Professional Documents

Culture Documents

Super Critical Power - Part78

Uploaded by

Dhiraj Satyam0 ratings0% found this document useful (0 votes)

26 views1 pageSuper Critical Power_Part78

Original Title

Super Critical Power_Part78

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSuper Critical Power_Part78

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views1 pageSuper Critical Power - Part78

Uploaded by

Dhiraj SatyamSuper Critical Power_Part78

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Standard Technical Features of BTG System for Supercritical 660/800 MW Thermal Units

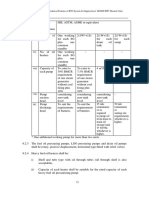

8.5.11 Materials of construction

The material of construction of wear parts shall be selected taking into account

highly abrasive nature of coal resulting from coal contamination with silica

sand and Alpha-quartz as specified.

Mill component Specification

i) Classifier cone Lined with minimum 15 mm thick

ceramic tiles on both inside and outside

surfaces of the cone

ii) Grinding rings/ race Material with hardness 550 BHN (min.) at

surface (with adequate chilled depth)

iii) Grinding balls/ rolls Material with hardness 350 BHN (min.)

iv) Minimum difference in 100 BHN

hardness of rings/ rolls and

race/ balls

8.5.12 Minimum guaranteed life of coal pulverizer wear parts

The guaranteed life of different mill components in "equivalent hours" of

continuous mill operation at its rated capacity, while firing the specified range

of coals and without requiring any in between repair or replacement shall be as

under:

Item Minimum life in

equivalent hours

i) Grinding elements (rolls/ balls and rings/ 7200 [See notes

race) below]

ii) Mill discharge valves 15000

iii) Seals 20000

iv) Classifier cone and other items lined with 25000

ceramic material

Notes:

a) The expected wear life of mill grinding elements (rolls/ balls and rings/

race) in equivalent hours, under conditions stipulated above shall be in the

range of 7200 to 8000 hours.

b) A curve indicating the variation in guaranteed wear life with variation in

YGP index of coal fired (measured as per BS Standard BS-1016 Part-111)

shall be furnished. Separate curves for different wear elements of mill

shall be furnished e.g. for grinding rolls, grinding rings, clearly indicating

its relationship with YGP index of coal.

8.5.13 Minimum mill turn-down ratio of 2:1 shall be ensured.

67

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Partnership Digest Obillos Vs CIRDocument2 pagesPartnership Digest Obillos Vs CIRJeff Cadiogan Obar100% (9)

- Reaction PaperDocument3 pagesReaction PaperLois DolorNo ratings yet

- The Anti-PaladinDocument9 pagesThe Anti-PaladinBobbyNo ratings yet

- MEMORANDUM OF AGREEMENT DraftsDocument3 pagesMEMORANDUM OF AGREEMENT DraftsRichard Colunga80% (5)

- Economics Exam Technique GuideDocument21 pagesEconomics Exam Technique Guidemalcewan100% (5)

- Chapter-10 Electrostatic Precipitator: 10.1 Design DataDocument1 pageChapter-10 Electrostatic Precipitator: 10.1 Design DataDhiraj SatyamNo ratings yet

- Super Critical Power - Part92Document1 pageSuper Critical Power - Part92Dhiraj SatyamNo ratings yet

- Super Critical Power - Part91Document1 pageSuper Critical Power - Part91Dhiraj SatyamNo ratings yet

- Super Critical Power - Part81Document1 pageSuper Critical Power - Part81Dhiraj SatyamNo ratings yet

- Super Critical Power - Part86Document1 pageSuper Critical Power - Part86Dhiraj SatyamNo ratings yet

- Super Critical Power - Part88Document1 pageSuper Critical Power - Part88Dhiraj SatyamNo ratings yet

- Super Critical Power - Part85Document1 pageSuper Critical Power - Part85Dhiraj SatyamNo ratings yet

- Suitable For Remote Manual OperationDocument1 pageSuitable For Remote Manual OperationDhiraj SatyamNo ratings yet

- Super Critical Power - Part57Document1 pageSuper Critical Power - Part57Dhiraj SatyamNo ratings yet

- Super Critical Power - Part83Document1 pageSuper Critical Power - Part83Dhiraj SatyamNo ratings yet

- Super Critical Power - Part79Document1 pageSuper Critical Power - Part79Dhiraj SatyamNo ratings yet

- Super Critical Power - Part77Document1 pageSuper Critical Power - Part77Dhiraj SatyamNo ratings yet

- Super Critical Power - Part80Document1 pageSuper Critical Power - Part80Dhiraj SatyamNo ratings yet

- Super Critical Power - Part81Document1 pageSuper Critical Power - Part81Dhiraj SatyamNo ratings yet

- Super Critical Power - Part76Document1 pageSuper Critical Power - Part76Dhiraj SatyamNo ratings yet

