Professional Documents

Culture Documents

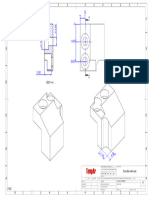

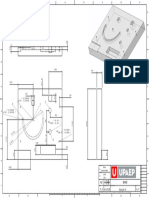

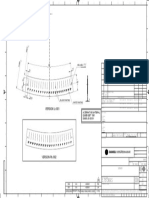

Integrated: Rough Machine Intermediate Flange Large Bore Shear 7 1/16"-5000 MWP

Uploaded by

Arjun PrajapatiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Integrated: Rough Machine Intermediate Flange Large Bore Shear 7 1/16"-5000 MWP

Uploaded by

Arjun PrajapatiCopyright:

Available Formats

8 7 6 5 4 3 2 1

NOTES:

1. ALL MARKINGS LOW STRESS .25" MINIMUM HEIGHT CHARACTERS.

2. CHECK AND MARK HARDNESS AT THIS LOCATION: 207-235 HBW.

D 3. FORGING WILL BE FREE FROM DEFECTS SUCH AS PITS, CRACKS, FILINGS, ETC. D

4. UNSPECIFIED RADII TO BE R.25" AND CHAMFER .13 X 45 . MARK:

95-02070520281 REV - -

5. UT BEFORE MACHINING PER QS/MS/502. R/M INTERMEDIATE FLANGE

HEAT NUMBER _ _ _

6. MT EXAMINATION OF ALL MACHINED SURFACES PER QS/MS/500. SERIAL NUMBER _ _ _

20.30 +- .12

.00

= =

5.80 +- .12

.00

A

2

C C

13.10 +- .12

.00 2.00 +- .00

.12

B B

=

A SECTION A-A

APPROXIMATE WEIGHT: 432 LBS (196 KGS)

THIS DOCUMENT AND ALL THE UNLESS OTHERWISE SPECIFIED REV ECN ECN DESCRIPTION DATE BY DESCRIPTION DWG SIZE

INFORMATION CONTAINED HEREIN IS NO. NAME DATE

DO NOT SCALE THIS DRAWING. TOLERANCE

A THE SOLE AND EXCLUSIVE PROPERTY

OF INTEGRATED EQUIPMENT AND SHALL

NOT BE USED, DISCLOSED, OR COPIED

ALL DIMENSIONS IN INCHES.

ALL FLANGE DRILLING MUST STRADDLE

FRACTION 1/16 ROUGH MACHINE DWN INTEGRATED D A

WITHOUT THE EXPRESS WRITTEN

PERMISSION OF INTEGRATED

COMMON CENTERLINE.

RFS EXCEPT WHEN M MODIFIED.

.X

.XX

.03

.015

INTERMEDIATE FLANGE PRAKASH 2/10/2017 EQUIPMENT

EQUIPMENT. THIS DOCUMENT IS LOANED

PURSUANT TO AGREEMENT TO THE

BREAK SHARP EDGES .015 MAXIMUM

CORNER RADII .030 MINIMUM

.XXX .005 LARGE BORE SHEAR CHK PART NO. SHEET

FOREGOING AND SHALL BE RETURNED

TO INTEGRATED EQUIPMENT. UPON

CONCENTRICITY .010 T.I.R. ANGLES

7 1/16"-5000 MWP AKS 2/10/2017

95-02070520281 1 /1

SQUARENESS .010 IN 10". X 30'

DEMAND, INTEGRATED EQUIPMENT

RESERVES THE RIGHT TO CHANGE PARALLELISM .010 IN 10". X.X 15' APP DSGN DWG NO. REV

DESIGNS, MATERIALS, AND

SPECIFICATIONS WITHOUT NOTICE.

