suction. The pump vendor shall supply the calibration pot.

6.14 Positive displacement pump capacity control

Refer to figure 17 for typical depictions of positive displacement pump capacity control. Following

notes are to be read in conjunction with figure 17.

1. Since the PD pump volumetric capacity if fixed, in case of varying process flow, the excess

flow is returned to the suction vessel. The control is based on maintaining the desired pressure

at the user point. PIC to be located at user location.

2. The return line is tapped close to the user point for better controllability.

3. The control valve is sized for full pump flow and is FO type.

4. A self-actuated pressure-regulating valve may be used instead of the control valve assembly if

the duty is not critical.

5. Capacity control can also be achieved by adjusting the stroke length of the pump.

6.15 Atmospheric storage tank venting arrangement

Refer to figure 18 for typical depictions of atmospheric storage tank venting arrangement.

Following notes are to be read in conjunction with figure 18.

1. Vent with gooseneck, check need for flame arrestor based on flash point of material stored.

2. Manhole with emergency vent for hydrocarbon storage.

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 19 of 38

6.16 Blanketed tanks

Refer to figures 19 and 20 for typical depictions of blanketed tanks. Figure 19 refers to pressure

controller version and figure 20 is for self actuated PCV case. Following notes are to be read in

conjunction with figures 19 and 20.

1. Blanketing arrangement with split range PIC controller is used when instrument air is available

in the offsite area.

2. Self-actuated PCVs do not need instrument air. The 3 PCVs come as an assembly.

3. Pressure-Vacuum relief breather valve to be provided.

4. Manhole with emergency vent for hydrocarbon storage.

6.17 Tank heating arrangement

Refer to figure 21 and 22 for typical depictions of tank heating arrangement. Figure 21 is for

manual control case, while figure 22 depicts automatic control operation. Following notes are to be

read in conjunction with figures 21 and 22.

1. Manual control of heating steam to coil if the duty is not very critical. Manual control by globe

valve in steam line.

2. Local temperature indication to be in visible from globe valve for ease of control.

3. If non-IBR (less than 3.5kg/cm2g design pressure) is used for tank heating no spec break is

required to be indicated. If higher pressure steam is used and condensate is drained to

atmosphere, spec break to be indicated downstream of globe valve.

4. Standard steam trap assembly draining to grade to be provided in case of no condensate

recovery.

5. When control of temperature of tank contents is required, control valve assembly to be provided

to regulate steam flow into the tank coil.

6. Standard steam trap assembly draining to grade or to condensate header to be provided based on

condensate recovery philosophy.

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 20 of 38

6.18 Typical floating roof tank installation

Refer to figure 23 for typical depictions of floating roof tank installation. Following notes are to be

read in conjunction with figure 23.

1. For flammable liquid, foam supply line to be provided around the tank & the foam supply line

shall form ring around the tank. The line size & the scope of supply of this are included in

vendors scope.

2. Floating roof tank shall have rim vent and breather valve. For flammable liquids all PVRV shall

have flame arrestor. Vendor shall decide the size & number of rim vents.

3. Tank shall be located in dyke wall.

4. Double deck type tank shall have pontoon manhole. The number of manhole & the size shall be

decided by vendor / mechanical.

5. Clean out door (rectangular type) shall be provided on shell.

6. All the nozzles on shell body of the tank except LSH nozzle shall be provided at a minimum

distance from bottom.

7. Tank shall be provided with level transmitter for measurement of low level. Low low level

alarm shall be configured in level transmitter. Tank outlet valves shall close & tank outlet pump

shall trip on activation of low low-level alarm.

8. Size of Roof drain nozzle to be decided by vendor.

9. Bleeder vent shall be used for out-breathing of air during initial filling & in-breathing of air

during tank draining. Tank isolation valves shall correspond to piping specification of the given

project.

10. Portable pump shall be provided for complete draining of tank.

11. Auto tank gauging system (ATG) shall be considered for floating roof tanks. This system

consists of measuring the level in the tank based on change in the ambient temperature of the

product stored. For this purpose the density transmitter shall be provided on shell at a minimum

level from bottom. Separate temperature element nozzle shall be provided on roof of the tank

with a dip pipe. Temperature & density transmitter signal shall be coupled with level transmitter

provide on roof. Output from level transmitter shall be taken to three places

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 21 of 38

Local indicator shall be provided at grade level outside the dyke wall.

Indication in DCS.

