Professional Documents

Culture Documents

Nas 64 (Uns s32506) - Improved 329j1

Uploaded by

Afronie Cepoz D'nextOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nas 64 (Uns s32506) - Improved 329j1

Uploaded by

Afronie Cepoz D'nextCopyright:

Available Formats

High temperature strength is similar to Type 430 in the range of 1150~950C.

Workability

However the steel shows rapid increase in the strength below 900C. Regarding

NAS 64 (UNS S32506)

cold workability, care is required as proof stress is high and elongation is low in

comparison with Type 304.

Various welding methods are applicable in the same manner as with the standard

NAS High Corrosion Resistant Duplex Stainless Steel

Weldability

austenitic stainless steels, including shielded metal arc welding, TIG welding, and NAS 64 (SUS 329J4L, UNS S32506, ASME Code Case 2543) is an austenitic-ferritic stainless steel which was

plasma welding. Same duplex grade type welding consumable should be used. developed by Nippon Yakin, and provides excellent corrosion resistance against phosphoric acid, acetic acid, vari-

ous sulfur compounds, etc. In particular, due to its ultra-low C, high Mo composition, its local corrosion resistance

is particularly improved in comparison with Type 329J1. Nippon Yakin supplies this product in plate, sheet and strip

NAS 64 is not hardened by heat treatment. After heating to a solution treatment form.

Heat Treatment

temperature of 1050~1080C, quenching is necessary. Cooling must be performed

as rapidly as possible so at to minimize the time when the material is exposed to the

embrittlement temperature range (475C embrittlement, phase embrittlement).

Steel Grade/Standard

A mixture of nitric acid and fluoric acid is used in pickling. However, because NAS JIS G4304/4305 ASTM A240 EN

Pickling

descaling is somewhat difficult in comparison with Type 304, alkali immersion NAS 64 SUS 329J4L UNS S32506

before acid pickling, and if possible, shot blasting are extremely effective.

Chemical Composition

NAS 64 is suitable as material for a wide range of chemical equipment in environ-

Applications [wt %]

ments which Type 316 cannot withstand, including various types of pollution

prevention equipment and equipment handling petrochemicals, fibers, pulp, impure C Si Mn P S Ni Cr Mo N W

hot water, seawater, etc. Because it also possesses high strength, NAS 64 can Specification 5.50~ 24.00~ 2.50~ 0.08~

0.030 1.00 1.50 0.040 0.030

be used in applications which require both mechanical strength and corrosion (SUS 329J4L) 7.50 26.00 3.50 0.30

resistance, such as water gates, OCTG, geothermal power generation plants, etc. Specification 5.5~ 24.0~ 3.0~ 0.08~ 0.05~

0.030 0.90 1.00 0.040 0.015

(UNS S32506) 7.2 26.0 3.5 0.20 0.30

Physical Properties

Density [g/cm3] 7.80

Specific heat [J/kg . K] 25C 460

Electrical resistivity [ . cm] 88.7

Thermal conductivity [W/m . K] 25C 12.6

-6

Average coefficient of thermal expansion [10 /C] 30~200C 10.5

30~300C 11.4

30~400C 12.2

Youngs modulus [MPa] 19.6 104

For more information, please contact: Note regarding the handling of property data:

Nippon Yakin Kogyo Co., Ltd. The technical information contained in this product guide is Magnetism Y (magnetizable)

representative values obtained in property tests and other

Material Solutions Sales Department items used to explain the performance of the product. With

Melting range [C] 1420~1462

San-Ei Bldg., 5-8, 1-chome Kyobashi, Chuo-ku, Tokyo 104-8365 Japan the exception of items specifically mentioned as provisions

of a Standard, the contents do not represent guaranteed

TEL: +81-3-3273-4649 FAX: +81-3-3273-4642 upper limit or lower limit values. This information is also

E-Mail: inquiry@nyk.co.jp subject to change in the future without notice. To obtain the

most recent information, please contact Nippon Yakin.

