Professional Documents

Culture Documents

Plate Heat Exchanger Design in Excel

Uploaded by

amitkray67%(12)67% found this document useful (12 votes)

7K views6 pagesComplete design of Plate Heat Exchanger made in excel

Original Title

Plate Heat Exchanger design in excel

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentComplete design of Plate Heat Exchanger made in excel

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

67%(12)67% found this document useful (12 votes)

7K views6 pagesPlate Heat Exchanger Design in Excel

Uploaded by

amitkrayComplete design of Plate Heat Exchanger made in excel

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 6

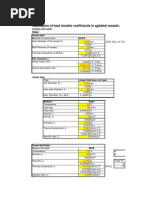

PLATE HEAT EXCHAN

SIDE-I

FLUID: Water

Flow Rate m3/hr 139.32

in kg/s 38.68

Properties @ 43.5 C

Specific Heat J/Kg-K 4190

Thermal Conductivity Watt/mK 0.586

Viscocity Ns/m2*(10^-3) 0.0013

Density Kg/m3 999.564

Dirt Coefficient from Coulson and

Richardson table 12.9 30000

Thermal Conductivity of Alloy 316 @ 23 C W/m-K 16.3

Temperature In C 49

Temperature Out C 38

Average Temp for calculating Properties 43.5

TD1=TI1-TO2 12.879

TD2=TO1-TI2 8

Logarithmic Mean Temp Diff 10.247

No of Transfer Units=(TI1-TO1)/LMTD 1.074

Ft found from fig:12.62 of Ch Engg Design

by Coulson and Richardson is

2:2 pass arrangement assumed passes 2

U(Overall Heat Transfer Coeficient)

assumed is from fig 12.2 W/m2-K 3088

Mass Flow Rate Kg/s 38.683

Heat Duty is W 1782887

HT Area required m2 60.92

Plate Length m 0.8

Plate Width m 0.7

Plate thickness m 0.0005

Plate Spacing m 0.003

No of Plates per pass 54.5

Plate (Length * width) m2 0.56

Number of Channels/pass 54

No of Plates Required Plates 108.78

Number of Plates rounded up Plates 109

Channel Cross section area is (width *

spacing) 0.0021

De or hydraulic mean radius is m 0.006

Calculation for Channel Velocity

SIDE-1 Water

Channel Velocity (MFR/(D*Channel CS* no

of channels/pass) m/s 0.34

Reynolds Number (Nre) 1637.36

Prandtl Number Npr 8.94

Heat Transfer Coefficient is W/m2-K 7488.67

Overall Heat Transfer Coefficient

calculated W/m2-K 3088.3

Pressure Drop Calculation

The Plate Pressure drop can be estimated

using a form of the equation for flow in the

conduit Pp= 8jf(Lp/de)(up2/2)

The path Length Lp

Gp/ up

Friction Factor jf= 0.6x Re^(-0.3)

For this PHE

jf= 0.065

Path Length = Plate length x Number of Passes

1.600 m

Pp= 8089.7 N/m2

The Port Pressure drop due to contraction

and expansion losses through the ports in

the plates must be added to the friction

loss Ppt= 1.3Np(upt2/2)

The velocity through the ports=w/Ap, m/s upt

mass flow through the ports, kg/s w

Area of the ports, m2 (dpt2)/4

Port diameter,m dpt

Number of Passes Np

Take Port Diameter as 125 mm

Port Area is 0.012 m2

Velocity through Port 3.152 m/s

Ppt= 12912.1 N/m2

Total Pressure drop= 21001.8 N/m2

0.2 bar

PLATE HEAT EXCHANGERS

SIDE-II

FLUID Water

Flow Rate m3/hr 250.00

in kg/s 69.43

Properties @ 33.8 C

Specific Heat J/Kg-K 4196

Thermal Conductivity Watt/mK 0.583

Viscocity Ns/m2*(10^-3) 0.0013

Density Kg/m3 999.75

Dirt Coefficient from Coulson and Richardson

table 12.9 30000

Temperature In C 30

Temperature Out C 36.1

Avg Temp for calculating Properties 33.1

0.925

Mass Flow Rate Kg/s 69.43

SIDE-2 Water

Channel Velocity (MFR/(D*Channel CS* no of

channels/pass) m/s 0.61

Reynolds Number (Nre) 2766.11

Prandtl Number Npr 9.56

Heat Transfer Coefficient is W/m2-K 10760.98

Overall Heat Transfer Coefficient Asumed W/m2-K 3088

sure Drop Calculation

The Plate Pressure drop can be estimated

using a form of the equation for flow in the

conduit Pp= 8jf(Lp/de)(up2/2)

The path Length Lp

Gp/ up

Friction Factor jf= 0.6x Re^(-0.3)

For this PHE

jf= 0.056

Path Length = Plate length x Number of Passes

1.600 m

Pp= 6913.5 N/m2

The Port Pressure drop due to contraction and

expansion losses through the ports in the

plates must be added to the friction loss Ppt= 1.3Np(upt2/2)