DRAWING IS A THIRD

ANGLE PROJECTION. FINISH 250 RMS MATERIAL: QS/MS/117 VINAY 2/10/2017

95-02070520281 --

8 7 6 5 4 3 2 1

You might also like

- Placa ActivaDocument1 pagePlaca ActivaMădălina EmanuelaNo ratings yet

- 960.00 4 X 7.00 Thru All 12.00 X 90°: RP Laser Tech (P) LTDDocument1 page960.00 4 X 7.00 Thru All 12.00 X 90°: RP Laser Tech (P) LTDvikasNo ratings yet

- Eng CD 1355881 A2Document1 pageEng CD 1355881 A2egaahmad2012_8951071No ratings yet

- CCDC Ubbm30 02Document1 pageCCDC Ubbm30 02Luong LeNo ratings yet

- BoruBükme KızakDocument1 pageBoruBükme KızakÖmer TAŞNo ratings yet

- 2SC2022 KTC2022 BrotherDocument2 pages2SC2022 KTC2022 Brotherxerox4512No ratings yet

- STPRO1358510000-05 Cameron Double BOP 16 - 5 000 Psi - Type U - BodyDocument3 pagesSTPRO1358510000-05 Cameron Double BOP 16 - 5 000 Psi - Type U - BodyPaco RiberaNo ratings yet

- Trazo PDFDocument1 pageTrazo PDFkendy chavez ccahuanaNo ratings yet

- Plano TRAZODocument1 pagePlano TRAZOkendy chavez ccahuanaNo ratings yet

- WT SMR - 0.05: BordersDocument1 pageWT SMR - 0.05: BordersSayful AmmarNo ratings yet

- Arm 1Document4 pagesArm 1SanjaNo ratings yet

- Semiconductor KIA7905F/PI KIA7924F/PI: Technical DataDocument16 pagesSemiconductor KIA7905F/PI KIA7924F/PI: Technical DataNathan VeRaNo ratings yet

- Analisis Keausan RantaiDocument1 pageAnalisis Keausan RantaiRomly MechNo ratings yet

- Prensa de Esmeril Acotados - PDF - Extract - 1 PDFDocument1 pagePrensa de Esmeril Acotados - PDF - Extract - 1 PDFNicole GuevaraNo ratings yet

- 8.0 OD, 6 Reg X 6 RegDocument1 page8.0 OD, 6 Reg X 6 RegSMEETNo ratings yet

- Taller Critica Domingo-Presentación2Document1 pageTaller Critica Domingo-Presentación2Mily Cueva ElgueraNo ratings yet

- Test Fixture Optical MountDocument1 pageTest Fixture Optical Mounti50229No ratings yet

- KTA1040Document2 pagesKTA1040marconi damascenoNo ratings yet

- Prensa de Esmeril Acotados - PDF - Extract PDFDocument1 pagePrensa de Esmeril Acotados - PDF - Extract PDFNicole GuevaraNo ratings yet

- ZC 40243 NATO Picatinny Rail Stanag4694Document1 pageZC 40243 NATO Picatinny Rail Stanag4694Ahmet GençNo ratings yet

- RedactedDocument1 pageRedactedJose PerezNo ratings yet

- SF 30 e 10 64 Peek Bush SF 30Document1 pageSF 30 e 10 64 Peek Bush SF 30jituniNo ratings yet

- 1:1 4.013 1/1 A2 Base: Equipo 6Document1 page1:1 4.013 1/1 A2 Base: Equipo 6Rafa MartinezNo ratings yet

- REV Zone Description Date Name - : Sleeve Bearing #3Document1 pageREV Zone Description Date Name - : Sleeve Bearing #3Aditya PrajasNo ratings yet

- Semiconductor KTC2020D/L: Technical DataDocument2 pagesSemiconductor KTC2020D/L: Technical DatamohanNo ratings yet

- Socle Manal TahtahDocument1 pageSocle Manal TahtahManal TahtahNo ratings yet

- Part No.1: 4.252115.X Fixed Roll - LooperDocument1 pagePart No.1: 4.252115.X Fixed Roll - Loopersameh mamdouhNo ratings yet