URL: http://www.nyk.co.jp/en/

2011.2.1

NAS 64 (UNS S32506)

SCC Resistance

Mechanical Properties

Test method: U-bend test piece, test time: 240~300hr; for NAS 64, 336hr

Mechanical Properties at Room Temperature Test conditions 20%NaCl+ (107C) 1130ppm Cl-

Steel grade 1% NaO2 1/4% CrCl3 1%Na2Cr2O7 . 2H2O 250C

0.2% proof stress Tensile strength Elongation Hardness

Type 304

[MPa] [MPa] [%] [Hv] [HB] (2/2) (2/3) (3/3) (3/3) (2/2)

Specification (SUS 329J4L) 450 620 18 320 302 p

Type 316

Specification (UNS S32506) 450 620 18 302 (0/2) (1/3) (1/3) (3/3)

Cold-rolled sheet 1.6mm t

732 853 23 258 248 p p p p p

Example NAS 64

Hot-rolled plate 10mmt 657 800 26 252 (0/2) (0/2) (0/2) (0/2) (0/2)

p p p p

Type 329J1

(0/2) (0/2) (0/2) (0/3)

: All pieces cracked : Some pieces cracked p: No cracking

Numbers in parentheses show No. of cracked test pieces/Total No. of test pieces.

NAS 64 has excellent local corrosion resistance, including pitting corrosion and stress

Corrosion Resistance

corrosion cracking resistance, and can be used in environments which Type 316L

cannot withstand. In comparison with Type 329J1, its pitting corrosion resistance is Acid Resistance

more than double, and in particular, its crevice corrosion resistance is far superior. Corrosion rate: g/m2/hr

Test conditions 49%P2O5, 0.5%F-

Pitting Corrosion Resistance 5% sufuric acid,

1% HCl, boiling, 6hr 5%H2SO4, 0.05%Cl-

boiling, 6hr

Shape 1.0%e3+, 80C

Temperature dependency of pitting potential (in 4%NaCl, Ar degassing) NAS 64 Cold-rolled sheet (2.0mm) 0.36 0.1 0.1

NAS 64 Hot-rolled plate sheet (10.0mm) 0.53 0.1

Type 316L 4.50 46.7 95.8

Pitting potential [Vc10 vs S.C.E]

Type 329J1 Cold-rolled sheet (2.0mm) 1.26 0.1

1.0

NAS 64

(SUS 329J4L)

Type 329J1

0.5

Type 316L

0.0

20 40 60 80

Test temperature [C]

Pitting corrosion resistance of bead and HAZ after TIG welding

Test Pitting corrosion resistance

Vc10 70C 3.5% NaCl 10%FeCl3 . 6H2O 40C 4hr

Steel grade (Vc10 vs SCE) (g/m2/h)

NAS 64 Welding material/base material 0.39 / 0.68 0.1

Type 329J1 Welding material/base material 0.14 / 0.26 1.0~5.0

NAS 64 (UNS S32506)

SCC Resistance

Mechanical Properties

Test method: U-bend test piece, test time: 240~300hr; for NAS 64, 336hr

Mechanical Properties at Room Temperature Test conditions 20%NaCl+ (107C) 1130ppm Cl-

Steel grade 1% NaO2 1/4% CrCl3 1%Na2Cr2O7 . 2H2O 250C

0.2% proof stress Tensile strength Elongation Hardness

Type 304

[MPa] [MPa] [%] [Hv] [HB] (2/2) (2/3) (3/3) (3/3) (2/2)

Specification (SUS 329J4L) 450 620 18 320 302 p

Type 316

Specification (UNS S32506) 450 620 18 302 (0/2) (1/3) (1/3) (3/3)

Cold-rolled sheet 1.6mm t

732 853 23 258 248 p p p p p

Example NAS 64

Hot-rolled plate 10mmt 657 800 26 252 (0/2) (0/2) (0/2) (0/2) (0/2)

p p p p

Type 329J1

(0/2) (0/2) (0/2) (0/3)

: All pieces cracked : Some pieces cracked p: No cracking

Numbers in parentheses show No. of cracked test pieces/Total No. of test pieces.

