Professional Documents

Culture Documents

QC Stage Inspection Process

Uploaded by

Engr Saeed AnwarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QC Stage Inspection Process

Uploaded by

Engr Saeed AnwarCopyright:

Available Formats

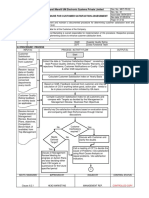

QA/QC Department

Stage Inspection Flow Process Chart

Persons Involved:

Feed back in case of missing stage

Requisition received from PPCD

Department Factory Head

Lead QA/QC Engineer

QA/QC Officer

PPCD Engineer

Previous Record Verification QC Inspector

inspection

Process Description:

Inspection time & Date

1. Initially Project stage inspection

requisition generates from PPCD

Deptt & received by QA/QC Officer.

2. QA/QC officer evaluates & match

Visual Inspection with previous records.

3. If records didnt match, he gives

If found not Ok, Hold & Feed Back to PPCD

Engr & Final Decision made by Factory

feedback to Lead QA/QC Engr.

4. Lead QA/QC Engr discuss the issue

with PPCD Engr.

Specific Stage inspection 5. If record match, then a time & date

for inspection is issued.

6. QA/QC Engr lead the team for stage

inspection.

7. QA/QC Engr visually inspect the part

If found Ok, GO Head for next process 8. If found ok in Visual inspection then

QA/QC Officer & QC Inspector

Head

inspect the part

9. If stage inspection is OK, they report

to Lead QA/QC Engr.

Record Updated & Attached file of Stage 10. Lead QA/QC Engr then give the Go

inspection head for next process.

11. If stage inspection found errors,

then the Part is hold.

12. Lead QA/QC Engr reports the

Waiting for the next Stage inspection factory head for taking further

until last decision.

You might also like

- EU-Type Exam Certificate for Dual Band RadioDocument3 pagesEU-Type Exam Certificate for Dual Band RadioanshadNo ratings yet

- Flow Chart For New Enquiry HandlingDocument1 pageFlow Chart For New Enquiry HandlingVinod Sale100% (1)

- Chapter 15. Monitoring and Measurement Resources Related: (Clause Description-Paraphrase)Document12 pagesChapter 15. Monitoring and Measurement Resources Related: (Clause Description-Paraphrase)Vikram BillalNo ratings yet

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical WorkDocument53 pagesA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical WorkDan CosacNo ratings yet

- Control of Calibrated Equipment ProcedureDocument8 pagesControl of Calibrated Equipment ProcedureFaisalNo ratings yet

- Internal Audit Checksheet ReviewDocument32 pagesInternal Audit Checksheet ReviewRambir KaushikNo ratings yet

- Controlled Quality ManualDocument51 pagesControlled Quality ManualMoment BatureNo ratings yet

- Samples Inspection ReportDocument5 pagesSamples Inspection ReportArun GuptaNo ratings yet

- Tier-2 Audit ChecksheetDocument17 pagesTier-2 Audit ChecksheetSilambarasan KNo ratings yet

- Sound Velocity ChartDocument1 pageSound Velocity Chartmohsinmajeed08No ratings yet

- Asme Section IxDocument47 pagesAsme Section Ixمحمودالوصيف100% (8)

- WPS For Different Materail by BhelDocument176 pagesWPS For Different Materail by Bhelsaisssms911691% (46)

- 6.419x Module 2 Report: Part 1: VisualizationDocument2 pages6.419x Module 2 Report: Part 1: VisualizationBegad HosniNo ratings yet

- A Stone Sat Still Teacher GuideDocument7 pagesA Stone Sat Still Teacher GuideChronicleBooksNo ratings yet

- JD KRA LAB TeamDocument27 pagesJD KRA LAB TeamANILNo ratings yet

- WI-824-003 First Article InspectionDocument2 pagesWI-824-003 First Article InspectionAndreas Schlager100% (1)

- Anicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateDocument9 pagesAnicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateAnicon Flowcontols llpNo ratings yet

- D.Muthu Swamy: QMS Lead AuditorDocument4 pagesD.Muthu Swamy: QMS Lead Auditormuthuswamy77No ratings yet

- 1635 - 03 Control of Non Conforming Products Rev. 01Document5 pages1635 - 03 Control of Non Conforming Products Rev. 01Senthilkumar NarayananNo ratings yet

- Report No Date Customer Name Heat No Material Grade Size No of Pieces Weight Color CodeDocument1 pageReport No Date Customer Name Heat No Material Grade Size No of Pieces Weight Color CodeRohit VishwakarmaNo ratings yet

- Internal Quality Audit: Ogive Technology LLP Quality System ProcedureDocument2 pagesInternal Quality Audit: Ogive Technology LLP Quality System Proceduretrivesh100% (1)