Indication on ATG panel provided in DCS separately.

ATG local indicators shall be mounted at the grade level outside the dyke wall.

12. Unexpected liquid movement alarm shall be configured in ATG.

13. Temperature indicator nozzle shall be provided with 4 steel well.

14. Radar type level indicator & level dip hatch shall be provided with 8 steel well.

15. Tank shall be provided with separate high high level switch. Tank inlet pumps shall tr

16. During roof drain choking, if liquid level on roof rises beyond the design capacity, the roof may

sink. To avoid such incidence an emergency drain is provided. In that case the rise in level

beyond the design capacity on roof cause the liquid to enter in the tank.

6.19 Truck loading arm

Refer to figure 24 for typical depictions of truck loading arms. Following notes are to be read in

conjunction with figure 24.

1. Overfill protection switch shall be provided on loading arm to avoid overfilling of truck while

loading the liquid. FCV provided at the upstream of loading arm shall close on activation of this

switch.

2. Provide funnel for collecting the loading arm drip.

3. Indicate the bay number.

4. Unloading hose with blind flange shall be provided in each bay to unload sick tanker.

Unloading hose length shall be 3 meter. Elevation of unloading line shall be 450 mm.

5. Parking switch shall be provided on loading arm to avoid opening of FCV provided at the

upstream of loading arm when loading arm is in parking position.

6. Drop down access platform shall be provided in loading bay & earth straps shall be provided in

case of flammable liquid.

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 22 of 38

Figure 1: Typical control valve installation

FV

FO

20

FV

FC

20 20

Figure 2: Steam trap assembly

CONDENSATE

HEADER

T

20

20

IH IP

TO DRAIN AT GRADE

IH

IP

20 T

TO DRAIN AT GRADE

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 23 of 38

Figure 3: Battery limit installation

FROM B/L NOTE 1,2

TO PROCESS PLANT

20

NOTE 3

FROM B/L NOTE 1,2

NOTE 4

TO PROCESS PLANT

20

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 24 of 38

Figure 4: Cooling water header

CWS MIN.

NOTE 1,2

20

USERS

NOTE 5

CWR NOTE 1,2

MIN.

20

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 25 of 38

Figure 5: Flare header

NOTE 8,9 FROM B/L

NOTE 1,2

LO

NOTE 7 6M MIN. NOTE 6

50

LOW TEMP

SPEC. UC

XXX

NOTE 10

YYY

RO

NITROGEN / FUEL GAS

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 26 of 38

Figure 6: Safety valve discharging to atmosphere

XXX YYY

PSV

NO POCKETS

SLOPE

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 27 of 38

Figure 7: Thermal relief valve discharging to atmosphere

PSV

Figure 8Single PSV discharging to closed system

XXX YYY

PSV

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 28 of 38

Figure 9: PSV with spare discharging to closed system

INTERLOCK

NO POCKETS

NO POCKETS

SLOPE

SLOPE

Figure 10: Desuperheater

BFW

20 20

H

TIC PI

STEAM

10D

STRAIGHT

LENGTH 10D MIN.

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 29 of 38

Figure 11: Typical centrifugal pump installation

NOTE 2

NOTE 8

PI

NOTE 7

I

NOTE 2

NOTE 5

XA

NOTE 6

NOTE 1 NOTE 3

STOP

P-101 HS

NOTE 4

NOTE 4

Figure 12: Pump vent/drain

ALTERNATE VENT

IF PROCESS IS

NOTE 5 HOT INSULATED

IH IS

NOTE 2

20

NOTE 1

PROCESS

20 20 SPEC

CLOSED

DRAIN

SYSTEM

NOTE 3

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 30 of 38

Figure 13: Pump vent/drain (lights)

NOTE 7 25

25 NOTE 4

600MM

20

PROCESS

SPEC

FLARE

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 31 of 38

Figure 14: Minimum flow bypass with restriction orifice

TO SUCTION VESSEL

RO

NOTE 1

TO SUCTION

VESSEL

RO

NOTE 2

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 32 of 38

Figure 15: Minimum flow bypass with control valve

TO SUCTION

VESSEL

NOTE 3

FO

FIC

TO SUCTION

VESSEL

FO

FIC

FORWARD FLOW

TO PROCESS

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 33 of 38

Figure 16: Typical positive displacement pump installation

NOTE 1

PSV

NOTE 2

NOTE 12

LO

NOTE 12

V V

(F)