NAS 64 has excellent local corrosion resistance, including pitting corrosion and stress

Corrosion Resistance

corrosion cracking resistance, and can be used in environments which Type 316L

cannot withstand. In comparison with Type 329J1, its pitting corrosion resistance is Acid Resistance

more than double, and in particular, its crevice corrosion resistance is far superior. Corrosion rate: g/m2/hr

Test conditions 49%P2O5, 0.5%F-

Pitting Corrosion Resistance 5% sufuric acid,

1% HCl, boiling, 6hr 5%H2SO4, 0.05%Cl-

boiling, 6hr

Shape 1.0%e3+, 80C

Temperature dependency of pitting potential (in 4%NaCl, Ar degassing) NAS 64 Cold-rolled sheet (2.0mm) 0.36 0.1 0.1

NAS 64 Hot-rolled plate sheet (10.0mm) 0.53 0.1

Type 316L 4.50 46.7 95.8

Pitting potential [Vc10 vs S.C.E]

Type 329J1 Cold-rolled sheet (2.0mm) 1.26 0.1

1.0

NAS 64

(SUS 329J4L)

Type 329J1

0.5

Type 316L

0.0

20 40 60 80

Test temperature [C]

Pitting corrosion resistance of bead and HAZ after TIG welding

Test Pitting corrosion resistance

Vc10 70C 3.5% NaCl 10%FeCl3 . 6H2O 40C 4hr

Steel grade (Vc10 vs SCE) (g/m2/h)

NAS 64 Welding material/base material 0.39 / 0.68 0.1

Type 329J1 Welding material/base material 0.14 / 0.26 1.0~5.0

High temperature strength is similar to Type 430 in the range of 1150~950C.

Workability

However the steel shows rapid increase in the strength below 900C. Regarding

NAS 64 (UNS S32506)

cold workability, care is required as proof stress is high and elongation is low in

comparison with Type 304.

Various welding methods are applicable in the same manner as with the standard

NAS High Corrosion Resistant Duplex Stainless Steel

Weldability

austenitic stainless steels, including shielded metal arc welding, TIG welding, and NAS 64 (SUS 329J4L, UNS S32506, ASME Code Case 2543) is an austenitic-ferritic stainless steel which was

plasma welding. Same duplex grade type welding consumable should be used. developed by Nippon Yakin, and provides excellent corrosion resistance against phosphoric acid, acetic acid, vari-

ous sulfur compounds, etc. In particular, due to its ultra-low C, high Mo composition, its local corrosion resistance

is particularly improved in comparison with Type 329J1. Nippon Yakin supplies this product in plate, sheet and strip

NAS 64 is not hardened by heat treatment. After heating to a solution treatment form.

Heat Treatment

temperature of 1050~1080C, quenching is necessary. Cooling must be performed

as rapidly as possible so at to minimize the time when the material is exposed to the

embrittlement temperature range (475C embrittlement, phase embrittlement).

Steel Grade/Standard

A mixture of nitric acid and fluoric acid is used in pickling. However, because NAS JIS G4304/4305 ASTM A240 EN

Pickling

descaling is somewhat difficult in comparison with Type 304, alkali immersion NAS 64 SUS 329J4L UNS S32506

before acid pickling, and if possible, shot blasting are extremely effective.

Chemical Composition

NAS 64 is suitable as material for a wide range of chemical equipment in environ-

Applications [wt %]

ments which Type 316 cannot withstand, including various types of pollution

prevention equipment and equipment handling petrochemicals, fibers, pulp, impure C Si Mn P S Ni Cr Mo N W

hot water, seawater, etc. Because it also possesses high strength, NAS 64 can Specification 5.50~ 24.00~ 2.50~ 0.08~

0.030 1.00 1.50 0.040 0.030

be used in applications which require both mechanical strength and corrosion (SUS 329J4L) 7.50 26.00 3.50 0.30

resistance, such as water gates, OCTG, geothermal power generation plants, etc. Specification 5.5~ 24.0~ 3.0~ 0.08~ 0.05~

