Professional Documents

Culture Documents

Energy Command 20 Manual

Uploaded by

danialCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Energy Command 20 Manual

Uploaded by

danialCopyright:

Available Formats

Operation and Installation Manual

Energy Command 20

Printed in U.S.A. 900-0543 12006

(Cummins PN 018-01043 Rev 1.7a)

Redistribution or publication of this document

by any means, is strictly prohibited.

Operation and Installation Manual

PN 018-01043 Rev 1.7a

Energy Command 20

General

The Energy Command 20 (EC-20) is a Generator Safety Precautions

Controller that allows manual starting and stopping of Exposure to carbon monoxide, moving parts, and

Onan Diesel, Gas oline, and Liquid Propane (LP) engine

electricity hazards is possible.

driven AC generators (referred to in this manual as a

genset). EC-20 provides system information such as !!WARNING!!

the battery state-of-charge as well as key operational

information such as genset service and fault messages.

CARBON MONOXIDE is deadly! MOVING

PARTS and ELECTRICITY can cause severe

This system is only for use with Onan Recreational personal injury or death. To reduce exposure

Vehicle genset (Quiet Diesel gensets, and to these hazards, do not operate the genset

Gasoline/LP gensets). when:

Sleeping in vehicle, unless vehicle has a

For personal safety and to avoid equipment

damage;

working CARBON MONOXIDE detector

Thoroughly read and understand this When vehicle is parked in garage or

Operation and Installation Manual before confined space

using or installing.

The E C-20 should be installed by qualified Servicing batteries

persons following wiring and installation Servicing electrical appliances

details provided in this Operation and

Installation Manual Fueling vehicle.

If these instructions conflict with the genset Before storing or servicing, disable genset by

manuals, the genset manuals should take disconnecting battery or genset remote harness.

precedence.

Keep these instructions with the genset

manuals.

Page 1

Redistribution or publication of this document

by any means, is strictly prohibited.

OPERATION PANEL QUICK REFERENCE

START/STOP: Works exactly like the

genset switch. If the genset switch has a

run light and flashes diagnostics, the EC- UP/DOWN: This key is

used to scroll through

20 run light will also be on when the

genset is running, flash during preheat, display choices and

change values that can

and flash genset fault messages.

be SET.

ENTER: This key is used to

store values that have been

changed, and to respond to

display commands.

SET: This key is used to

display and change

settable values.

Page 2

Redistribution or publication of this document

by any means, is strictly prohibited.

Operation of the Energy Command 20

Overview Using the Displays

This section describes how to use the Energy See Figure #1 Main Display Map.

Command 20 (E C-20). The Quick Reference

page defines key locations and Figures 1, and 2 House Battery Charge Level Indicator

are the display screen flow charts. The house battery charge level indicator uses both

short and long term voltage trends to determine

Manual Genset Operation the battery level. It is intended as a guide to the

state-of-charge (SOC) of the battery and its ability

STOP/START Switch to sustain the load.

The Energy Command 20 (EC-20) START/STOP

switch is used to manually start and stop the

genset. This switch functions exactly like the

House Battery Voltage

The house battery voltage can be used to assess

stop/start switch located on the genset.

the performance of the charging system and to

The EC-20 START/STOP switch has a red estimate the battery SOC. To estimate battery

SOC, no loads should be on and the battery

backlight to indicate the genset is running. If the

genset is equipped with diagnostics the EC-20 will should not be charging. Ideally, the battery will

also flash fault messages. It will also decode the have rested in this state for 24 hours. Letting the

battery rest for 30 minutes will give an idea but the

flashing fault message and display a text fault

message. SOC estimate will be less accurate.

Open Circuit Voltage vs. State -of-Charge

The genset may be started using the 12 Volt Batteries of Various Types

START/STOP switch even if there is no power to

the EC-20. Once the genset is running the E C-20 State of Battery Electrolyte Type

display will turn on. Charge Liquid AGM Gelled

100% 12.6 12.9 12.8

Default Display 75%

50%

12.4

12.2

12.7

12.4

12.6

12.3

The House Battery Voltage and the charge level 25% 12.0 12.0 12.0

indicator are displayed on power up. After 10 0% 11.8 11.8 11.8

minutes with no key presses the backlight is

turned off to save power. Touch any key to turn

the backlight on.

Engine (Chassis) Battery

If a separate engine battery is wired to the E C-20

it is shown in the ENGINE Bat V display. There is

Using the Keys no display if this feature is not wired. This is an

UP/DOWN Key optional feature.

UP/DOWN key is used to navigate through the

display menu and to change values or parameters SERVICE IN Display

that can be set by the user. If the UP/DOWN key The SERVICE IN display is a countdown service

is held the display will scroll through the menu. hour meter that indicates the genset next required

servi ce interval. To determine specific service

SET Key items see the genset manual. When the service

SET is used to start the process of changing interval has elapsed the display alternates as

values that can be set by the user. shown below.

ENTER Key SERVICE ENTER to

ENTER is used to store a value that has been

changed. It is also used to ENTER the SETUP &

DUE Reset

INFO DISPLAYS. The ENTER key may also be

required to exit a screen or to acknowledge an Display Alternates

action. Press ENTER to Reset

Service Hour-Meter

Page 3

Redistribution or publication of this document

by any means, is strictly prohibited.