- Roller AssemDocument1 pageRoller AssemMoustafa HammadNo ratings yet

- Placa de BazaDocument1 pagePlaca de BazaMădălina EmanuelaNo ratings yet

- Semiconductor KRC401 KRC406: Technical DataDocument7 pagesSemiconductor KRC401 KRC406: Technical DataPLSNo ratings yet

- TavaDocument1 pageTavaÖmer TAŞNo ratings yet

- 01 - Absorbeur Droite InfDocument1 page01 - Absorbeur Droite InfZakaria KchiriNo ratings yet

- Vastago PDFDocument1 pageVastago PDFYesiikPaolaNo ratings yet

- Master Frame of HPPDocument1 pageMaster Frame of HPPYadi KusmayadiNo ratings yet

- 2D Technical DrawingDocument1 page2D Technical DrawingJuan Diego ZambranoNo ratings yet

- Piston of A Petrol Engine: Aluminium Alloy HCS ChlorineDocument1 pagePiston of A Petrol Engine: Aluminium Alloy HCS ChlorineMiki BaneNo ratings yet

- Cancellous 6.5mm Fully ThreadedDocument1 pageCancellous 6.5mm Fully ThreadedAng NanhNo ratings yet

- PK (PD, Pe) 90FGDocument2 pagesPK (PD, Pe) 90FGIhtisham uddinNo ratings yet

- 523ADocument1 page523AJaikoNo ratings yet

- Circlip 13 X 1 N (Part 1)Document1 pageCirclip 13 X 1 N (Part 1)Cbh FastenersNo ratings yet

- Pieza CDocument1 pagePieza CKevin david Sanchez ortizNo ratings yet

- Isometric View: MC 200 - IS 808 200x75x6.2Document1 pageIsometric View: MC 200 - IS 808 200x75x6.2rajitkumar.3005No ratings yet

- Plan ParterDocument1 pagePlan ParterRobert BăgăianNo ratings yet

- 20-128 - Sheet1Document1 page20-128 - Sheet1Bala MuruganNo ratings yet

- Donotscale: Fractions Decimals Angle X/XX .25 X.X° .XXXDocument1 pageDonotscale: Fractions Decimals Angle X/XX .25 X.X° .XXXCarlos JiménezNo ratings yet

- Part Number Material Finish Make From (Strip) : Insul - Range Wire Range 2,0-2,5mm (.080-.100) 0,75-1,50mm (18-16 AWG)Document1 pagePart Number Material Finish Make From (Strip) : Insul - Range Wire Range 2,0-2,5mm (.080-.100) 0,75-1,50mm (18-16 AWG)Emanuel RochaNo ratings yet

- 5.757369.S 001 00BDocument1 page5.757369.S 001 00Brajitkumar.3005No ratings yet

- pj2000171611 15Document1 pagepj2000171611 15karan singh solankiNo ratings yet

- Circular Hollow Section 60.3X4.5 Yst 310-Is 1161Document1 pageCircular Hollow Section 60.3X4.5 Yst 310-Is 1161rajitkumar.3005No ratings yet

- API 6A Valve Body 2 One by Sixteen Inches 3000psiDocument1 pageAPI 6A Valve Body 2 One by Sixteen Inches 3000psikunal josephNo ratings yet

- Arquitectura 23Document1 pageArquitectura 23juan lunaNo ratings yet

- PA000008-Bearing PreloaderDocument1 pagePA000008-Bearing PreloaderYAGNA V YAGNA VNo ratings yet

- TB-55-105 - Cylinder Piston PinDocument1 pageTB-55-105 - Cylinder Piston PinAnuj BhardwajNo ratings yet

- 5 x4 Tehnicki Polirana Povrsina: Cavity - 0420Document2 pages5 x4 Tehnicki Polirana Povrsina: Cavity - 0420Stefan MilojevicNo ratings yet