0.030 0.90 1.00 0.040 0.015

(UNS S32506) 7.2 26.0 3.5 0.20 0.30

Physical Properties

Density [g/cm3] 7.80

Specific heat [J/kg . K] 25C 460

Electrical resistivity [ . cm] 88.7

Thermal conductivity [W/m . K] 25C 12.6

-6

Average coefficient of thermal expansion [10 /C] 30~200C 10.5

30~300C 11.4

30~400C 12.2

Youngs modulus [MPa] 19.6 104

For more information, please contact: Note regarding the handling of property data:

Nippon Yakin Kogyo Co., Ltd. The technical information contained in this product guide is Magnetism Y (magnetizable)

representative values obtained in property tests and other

Material Solutions Sales Department items used to explain the performance of the product. With

Melting range [C] 1420~1462

San-Ei Bldg., 5-8, 1-chome Kyobashi, Chuo-ku, Tokyo 104-8365 Japan the exception of items specifically mentioned as provisions

of a Standard, the contents do not represent guaranteed

TEL: +81-3-3273-4649 FAX: +81-3-3273-4642 upper limit or lower limit values. This information is also

E-Mail: inquiry@nyk.co.jp subject to change in the future without notice. To obtain the

most recent information, please contact Nippon Yakin.

URL: http://www.nyk.co.jp/en/

2011.2.1

You might also like

- Fundamentals of Biological Wastewater Treatment - PrefaceDocument4 pagesFundamentals of Biological Wastewater Treatment - Prefaceabhi_nddNo ratings yet

- Calculation For Backpressure by Liquid SealDocument2 pagesCalculation For Backpressure by Liquid SealDodiya NikunjNo ratings yet

- Volume 3 Section 2 Process Requirements-FINAL 10062010Document63 pagesVolume 3 Section 2 Process Requirements-FINAL 10062010Pavle DimitrijevicNo ratings yet

- Type k1 (Re 1) NP (Re 10 5) : Anchor 0.7 LaminarDocument3 pagesType k1 (Re 1) NP (Re 10 5) : Anchor 0.7 LaminarRobinNo ratings yet

- Ac Sizing - Duct SizingDocument9 pagesAc Sizing - Duct SizingHarpreet SinghNo ratings yet

- Membrane Nitrogen GeneratorsDocument2 pagesMembrane Nitrogen GeneratorsRoozbeh PNo ratings yet

- CHAPTER 8 Sizing and CostingDocument20 pagesCHAPTER 8 Sizing and CostingNurul Amelia Mustaffa0% (1)

- Abu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003Document8 pagesAbu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003fermortaraNo ratings yet

- Minor Loss Coefficients in Pipes and Tubes ComponentsDocument2 pagesMinor Loss Coefficients in Pipes and Tubes ComponentsSurendra ReddyNo ratings yet

- Hood Types: Enclosing Hoods Are Those in Which The Source Is Either Partially or Totally Enclosed To Provide TheDocument11 pagesHood Types: Enclosing Hoods Are Those in Which The Source Is Either Partially or Totally Enclosed To Provide TheSudhakar KarnanNo ratings yet

- Recovery PhosphateDocument4 pagesRecovery PhosphateYuni HapsariNo ratings yet

- Scale Up of Paddle DryerDocument4 pagesScale Up of Paddle DryerRavindra V. Lakhapati100% (1)

- Basic Control Valve Sizing and SelectionDocument38 pagesBasic Control Valve Sizing and SelectionmohamedNo ratings yet

- MicrofilterDocument17 pagesMicrofilterArrianne Jaye MataNo ratings yet

- Ozone Solubility ChartDocument0 pagesOzone Solubility ChartWONG TSNo ratings yet

- Calculation of The Built Up Back Pressure - LESERDocument4 pagesCalculation of The Built Up Back Pressure - LESERArjed Ali ShaikhNo ratings yet

- Zero Water Discharge in Process Industry-MainDocument21 pagesZero Water Discharge in Process Industry-Maineagle_snake2002No ratings yet

- CPI DesignDocument6 pagesCPI Designprasad336No ratings yet

- ProMinent Operating Instructions Meta HM-HKDocument20 pagesProMinent Operating Instructions Meta HM-HKivan_shterevNo ratings yet

- Packed Towers: 12.1 Device TypeDocument10 pagesPacked Towers: 12.1 Device TypeSagar BhavsarNo ratings yet