The SERVICE DUE message is displayed as soon

as the service interval has elapsed. The

UP/DOWN key still allows navigation through the

main displays and all functions still work. After

the genset is serviced navigate to the SERVICE

DUE message and ENTER to reset the service

interval hour-meter.

If the genset is serviced prior to the next service

reminder, go to the SERVICE IN display and press

SET, press ENTER to reset the service interval

hour-meter.

The SERVICE IN display is also used to display

genset faults and errors that may occur. If a fault

or error has occurred, it will be displayed even if it

no longer exists. When any key is pressed the

message will be cleared.

The last fault message may be displayed by

pressing the STOP switch three times. See the

genset operating manual for details on the error

codes and messages.

Genset Hour-meter

The genset hour meter displays the total elapsed

time the genset has run since the EC-20 was

installed. If the EC-20 is installed on an existing

generator, see the SETUP section of this manual

to adjust the hour meter.

Page 4

Redistribution or publication of this document

by any means, is strictly prohibited.

Setting Up and Testing the Energy Command 20

key is used to navigate through the available

displays. Use the ENTER To Exit display to

Overview continue through the previous displays or:

This section describes how to Setup and Test the EC-

20. Before using the E C-20 for the first time check

to be sure that the unit is setup appropriately for the

SYSTEM INFO Display

system. Also see Figures #1-4.

VERSION Display

Setting GEN TYPE Is Required The VERSION display shows the version control

The very first time the EC-20 is turned on (power number for EC-20. Should it be necessary to

contact customer service this number will help

applied) an initial setup procedure begins. The E C-

20 requires setup of the GEN TYPE. determine the specific configuration of your E C-20.

The genset type sets the Service Interval for service SETUP GENSET Displays

messages. The first service interval is 50 hours for The SETUP GENSET displays are used to select

all models. See SETUP GENSET to change the the type of genset used with the EC-20 and to adjust

genset type after first power up. the genset hour meter.

Setting GEN TYPE SETUP GENSET Display

Genset type must be selected (SET) at first power To change the GEN TYPE after initially setting

up. navigate to the SETUP & INFO display and press

ENTER. Now navigate to the SETUP GENSET

GEN TYPE display and press ENTER. The GEN TYPE will be

displayed. Press SET, the display will flash. Use

SET NOW the UP/DOWN key to select the GEN TYPE and

For Auto press ENTER when the appropriate type is

displayed. The GEN TYPE is stored in permanent

GEN TYPES TABLE 1 memory and will not have to be changed unless the

GEN TYPE MODEL Service In EC-20 is installed on a different type genset.

QD 10/12 Quiet Diesel 250 hours

QD 7.5/8 Quiet Diesel 150 hours SET Gen Hour Display

QD 5.5 Quiet Diesel 150 hours If the EC-20 is installed on an existing genset check

GAS/LP Marquis, Microlite, 150 hours its hour-meter and record the reading. ENTER the

Micro Quiet, SETUP & INFO menu and navigate to the SETUP

CampPower GENSET display. Press ENTER and use the

DOWN key to select the SET gen hours display.

The words SET NOW will be flashing. Use the Press SET. The next display says, ENTER to

UP/DOWN key and the table above to select the unlock. This prevents unauthorized changes to the

correct genset type. Press ENTER when the correct hour-meter. Press ENTER to continue.

genset is displayed.

The display will flash. Hold down the UP/DOWN key

and scroll until the left most digit matches the

SETUP & INFO Displays desired value. Release the UP/DOWN key and wait

The SETUP & INFO displays are used to tailor the four seconds for the underline to move to the next

EC-20 to the installed genset. Refer to Figure #1 for digit to the right and scroll t o its desired value. Set

the various main displays that are available. To each successive digit to the right until the correct

access the SETUP & INFO displays use the genset hours are displayed press ENTER. The

UP/DOWN key to navigate to the SETUP & INFO value is stored in permanent memory and will not

display and press ENTER. (See Figure #2: Setup & have to be changed unless the E C-20 is installed on

Info Displays) The UP/DOWN key now allows a different genset. The hour-meter in the E C-20 and

scrolling through the various choices. To access a the hour meter at the genset may differ slightly over

choice press the ENTER key. Again the UP/DOWN time due to small differences in accuracy.

Page 5

Redistribution or publication of this document

by any means, is strictly prohibited.

Installing the Energy Command 20

Overview Specifications

This section describes how to install the Energy Operating -20 to 70 degrees C

Command 20 (E C-20). Temperature: (-4F to 158F)

Storage -40 to 70 degrees C

General Temperature: (-40F to 158F)

This system is only for use with Onan Recreational Battery System: 12 Volt DC

Vehicle genset (Quiet Diesel gensets, and Voltage Range: 8 35VDC

Gasoline/LP gensets). Typical Current 47mA @ 12V

Draw:

The control circuitry is a 3-wire ground to start/stop L x W x D: 80.98 x 130.12 x 30.48 mm

type. Before installing, refer to the System Diagram, (3.188 x 5.125 x 1.20 inches)

Figure 4, and select the appropriate wiring diagram,

Figures 5 - 7, for connection to your genset. Consult INSTALLATION CODES AND

an Onan distributor with any questions.