- Super Critical Power - Part62Document1 pageSuper Critical Power - Part62Dhiraj SatyamNo ratings yet

- Super Critical Power - Part71Document1 pageSuper Critical Power - Part71Dhiraj SatyamNo ratings yet

- Super Critical Power - Part59Document1 pageSuper Critical Power - Part59Dhiraj SatyamNo ratings yet

- Super Critical Power - Part61Document1 pageSuper Critical Power - Part61Dhiraj SatyamNo ratings yet

- Super Critical Power - Part54Document1 pageSuper Critical Power - Part54Dhiraj SatyamNo ratings yet

- Super Critical Power - Part58Document1 pageSuper Critical Power - Part58Dhiraj SatyamNo ratings yet

- Super Critical Power - Part60Document1 pageSuper Critical Power - Part60Dhiraj SatyamNo ratings yet

- Super Critical Power - Part56Document1 pageSuper Critical Power - Part56Dhiraj SatyamNo ratings yet

- Super Critical Power - Part49Document1 pageSuper Critical Power - Part49Dhiraj SatyamNo ratings yet

- Super Critical Power - Part47Document1 pageSuper Critical Power - Part47Dhiraj SatyamNo ratings yet

- Super Critical Power - Part53Document1 pageSuper Critical Power - Part53Dhiraj SatyamNo ratings yet

- Super Critical Power - Part52Document1 pageSuper Critical Power - Part52Dhiraj SatyamNo ratings yet

- Super Critical Power - Part50Document1 pageSuper Critical Power - Part50Dhiraj SatyamNo ratings yet

- Super Critical Power - Part48Document1 pageSuper Critical Power - Part48Dhiraj SatyamNo ratings yet

- Chapter 13 Current Liabilities Test Bank Versi 2Document72 pagesChapter 13 Current Liabilities Test Bank Versi 2Slamet Tri PrastyoNo ratings yet

- JEE Mains Paper 1 (12 Apr 2019 Shift 2) EnglishDocument131 pagesJEE Mains Paper 1 (12 Apr 2019 Shift 2) EnglishRudraksha KushwahaNo ratings yet

- Cln4u Task Prisons RubricsDocument2 pagesCln4u Task Prisons RubricsJordiBdMNo ratings yet

- Final - Anarchy One-Sheet Sell SheetDocument2 pagesFinal - Anarchy One-Sheet Sell SheetMaddanie WijayaNo ratings yet

- DHA - Jebel Ali Emergency Centre + RevisedDocument5 pagesDHA - Jebel Ali Emergency Centre + RevisedJam EsNo ratings yet

- Fin Accounting IFRS 2e Ch13Document62 pagesFin Accounting IFRS 2e Ch13Nguyễn Vinh QuangNo ratings yet

- 6int 2008 Dec ADocument6 pages6int 2008 Dec ACharles_Leong_3417No ratings yet

- Polyether Polyol Production AssignmentDocument9 pagesPolyether Polyol Production AssignmentanurdiaNo ratings yet

- Vanguard 44 - Anti Tank Helicopters PDFDocument48 pagesVanguard 44 - Anti Tank Helicopters PDFsoljenitsin250% (2)

- Eng Notes2Document10 pagesEng Notes2Arti KapurNo ratings yet

- HDO OpeationsDocument28 pagesHDO OpeationsAtif NadeemNo ratings yet

- Guidelines For Doing Business in Grenada & OECSDocument14 pagesGuidelines For Doing Business in Grenada & OECSCharcoals Caribbean GrillNo ratings yet

- Pogon Lifta MRL PDFDocument128 pagesPogon Lifta MRL PDFMašinsko ProjektovanjeNo ratings yet

- Fertilisation and PregnancyDocument24 pagesFertilisation and PregnancyLopak TikeNo ratings yet

- BarricadeDocument6 pagesBarricadeJithu PappachanNo ratings yet

- SY22-23+Annual+Report FinalDocument47 pagesSY22-23+Annual+Report FinalNorus LizaNo ratings yet

- Investigation Data FormDocument1 pageInvestigation Data Formnildin danaNo ratings yet

- Stratum CorneumDocument4 pagesStratum CorneumMuh Firdaus Ar-RappanyNo ratings yet

- Painters Rates PDFDocument86 pagesPainters Rates PDFmanthoexNo ratings yet

- You Can't Blame A FireDocument8 pagesYou Can't Blame A FireMontana QuarterlyNo ratings yet

- Present Tenses ExercisesDocument4 pagesPresent Tenses Exercisesmonkeynotes100% (1)

- Air Blower ManualDocument16 pagesAir Blower ManualshaiknayeemabbasNo ratings yet

- Tata NanoDocument25 pagesTata Nanop01p100% (1)

- Tax Havens IMF PDFDocument59 pagesTax Havens IMF PDFClassic PhyXNo ratings yet

- Fashion DatasetDocument2,644 pagesFashion DatasetBhawesh DeepakNo ratings yet