Professional Documents

Culture Documents

USM Vision 1.2

Uploaded by

pokeboy19Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

USM Vision 1.2

Uploaded by

pokeboy19Copyright:

Available Formats

GE

Measurement & Control

NEW USM Vision 1.2

A Total Weld Inspection Solution to Increase

Productivity in New Process Pipework Fabrication

16/128

16/128 16/128

Parallel scanning Linear scan More channels

Introduction Compliance codes

The USM Vision has been developed to meet a market need ASME V

to transition from radiographic inspection to ultrasonic B31.3

inspection in the fabrication of new process pipework for API 1104

the process, water, power generation and oil & gas sectors. ASTM E 2373

Conventional film radiography has long been the preferred B31 Case 181

method of weld inspection in fabrication shops and it Code Case 2235

provides excellent results, which are easy to understand.

EN ISO 17640

However, film radiography is necessarily accompanied EN ISO 10863

by significant restraints, such as safety considerations, Pr EN ISO 13588

chemicals storage, waste disposal, long film development

times, and film archiving. DICONDE

Ultrasonic inspection suffers from none of these restraints

and, although it cannot be used instead of radiography in

every instance, it offers accurate, code-compliant, reliable

and fast data. Unfortunately, this type of inspection

requires a qualified ultrasonics inspector. And highly skilled

ultrasonics inspectors can often be very difficult to find.

NEW USM Vision 1.2

Following user feedback, the scope and functionality of the

USM Vision has been extended. This field-proven, pipe weld

inspection system now features parallel scanning, and

supports 128 element Phased Array Probes. With parallel

scanning, both sides of the weld are scanned in one pass,

effectively doubling productivity. The system also

incorporates the ability to use up to 128 element Phased

Array probes instead of 64 element versions, so that linear

Phased Array scans can now be carried out for pipes of

even greater wall thickness.

USM Vision, the Efficient

Solution to Managing Task

Sharing

The USM Vision provides a cost-effective and elegant

solution to the problem. It allows ultrasonics to be applied

to pipe weld inspection, eliminating the constraints

of film radiography and allows tasks in the inspection

process to be shared among non-ultrasonics specialists

(e.g. radiography inspectors with minimum ultrasonics

training) and highly qualified ultrasonics experts, so that

optimum use is made of the time of all levels of NDT

technicians. The highly qualified ultrasonic personnel

can focus on the task for which he is most valuable, like

set-ups validation and data analysis, and manage several

UT trained operators doing inspection plan creation,

calibration and field data acquisition.

And all this with no compromise on accuracy and reliability

of data and a significant improvement in productivity.

USM Vision Rationalizes

Inspections Plan Creation and Validation

Creating an Inspection Plan

No ultrasonic knowledge is required to create and populate

an inspection plan. All that is required is to describe the

inspection task, and enter the basic information such as site

location, number of welds, pipe diameter, thickness and

material, weld preparation, procedure and method to be

used. The software will then calculate and generate all the UT

set-ups required to perform TOFD and/or Phased Array

inspection of the specified welds. These set-ups include:

selection of the correct probes and wedges from a database

positioning of the probe

positioning of the required UT parameters

to perform an efficient inspection according to the standard

and code-based procedure selected.

Validating an Inspection Plan

A technician qualified in ultrasonics must then validate the

set-ups. Each weld is split in one or several passes with TOFD

or PA technique. The UT specialists have to validate these

passes by using a ray tracing tool. They also have the ability

to modify them by selecting another probe from the data-

base, adjusting the probe(s) position(s). When all the passes

are validated, the inspection plan can be exported to the

acquisition unit.

NEW The import and export function for

inspection plan files is simplified so that the

inspection plan can be exported without forwarding the

entire database.

s the Weld Inspection Pro

Calibration and Data Acquisition

Calibration

As the data acquisition is 100% guided, this task doesnt

require a highly trained UT operator. The technician merely

selects an inspection plan, and is then guided through a

step-by-step process from the probe and wedge validation,

UT calibration (PCS and sensitivity calibration for TOFD,

element and wedge check, DAC / TCG curve recording for PA),

scanner settings and calibration.