STANDARDS FOR SAFETY

Appendix A shows the Onan gensets that are The vehicle builder or EC-20 installer bears sole

compatible with the EC-20 and the correct wiring responsibility for the appropriate selection of

figures and harnesses to use for each genset. components, for proper installation and for obtaining

approvals from any authorities having jurisdiction for

!CAUTION! For personal safety and prevention of the installation. EC-20 is suitable for installation in

equipment damage, only experienced personnel accordance with:

should install this system. The installer must wear ANSI A 1192 (NFPA No. 1192)-Standard on

safety glasses and protective clothing necessary Recreational Vehicles

for personal safety. NFPA No.70, Article 551-Recreational

Vehicles and RV Parks

Installation Precautions CAN/CSA-Z240.6.2 Recreational Vehicles

Federal, State and local codes, such as the California

Administrative Code - Title 25 (RV installation), might

CAUTION! Always disconnect a battery charger

also be applicable. Installation codes and

from its AC source before disconnecting the

recommendations may change over time and vary

battery cables. Otherwise, disconnecting the

between countries, states and municipalities. It is

cables can result in voltage spikes high enough

recommended that the standards in Table 2 be

to damage the DC control circuits of the genset.

obtained for reference.

! WARNING! Unexpected starting of the genset

TABLE 2 REFERENCE CODES AND STANDARDS

set while working on it can cause severe <NA for control systems>

personal injury or death. Prevent unexpected or NFPA 70 National Fire Protection

accidental starting by disconnecting the genset National Electric Code Association

battery cables {negative (-) first}, or by 470 Atlantic Avenue

Boston, MA 02210

disconnecting the remote harness at the genset.

ANSI A119.2 (NFPA 1192) Recreational Vehicle

Standard on Recreational Industry Association

!WARNING! Arcing can ignite explosive Vehicles 14650 Lee Road

hydrogen gas given off by batteries, causing Chantilly, VA 22021

severe personal injury. Arcing can occur if the California Administrative Code State of California

Title25, Chapter 3 Documents Section

negative (-) battery cable is connected and a tool P.O. Box 1015

being used to connect or disconnect the positive North Highlands, CA 95660

(+) battery cable accidentally touches the frame

or other grounded metal part of the genset set or CAN/CSA-Z240.6.2 Canadian Standards

vehicle frame. To prevent arcing always remove Recreational Vehicles Association Housing and

the negative (-) cable first, and reconnect it last. Construction Materials Section

I178 Rexdale Blvd

Rexdale, Ontario, Canada

M9W 1 R3

Page 6

Redistribution or publication of this document

by any means, is strictly prohibited.

Wires must be protected from all

OEM Supplied Equipment hot, sharp, and abrasive surfaces.

2) Prepare the chosen location for the genset

controller.

Required for Installation Manufacturer & PN

a. Use scissors to cut out the template.

Mating Connector Housing Tyco/AMP 770583-1

b. Tape the template to the mounting

Pins (Up 16 required) Tyco/AMP 171637-1

surface to be cut out, make sure

2 or 3 5A DC Inline Fuses Installers choice that the template is square or level

Tools with the mounting surface.

Pro-Crimper II W/Die 16-20 Tyco/AMP 189727-1 c. Using a center punch and a

Contact Extraction Tool Tyco/AMP 90760-1 hammer, punch a mark through the

template for each fastener and at

Removing Magnetic Overlay the perimeters of the cutout area.

Insert fingernail beside the Stop/Start Switch and lift d. Remove the template.

gently to remove magnetic overlay. 3) Drill the cutout starter holes at the four

corners of the cutout area. Cut between

them and remove the cutout.

NOTE: Because the location of the genset

controller will vary by installation, the tools

to be used and the cutout material (wood,

metal, plastic, etc.) will differ. Therefore, the

size of the cutout starter holes and the

procedure for cutting between the starter

holes must be determined by the installer.

4) Drill 1/8-inch diameter holes for the control

panel fastening screws.

5) This completes the preparation of the

mounting hole for the control panel. Do not

mount until wiring is complete.

Wiring Guidelines

Installation Procedure The wiring for the E C-20 may be single conductors

This procedure describes the physical installation of of 16-20 AWG wire formed into a wiring harness.

the unit. The wire must be rated for the environment,

temperature, and applicable standards.

Preparing to Mount the EC-20

1) Select a location: Separation from sources of Electro-magnetic

a. Use the Mounting Template and the Interference (EMI): All cabling should be installed in

EC-20 itself to determine an such a way as to comply with the minimum

appropriate location. It should be separation of 5 inches (127 mm) from AC power

located in a visible location where it sources.

can be easily operated.

b. CAUTION! Check the backside Tension: All wires should be free from tension at

(inside) of the chosen location to both ends, as well as over the length of each run.

verify that nothing will interfere with

drilling and cutting the opening for UTP cable bends: UTP cable bends or radii should

the remote, or with the fasteners, be no less than eight times the cable diameter.

harness plug, or enclosure on the

back of the EC-20. !CAUTION! Incorrect connections can damage

c. Determine the feasibility of routing genset controls, remote devices, and interconnect

the control wires from the genset to wiring. Make sure that the leads between the

the remote. Verify that the route of connections are properly connected.

the control wires meets all

applicable national and local codes.