- Prediction of HETP For Randomly Packed Towers Operation:integration of Aqueous and Non-Aqueous Mass Transfercharacteristics Into One Consistent CorrelationDocument18 pagesPrediction of HETP For Randomly Packed Towers Operation:integration of Aqueous and Non-Aqueous Mass Transfercharacteristics Into One Consistent Correlationcamilo_ortiz_6No ratings yet

- Main CatalogueDocument10 pagesMain CatalogueMohamed SalahNo ratings yet

- How Equilibrium Calculations Can Be Applied To Complex SystemsDocument16 pagesHow Equilibrium Calculations Can Be Applied To Complex SystemsOsama HussainNo ratings yet

- Effluent ClarifierDocument2 pagesEffluent ClarifierSutra IrawanNo ratings yet

- Experiments and Modeling of Bubble Column Dehumidifier PerformanceDocument11 pagesExperiments and Modeling of Bubble Column Dehumidifier PerformanceAl-Kawthari As-SunniNo ratings yet

- OtherDocument20 pagesOtherVineet Chaudhary100% (1)

- Design of Flash DrumDocument7 pagesDesign of Flash DrumJonathan OrNo ratings yet

- Lab DI Water SystemsDocument6 pagesLab DI Water SystemsHaidee Che RizminNo ratings yet

- Tank EductorDocument3 pagesTank Eductorkonainglincho001No ratings yet

- Random PackingDocument4 pagesRandom PackingAadam AryanNo ratings yet

- Settling TankDocument70 pagesSettling TankHemant SonawadekarNo ratings yet

- HEATEXDocument34 pagesHEATEXSiddharthNo ratings yet

- KOCH MBR Brochure Ver.2016Document8 pagesKOCH MBR Brochure Ver.2016quysuvn88No ratings yet

- Partially Full Pipe Flow Calculations - S.I. Units: Workbook ContentsDocument29 pagesPartially Full Pipe Flow Calculations - S.I. Units: Workbook ContentsdiegoNo ratings yet

- Venturi Scrubber ProjectDocument1 pageVenturi Scrubber ProjectChristopher LloydNo ratings yet

- Calculation of Flow Rate For Orifice Venturi or Flow Nozzle Meter Si UnitsDocument18 pagesCalculation of Flow Rate For Orifice Venturi or Flow Nozzle Meter Si UnitsPrakash WarrierNo ratings yet

- HETP LectureDocument4 pagesHETP LectureaadipakiNo ratings yet

- FL1627Document2 pagesFL1627Isaac Montero BarreraNo ratings yet

- Thermal Conductivity of FRP CompositesDocument69 pagesThermal Conductivity of FRP Compositesjppmj100% (1)

- SPE 131137 Steady-State Heat Transfer Models For Fully and Partially Buried PipelinesDocument27 pagesSPE 131137 Steady-State Heat Transfer Models For Fully and Partially Buried Pipelinesmostafa shahrabi100% (1)

- Brosur - UF Membrane (A) PDFDocument8 pagesBrosur - UF Membrane (A) PDFigo badr100% (1)

- Yazd-System Description For Clean Drain System PDFDocument7 pagesYazd-System Description For Clean Drain System PDFace-winnieNo ratings yet

- Spreadsheet Based Scaling Calculations and Membrane PerformanceDocument16 pagesSpreadsheet Based Scaling Calculations and Membrane PerformanceWaleed EmaraNo ratings yet

- Liu Yi-Design and Construction of Biogas Digester 2017Document74 pagesLiu Yi-Design and Construction of Biogas Digester 2017Stanley Wishmore MukuraNo ratings yet

- C 100 PDFDocument6 pagesC 100 PDFZeeshan TalibNo ratings yet

- Coulson Richardson's Chemical Engineering Vol.6 Chemical Engineering Design 4th EditionDocument2 pagesCoulson Richardson's Chemical Engineering Vol.6 Chemical Engineering Design 4th EditionClaChristinaNo ratings yet

- Nitrification DenitrificationDocument4 pagesNitrification DenitrificationDon Javier HubbleNo ratings yet