Acquiring the Inspection Data

The inspection data for each weld, is simply acquired by

following the inspection plan and the different TOFD and PA

passes calculated by the IPC. After each pass the software

will propose the next weld or pass to be inspected helping the

operator to use the best, most productive way in the

inspection plan. Data can be exported, for one pass, one weld

or for the complete inspection plan, for analysis and reporting

at any time during the inspection.

NEW For Phased Array, the system can inspect the

two sides of the weld with one physical scan

which effectively doubles productivity. The instrument can

now perform inspection with linear Phased Array scans as

recommended in some codes. USM Vision 1.2 can handle

probes up to 128 elements which means that pipes of

greater wall thickness can be inspected with linear scans.

Photo Countesy of Fabricom

ocess Ensuring Efficient an

Data Analysis and Reporting

Analyzing the Inspection Data

All inspection data is communicated to an analysis station

using the Rhythm software platform. Here the suitably

qualified ultrasonic inspector can review and analyze the

inspection data, using advanced analysis tools such as real

time, volume-corrected imaging, as well as conventional

digital tools features for image analysis, enhancement and

measurement. In addition, a variety of measurement and

viewing tools is contained within the analysis software.

Reporting

Expert interpretation of inspection results can be provided

immediately and reports can be printed off in real time.

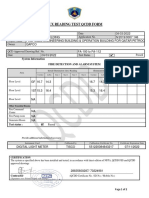

This offers a very fast assessment of the weld status as GEInspectionTechnologies

feedback for weld repairs.

(ServiceCompanyinchargeoftheinspection)

Inspection plan name Inspection Plan Number 1

Reference of the inspection 12345

(PO number)

Customer name GEIT

Customer address Address

Site location/name Site 1

Inspection plan validated by:

Operator 1 Level III 15/07/2010

Operator Level Date Validation Signature

Report validated by:

Operator 2 Level III 16/07/2010

Operator Level Date Validation Signature

Report reviewed by:

Operator 3 Level III 16/07/2010

Operator Level Date Validation Signature

Reference Procedure Status

(Line/Weld nbr)

Plate20mmLOF DEM8inW60LW RESCAN

Id Defect 1 Length (along index 2 mm

axis)

Real diameter 25.000000 Pass 1 0 mm

Pass Position (along depth

Real Thickness 19.050 MM axis)

Type of defect LOF Length (along depth 6 mm

axis)

Position (along 110 mm Maximum amplitude in 120 %

scan axis) PA

Length (along 25 mm Status Rejected

Pass scan axis)

PassName 115 Status Acquired Position (along 5 mm Comment To be repaired

index axis)

KIS instrument

Id Defect 2 Length (along index 2 mm

axis)

Pass 2 Position (along depth 0

axis)

Type of defect LOF Length (along depth 6 mm

axis)

Position (along 110 mm Maximum amplitude in 120 %

scan axis) PA

Length (along 25 mm Status Rejected

scan axis)

sition (along 5 mm Comment To be repaired

index axis)

nd Accurate Inspection

Archive and Share Data

Archiving the Inspection Data

The inspection data are saved in the Rhythm Archive

software, allowing to save the raw data with necessary tags.

Input and retrieval of information is quick and easy. This

accepts data from any number of LAN-connected, remote

Rhythm Review workstations and stores them using various

compression techniques to save storage space without

sacrificing data quality

Sharing the Inspection Data

All inspection data can be shared with other interested

parties, either as enhanced imagery or as raw data. It can be

transmitted to other Rhythm Review stations for third party

verification.

Turning information into intelligence and

sharing inspection data across experts and

locations with ease!