(F)

(F)

NOTE 6 NOTE 8

NOTE NOTE 5

14 PI

NOTE 2

20 NOTE 9,10,11

NOTE 1 NOTE 3 20

NOTE 9,10,11 I STOP

HS

XA

NOTE 7

Figure 17: Positive displacement pump capacity control

FO

PIC

NOTE 2 NOTE 1

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 34 of 38

Figure 18: Atsmopheric storage tank venting arrangement

PSV

Figure 19: Blanketed tanks (pressure controller)

SPLIT RANGE

PIC

UTILITY PROCESS

SPEC SPEC

INERT FLARE OR ATM

FREE FREE

DRAIN DRAIN

FC FO

NOTE 1

PVRV PROCESS

PSV

SPEC

VAC PRESS

NOTE 3 NOTE 4

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 35 of 38

Figure 20: Blanketed tanks (self actuated PCV)

PCV

FUEL GAS/

NAT GAS

NOTE 2

PVRV

PCV PCV

NOTE 3

PSV

NOTE 4

Figure 21: Tank heating (manual control)

NOTE 2

IN VIEW

PI TI

STEAM NOTE 1

IBR NON-IBR

NOTE 3 T

GRADE

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 36 of 38

Figure 22: Tank heating (automatic control)

TIC

STEAM

FC

20 20

CONDENSATE

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 37 of 38

Figure 23: Typical floating roof tank installation

Kvaerner Powergas India Pvt Ltd

Typical Systems Depiction PS.05.03-04 Rev. 00

Kvaerner Powergas

for P&IDs Page 38 of 38

Figure 24: Truck loading arm

Kvaerner Powergas India Pvt Ltd

You might also like

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsFrom EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahNo ratings yet

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979From EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonNo ratings yet

- Iit MumbaiDocument243 pagesIit MumbaiYogesh JagdaleNo ratings yet

- Pi Ups 1004Document39 pagesPi Ups 1004JOEL ARNAO CORTEGANANo ratings yet

- (SKP) PFD & P&idDocument43 pages(SKP) PFD & P&idSuresh Haldipur100% (1)

- 11-3085 Energy Analyzer Jump StartDocument26 pages11-3085 Energy Analyzer Jump StartOmesh BoroleNo ratings yet

- Material Selection For Low-Temperature Applications - HP - July 2004Document12 pagesMaterial Selection For Low-Temperature Applications - HP - July 2004onizuka-t2263No ratings yet

- Pi Ups 1007Document30 pagesPi Ups 1007JOEL ARNAO CORTEGANANo ratings yet

- Relief System PipingDocument7 pagesRelief System PipingbalajikrishnanNo ratings yet

- Process STD 103 PDFDocument58 pagesProcess STD 103 PDFaliNo ratings yet

- Toyo 1-55Document435 pagesToyo 1-55Yuda Satria100% (1)

- FRS-DU-5056-E.1 Sizing & Selection of PSVDocument25 pagesFRS-DU-5056-E.1 Sizing & Selection of PSVShivani DubeyNo ratings yet

- A 02Document30 pagesA 02senioor2004No ratings yet

- Plot Plans PDFDocument194 pagesPlot Plans PDFLuis Enrique Leyva Ovalle100% (1)

- Piping Design SpecificationsDocument33 pagesPiping Design SpecificationsMajid DixonNo ratings yet

- Column Piping: Study Layout, Nozzle Orientation & Platforms RequirementsDocument23 pagesColumn Piping: Study Layout, Nozzle Orientation & Platforms Requirementsreach_arindomNo ratings yet

- DYNSIM Best Practices 2 - Distillation ColumnDocument26 pagesDYNSIM Best Practices 2 - Distillation ColumnJorge Luis HernándezNo ratings yet

- SWS Process Flow DiagramDocument1 pageSWS Process Flow DiagramNKNo ratings yet

- 1.review of PFD, Pid, PdsDocument10 pages1.review of PFD, Pid, PdssuhailfarhaanNo ratings yet

- Plot Plan Design Criteria For Process UnitsDocument11 pagesPlot Plan Design Criteria For Process UnitsEddie SantillánNo ratings yet

- Process Plant Design - Training Course - Day 1 - 23 Dec 2017 PDFDocument77 pagesProcess Plant Design - Training Course - Day 1 - 23 Dec 2017 PDFNgàyMưaNo ratings yet

