Professional Documents

Culture Documents

6 Jan 14 UT - Metallurgy

Uploaded by

ramash75Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6 Jan 14 UT - Metallurgy

Uploaded by

ramash75Copyright:

Available Formats

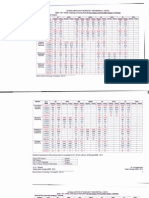

Q.No.

Series : 6/1/13-14

CHEMISTRY

General Principles and Processes of Isolation of Elements

Time Allowed : 2 hours] [Max. Marks : 40

________________________________________________________________________________________________

General Instructions :

1. All questions are compulsory.

2. Question no. 1 8 are very short answer questions and carry 1 mark each.

3. Question no. 9 15 are short answer questions and carry 2 marks each.

4. Question no. 16 21 are also short answer questions and carry 3 marks each.

_________________________________________________________________________________________________

1. What is meant by the term Pyrometallurgy? [1]

2. Why is electrolytic reduction preferred over chemical reduction for the isolation of certain metals? [1]

3. Why is it that only sulphide ores are concentrated by froth floatation process ? [1]

4. Although thermodynamically feasible, in practice, magnesium metal is not used in for the reduction

of alumina in the metallurgy of aluminium. Why? [1]

5. What is a slag? [1]

6. You are provided with samples of some impure metals such as zinc, copper and germanium.

Which methods would you recommend for the purification of each of these metals? [1]

7. Most of the ores in the earth crust are either oxides, sulphides or halides but not nitrides. Explain. [1]

8. Why is the reduction of a metal oxide easier if the metal formed is in liquid state at the temperature

of reduction ? [1]

9. (i) Which solution is used for the leaching of silver metal in the presence of air in the metallurgy of Ag? [2]

(ii) Out of C and CO, which is a better reducing agent in the lower temperature range in the blast

furnace to extract iron from the oxide ore?

10. Why are sulphide ores generally roasted to form oxides for the extraction of metals instead of

being directly reduced? [2]

11. Differentiate between Minerals and Ore. [2]

12. Describe the method of refining of nickel. [2]

13. The value of fGo for the formation of Cr2O3 is 540 kJ mol1 and that of Al2O3 is 827 kJ mol1.

Is the reduction of Cr2O3 possible with aluminium? [2]

14. How is chemical reduction different from electrolytic reduction? Give one metal reduction reaction

as example for each case. [2]

15. Describe the principle controlling each of the following processes. [2]

(i) Vapour phase refining of titanium metal

(ii) Froth floatation method of concentrating sulphide ore.

16. What is the chief ore of iron? Write chemical reactions of the extraction of iron from its ore. [3]

17. (i) Name the principle ore of aluminium. [3]

(ii) Describe the leaching of alumina.

18. (i) Write the names of two ores of copper. [3]

(ii) Which method is commonly used to extract copper?

19. (i) Write the names of any two principle ore of zinc. [3]

(ii) What are its uses?

20. Write chemical reactions taking place in the extraction of copper from sulphide ore. [3]

21. What chemical principle is involved in choosing a reducing agent for getting the metal from its oxide

ore? Consider the metal oxides Al2O3 and Fe2O3, and justify the choice of reducing agent in each case. [3]

You might also like

- fx-570 - 991ES - PLUS - EN ManualDocument46 pagesfx-570 - 991ES - PLUS - EN ManualJack Skb SmithNo ratings yet

- Arthashastra of Chanakya - EnglishDocument614 pagesArthashastra of Chanakya - EnglishHari Chandana K83% (6)

- Format of OBC Certificate: Form of Certificate To Be Produced by Other Backward Classes (NCL)Document1 pageFormat of OBC Certificate: Form of Certificate To Be Produced by Other Backward Classes (NCL)RamaDinakaranNo ratings yet

- GATE 2018 Information Brochure - v1Document39 pagesGATE 2018 Information Brochure - v1Charan ReddyNo ratings yet

- Yoga (Kundalini)Document168 pagesYoga (Kundalini)Alesha Rose100% (25)

- Std12 Phy Vol 1Document237 pagesStd12 Phy Vol 1Aaron Merrill50% (2)

- M.tech-Curriculum 0 PDFDocument49 pagesM.tech-Curriculum 0 PDFsrinivasan_a1996No ratings yet

- Advertisement Material For M.S-PH.DDocument1 pageAdvertisement Material For M.S-PH.Dramash75No ratings yet

- 2015 Auto Industry Jobs ReportDocument57 pages2015 Auto Industry Jobs Reportramash75No ratings yet

- Ece LibraryDocument5 pagesEce LibraryAshok SutharNo ratings yet

- Ancestral Foods Cholesterol Hypothyroidism GoutDocument13 pagesAncestral Foods Cholesterol Hypothyroidism Goutramash75No ratings yet

- Std12 Phy Vol 1Document237 pagesStd12 Phy Vol 1Aaron Merrill50% (2)

- Water and YouDocument82 pagesWater and YouMrudula V.100% (8)

- 315 StrategyDocument33 pages315 StrategyRaghav Sampath100% (1)

- Electronics Industry in IndiaDocument13 pagesElectronics Industry in Indiaramash75No ratings yet

- Sivagamiyin Sabatham Part2Document140 pagesSivagamiyin Sabatham Part2api-19854516No ratings yet

- Vsa Basics PDFDocument31 pagesVsa Basics PDFdiogonbig100% (1)

- Trade ScoreDocument30 pagesTrade Scoresangram1705100% (1)

- Neo Wave PatternsDocument22 pagesNeo Wave PatternsMuh Akbar Z100% (2)

- GannDocument11 pagesGannrajivnk100% (1)