Scope of Applications

The USM Vision has been developed to simplify and to democratize the Ultrasonic

Inspection according to the international codes and standards through:

Optimizing the use of specialized inspection personnel

Increase productivity

Reducing the current weld inspection radiographic constraints

Reducing the ultrasonic weld inspection complexity

USM Vision is especially dedicated to:

Energy construction industry

Carbon steel and Stainless steel pipes

Covers the Normalized Pipe Size (NPS) in automatic setup

- Diameters from 73 mm (2.875) up to 1219 mm (48)

- Thicknesses from 6 mm (1/4) up to 50 mm (2)

- Higher thickness and diameter in manual setting

Circumferential welds

Short exit point wedges and short scanner arms available

for pipe to elbow and pipe to flange Photo Countesy of Fabricom

Photo Countesy of Fabricom

USM Vision a Total Weld Inspection Solution

The USM Vision is supplied as a complete weld inspection solution, consisting of:

IPC software for creation of the inspection plan and automatic generation of the UT set-ups.

Integrate a database with procedures based on international codes and standards and ray tracing

functionality for the validation of the UT parameters.

The USM Vision hand-held flaw detector, featuring:

Conventional channel, TOFD, 16/64 or 16/128 Phased Array, Real Time Volume Corrected

Images, A-scan saving

Unique user interface to operate a pointing device by two trackballs

Ease of use for untrained operators

26,5 cm (10.4) color touch screen with 1024 x 768 resolution

Weighs only 4 kg (8.8 lb)

Hot swap battery exchange for continuous operation

Robust, rubber housing, IP 54

Dimensions:

Length top: 367 mm (144.4)

Length bottom: 310 mm (122)

Width: 250 mm (98.4)

Heigth: varying from 60 to 100 mm (23.6 to 39.3)

Modern PC interfaces including USB, Ethernet, wireless connection (WiFi)

IPC and analysis software can be operated from the USM Vision

Transport case

An encoder-scanner, designed for TOFD and Phased Array manual acquisition including:

Manual handle cart with magnetic wheels

Optional chain for the inspection of pipes

Arm with probe and center line pointer holders, forks for TOFD and PA wedges

Transport case

Set of probes and wedges relating to the specified pipe ranges and inspection codes

Rhythm Review 4.2 software for the analysis and reporting Windows 7

Optional Rhythm modules for archiving, sharing and advance reporting functionalities

Regional Contact Information

North America Europe Asia

50 Industrial Park Road Robert-Bosch-Strasse 3 5F, Building 1, No.1 Huatuo Road,

Lewistown, PA 17044 50354 Huerth Zhangjiang High-Tech Park,

USA Germany Shanghai 201203

China

+1866 243 2638 (toll free) +49 2233 6010

+1 717 242 0327 +86 800 915 9966 (toll-free)

+86 (0) 21-3877 7888

www.geinspectiontechnologies.com

GEIT-20058EN (01/12)

2012 General Electric Company. All Rights Reserved. Specifications are subject to change without notice. GE is a registered trademark of General Electric Company. Other company or product names

mentioned in this document may be trademarks or registered trademarks of their respective companies, which are not affiliated with GE.

You might also like

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- NDT Magnetic Particle Inspection ProcedureDocument7 pagesNDT Magnetic Particle Inspection ProcedureCharlesNo ratings yet

- OQ AHU P02Document147 pagesOQ AHU P02santosh yadavNo ratings yet

- NDT-SA-SATORP-UTT-60-RV00 Date-15 Aug-2023Document10 pagesNDT-SA-SATORP-UTT-60-RV00 Date-15 Aug-2023Md Abu Hanif RajuNo ratings yet

- Air Balance Test QCDD FormDocument2 pagesAir Balance Test QCDD FormSamir AminNo ratings yet

- QC Welding Inspector NotesDocument26 pagesQC Welding Inspector NotesSohail Aziz Ahmad MalikNo ratings yet

- Shic A 0005Document2 pagesShic A 000501095902062ahmedNo ratings yet

- Wheel Inspection ReportDocument3 pagesWheel Inspection Reportsudipta dasNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 22-Jan-18 MechaneeshNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- Saudi Aramco Radiography ChecklistDocument15 pagesSaudi Aramco Radiography ChecklistAnonymous hBBam1nNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 17-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 17-Mar-16 MechGOSP3 QC Mechanical100% (1)