- Cylinder Valve Inlet TypeDocument2 pagesCylinder Valve Inlet TypeGore JiangNo ratings yet

- 6 Crystallizer Design and Operation1Document22 pages6 Crystallizer Design and Operation1Dhrumil GandhiNo ratings yet

- Specification of Rotameters: S.NO. Description SpecificationsDocument2 pagesSpecification of Rotameters: S.NO. Description Specificationssushant_jhawerNo ratings yet

- Mechanical Vapour Recompression System For The Evaporation of Water From Salt Containing Solution: BackgroundDocument2 pagesMechanical Vapour Recompression System For The Evaporation of Water From Salt Containing Solution: BackgroundjokishNo ratings yet

- PB Filter Press Sidebar Me1500 Me2500 en Web DataDocument4 pagesPB Filter Press Sidebar Me1500 Me2500 en Web DataTiago J C MachadoNo ratings yet

- Datasheet - Fresh Water Pump PDFDocument8 pagesDatasheet - Fresh Water Pump PDFalliancemarine2011No ratings yet

- Reaction Mechanisms in Environmental Engineering: Analysis and PredictionFrom EverandReaction Mechanisms in Environmental Engineering: Analysis and PredictionNo ratings yet

- Water Treatment Plant Performance Evaluations and OperationsFrom EverandWater Treatment Plant Performance Evaluations and OperationsNo ratings yet

- Handbook of RefractoryDocument331 pagesHandbook of RefractoryAamirMalikNo ratings yet

- Katalog Gasket TOMBODocument3 pagesKatalog Gasket TOMBOAfronie Cepoz D'nextNo ratings yet

- Flange DrawingDocument1 pageFlange DrawingAfronie Cepoz D'nextNo ratings yet

- Sec 1 PT PBDocument9 pagesSec 1 PT PBAfronie Cepoz D'nextNo ratings yet

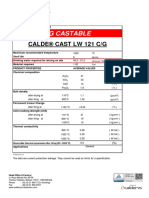

- Tds Calde Cast LW 121 CGDocument1 pageTds Calde Cast LW 121 CGAfronie Cepoz D'nextNo ratings yet

- Asme Sec I A2001Document4 pagesAsme Sec I A2001Sidney LinsNo ratings yet

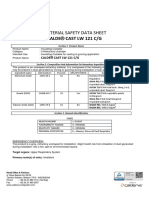

- Msds Calde Cast LW 121 CGDocument5 pagesMsds Calde Cast LW 121 CGAfronie Cepoz D'nextNo ratings yet

- Zeron 100-Data SheetDocument8 pagesZeron 100-Data SheetAfronie Cepoz D'nextNo ratings yet

- List of Volumes ASM Metal HandbookDocument1 pageList of Volumes ASM Metal HandbookAfronie Cepoz D'nextNo ratings yet

- p91 WeldingDocument5 pagesp91 Weldingsaji_t1984100% (1)

- CertificateDocument18 pagesCertificateAfronie Cepoz D'nextNo ratings yet

- Sus 329j4lDocument3 pagesSus 329j4lAfronie Cepoz D'nextNo ratings yet

- Pipe Schedule Segun ASME B36.1 PDFDocument1 pagePipe Schedule Segun ASME B36.1 PDFalberthf_1No ratings yet

- CR Mo VabbPQR PresentationDocument7 pagesCR Mo VabbPQR PresentationAfronie Cepoz D'nextNo ratings yet

- NPT (Asme B1.20.1)Document5 pagesNPT (Asme B1.20.1)Afronie Cepoz D'nextNo ratings yet

- Incoloy Alloy 825Document4 pagesIncoloy Alloy 825Roman PaduaNo ratings yet

- Cooling TowersDocument23 pagesCooling TowersAfronie Cepoz D'nextNo ratings yet

- ME WT 2016 - Curriculum and Syllabi PDFDocument37 pagesME WT 2016 - Curriculum and Syllabi PDFKarthi KeyanNo ratings yet

- DENAIR Dry Oil Free PPT (DWW 55-315KW)Document15 pagesDENAIR Dry Oil Free PPT (DWW 55-315KW)GrumetcomNo ratings yet