Page 7

Redistribution or publication of this document

by any means, is strictly prohibited.

Wiring Installation Wire #3 START/PREHEAT: This wire supplies the

1. Use wire tags or labels to label each end of start/preheat signal to the genset. It is controlled by

every wire. Use Figures 5 - 7 to determine the STOP/START switch and in the automatic mode

the correct labels and connections. by the EC-20.

2. At the controller end of the harness, insert

the terminated and labeled wires into the Wire #4 NOT USED

correct positions in the connector body. Use

Figures 5 - 7 to determine the correct Wire #5 Switched B+ From Genset: This wire is

positions. switched to the battery positive voltage when the

3. At the genset end of the harness, insert the genset is running. It is used to provide a signal for

terminated and labeled wires into the correct the genset hour meter and to indicate the genset is

positions in the connector body. Use Figures running.

5 - 7 to determine the correct positions.

Wire #6 Genset Status Light: This wire supplies a

Use tie wraps at not less than 20-inch intervals to diagnostic output from the genset that flashes the

keep the wire bundle neat. Use protective sheathing red light in the START/STOP switch to indicate a

where necessary to protect the wires from sharp genset fault. The status light output is decoded by

edges. the EC-20 to display a text fault message.

Genset Harness Installation Power and Voltage Connections

1. Route the harness from the genset to the WIRE #7 8-35VDC Power +: This wire is the

control panel, making sure that the positive power supply to the EC-20. It may be

supplied from the distribution side of the DC

connectors on the harness match the

corresponding connectors at each end. disconnect if it is desirable to have all DC loads off

Wires must be protected from all hot, sharp, when the disconnect is off. It must be protected by a

5A inline fuse located as close to the battery or

and abrasive surfaces.

source as possible. Do not install the fuse until

!CAUTION! When DC wires are run with AC the installation is complete. Install fuse just

wires, electrical induction can occur and prior to testing the installation.

cause operational problems. Route the

controller harness separately from AC load WIRE #8 House Battery Sense 12-24VDC: This

wires. wire supplies the positive sense voltage to the unit

which is displayed as the house battery voltage and

2. Seal any holes where the harness passes is used to determine the house battery state-of-

through bulkheads. charge indicator. It must be connected directly to the

battery. It must be protected by a 5A inline fuse

!WARNING! Exhaust gases are hazardous and located as close to the battery as possible. Do not

my cause severe personal injury or death. Seal install the fuse until the installation is complete.

all holes to prevent the entrance of exhaust Install fuse just prior to testing the installation.

gasses into the vehicle interior.

WIRE #9 Engine Battery Sense 12-24VDC: This

wire supplies the positive sense voltage for the

Connections (Definitions) engine starting battery. This is an optional feature.

This section describes each connection to the EC-20. The engine battery voltage will only be displayed if it

is connected. It must be connected directly to the

Genset Connections battery. It must be protected by a 5A inline fuse

WIRE #1 BATTERY GROUND (NEGATIVE): This located as close to the battery as possible. Do not

wire supplies the ground or negative side of the install the fuse until the installation is complete.

circuit for the EC-20. It must be supplied from the Install fuse just prior to testing the installation.

genset.

WIRES #10 #16 NOT USED

WIRE #2 STOP OUTPUT: This wire supplies the

stop signal to the genset. It is an active low or

grounded output. It is controlled by the

STOP/START switch.

Page 8

Redistribution or publication of this document

by any means, is strictly prohibited.

Final Connections and Testing Meter display and confirm that it is

This section describes the final connections and the operating.

test procedure to verify that the unit has been 7. Stop the genset at the controller and check

installed correctly and is operating properly. the following:

a. The genset stops

1. Plug the genset end of the connector into b. The indicator light in the Start/Stop

the genset. switch turns off.

2. Pass the controller end of the harness c. The Hour Meter stops.

through the cutout for the controller.

3. Plug the controller end of the harness into

the controller.

4. Insert the controller in the cutout hole and

secure it with the screws supplied with the

controller. DO NOT OVER-TIGHTEN

MOUNTING SCREWS, IT MAY DAMAGE

OR DISTORT THE ENCLOSURE.

5. Install the magnetic overlay.

Test Procedure

The following test procedure describes a systematic

method of testing both the installation and operation

of the EC-20. It is highly recommended that the

installer follow these steps:

1. Reconnect the genset negative (- ) battery

cable.

2. Insert the fuse in the fuse holders for: Wire

#7 8-35VDC Power, Wire # 8 House Battery

Sense, and Wire #9 Engine Battery Sense.

3. Refer to Setting Up section of this manual to

select the genset type.

4. Setting the Hour-Meter: If the EC-20 is

installed on a new genset this step may

be skipped. See Setting Up section of this

manual.

5. Start and stop the genset using the

Stop/Start switch located at the genset. This

confirms the genset operation.