- Close Non-Conformance Reports (NCRs) QuicklyDocument3 pagesClose Non-Conformance Reports (NCRs) QuicklyRsjBugtong100% (1)

- DPT Report 02Document2 pagesDPT Report 02Amit Hasan100% (1)

- Department Quality & FS Objective (Revision2015) - SampleDocument1 pageDepartment Quality & FS Objective (Revision2015) - SampleRachel YapNo ratings yet

- NCRDocument1 pageNCRUmair BaBer100% (1)

- Internal Audit Check Sheet StoreDocument5 pagesInternal Audit Check Sheet StoreRamdas PaithankarNo ratings yet

- Bgl-Pm-Qa-12 Control of Non Conforming OutputsDocument4 pagesBgl-Pm-Qa-12 Control of Non Conforming OutputsMohit SinghNo ratings yet

- Route Card Implementation (In In-House and Supplier)Document10 pagesRoute Card Implementation (In In-House and Supplier)Manoharar RNo ratings yet

- QA Non Conformance Report Word TemplateDocument2 pagesQA Non Conformance Report Word TemplateTomi Kazuo100% (1)

- Qap 900000236 R0Document4 pagesQap 900000236 R0meet bhavsarNo ratings yet

- BDL Ed QM 1Document162 pagesBDL Ed QM 1Sai DhruvNo ratings yet

- Calibration Procedure FOR Calipers General: Technical ManualDocument8 pagesCalibration Procedure FOR Calipers General: Technical ManualrcmetrologyNo ratings yet

- Design Process Flow ChartDocument3 pagesDesign Process Flow Chartjiten5591No ratings yet

- Project Name: Report Number: Project Code: Inspection Date: Costumer: Inspector NameDocument1 pageProject Name: Report Number: Project Code: Inspection Date: Costumer: Inspector NameprasongNo ratings yet

- QP-55-03 Customer Complaint Suggestion Comment & SurveyDocument6 pagesQP-55-03 Customer Complaint Suggestion Comment & SurveySamsudin AhmadNo ratings yet

- Management System Manual Iso 90014 fEB-11Document23 pagesManagement System Manual Iso 90014 fEB-11ilgarNo ratings yet

- 07.01.05 Fabrication Galvanizing R1Document11 pages07.01.05 Fabrication Galvanizing R1Bhanu Pratap ChoudhuryNo ratings yet

- ESSAR BULK TERMINAL LIMITED - HAZIRA HAZARD IDENTIFICATIONDocument4 pagesESSAR BULK TERMINAL LIMITED - HAZIRA HAZARD IDENTIFICATIONsrinibas mohapatraNo ratings yet

- Inspection standards for foam packing partsDocument9 pagesInspection standards for foam packing partsBalvinder SinghNo ratings yet

- Equivalent Steel GradesDocument3 pagesEquivalent Steel Gradesbasiri jayadeepNo ratings yet

- Rejection Record.Document10 pagesRejection Record.karan shahNo ratings yet

- QSV 2 Product Release Procedure EN 01Document6 pagesQSV 2 Product Release Procedure EN 01prashanthNo ratings yet

- QSP-002 R0 QSP For Document and Data ControlDocument17 pagesQSP-002 R0 QSP For Document and Data ControljennyNo ratings yet

- 00251900DAST66718 - EXCO00 (Rev. A)Document7 pages00251900DAST66718 - EXCO00 (Rev. A)Mustafa msiNo ratings yet

- Iso TS 16949 2009Document30 pagesIso TS 16949 2009AndroidFlaghipNo ratings yet

- MM/COP/HR/F/08 - Mahabal Metals Staff Induction Training RecordsDocument3 pagesMM/COP/HR/F/08 - Mahabal Metals Staff Induction Training RecordsNitin KambleNo ratings yet

- Quality InductionDocument15 pagesQuality InductionaleemmurtazaNo ratings yet

- Supplier Audit Check Sheet For New & NON ISO SupplierDocument7 pagesSupplier Audit Check Sheet For New & NON ISO SupplierManoj Kaushik100% (1)

- Process Analysis: SL No Process Proces S Owner Input Output Methods Interfaces With Measure of Performance (MOP)Document12 pagesProcess Analysis: SL No Process Proces S Owner Input Output Methods Interfaces With Measure of Performance (MOP)DhinakaranNo ratings yet

- Api q1 - Iso 9001Document2 pagesApi q1 - Iso 9001Ivan Gutierrez0% (1)

- Quality Management PlanDocument67 pagesQuality Management PlanHamza El FadiliNo ratings yet

- ISO 9001:2015 Audit ChecklistDocument4 pagesISO 9001:2015 Audit ChecklistyuniNo ratings yet