The velocity through the ports=w/Ap, m/s upt

mass flow through the ports, kg/s w

Area of the ports, m2 (dpt2)/4

Port diameter,m dpt

Number of Passes Np

Take Port Diameter as 125 mm

Port Area is 0.012 m2

Velocity through Port 5.657 m/s

Ppt= 41585.4 N/m2

Total Pressure drop= 48498.9 N/m2

0.5 bar

You might also like

- Plate Heat Exchanger Design in ExcelDocument6 pagesPlate Heat Exchanger Design in ExcelSteve WanNo ratings yet

- TankjktDocument57 pagesTankjktAnonymous 20VAru100% (2)

- Process Heat Transfer: Principles, Applications and Rules of ThumbFrom EverandProcess Heat Transfer: Principles, Applications and Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (11)

- Coil DesignDocument7 pagesCoil DesignSajal Kulshrestha100% (2)

- Jacket Area CalculationDocument12 pagesJacket Area CalculationPraveen Prajapati100% (2)

- How 50 Million People Are Changing the WorldDocument5 pagesHow 50 Million People Are Changing the WorldCTRCTR0% (1)

- Shell and Tube Heat ExchangerDocument19 pagesShell and Tube Heat Exchangerhuangjl33% (3)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersFrom EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersRating: 4 out of 5 stars4/5 (13)

- Condenser CalculationsDocument9 pagesCondenser CalculationsAngelo Imbo100% (2)

- SCR Heat Exchanger Design 2018 For NO PHASE CHANGEDocument37 pagesSCR Heat Exchanger Design 2018 For NO PHASE CHANGEAnonymous 1uUqRkc9p8100% (1)

- Sizing For Vaporiser/Flash Vessel: InputsDocument3 pagesSizing For Vaporiser/Flash Vessel: InputsSaravana ChandranNo ratings yet

- EjectorDocument6 pagesEjectorbadelitamarius100% (1)

- Round Tube and Plate Fin Air Cooled Condenser CalculationDocument8 pagesRound Tube and Plate Fin Air Cooled Condenser Calculationjamil100% (1)

- Design of Plate Type Heat Exchanger ProjectDocument32 pagesDesign of Plate Type Heat Exchanger Projectraviawade92% (26)

- HE Design CalculationDocument4 pagesHE Design CalculationkishoreprithikaNo ratings yet

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument7 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateAnonymous xrBCp9Ej50% (4)

- Jacket and Coils of Agitated Vessels PDFDocument2 pagesJacket and Coils of Agitated Vessels PDFlolofm25No ratings yet

- TEMA Sheet Heat Exchanger SpecificationDocument3 pagesTEMA Sheet Heat Exchanger SpecificationSonNguyenNo ratings yet

- Ejector Working PrincipleDocument11 pagesEjector Working Principleanuram66100% (3)

- Internal Coil CalculationDocument19 pagesInternal Coil CalculationMr Incognito100% (3)

- Condenser DesignDocument2 pagesCondenser DesignrcalaforraNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Bahasa InggrisDocument8 pagesBahasa InggrisArintaChairaniBanurea33% (3)

- Anatomy 090819Document30 pagesAnatomy 090819Vaishnavi GourabathiniNo ratings yet

- Plate Heat Exchanger CalculationDocument2 pagesPlate Heat Exchanger CalculationTint Tiger100% (2)

- Technical Data Sheet For Shell and Tube Heat Exchager Design SpecificationDocument5 pagesTechnical Data Sheet For Shell and Tube Heat Exchager Design SpecificationSakthi VelNo ratings yet

- Heat Exchanger - Preliminary Data SheetDocument4 pagesHeat Exchanger - Preliminary Data SheetgksakthiNo ratings yet

- Plate Heat Exchanger CalculationDocument6 pagesPlate Heat Exchanger CalculationNgoVietCuongNo ratings yet

- Jacketed Vessel DesignDocument5 pagesJacketed Vessel DesignfunkkkkyNo ratings yet

- Heat Exchanger DesignDocument37 pagesHeat Exchanger DesignAnurag IngleNo ratings yet

- Process Heat Transfer - D. Q. KernDocument273 pagesProcess Heat Transfer - D. Q. KernMuhammad Andrifar Empatpuluhlima0% (1)

- Calculation Overall Heat TransferDocument4 pagesCalculation Overall Heat TransferDavid LambertNo ratings yet

- TankHeatingCoil&BoilerCapacityRequirement Rev 2Document1 pageTankHeatingCoil&BoilerCapacityRequirement Rev 2sooner123456No ratings yet

- Plate Heat ExchangersDocument34 pagesPlate Heat ExchangersGautam Sharma100% (1)

- Shell Tube Heat Exchanger DesignDocument7 pagesShell Tube Heat Exchanger DesignMakhdoom Ibad HashmiNo ratings yet

- Heat Exchanger Specification Sheet: MM M? M? Performance of One UnitDocument9 pagesHeat Exchanger Specification Sheet: MM M? M? Performance of One UnitGladys ZiSing LeeNo ratings yet

- Radiation and Convection Heat TransferDocument5 pagesRadiation and Convection Heat TransfergsdaundhNo ratings yet