- GR TWC1 7211 5202Document97 pagesGR TWC1 7211 5202Sulist N WahyudieNo ratings yet

- Typical Arrangement of Air Cooler PipingDocument4 pagesTypical Arrangement of Air Cooler Pipingvedadon100% (1)

- Flare System Design TipsDocument5 pagesFlare System Design TipsbalajikrishnanNo ratings yet

- Pi Ups 1006Document27 pagesPi Ups 1006JOEL ARNAO CORTEGANANo ratings yet

- G3ir 1000 25 SP 9001 - R1Document72 pagesG3ir 1000 25 SP 9001 - R1Ramu NallathambiNo ratings yet

- Line List Input Design GuideDocument38 pagesLine List Input Design GuideCivil Friend86% (7)

- Process Design CriteriaDocument23 pagesProcess Design CriteriaDoctorOberman100% (1)

- Shahdol-Phulpur Gas Pipeline ProjectDocument50 pagesShahdol-Phulpur Gas Pipeline Projectanub0025No ratings yet

- SEM 3037E Tower Piping.Document52 pagesSEM 3037E Tower Piping.Kodali Naveen KumarNo ratings yet

- 12 - SmartPlant P-IDDocument22 pages12 - SmartPlant P-IDIslam SolimanNo ratings yet

- Offsites and UtilitiesDocument70 pagesOffsites and Utilitiesankitalalwani100% (1)

- Training Manual - Instruments: Globe Control ValveDocument14 pagesTraining Manual - Instruments: Globe Control ValveSanjay SoniNo ratings yet

- Ashwin Udhe 1 Introduction To Piping Engineering PDFDocument6 pagesAshwin Udhe 1 Introduction To Piping Engineering PDFPoonam AshwinNo ratings yet

- Air Coolers Versus Shell-And-tube Water CoolersDocument8 pagesAir Coolers Versus Shell-And-tube Water CoolersDefenceDog67% (3)

- Process Lead ResponsibilitiesDocument4 pagesProcess Lead ResponsibilitiesChem.EnggNo ratings yet

- Flare BloDocument14 pagesFlare BloKalyana AyyaswamyNo ratings yet

- PSV Webinar FinalDocument37 pagesPSV Webinar FinalHoracio RodriguezNo ratings yet

- Engineering Standard: IPS-E-PR-330Document30 pagesEngineering Standard: IPS-E-PR-330Akmal ZuhriNo ratings yet

- Trg-b1003 Piping Study Column PipingDocument53 pagesTrg-b1003 Piping Study Column Pipingfronjose100% (3)

- Typical P&ID Arrangement For Centrifugal Compressor SystemsDocument2 pagesTypical P&ID Arrangement For Centrifugal Compressor SystemsajaysapruNo ratings yet

- Reboiler Calculations Design Guide PDF FreeDocument12 pagesReboiler Calculations Design Guide PDF FreeSabba CabbaNo ratings yet

- Check List - 3D Model ReviewDocument28 pagesCheck List - 3D Model ReviewNikhil ChaundkarNo ratings yet

- Pressure Testing of Unfired Pressure Vessels: ScopeDocument9 pagesPressure Testing of Unfired Pressure Vessels: Scopebenedicto soto mestanzaNo ratings yet

- Piping Class SpecificationDocument6 pagesPiping Class Specificationcitra puspita sariNo ratings yet

- Checklist For Line-By-Line ReviewDocument3 pagesChecklist For Line-By-Line ReviewSusanna Paul100% (1)

- G SF 240 PDFDocument29 pagesG SF 240 PDFAmirhosein605334No ratings yet

- Process Isolation Guidelines - Refining, Hydrocarbons, Oil, and Gas - CheresourcesDocument5 pagesProcess Isolation Guidelines - Refining, Hydrocarbons, Oil, and Gas - Cheresourcesjayrolling dollazNo ratings yet

- Indus - PGD Process Design EngineeringDocument2 pagesIndus - PGD Process Design EngineeringAmarjeet SandhuNo ratings yet

- PSV Calculations FlareDocument0 pagesPSV Calculations FlareSrinivas BobbyNo ratings yet

- DataSheets TipsDocument3 pagesDataSheets TipsChem.Engg100% (1)

- Genesis Process Design Guidelines RDocument96 pagesGenesis Process Design Guidelines RDavid Gustavo Duran TangoNo ratings yet