6. Start the genset at the EC-20 and check the

following:

a. The indicator light in the controller

Start/Stop switch flashes while the

genset engine is cranking. This

verifies that the diagnostic wiring is

correct. (Only for units with

diagnostics.)

b. Genset starts and continues to run.

c. The indicator light in the Start/Stop

switch remains illuminated when the

genset is running.

d. Use the Up/Down Switch to the right

of the display to scroll to the Hour

Meter display and confirm that it is

operating.

e. Use the Up/Down Switch to the right

of the display to scroll to the Volt

Page 9

Redistribution or publication of this document

by any means, is strictly prohibited.

Troubleshooting !WARNING! Improper service or replacement of

If controller functions do not operate properly, parts can result in severe personal injury, death,

proceed as follows;. and/or equipment damage. Service personnel

1. Does the genset operate correctly from the must be trained and experienced to perform

genset controls? If it does not, the problem electrical and/or mechanical service.

is in the genset, not the EC-20 controller.

See the genset Operator, Installation, and Warranty Policy

Service Manuals. . The ONAN limited warranty covers your Energy

2. If the genset operates correctly from the Command 20/30 Control for the first three (3) years

genset controls, Confirm that the correct you own your EC 20/30 if purchased at the same

connection diagram (Figures 5 - 7) was time as an Onan generator. Energy Command

used, then check EC 30 wiring connections. 20/30 Controllers sold separately are covered for 90

3. Confirm that the correct voltages are present

days.

on each terminal.

4. Check all terminal connections on both ends

For complete Onan Limited Warranty details contact

of the wiring harness. Are harness

your Onan RV Service and Parts dealer or call:

connectors properly joined?

1-800-888-ONAN (1-800-888-6626).

5. Repeat the TEST SYSTEM procedure as

described in this Operation and Installation

Manual.

How to Obtain Customer Service

If you require service, parts, or product literature,

contact the nearest Onan dealer or distributor. To

locate the nearest authorized dealer or distributor, in

the United States or Canada call 1-8OO-888-ONAN

for name and telephone number (This automated

service utilizes touch-tone phones only). By calling

this number, you can also request a directory of

authorized RV servi cing dealers:

RV Sales and Service Directory F-919.

To get service, contact the authorized dealer or

distributor nearest you. Explain the problem and

make an appointment. If you have difficulty in

arranging for service or resolving a problem, please

contact the dealer coordinator or service manager at

the nearest Onan dealer for assistance.

Before calling for service, have the following

information available:

1. The complete model number and serial

number.

2. Software version number, as shown in the

SYSTEM INFO displays.

3. The date of purchase.

4. The nature of the problem.

To enjoy the benefits the product offers requires an

understanding of this manual. If you have ideas for

its improvement we happily accept editorial

comments.

Page 10

Redistribution or publication of this document

by any means, is strictly prohibited.

Page 11

Redistribution or publication of this document

by any means, is strictly prohibited.

Page 12

Redistribution or publication of this document

by any means, is strictly prohibited.

Page 13

Redistribution or publication of this document

by any means, is strictly prohibited.

Page 14

Redistribution or publication of this document

by any means, is strictly prohibited.

Page 15

Redistribution or publication of this document

by any means, is strictly prohibited.

Page 16

Redistribution or publication of this document

by any means, is strictly prohibited.

Page 17

Redistribution or publication of this document

by any means, is strictly prohibited.

Appendix A Onan Gensets for Use With the EC-20/30

QUIET DIESELS

EC-20/30 Service Connection Onan IN

MODEL KW PRODUCT GEN TYPE IN Hours Figure Cable No.

HDCAx 10/12 Quiet Diesel QD 10/12 250 5 044-00076

HDKCx 10/12 Quiet Diesel QD 10/12 250 5 044-00076

HDKAx 7.5/8 Quiet Diesel QD 7.5/8 150 5 044-00076

HDKBx 5.5 Quiet Diesel QD 5.5 150 5 044-00076

GASOLINE/LIQUID PETROLEUM (LP) (with Status Light)

EC-20/30 Service Connection Onan IN

MODEL KW PRODUCT GEN TYPE IN Hours Figure Cable No.

HGJAx 7.0 Marquis GAS/LP 150 6 044-00075

Platinum

HGJAx 5.5 Marquis Gold GAS/LP 150 6 044-00075

KY 4.0/3.6 MicroQuiet GAS/LP 150 6 044-00075

KYD 4.0/3.6 CampPower GAS/LP 150 6 044-00075

GASOLINE/LIQUID PETROLEUM (LP) (without Status Light)

Note 1: This genset model does not support diagnostic fault codes.

EC-20/30 Service Connection Onan IN

MODEL KW PRODUCT GEN TYPE IN Hours Figure Cable No.

KVD 2.8/2.5 CampPower GAS/LP 150 7 044-00074

(Note 1)

KV 2.8/2.5 MicroLite GAS/LP 150 7 044-00074

(Note 1)

25 foot cables available through Onan IN. Cables have mating connectors for EC20/30

and genset, flying leads for other connections.

Also available is an 18 pigtail, part number 044-00077, without the genset connector

that mates to the EC20/30.

Page 18

Redistribution or publication of this document

by any means, is strictly prohibited.