- Quality Manual1111Document35 pagesQuality Manual1111Nizar KhalidNo ratings yet

- Sample Report AudioDocument33 pagesSample Report AudioraulNo ratings yet

- NcManagement - SA1 - 2021Document13 pagesNcManagement - SA1 - 2021Nagarajan100% (1)

- IQA-Incoming Inspection Flow ChartDocument1 pageIQA-Incoming Inspection Flow ChartmohNo ratings yet

- YHGfL Quality Manual OverviewDocument27 pagesYHGfL Quality Manual Overviewadarshdk1No ratings yet

- MKT Procedure - Evaluating Customer Satisfaction P1Document1 pageMKT Procedure - Evaluating Customer Satisfaction P1sumanNo ratings yet

- Manufacturing Quality PlanDocument4 pagesManufacturing Quality PlanDIENSHNo ratings yet

- Ministry planning document risk registerDocument17 pagesMinistry planning document risk registerSh Tanzeel Ur RehmanNo ratings yet

- Quality PlanDocument2 pagesQuality PlanSekar Krish100% (1)

- QMS 3Document11 pagesQMS 3Ram MohanNo ratings yet

- PEIPL-SOP-01 For Incoming Material Insp.Document1 pagePEIPL-SOP-01 For Incoming Material Insp.Balkishan DyavanapellyNo ratings yet

- In Process Inspection Stage Flow Chart: Spacechem EnterprisesDocument6 pagesIn Process Inspection Stage Flow Chart: Spacechem EnterprisesSourav SharmaNo ratings yet

- EN 388 StandardDocument11 pagesEN 388 StandardEngr Saeed Anwar100% (1)

- An Analysis of STEM in Early Childhood Education 8 MarchDocument60 pagesAn Analysis of STEM in Early Childhood Education 8 MarchEngr Saeed AnwarNo ratings yet

- Faisal Anwar CV UpdatedDocument2 pagesFaisal Anwar CV UpdatedEngr Saeed AnwarNo ratings yet

- Faisal New 15 March PDF UdatedDocument54 pagesFaisal New 15 March PDF UdatedEngr Saeed AnwarNo ratings yet

- ASME Section VIII Div. 1 Pressure Vessel Inspection GuideDocument47 pagesASME Section VIII Div. 1 Pressure Vessel Inspection GuideTayfunwNo ratings yet

- Heliyon: Lam Thi Bich Le, Toan Thai Tran, Ngoc Hai TranDocument7 pagesHeliyon: Lam Thi Bich Le, Toan Thai Tran, Ngoc Hai TranMUHAMMAD ARIF DZIKRI ASMADINo ratings yet

- Arc Welding Filler Metal Selection ChartDocument7 pagesArc Welding Filler Metal Selection Chartepriyono0% (1)

- ElectrodosDocument14 pagesElectrodosanon-635614100% (6)

- General Subject Teacher ApplicationDocument1 pageGeneral Subject Teacher ApplicationEngr Saeed AnwarNo ratings yet

- General Subject Teacher ApplicationDocument1 pageGeneral Subject Teacher ApplicationEngr Saeed AnwarNo ratings yet

- Challan FormDocument1 pageChallan FormFurqan ButtNo ratings yet

- Effective Interviewing TechniquesDocument17 pagesEffective Interviewing TechniquesEngr Saeed AnwarNo ratings yet

- QAQCDocument14 pagesQAQCEngr Saeed AnwarNo ratings yet

- Selection of An NDT Method and The Extent of TestingDocument8 pagesSelection of An NDT Method and The Extent of TestingEngr Saeed AnwarNo ratings yet

- Standard Operating Procedure Control of Quality Records: SOP-05 Document No.: Sop/Instruction/01Document3 pagesStandard Operating Procedure Control of Quality Records: SOP-05 Document No.: Sop/Instruction/01Engr Saeed AnwarNo ratings yet

- 8607 PDFDocument31 pages8607 PDFEngr Saeed AnwarNo ratings yet

- SopDocument60 pagesSopanon-6927682% (11)

- E205 PDFDocument24 pagesE205 PDFFikri RahimNo ratings yet

- Mild & Low Alloy Steel Bare WireDocument6 pagesMild & Low Alloy Steel Bare WireEngr Saeed AnwarNo ratings yet

- Pyramid Steel Structures (PVT.) Limited: Welding Consumable Control ProcedureDocument8 pagesPyramid Steel Structures (PVT.) Limited: Welding Consumable Control ProcedureEngr Saeed AnwarNo ratings yet

- Quality Inspection Status For Main Shed Pyramid Steel Structure (PVT.) LTDDocument92 pagesQuality Inspection Status For Main Shed Pyramid Steel Structure (PVT.) LTDEngr Saeed AnwarNo ratings yet