- Level Switch Data SheetDocument3 pagesLevel Switch Data SheetNikhil KarkeraNo ratings yet

- Inspection and Quality Control PlanDocument3 pagesInspection and Quality Control Planmanunited unitedNo ratings yet

- Bis-Dk-Ut 1152 - 1200-24-VC01Document6 pagesBis-Dk-Ut 1152 - 1200-24-VC01TomasPavlovicNo ratings yet

- Table 5: Requirements For Drill Pipe Inspection ReportingDocument1 pageTable 5: Requirements For Drill Pipe Inspection ReportingJosue FishNo ratings yet

- Iso Work InstructionsDocument115 pagesIso Work InstructionsEkondroNo ratings yet

- Inimize Your Cost For Phased Array and TOFDDocument12 pagesInimize Your Cost For Phased Array and TOFDJhoseph RoqueNo ratings yet

- Other Requirement: BA-0496 Refap1 Project Disengager / Stripper R-300002, R-300003Document7 pagesOther Requirement: BA-0496 Refap1 Project Disengager / Stripper R-300002, R-300003GLEDSONNo ratings yet

- Ope LuxDocument2 pagesOpe LuxAhmed abouelazayemNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 24-Mar-16 MechSajid ShaikhNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 30-Apr-13 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 30-Apr-13 MechPradeepNo ratings yet

- Ilevil 3 AW Company Standards 1Document11 pagesIlevil 3 AW Company Standards 1George Cunha LimaNo ratings yet

- Satr A 2002Document2 pagesSatr A 2002ansar aliNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test Report: Mech-Calibration Test Report-Pressure Recorder SATR-A-2004 25-May-05Document1 pageSaudi Aramco Test Report: Mech-Calibration Test Report-Pressure Recorder SATR-A-2004 25-May-05Anonymous S9qBDVkyNo ratings yet

- Audit ReportDocument9 pagesAudit ReportVIVEK100% (1)

- Client:: Olectra Greentech LTDDocument1 pageClient:: Olectra Greentech LTDnareshNo ratings yet

- Satr A 2002Document2 pagesSatr A 2002ramshad k aNo ratings yet

- 00257650-0000-33EG-0001 - Rev PB - Attachment A - ITP ExampleDocument4 pages00257650-0000-33EG-0001 - Rev PB - Attachment A - ITP ExampleSubrata Das100% (1)

- ITP For False Ceiling Works of BuildingsDocument4 pagesITP For False Ceiling Works of BuildingsYay B. Gico0% (1)

- Maintenance Protocol Siemens Iconos R200Document21 pagesMaintenance Protocol Siemens Iconos R200cankutayhotmail.comNo ratings yet

- SATR-A-2002Document2 pagesSATR-A-2002razzak.me.enggNo ratings yet

- Report-1683-1 B1 25mm 14 10 2020Document7 pagesReport-1683-1 B1 25mm 14 10 2020sakthi velNo ratings yet

- Powder Coating (On Steel) Audit Check Sheet - 23.02.2021 - Rev 1.0Document7 pagesPowder Coating (On Steel) Audit Check Sheet - 23.02.2021 - Rev 1.0N. GuptaNo ratings yet

- Inspection and Testing Plan: (Insert Project Name)Document10 pagesInspection and Testing Plan: (Insert Project Name)vin ssNo ratings yet

- Calibrate Pressure GaugeDocument1 pageCalibrate Pressure GaugeAnonymous S9qBDVkyNo ratings yet

- Itp-22!11!1 Rev.0 en 10219-Bare Pipe Somatm SaDocument12 pagesItp-22!11!1 Rev.0 en 10219-Bare Pipe Somatm Samahmut gelNo ratings yet

- PIPING INSPECTION REQUESTDocument10 pagesPIPING INSPECTION REQUESTAnand NarayananNo ratings yet