Page 19

Redistribution or publication of this document

by any means, is strictly prohibited.

Page 20

Redistribution or publication of this document

by any means, is strictly prohibited.

Cummins Power Generation

1400 73rd Avenue N.E.

Minneapolis, MN 55432

763-574-5000

Fax: 763-5287229

Cummins and Onan are registered trademarks of Cummins Inc.

Redistribution or publication of this document

by any means, is strictly prohibited.

You might also like

- 288manual Regulator Type A V1.0Document32 pages288manual Regulator Type A V1.0SridarNo ratings yet

- User Manual: Platinum 100A-HV-V3Document1 pageUser Manual: Platinum 100A-HV-V3gaveron69No ratings yet

- Diesel Generator User Manual: Www. Co - ZaDocument11 pagesDiesel Generator User Manual: Www. Co - ZaSteyn VisserNo ratings yet

- APFC RT Instruction ManualDocument4 pagesAPFC RT Instruction Manualpedro perezNo ratings yet

- APFC RT Instruction Manual PDFDocument4 pagesAPFC RT Instruction Manual PDFKamesh MarwadeNo ratings yet

- Renogy Rover 20 A 203040-ManualDocument64 pagesRenogy Rover 20 A 203040-ManualJacques MorvanNo ratings yet

- Power CorrectionDocument4 pagesPower CorrectionHafizudin Md IsaNo ratings yet

- POW M60 PRO Manual 20220512Document17 pagesPOW M60 PRO Manual 20220512Dimaguila, Sir EdwardNo ratings yet

- No Start No CrankDocument11 pagesNo Start No CrankRH100% (1)

- Rover 203040 ManualDocument28 pagesRover 203040 Manualdavid gomezNo ratings yet

- BAsicDocument10 pagesBAsicWahyudi DardjatNo ratings yet

- CMLMPPT Manual V20 - 2 1Document24 pagesCMLMPPT Manual V20 - 2 1Jean-Max RigaudNo ratings yet

- Rutland 1200 Manual E Part 2 01.08.19Document2 pagesRutland 1200 Manual E Part 2 01.08.19RokasBabrauskasNo ratings yet

- Automatic Engine Control Unit Operators ManualDocument11 pagesAutomatic Engine Control Unit Operators ManualAhmad ArpaniNo ratings yet

- Must InverterDocument36 pagesMust InverterBradNo ratings yet

- Kuhse: Operating Instructions Control Unit For Gen. Power SetsDocument25 pagesKuhse: Operating Instructions Control Unit For Gen. Power SetsrafatNo ratings yet

- Axpert Max7.2K Service Manual 20210615Document29 pagesAxpert Max7.2K Service Manual 20210615fritzzag100% (1)

- User Manual: 3.2K / 5.2K 48V I NverterDocument38 pagesUser Manual: 3.2K / 5.2K 48V I NverterAbbasNo ratings yet

- Vortex ManualDocument43 pagesVortex ManualNovan WPNo ratings yet

- Maintenance Instruction For Superlight Sl-2Document15 pagesMaintenance Instruction For Superlight Sl-2Scripd4dogsonlyNo ratings yet

- Corona VetaphoneDocument64 pagesCorona VetaphoneMellissa E Fernando100% (2)

- Neptune Apfc RM Series ManualDocument4 pagesNeptune Apfc RM Series ManualsubhashsomaNo ratings yet

- ALFA 5KVA Service Manual 201509ADocument46 pagesALFA 5KVA Service Manual 201509Asaif ul noorNo ratings yet

- Elite Series 10A 30A PDFDocument23 pagesElite Series 10A 30A PDFttnaingNo ratings yet

- Kea 081 AnlDocument17 pagesKea 081 Anlamin shirkhaniNo ratings yet

- Ps 0500Document4 pagesPs 0500vjvijay88100% (1)

- Ficha Técnica Panel POWER START 0500 PDFDocument4 pagesFicha Técnica Panel POWER START 0500 PDFSeba CarrielNo ratings yet

- Cummins Efc Troubleshooting Guide 2Document2 pagesCummins Efc Troubleshooting Guide 2andrew100% (50)

- Locomotive: Service ManualDocument5 pagesLocomotive: Service ManualGabrielaNo ratings yet

- Manual BlueSolar Charge Controller MPPT 75 10, 75 15, 100 15, 100 20 48V EN NL FR DE ES SE ITDocument100 pagesManual BlueSolar Charge Controller MPPT 75 10, 75 15, 100 15, 100 20 48V EN NL FR DE ES SE ITEdhoy ChaosNo ratings yet

- Yaskawa A1000 Quick StartDocument52 pagesYaskawa A1000 Quick StartAnuragNo ratings yet

- Com01 Manual EnglishDocument89 pagesCom01 Manual EnglishMauricio Rodríguez QuirogaNo ratings yet

- EA230 Manual PDFDocument4 pagesEA230 Manual PDFJulia ArguetaNo ratings yet

- TJ Starting Systems 8B - 1Document10 pagesTJ Starting Systems 8B - 1Art DoeNo ratings yet