- ABC 5edDocument93 pagesABC 5edJuan Diego Garcia EsquenNo ratings yet

- Quality Inspection Process for Main Shed StructureDocument92 pagesQuality Inspection Process for Main Shed StructureEngr Saeed AnwarNo ratings yet

- Request For Inspection: SR No Activity. Description. Drawing No. Quality Performance Poor Avrg. GoodDocument4 pagesRequest For Inspection: SR No Activity. Description. Drawing No. Quality Performance Poor Avrg. GoodEngr Saeed AnwarNo ratings yet

- Rashid KhanDocument2 pagesRashid KhanEngr Saeed AnwarNo ratings yet

- Request for Steel Structure InspectionDocument4 pagesRequest for Steel Structure InspectionEngr Saeed AnwarNo ratings yet

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDocument4 pagesProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarNo ratings yet

- Master Thesis Topics in AviationDocument7 pagesMaster Thesis Topics in Aviationhwxmyoief100% (2)

- PHED 111 HealthDocument19 pagesPHED 111 HealthApril Ann HortilanoNo ratings yet

- The Eleven Principles of Leadership PDFDocument1 pageThe Eleven Principles of Leadership PDFMwanja MosesNo ratings yet

- Creative TeachingDocument254 pagesCreative TeachingYusuf Rizal100% (1)

- Ipcrf Draft 2020Document32 pagesIpcrf Draft 2020Anne Besin100% (1)

- CRC Certification Guide201107Document39 pagesCRC Certification Guide201107Natalie CNo ratings yet

- Seminar ReportDocument42 pagesSeminar Reportsammuel john100% (1)

- Math 120 Past Exam QuestionsDocument199 pagesMath 120 Past Exam Questions19cerena03No ratings yet

- Health Safety Environment Engineer - Murata - LinkedInDocument1 pageHealth Safety Environment Engineer - Murata - LinkedInudbarryNo ratings yet

- Supranuclear Control Opf Eye MovementsDocument162 pagesSupranuclear Control Opf Eye Movementsknowledgeguruos179No ratings yet

- The Obstructive ObjectDocument13 pagesThe Obstructive ObjectCarla Santos100% (1)

- Anchoring Effect in Making DecisionDocument11 pagesAnchoring Effect in Making DecisionSembilan Puluh DuaNo ratings yet

- Delhi Public School Internationa Kampala Uganda Annual Planner 23 24 CirculationDocument2 pagesDelhi Public School Internationa Kampala Uganda Annual Planner 23 24 Circulationgaurang1111No ratings yet

- Hbet 4603 AssignmentsDocument13 pagesHbet 4603 Assignmentschristina lawieNo ratings yet

- ORIENTATION On The Conduct of PHIL-IRI 2018Document44 pagesORIENTATION On The Conduct of PHIL-IRI 2018Janine Armamento100% (1)

- Sci GDocument12 pagesSci GEvans KipyegoNo ratings yet

- Final Year Project Examination Time TableDocument7 pagesFinal Year Project Examination Time TableVid YashaNo ratings yet

- Factors Affecting "Entrepreneurial Culture": The Mediating Role of CreativityDocument21 pagesFactors Affecting "Entrepreneurial Culture": The Mediating Role of CreativitySalsabila BahariNo ratings yet

- Nursing: Student Name Affiliation Course Instructor Due DateDocument8 pagesNursing: Student Name Affiliation Course Instructor Due DateHAMMADHRNo ratings yet

- J. Zamora Elementary School Budget ProposalDocument18 pagesJ. Zamora Elementary School Budget ProposalNnz Tugnao100% (1)

- Certification Gramarrian MalmaDocument3 pagesCertification Gramarrian MalmaSteffi GraceNo ratings yet

- The 2017 Terahertz Science and Technology Roadmap: Journal of Physics D: Applied PhysicsDocument50 pagesThe 2017 Terahertz Science and Technology Roadmap: Journal of Physics D: Applied PhysicsNUR AZIZATUL ULYANo ratings yet

- Club Proposal FormDocument3 pagesClub Proposal FormSyed Fahim RahmanNo ratings yet

- Module 1 Chapter 1Document10 pagesModule 1 Chapter 1MarckNo ratings yet

- PBL GoalsDocument2 pagesPBL GoalsjabdullahADSNo ratings yet

- TLE10 CSS Q3 M8 Installing-Configuring-Computer-Systems FVa-1Document10 pagesTLE10 CSS Q3 M8 Installing-Configuring-Computer-Systems FVa-1TsoondaNo ratings yet

- Module 5 - Gender and The SexDocument15 pagesModule 5 - Gender and The SexKrishna LiamNo ratings yet

- ReviewDocument182 pagesReviewRea Aguilar San PabloNo ratings yet