- Astm f899 PDFDocument6 pagesAstm f899 PDFengineNo ratings yet

- Iron MakingDocument135 pagesIron MakingSandeep Bandyopadhyay50% (2)

- Module 9Document6 pagesModule 9Kurt MarfilNo ratings yet

- LEEA Correspondence Courses: Assignment 1.3Document3 pagesLEEA Correspondence Courses: Assignment 1.3Primelift Safety Resources LimitedNo ratings yet

- DPR Selwa 02.07.2020Document22 pagesDPR Selwa 02.07.2020ravibelavadiNo ratings yet

- DNV Materials RulesDocument224 pagesDNV Materials RulesJim GrayNo ratings yet

- Fabrication Procedure Steel Structure TSEDocument21 pagesFabrication Procedure Steel Structure TSEspazzbgt67% (6)

- Atlas of Fatigue CurvesDocument534 pagesAtlas of Fatigue CurvesCristiana Costa100% (1)

- Workshop Fe Applications I-2021Document115 pagesWorkshop Fe Applications I-2021Owen WangNo ratings yet

- Avesta MA 253Document2 pagesAvesta MA 253Alif Nur FirdausNo ratings yet

- Ador - Welding RodDocument4 pagesAdor - Welding RodManoj DoshiNo ratings yet

- What Is MIG WeldingDocument2 pagesWhat Is MIG Weldingbrajeshme11012No ratings yet

- 500 Series: Submittal Sheet ASME Section VIII Safety Relief ValveDocument9 pages500 Series: Submittal Sheet ASME Section VIII Safety Relief Valveantony nirmalaNo ratings yet

- CF Hydraulic Sampling Products.01Document18 pagesCF Hydraulic Sampling Products.01Patrick FoNo ratings yet

- Ariete NS3045: Homogenizer & High Pressure Pump Technical DatasheetDocument2 pagesAriete NS3045: Homogenizer & High Pressure Pump Technical DatasheetJorge A. TorresNo ratings yet

- Astm A304Document48 pagesAstm A304Yherson Cerin Chavarria100% (2)

- Sec. II A - SA - 209Document6 pagesSec. II A - SA - 209RamuAlagappanNo ratings yet

- Paper 12Document5 pagesPaper 12Kani Al Bazir100% (1)

- AD 2000-Merkblatt: Cast Steel W5Document8 pagesAD 2000-Merkblatt: Cast Steel W5Diogo CunhaNo ratings yet

- SAIC-W-2085 Pre-Welding Inspection PDFDocument4 pagesSAIC-W-2085 Pre-Welding Inspection PDFkarioke mohaNo ratings yet

- Carbon Steel Billets, Blooms, Slabs and Bars For ForgingsDocument9 pagesCarbon Steel Billets, Blooms, Slabs and Bars For ForgingsHizkia Yarden SinagaNo ratings yet

- Kadvani Forge Limitennnd3Document133 pagesKadvani Forge Limitennnd3Kristen RollinsNo ratings yet

- Gibb PresentationDocument16 pagesGibb Presentationmohamed aliNo ratings yet

- Welding Olet As ASME B31.3Document1 pageWelding Olet As ASME B31.3Mohd Effiezool YaserNo ratings yet

- A Piping Tutorial: © EDA Ltd. 2002Document23 pagesA Piping Tutorial: © EDA Ltd. 2002GokulPrasadNo ratings yet

- Section 8 - Arc Equipment and Processes - tcm266-154565Document42 pagesSection 8 - Arc Equipment and Processes - tcm266-154565Maxmore KarumamupiyoNo ratings yet

- 3SS NW00 00007 PDFDocument10 pages3SS NW00 00007 PDFKarthikNo ratings yet

- Volksbolts Additional Options Stainless S Visit Our Home About Technical & FAQ How To Buy & Contact Terms & Conditions of Sale LinksDocument12 pagesVolksbolts Additional Options Stainless S Visit Our Home About Technical & FAQ How To Buy & Contact Terms & Conditions of Sale LinksAllan EscobarNo ratings yet