- Stadyne GovornorDocument4 pagesStadyne GovornorM. ShaatNo ratings yet

- Gcu 10 Manual enDocument11 pagesGcu 10 Manual enGhassan ABO ALINo ratings yet

- Manual BlueSolar Charge Controller MPPT 100 30 - 100 50 EN NL FR DE ES SEDocument100 pagesManual BlueSolar Charge Controller MPPT 100 30 - 100 50 EN NL FR DE ES SEELBAC0No ratings yet

- Eko Center Manual BlueSolar Charge Controller MPPT 100 30Document100 pagesEko Center Manual BlueSolar Charge Controller MPPT 100 30Bùi ViệtNo ratings yet

- Manual-Control MPPT-75-10-75-15-100-15-100-20Document96 pagesManual-Control MPPT-75-10-75-15-100-15-100-20C.Y. F. VenturaNo ratings yet

- Manual SmartSolar Charge Controller MPPT 75 10 75 15 100 15 100 20 EN NL FR DE ES SEDocument96 pagesManual SmartSolar Charge Controller MPPT 75 10 75 15 100 15 100 20 EN NL FR DE ES SEdanielbouwmeesterNo ratings yet

- StorEdgeTroubleshootingGuide FullDocumentDocument13 pagesStorEdgeTroubleshootingGuide FullDocumentJoe SeraphinNo ratings yet

- User Guide 310BC - 330BC: 7JA0001GB Rev 02 Page 1 of 6Document6 pagesUser Guide 310BC - 330BC: 7JA0001GB Rev 02 Page 1 of 6indianmakeNo ratings yet

- Auto Synchronizing and Auto Load SharingDocument24 pagesAuto Synchronizing and Auto Load Sharingravi_kumar_100% (1)

- Tennant t7 Rider Floor Scrubber Service ManualDocument48 pagesTennant t7 Rider Floor Scrubber Service ManualFernando ElyuNo ratings yet

- Installation and Service Manual AC Level 2 Electric Vehicle Supply Equipment (EVSE)Document20 pagesInstallation and Service Manual AC Level 2 Electric Vehicle Supply Equipment (EVSE)jorgepelayoNo ratings yet

- Bundu Power User Manual PDFDocument20 pagesBundu Power User Manual PDFDjamel BeddarNo ratings yet

- LV2424Document50 pagesLV2424Kerubiel AnikkuNo ratings yet

- B01mu0wmgt 20a Solar Charger ManualDocument8 pagesB01mu0wmgt 20a Solar Charger Manualdanysan2525No ratings yet

- SYC6714 Synchronizer: Ngine Overning YstemDocument4 pagesSYC6714 Synchronizer: Ngine Overning Ystemthanhhai31No ratings yet

- Manual Victron SmartSolar Charge Controller MPPT 75 10 75 15 100 15 100 20Document86 pagesManual Victron SmartSolar Charge Controller MPPT 75 10 75 15 100 15 100 20Popa EmilNo ratings yet

- Robart Electric Retract Series Instruction Manual: Thank YouDocument2 pagesRobart Electric Retract Series Instruction Manual: Thank YourobNo ratings yet

- Sdmo Telys 1 Control Panel ManualDocument40 pagesSdmo Telys 1 Control Panel ManualGONZALO100% (1)

- TI New (MTI) AddendumDocument3 pagesTI New (MTI) AddendumBojan KitanovskiNo ratings yet

- EV-100 Motor Controller RepairDocument23 pagesEV-100 Motor Controller RepairTan Jai100% (2)

- User Manual: Hybrid 2KW/3KW/5KW Inverter / ChargerDocument61 pagesUser Manual: Hybrid 2KW/3KW/5KW Inverter / ChargerStLisNo ratings yet

- Enc Instuction ManualDocument6 pagesEnc Instuction ManualDaniel SolerNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- SPLN 7D - 1978Document21 pagesSPLN 7D - 1978Inggrit Izzatul A'iniNo ratings yet

- Operational Amplifier: Masramdhani SaputraDocument16 pagesOperational Amplifier: Masramdhani SaputradanialNo ratings yet

- Table of ContentsDocument2 pagesTable of ContentsdanialNo ratings yet

- Trafoindo Catalogue Distribution Transformer SPLN D3Document4 pagesTrafoindo Catalogue Distribution Transformer SPLN D3danialNo ratings yet

- SBS Catalogue For WebDocument13 pagesSBS Catalogue For WebdanialNo ratings yet

- Table of ContentsDocument2 pagesTable of ContentsdanialNo ratings yet

- Chapter I, II, IIIDocument18 pagesChapter I, II, IIIdanialNo ratings yet

- Motor SBG DriverDocument2 pagesMotor SBG DriverdanialNo ratings yet

- Table of ContentsDocument1 pageTable of ContentsdanialNo ratings yet

- PrefaceDocument1 pagePrefacedanialNo ratings yet

- ICS2errata PDFDocument18 pagesICS2errata PDFdanialNo ratings yet

- Chapter 1Document15 pagesChapter 1danialNo ratings yet

- 15869Document4 pages15869danialNo ratings yet

- MG 1-2006 Rev 1 - ContentsDocument36 pagesMG 1-2006 Rev 1 - ContentsdanialNo ratings yet