- Line Sizing Philosophy Line Sizing PhilosophyDocument21 pagesLine Sizing Philosophy Line Sizing Philosophyjenish parekhNo ratings yet

- How To Design Piping For Reboiling SystemsDocument7 pagesHow To Design Piping For Reboiling SystemsSalim YilmazNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- 1200A and 1200D Electric Power Supplement TPD2144 Production Release V6 0Document91 pages1200A and 1200D Electric Power Supplement TPD2144 Production Release V6 0Mostafa Shanna83% (6)

- RBAI - Detailed Energy Audit Report 1Document86 pagesRBAI - Detailed Energy Audit Report 1Karthik VNo ratings yet

- Books Paper4Document170 pagesBooks Paper4Abu Hasnat Md. ShaedNo ratings yet

- Combined Heat and Power Systems: Reference Manual ForDocument284 pagesCombined Heat and Power Systems: Reference Manual ForKamyab PakistanNo ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleChagar HarshpalNo ratings yet

- Centrifuges For The Chemical IndustryDocument4 pagesCentrifuges For The Chemical IndustrypintaratNo ratings yet

- Weld WeightDocument10 pagesWeld WeightDivyesh PatelNo ratings yet

- Rectangular TankDocument6 pagesRectangular TankEsapermana RiyanNo ratings yet

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationmail_younes659283% (29)

- Heinkel Flyer Classifying Centrifuge v630 BK TiocentDocument2 pagesHeinkel Flyer Classifying Centrifuge v630 BK TiocentRaghNo ratings yet

- API 685 BrochureDocument8 pagesAPI 685 BrochureDenar PurnamaNo ratings yet

- Ro-Flo Packaging Guidelines ENG PDFDocument42 pagesRo-Flo Packaging Guidelines ENG PDFRaghNo ratings yet

- Tutorial Motor Basics Lecture PDFDocument23 pagesTutorial Motor Basics Lecture PDFBenjaminas OrlovasNo ratings yet

- Smaw and Tig WeldingDocument46 pagesSmaw and Tig WeldingRajesh Kumar Ravi100% (1)

- BS-2654 1989 Design Standard For Vert Steel Welded Storage TanksDocument103 pagesBS-2654 1989 Design Standard For Vert Steel Welded Storage TanksAndrew Ko100% (2)

- Ro-Flo BrochureDocument4 pagesRo-Flo BrochureRaghNo ratings yet

- AISC Design Guide 33 Curved Member Design 2018Document166 pagesAISC Design Guide 33 Curved Member Design 2018saital92% (12)

- Ro-Flo Iom Manual EngDocument52 pagesRo-Flo Iom Manual EngSlamet Purwadi S.T100% (1)

- Pressure Vessel HandBook Megyesy11th EdDocument247 pagesPressure Vessel HandBook Megyesy11th EdRaghNo ratings yet

- Tank ErectionDocument13 pagesTank Erectionsajay2010No ratings yet

- Lifting Lug - Skid - 2018.07.16Document4 pagesLifting Lug - Skid - 2018.07.16RaghNo ratings yet

- Methodology For RepairsDocument2 pagesMethodology For RepairsTaufik WhaeNo ratings yet

- Strength Calculation For PlatformDocument2 pagesStrength Calculation For PlatformRaghNo ratings yet

- TycoDocument69 pagesTycog4goharNo ratings yet

- Methodology For RepairsDocument1 pageMethodology For RepairsRaghNo ratings yet

- Specs For Aluminum Geodesic Batten Domes 2012Document5 pagesSpecs For Aluminum Geodesic Batten Domes 2012RaghNo ratings yet

- Engineering Standard Specification For Steam TracingDocument53 pagesEngineering Standard Specification For Steam Tracingkaruna346100% (1)

- Hi-T Pigalert IOM ManualDocument14 pagesHi-T Pigalert IOM ManualRaghNo ratings yet

- Hi-T Pigalert LiteratureDocument2 pagesHi-T Pigalert LiteratureRaghNo ratings yet

- STEAM TRACING Engineering - Guide PDFDocument0 pagesSTEAM TRACING Engineering - Guide PDFkresimir.mikoc9765No ratings yet

- Apt 60928 Evs TM 08 1Document108 pagesApt 60928 Evs TM 08 1Mohan JhaNo ratings yet

- Apt 60928 Evs TM 08 1Document108 pagesApt 60928 Evs TM 08 1Mohan JhaNo ratings yet