- In-Line Eddy Current Testing of Wire Rod: Technical InformationDocument7 pagesIn-Line Eddy Current Testing of Wire Rod: Technical InformationBK ICTNo ratings yet

- Construct Facilities Support MH-60R AircraftDocument3 pagesConstruct Facilities Support MH-60R AircraftAlvene TagocNo ratings yet

- SAUDI ARAMCO RADIOGRAPHIC TESTING INSPECTIONDocument24 pagesSAUDI ARAMCO RADIOGRAPHIC TESTING INSPECTIONmunnaNo ratings yet

- Request For Inspection: Client: Engineer: ContractorDocument1 pageRequest For Inspection: Client: Engineer: ContractorAouse YasinNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 22-Jan-18 MechaneeshNo ratings yet

- RFI FormatDocument1 pageRFI FormatVipin Kumar ParasharNo ratings yet

- Standard Qap Rev.00Document2 pagesStandard Qap Rev.00Suraj GuptaNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 24-Mar-16 MechSajid ShaikhNo ratings yet

- Ultrasonic Weld Exam ProcedureDocument7 pagesUltrasonic Weld Exam ProcedureRami KsidaNo ratings yet

- CA 1012134 Agc A01 A01 MSA GRR 3. Process Bracket AssemblyDocument25 pagesCA 1012134 Agc A01 A01 MSA GRR 3. Process Bracket AssemblyEnano000No ratings yet

- Client:: Sritech Electronics Systems PVT LTDDocument2 pagesClient:: Sritech Electronics Systems PVT LTDESHWAR CHARYNo ratings yet

- Painting of Structure Piping Equipment 22Document5 pagesPainting of Structure Piping Equipment 22Saurabh Kumar VermaNo ratings yet

- B00-MT-PRO-00045 - 0 RTR Validation ReportDocument16 pagesB00-MT-PRO-00045 - 0 RTR Validation ReportManik KNo ratings yet

- Bis-Dk-Ut 1149 - C081-Ip2022-Na-1Document6 pagesBis-Dk-Ut 1149 - C081-Ip2022-Na-1TomasPavlovicNo ratings yet

- Checkoutmac 500Document3 pagesCheckoutmac 500r.ashokskpNo ratings yet

- 3.9m & 7.4m TT2 Floor Scoop Bath Report1Document2 pages3.9m & 7.4m TT2 Floor Scoop Bath Report1MAHENDRANo ratings yet

- VT-WIN II BrochureDocument8 pagesVT-WIN II Brochurequantum_quantumNo ratings yet

- 10 606000 1100001344 Asb Civ Itp 000018 - 02Document10 pages10 606000 1100001344 Asb Civ Itp 000018 - 02Mahmudul Alam kanakNo ratings yet

- Shic A 0008Document3 pagesShic A 000801095902062ahmedNo ratings yet

- Inspection Report: 150 MW Dhamangaon Solar Project, MaharashtraDocument6 pagesInspection Report: 150 MW Dhamangaon Solar Project, Maharashtrakaushik21185No ratings yet

- Papers on the field QoS Measurement Of Services in mobile networks Using Aggregation MethodFrom EverandPapers on the field QoS Measurement Of Services in mobile networks Using Aggregation MethodRating: 4 out of 5 stars4/5 (2)

- GE Application Note - Mentor UT - Two Axis Scanner For Corrosion ApplicationDocument1 pageGE Application Note - Mentor UT - Two Axis Scanner For Corrosion Applicationpokeboy19No ratings yet

- GE - Robotic Fast UTDocument4 pagesGE - Robotic Fast UTpokeboy19No ratings yet

- Corrosion Scanning With HandHeld Array ProbeDocument1 pageCorrosion Scanning With HandHeld Array Probepokeboy19No ratings yet

- Gea33478 Palm Flat Scanner Brochure r2 HRDocument4 pagesGea33478 Palm Flat Scanner Brochure r2 HRpokeboy19No ratings yet