- 2072Document5 pages2072danialNo ratings yet

- Electrical Safety O MDocument225 pagesElectrical Safety O MHieu NguyenNo ratings yet

- Genset InstallationDocument2 pagesGenset InstallationgpriohardonoNo ratings yet

- Code Low Voltage InsDocument34 pagesCode Low Voltage InsdanialNo ratings yet

- Electrical Note 2Document3 pagesElectrical Note 2danialNo ratings yet

- Genset InstallationDocument2 pagesGenset InstallationgpriohardonoNo ratings yet

- 730 11Document23 pages730 11danialNo ratings yet

- IS33Document2 pagesIS33danialNo ratings yet

- Doa SholatDocument5 pagesDoa SholatdanialNo ratings yet

- Safety Incident ReportDocument10 pagesSafety Incident ReportMelanie BrittainNo ratings yet

- MQ-4C TritonDocument2 pagesMQ-4C TritonLeakSourceInfoNo ratings yet

- MT6603 DMS Unt 3 PDFDocument39 pagesMT6603 DMS Unt 3 PDFKarthi KeyanNo ratings yet

- Pressure SurgeDocument15 pagesPressure SurgesasikumarmarineNo ratings yet

- ITW Rust Inhibitive Primer 7CZ Product Data 1469103Document2 pagesITW Rust Inhibitive Primer 7CZ Product Data 1469103rihtak123No ratings yet

- Ijesrt: Modelling and Simulation of Solar Photovoltaic Array For Battery Charging Application Using Matlab-SimulinkDocument5 pagesIjesrt: Modelling and Simulation of Solar Photovoltaic Array For Battery Charging Application Using Matlab-Simulinksrinureddy2014No ratings yet

- Crane Operator Rigger TrainingDocument55 pagesCrane Operator Rigger TrainingAli Jalil80% (5)

- Weidmuller HazLoc Catalog 2014 LIT1315EDocument12 pagesWeidmuller HazLoc Catalog 2014 LIT1315Evaseem shaikNo ratings yet

- Adaptive Antenna Systems: Widrow, E. GoodeDocument17 pagesAdaptive Antenna Systems: Widrow, E. GoodeKhal ZeratulNo ratings yet

- 01-09-04MIL On, DTCs P1545, P0121, P0123, P0221 or P0222 Stored in ECM Fault MemoryDocument7 pages01-09-04MIL On, DTCs P1545, P0121, P0123, P0221 or P0222 Stored in ECM Fault MemoryKilobyte202005No ratings yet

- Stator Earth Fault in 200MW Generator-A Case StudyDocument5 pagesStator Earth Fault in 200MW Generator-A Case StudylrpatraNo ratings yet

- Microgel Particles and Their Effect On The Textural Properties of FoodsDocument9 pagesMicrogel Particles and Their Effect On The Textural Properties of Foodsmsa_imegNo ratings yet

- Oxygen Booster ManualDocument27 pagesOxygen Booster ManualAldo Tolaba Quiroga100% (3)

- Maz18 Maz38 ManualDocument5 pagesMaz18 Maz38 Manualheritage336No ratings yet

- Harsh SukhramaniDocument6 pagesHarsh SukhramaniHarsh SukhramaniNo ratings yet

- V 112Document4 pagesV 112simon_someone217No ratings yet

- Intro To Neutron ScatteringDocument191 pagesIntro To Neutron ScatteringEleni MitsiNo ratings yet

- Standard Rain GaugeDocument43 pagesStandard Rain GaugeAku PalsuNo ratings yet

- 14 Upgrading of Safety Measures in The Arlberg Railway TunnelDocument10 pages14 Upgrading of Safety Measures in The Arlberg Railway TunnelvijyantbNo ratings yet

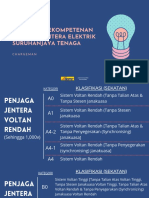

- Kategori Kompeten Penjaga Jentera Elektrik STDocument9 pagesKategori Kompeten Penjaga Jentera Elektrik STAbun ParadoxsNo ratings yet

- HFC1508EN - Hi-Force Condensed Catalogue PDFDocument76 pagesHFC1508EN - Hi-Force Condensed Catalogue PDFVladimir ShepelNo ratings yet

- Analysis of Water and Wastewater (Importantíssimo)Document61 pagesAnalysis of Water and Wastewater (Importantíssimo)carrielocamaraNo ratings yet

- How To Install Openbravo ERP On Debian LennyDocument4 pagesHow To Install Openbravo ERP On Debian LennyfromemNo ratings yet

- Datasheet: G185XW01V2Document33 pagesDatasheet: G185XW01V2فؤاد عشيشNo ratings yet

- Instructions VbamDocument2 pagesInstructions VbamAustin Yu LiuNo ratings yet

- How To Solve Turtle Logo QuestionsDocument13 pagesHow To Solve Turtle Logo QuestionsSadman SameerNo ratings yet

- COGNEX In-Sight Product GuideDocument16 pagesCOGNEX In-Sight Product GuidedollareNo ratings yet

- Design CalculationDocument13 pagesDesign CalculationSunil KumarNo ratings yet

- Repair ListDocument36 pagesRepair ListRizky SkrillexNo ratings yet