- Sweco CatDocument21 pagesSweco CatArmandoZacariasAcostaNo ratings yet

- UM - HX204 - EN User ManualDocument32 pagesUM - HX204 - EN User Manuals7631040No ratings yet

- Neeraj Pal 2Document1 pageNeeraj Pal 2NeerajPalNo ratings yet

- Reference Guide: TMS320C674x DSP CPU and Instruction SetDocument770 pagesReference Guide: TMS320C674x DSP CPU and Instruction SetSamreen tabassumNo ratings yet

- User Manual For P12S01Document40 pagesUser Manual For P12S01Behrouz HajianNo ratings yet

- Vacuum TubeDocument1 pageVacuum Tubejose condoriNo ratings yet

- Electrical BEE Latest 2022 2023 Quantum Series (Searchable)Document116 pagesElectrical BEE Latest 2022 2023 Quantum Series (Searchable)ritamlyrisNo ratings yet

- Studyprotocol Open Access: Yue Yan, Yalin Zhan, Xian 'E Wang and Jianxia HouDocument7 pagesStudyprotocol Open Access: Yue Yan, Yalin Zhan, Xian 'E Wang and Jianxia HouGery KrismawanNo ratings yet

- AutoCAD - Modify ToolbarDocument18 pagesAutoCAD - Modify ToolbarMarcusNo ratings yet

- EAPA Paper - Asphalt Pavements On Bridge Decks - 2013Document33 pagesEAPA Paper - Asphalt Pavements On Bridge Decks - 2013prdojeeNo ratings yet

- Spe Math p2 Revision Yr7Document24 pagesSpe Math p2 Revision Yr7Hadizah JulaihiNo ratings yet

- EEMDocument17 pagesEEMSandaruwan සුජීවNo ratings yet

- A204TPL-AISH-L-STD-0001-C3-Application of Standards Pipe Supports & Pipe Support Note PDFDocument77 pagesA204TPL-AISH-L-STD-0001-C3-Application of Standards Pipe Supports & Pipe Support Note PDFAjadNo ratings yet

- A Proof of The Black and Scholes Formula: Claudio Pacati May 30, 2012Document3 pagesA Proof of The Black and Scholes Formula: Claudio Pacati May 30, 2012AndresC.MedinaSanhueza100% (1)

- MKT4419 Final ReportDocument28 pagesMKT4419 Final ReportGlenn HengNo ratings yet

- HD 70 CDocument101 pagesHD 70 CPhamVanGiangNo ratings yet

- Tigear - 2 Gearing: Engineering CatalogDocument292 pagesTigear - 2 Gearing: Engineering Catalogrrobles011No ratings yet

- Excavators 1Document27 pagesExcavators 1Gold CubeNo ratings yet

- AnovaDocument17 pagesAnovaIshan ShahNo ratings yet

- Electronic Door LockDocument2 pagesElectronic Door LocktaindiNo ratings yet

- 5000 KW Gearbox High Pinion Bearing Temperatures 1644227029Document7 pages5000 KW Gearbox High Pinion Bearing Temperatures 1644227029MC ANo ratings yet

- WPS Chapter 7Document34 pagesWPS Chapter 7richemengNo ratings yet

- The Basics of Thread Rolling: Tools, Tips & Design ConsiderationsDocument108 pagesThe Basics of Thread Rolling: Tools, Tips & Design ConsiderationsVictor ParvanNo ratings yet

- Lte OptimizationDocument323 pagesLte Optimizationkumar100% (2)

- TRM Reb670Document490 pagesTRM Reb670jayapalNo ratings yet

- Bu3 Lecture1 Fundamentals of AcousticsDocument10 pagesBu3 Lecture1 Fundamentals of AcousticsPrincess HernandezNo ratings yet

- Monoprotic Acid-Base Equilibria: Review of FundamentalsDocument38 pagesMonoprotic Acid-Base Equilibria: Review of FundamentalsmakroniNo ratings yet

- Markov ChainDocument16 pagesMarkov Chainnaveenk903No ratings yet

- Mahesh - Informatica DeveloperDocument5 pagesMahesh - Informatica DeveloperMadhav GarikapatiNo ratings yet

- Jawaharlal Nehru Technological University Anantapur B.Tech. I - I Sem. L C 4 2 Part-A LABDocument2 pagesJawaharlal Nehru Technological University Anantapur B.Tech. I - I Sem. L C 4 2 Part-A LABHappa1No ratings yet