- Gea33447 Palm Scanner Brochure r3hr Nocrop-1Document4 pagesGea33447 Palm Scanner Brochure r3hr Nocrop-1pokeboy19No ratings yet

- 18-Gem-465 Mentor Ut Infographic WebDocument1 page18-Gem-465 Mentor Ut Infographic WebMarco MoncerrateNo ratings yet

- GE - Robotic Fast RVIDocument6 pagesGE - Robotic Fast RVIpokeboy19No ratings yet

- GE Lewistown Technology Solutions Center Welcome PacketDocument8 pagesGE Lewistown Technology Solutions Center Welcome Packetpokeboy19No ratings yet

- GE - Phasor Xs PosterDocument4 pagesGE - Phasor Xs Posterpokeboy19No ratings yet

- Flat Palm Scanner - GEDocument4 pagesFlat Palm Scanner - GEpokeboy19No ratings yet

- Phoenix DS - C Clamp Encoder PDFDocument2 pagesPhoenix DS - C Clamp Encoder PDFpokeboy19No ratings yet

- Ease of Use For Portable Ultrasonic Test InstrumentsDocument4 pagesEase of Use For Portable Ultrasonic Test Instrumentspokeboy19No ratings yet

- Test Rails More Thoroughly with the Modified GE Rail Tester SPG 2Document2 pagesTest Rails More Thoroughly with the Modified GE Rail Tester SPG 2pokeboy19No ratings yet

- Krautkramer Usm 36 BrochureDocument4 pagesKrautkramer Usm 36 Brochuresentamil vigneshwaran100% (1)

- Krautkramer Usm 36 BrochureDocument4 pagesKrautkramer Usm 36 Brochuresentamil vigneshwaran100% (1)

- Flawtech Catalog PDFDocument34 pagesFlawtech Catalog PDFpokeboy19100% (1)

- Portable LED ViewerDocument2 pagesPortable LED Viewerpokeboy19No ratings yet

- GE - Palm Scanner PipeDocument4 pagesGE - Palm Scanner Pipepokeboy19No ratings yet

- Flat Palm Scanner - GEDocument4 pagesFlat Palm Scanner - GEpokeboy19No ratings yet

- Weld Inspection Guide for TOFD, Phased Array, and Manual ScannersDocument2 pagesWeld Inspection Guide for TOFD, Phased Array, and Manual Scannerspokeboy19No ratings yet

- Zetec - Topaz 16Document6 pagesZetec - Topaz 16pokeboy19No ratings yet

- Mentor Visual IQ PosterDocument1 pageMentor Visual IQ Posterpokeboy19100% (1)

- Flat Palm Scanner - GEDocument4 pagesFlat Palm Scanner - GEpokeboy19No ratings yet

- MVIQ Commercial PDFDocument10 pagesMVIQ Commercial PDFpokeboy19No ratings yet

- Mentor EM Eddy Current Flaw DetectorDocument8 pagesMentor EM Eddy Current Flaw Detectorpokeboy19No ratings yet

- Medidor de Espesores Dm5e PDFDocument4 pagesMedidor de Espesores Dm5e PDFsolrac4371No ratings yet

- Medidor de Espesores Dm5e PDFDocument4 pagesMedidor de Espesores Dm5e PDFsolrac4371No ratings yet

- Mentor EM Eddy Current Flaw DetectorDocument8 pagesMentor EM Eddy Current Flaw Detectorpokeboy19No ratings yet

- Medidor de Espesores Dm5e PDFDocument4 pagesMedidor de Espesores Dm5e PDFsolrac4371No ratings yet

- Audit-Free Cloud Storage via Deniable Attribute-based EncryptionDocument15 pagesAudit-Free Cloud Storage via Deniable Attribute-based EncryptionKishore Kumar RaviChandranNo ratings yet

- CPG 0Document20 pagesCPG 0muhdshafiq12No ratings yet

- NT11 NT21: Programmable TerminalsDocument4 pagesNT11 NT21: Programmable TerminalsSetija BudiNo ratings yet