- Esignal Manual Ch6Document10 pagesEsignal Manual Ch6dee138100% (1)

- Amaidhiyum Aarokiyamum (Monthly Magazine) - May Month 2015Document32 pagesAmaidhiyum Aarokiyamum (Monthly Magazine) - May Month 2015ramash75No ratings yet

- WaveRatios PDFDocument14 pagesWaveRatios PDFshobhaNo ratings yet

- Ta BytesDocument14 pagesTa Bytesramash75No ratings yet

- OptionsDocument8 pagesOptionsramash75No ratings yet

- Brochure IitDocument140 pagesBrochure Iitramash75No ratings yet

- Basics Gorman WaveDocument150 pagesBasics Gorman WaveHiren Mandaliya100% (1)

- Article PositionsizingprimerDocument13 pagesArticle Positionsizingprimerramash75No ratings yet

- Air 2011 2012Document5 pagesAir 2011 2012Vanitha RavichandranNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Au in C - HutchingsDocument8 pagesAu in C - HutchingsLuis TolentinoNo ratings yet

- XJ (X350) Cooling System Drain Fill Bleed R&IDocument4 pagesXJ (X350) Cooling System Drain Fill Bleed R&IMattNo ratings yet

- Laser Cooling and Trapping of Neutral AtomsDocument21 pagesLaser Cooling and Trapping of Neutral Atomsdevendratiwari0No ratings yet

- Introductory Experiment: Calibration of Volumetric GlasswareDocument4 pagesIntroductory Experiment: Calibration of Volumetric GlasswareOcampo AmyNo ratings yet

- AGARD - Blading Design For Axial Turbomachines PDFDocument213 pagesAGARD - Blading Design For Axial Turbomachines PDFRadek Wasilewski100% (1)

- 2561 Rubber Based Adhesives For Automobile IndustryDocument14 pages2561 Rubber Based Adhesives For Automobile IndustryKaushik SenguptaNo ratings yet

- NRPU Application Form 2017Document22 pagesNRPU Application Form 2017Muhammad ArslanNo ratings yet

- MME 3518-Powder Metallurgy-1-2Document80 pagesMME 3518-Powder Metallurgy-1-2Mohammed GhisheerNo ratings yet

- BTech (Mechanical With Specialization in Energy Engineering) Curriculum For AY2012-13Document8 pagesBTech (Mechanical With Specialization in Energy Engineering) Curriculum For AY2012-13Akshat GargNo ratings yet

- Statistical and Optimization Techniques For Laundry Portfolio Optimization at Procter GambleDocument19 pagesStatistical and Optimization Techniques For Laundry Portfolio Optimization at Procter GambletyabNo ratings yet

- Diphenylamine and Derivatives in The Environment: A Review: Chemosphere January 2004Document11 pagesDiphenylamine and Derivatives in The Environment: A Review: Chemosphere January 2004Muhammad Taufik MahadikaNo ratings yet

- DR VipinDocument27 pagesDR VipinSam SamayaNo ratings yet

- Specialty Products: Drilling Fluids SolutionsDocument16 pagesSpecialty Products: Drilling Fluids SolutionsBjorn Kjell-eric AsiaNo ratings yet

- Chapter 5: Analytic Techniques: by Julia C. Drees, Matthew S. Petrie, Alan H.B. WuDocument15 pagesChapter 5: Analytic Techniques: by Julia C. Drees, Matthew S. Petrie, Alan H.B. WuTanveerNo ratings yet

- Lecture26 PDFDocument4 pagesLecture26 PDFgautamNo ratings yet

- Synthesis of Aspirin DataDocument3 pagesSynthesis of Aspirin DataAnonymous orNHXM0f0No ratings yet

- CGR 18650cgDocument2 pagesCGR 18650cgKonstantinos GoniadisNo ratings yet

- F. Winterberg - Fusion-Fission-Fusion Fast Ignition Plasma FocusDocument11 pagesF. Winterberg - Fusion-Fission-Fusion Fast Ignition Plasma FocusMutrexczNo ratings yet

- Continuum Electromechanics Cem - 811Document637 pagesContinuum Electromechanics Cem - 811kgrhoads100% (1)

- 6 Nutrition P3aDocument9 pages6 Nutrition P3aSharifah NurainNo ratings yet

- Metalsferrousandnonferrous 131023154745 Phpapp01Document29 pagesMetalsferrousandnonferrous 131023154745 Phpapp01Prasad RaikarNo ratings yet

- Schultz 1987Document18 pagesSchultz 1987Ruiz ManuelNo ratings yet

- Manual CAT4000Document36 pagesManual CAT4000windrider56No ratings yet

- 150ah C20Document2 pages150ah C20movick.25No ratings yet

- (PDF) a General LC-MS - MS Method for Monitoring Potential Β-Lactam Contamination in Drugs and Drug-Manufacturing SurfacesDocument16 pages(PDF) a General LC-MS - MS Method for Monitoring Potential Β-Lactam Contamination in Drugs and Drug-Manufacturing SurfacessppNo ratings yet

- Fluid Power CircuitsDocument176 pagesFluid Power CircuitsMike Fredskilde97% (29)

- Gold Cyanidation PresentationDocument25 pagesGold Cyanidation Presentationsatrioherbirowo100% (3)

- GC-MS Process and LimitationDocument10 pagesGC-MS Process and LimitationSalsabila P WahyudinNo ratings yet

- Itihasher Pathshalay (Moddhojug)Document321 pagesItihasher Pathshalay (Moddhojug)শিবলী আহমেদNo ratings yet

- Chromium Coated Piston Head Liner RingDocument56 pagesChromium Coated Piston Head Liner RingtechfiNo ratings yet