- Connecting RodDocument1 pageConnecting RodCốGắngNàoNo ratings yet

- Power Screw DetDocument1 pagePower Screw DetAshok TeliNo ratings yet

- Jig WS24 75 070 SpacerDocument1 pageJig WS24 75 070 SpacerLuong LeNo ratings yet

- DatasheetDocument2 pagesDatasheetLot UxNo ratings yet

- Wind Caribbean - Winds - NHC (Edit)Document28 pagesWind Caribbean - Winds - NHC (Edit)chrisNo ratings yet

- ATKP362341 Revb1 111116Document1 pageATKP362341 Revb1 111116Arjun PrajapatiNo ratings yet

- Stub Shaft Forging: ATKP362340/ATKP302958Document1 pageStub Shaft Forging: ATKP362340/ATKP302958Arjun PrajapatiNo ratings yet

- BU Motors and Generators: Prepared Separate Part List Title ScaleDocument1 pageBU Motors and Generators: Prepared Separate Part List Title ScaleArjun PrajapatiNo ratings yet

- Forged Donut: Proprietary and Confidential Unspecified ToleranceDocument1 pageForged Donut: Proprietary and Confidential Unspecified ToleranceArjun PrajapatiNo ratings yet

- Forged Plate: Proprietary and Confidential Unspecified ToleranceDocument1 pageForged Plate: Proprietary and Confidential Unspecified ToleranceArjun PrajapatiNo ratings yet

- QS MS 117Document5 pagesQS MS 117Arjun PrajapatiNo ratings yet

- ATKP362339 Revb1 111116Document1 pageATKP362339 Revb1 111116Arjun PrajapatiNo ratings yet

- Technical Annexure: EREQ No.: Split No.Document6 pagesTechnical Annexure: EREQ No.: Split No.Arjun PrajapatiNo ratings yet

- Bearing Housing: Proprietary and Confidential Unspecified ToleranceDocument1 pageBearing Housing: Proprietary and Confidential Unspecified ToleranceArjun PrajapatiNo ratings yet

- T3 0209 04 SPC - T3RevF PDFDocument4 pagesT3 0209 04 SPC - T3RevF PDFArjun PrajapatiNo ratings yet

- T3 0209 04 SPC - T3RevFDocument4 pagesT3 0209 04 SPC - T3RevFArjun PrajapatiNo ratings yet

- Specification For Plates and Forgings PDFDocument2 pagesSpecification For Plates and Forgings PDFArjun PrajapatiNo ratings yet

- Technical Card Gruppo Lucefin Revision 2013 All Rights ReservedDocument1 pageTechnical Card Gruppo Lucefin Revision 2013 All Rights ReservedArjun PrajapatiNo ratings yet

- Anov DWG 201Document1 pageAnov DWG 201Arjun PrajapatiNo ratings yet

- MS - 003400 - 01 Rev 29Document22 pagesMS - 003400 - 01 Rev 29Arjun PrajapatiNo ratings yet

- MS - 003400 - 01 Rev 29Document22 pagesMS - 003400 - 01 Rev 29Arjun PrajapatiNo ratings yet

- Property Of: Operation Activity: 0010 Receiving InspectionDocument2 pagesProperty Of: Operation Activity: 0010 Receiving InspectionArjun PrajapatiNo ratings yet

- Cameron: NotesDocument1 pageCameron: NotesArjun PrajapatiNo ratings yet

- 336.5 129.7 187.8 Proof DWG: Also Use For PN 291-FM1-8700PR, Rev.BDocument1 page336.5 129.7 187.8 Proof DWG: Also Use For PN 291-FM1-8700PR, Rev.BArjun PrajapatiNo ratings yet

- HYROTEST Procedure Tank NSIDocument4 pagesHYROTEST Procedure Tank NSIluhur prandika100% (1)

- L5PNFDocument2 pagesL5PNFmajdjasonNo ratings yet

- Marechal Decontactors Plug and Socket SwitchDocument4 pagesMarechal Decontactors Plug and Socket SwitchrocketvtNo ratings yet