- NSFAS Laptop FormDocument2 pagesNSFAS Laptop FormKagiso China'män NtsaneNo ratings yet

- 2020 LeanIX WhitePaper - Definitive Guide To Business CapabilitiesDocument14 pages2020 LeanIX WhitePaper - Definitive Guide To Business CapabilitiesCarlosBritoVonBodenburgNo ratings yet

- Ez Publish Basics PDFDocument2 pagesEz Publish Basics PDFKashiaNo ratings yet

- H264Document6 pagesH264acinsaNo ratings yet

- VisionDocument219 pagesVisionestevezcNo ratings yet

- Code of Ethics - UPDocument5 pagesCode of Ethics - UPhannah marvillaNo ratings yet

- 3G Counter LevelDocument27 pages3G Counter LevelDjungdjunan ArdyNo ratings yet

- 04 Handout 1 (Feedback)Document11 pages04 Handout 1 (Feedback)Kathleen Anne MendozaNo ratings yet

- PLC and SCADA Lab Experiments for Instrumentation CourseDocument4 pagesPLC and SCADA Lab Experiments for Instrumentation CourseAnonymous FKMfvCbNo ratings yet

- CV Project Manager Shivam SaxenaDocument6 pagesCV Project Manager Shivam SaxenaNedlloyd IndiaNo ratings yet

- Manage MySAP CRM Internet Sales 2.0BDocument38 pagesManage MySAP CRM Internet Sales 2.0BSuresh ReddyNo ratings yet

- Release Notes Sap 2000 V 2331Document8 pagesRelease Notes Sap 2000 V 2331sami touatiNo ratings yet

- BCAS Cicular - In-Line X-Ray - 11-2017Document26 pagesBCAS Cicular - In-Line X-Ray - 11-2017agarwalabhay3_991072No ratings yet

- IISP 2020 - B K RoyDocument37 pagesIISP 2020 - B K RoyHimangshu DekaNo ratings yet

- Arm Processor Based Speed Control of BLDC MotorDocument4 pagesArm Processor Based Speed Control of BLDC MotorUday WankarNo ratings yet

- Angelicum Immanuel Montessori - ThesisDocument60 pagesAngelicum Immanuel Montessori - ThesisIan GuevarraNo ratings yet

- Scholarship Management System: Team Members: BM10518, BM10527, BM10545 Class: II-MCADocument30 pagesScholarship Management System: Team Members: BM10518, BM10527, BM10545 Class: II-MCAJoe Nishanth100% (3)

- Introduction to Artificial Intelligence and its Applications in CybersecurityDocument2 pagesIntroduction to Artificial Intelligence and its Applications in CybersecurityritsNo ratings yet

- Digitalization and Its Influence On Business Model InnovationDocument18 pagesDigitalization and Its Influence On Business Model InnovationNegera AbetuNo ratings yet

- Innovating To Create IT-Based New Business Opportunities at UPSDocument17 pagesInnovating To Create IT-Based New Business Opportunities at UPSjieminaNo ratings yet

- HBL Tower Mechanical Floor EssayDocument3 pagesHBL Tower Mechanical Floor EssayHammadNo ratings yet

- 16 - Incident Response, Disaster Recovery & Business Continuity Section PDFDocument10 pages16 - Incident Response, Disaster Recovery & Business Continuity Section PDFnallamalli subramanyamNo ratings yet

- Test Logic Insertion For Optimization of Testing Parameters On Lower Technology NodeDocument6 pagesTest Logic Insertion For Optimization of Testing Parameters On Lower Technology NodeshaguftaNo ratings yet

- The Future History of Dissidence, Denis SenerDocument4 pagesThe Future History of Dissidence, Denis Senerdenissener100% (1)

- JAW Diagnostics Heat-up Test CheckDocument1 pageJAW Diagnostics Heat-up Test CheckDirk JonesNo ratings yet

- SCHEDULINGDocument29 pagesSCHEDULINGkishoreNo ratings yet

- Manual de ServicioDocument192 pagesManual de ServicioCrispin CrispianoNo ratings yet