- ASV ST50 Service ManualDocument114 pagesASV ST50 Service ManualbrunosamaeianNo ratings yet

- Operations Manual Tracks PDFDocument59 pagesOperations Manual Tracks PDFELMERNo ratings yet

- Process Synthesis For Coffee Husks To Energy Using Hierarchical Approaches PDFDocument12 pagesProcess Synthesis For Coffee Husks To Energy Using Hierarchical Approaches PDFJhonStevenNavarroHNo ratings yet

- Chapter 9 - Part 1Document63 pagesChapter 9 - Part 1muhammad izzul100% (1)

- Datasheet 74hct40103Document17 pagesDatasheet 74hct40103Yettie OgunduboyeNo ratings yet

- TDS 26140 Jotashield Colourlast Silk Euk GBDocument4 pagesTDS 26140 Jotashield Colourlast Silk Euk GBMido AbdoNo ratings yet

- PRV Catlogue-Samson (09!06!09)Document6 pagesPRV Catlogue-Samson (09!06!09)pkrishna984No ratings yet

- Chapter 10 - Precast Elements: WJ Martin 10.1 ScopeDocument12 pagesChapter 10 - Precast Elements: WJ Martin 10.1 ScopeChinwendu Cno Onwukwe100% (2)

- Acids, Alkalis and Salts RevisionDocument19 pagesAcids, Alkalis and Salts RevisionJames EzardNo ratings yet

- Kobe Welding Handbook 2004Document183 pagesKobe Welding Handbook 2004Nasywafi AlyaNo ratings yet

- Astm D7522M-21Document6 pagesAstm D7522M-21Edgar Joel Perez CarvajalNo ratings yet

- Solar Thermal TechnologiesDocument48 pagesSolar Thermal TechnologiesVinoth MalaikaniNo ratings yet

- Cherry RedDocument1 pageCherry Redjcordon-2No ratings yet

- 1-Bolt Geometry, Symbol of Bolts in Proj (19 Files Merged) PDFDocument28 pages1-Bolt Geometry, Symbol of Bolts in Proj (19 Files Merged) PDFSimi NagyNo ratings yet

- Wiremesh InstallationDocument3 pagesWiremesh InstallationFitriansyah Adi Putra IrwanNo ratings yet

- Materials Selection Lecture Full 2023.Document203 pagesMaterials Selection Lecture Full 2023.Goddy NanaNo ratings yet

- Light Transmitting ConcreteDocument13 pagesLight Transmitting ConcreteShivam SumanNo ratings yet

- CP13 1999Document55 pagesCP13 1999Nyan Myint TunNo ratings yet

- Hojas de Sierra Wood-Mizer.Document8 pagesHojas de Sierra Wood-Mizer.Enrique HernandezNo ratings yet

- EarthDocument2 pagesEarthxs1zameenNo ratings yet

- ASME B31.4 - 2006 (Excerpt - Pgs. 39, 40 & 41)Document3 pagesASME B31.4 - 2006 (Excerpt - Pgs. 39, 40 & 41)Paul CassellsNo ratings yet

- Structural Steel Design BowlesDocument276 pagesStructural Steel Design BowlesIonut Narcis Iuga88% (8)

- Sae As1650b-2010Document23 pagesSae As1650b-2010EchoZhangNo ratings yet

- Residual Stress in Induction HardeningDocument2 pagesResidual Stress in Induction HardeningRajesh MalikNo ratings yet

- Make ShiftDocument6 pagesMake ShiftAnnamarie SanDiegoNo ratings yet

- Automated Car Jack PDFDocument3 pagesAutomated Car Jack PDFakashlogic100% (1)

- Lambda + Chlorantraniliprole - Cómo Estabilizar La SuspensiónDocument8 pagesLambda + Chlorantraniliprole - Cómo Estabilizar La SuspensiónAlfredo MéndezNo ratings yet