- Heat ExchangerDocument53 pagesHeat ExchangerNurulHidayahNo ratings yet

- Calculation of Scrubber DiameterDocument44 pagesCalculation of Scrubber DiameterRamakrishna SomuNo ratings yet

- Shell and Tube VaporizerDocument17 pagesShell and Tube VaporizercontinentalflossNo ratings yet

- Jacketed Vessel Design CalculusDocument4 pagesJacketed Vessel Design Calculusmaspiqdo100% (1)

- Film Temp Calculation For Thermic Fluid ApplicationDocument2 pagesFilm Temp Calculation For Thermic Fluid ApplicationmayurjannuNo ratings yet

- Chiller Estimator 4.0Document25 pagesChiller Estimator 4.0Prince RajaNo ratings yet

- Ejector BasicsDocument2 pagesEjector Basicsa234f56No ratings yet

- Heat Transfer Area For Fin Tube Heat Exchanger For FBDDocument8 pagesHeat Transfer Area For Fin Tube Heat Exchanger For FBDPrathmesh GujaratiNo ratings yet

- Autoclave ReactorDocument24 pagesAutoclave ReactorMeredith Villarete100% (1)

- Preliminary Heat Exchanger Design EstimationDocument2 pagesPreliminary Heat Exchanger Design EstimationahmadlieNo ratings yet

- Vapor Liquid Vertical SeparatorDocument4 pagesVapor Liquid Vertical SeparatorIoana Popescu100% (1)

- REFREG CHARGE CALCDocument12 pagesREFREG CHARGE CALCKhadija MirajNo ratings yet

- Pressure Vessel WEIGHT PresentDocument17 pagesPressure Vessel WEIGHT PresentErol Aydin100% (3)

- Condenser Calculation - Shell and TubeDocument3 pagesCondenser Calculation - Shell and TubedeeptimisraNo ratings yet

- Calculate Heat-Cool Time - Batch ReactorDocument2 pagesCalculate Heat-Cool Time - Batch ReactorGargiulo Anita100% (1)

- Ammonia Flooded EvaporatorDocument3 pagesAmmonia Flooded Evaporatorreclatis14100% (1)

- Storage-Tank Heat TransferDocument57 pagesStorage-Tank Heat Transfervitcon87100% (12)

- Vacuum Pump SizingDocument1 pageVacuum Pump SizingMuhammad HassamNo ratings yet

- Engineering Data Book-Spirax Sarco (2009) PDFDocument187 pagesEngineering Data Book-Spirax Sarco (2009) PDFVILLANUEVA_DANIEL2064100% (1)

- Shell and Tube Heat Exchanger SpreadsheetDocument2 pagesShell and Tube Heat Exchanger SpreadsheetHernan Cardenas Franco100% (1)

- Shell and Tube Heat Exchanger1Document19 pagesShell and Tube Heat Exchanger1Lily NurdianaNo ratings yet

- Condenser DesignDocument2 pagesCondenser DesignRahul ParmarNo ratings yet

- Document From SuperjimmyDocument4 pagesDocument From SuperjimmyNoverian Ruzqia SyardiNo ratings yet

- Chap 8. CondenserDocument9 pagesChap 8. CondenserAli Ahsan100% (1)

- PED (Design of Shell and Tube Heat Exchanger) 63Document5 pagesPED (Design of Shell and Tube Heat Exchanger) 63DineshNo ratings yet

- Heat Exchanger Calculation Sheet - 1Document10 pagesHeat Exchanger Calculation Sheet - 1Ritesh Dev MaityNo ratings yet

- Helical Super Heater DesignDocument13 pagesHelical Super Heater DesignG S DeshpandeNo ratings yet

- Audio System DiagramsDocument1 pageAudio System DiagramsamitkrayNo ratings yet

- Svyasa Admission FormDocument2 pagesSvyasa Admission FormamitkrayNo ratings yet

- A Gentle Introduction To Logistic RegressionDocument12 pagesA Gentle Introduction To Logistic RegressionamitkrayNo ratings yet

- Wings PPT For Call Centre & CSCsDocument12 pagesWings PPT For Call Centre & CSCsamitkrayNo ratings yet

- NMPEDDocument1 pageNMPEDamitkrayNo ratings yet

- Aircooled Heat Exchanger Process Data SheetDocument2 pagesAircooled Heat Exchanger Process Data SheetamitkrayNo ratings yet

- Rental Agreement SampleDocument2 pagesRental Agreement SampleamitkrayNo ratings yet

- Jet Pumps and EjectorsDocument1 pageJet Pumps and EjectorsamitkrayNo ratings yet

- Expressing a tensor in different coordinate systemsDocument8 pagesExpressing a tensor in different coordinate systemsRajat Yadav YaduvanshiNo ratings yet

- Two Phase Flow and Heat Transfer - Unit 1 - How To Access The PortalDocument4 pagesTwo Phase Flow and Heat Transfer - Unit 1 - How To Access The PortalamitkrayNo ratings yet

- Run No Ip When Debian BootedDocument3 pagesRun No Ip When Debian BootedamitkrayNo ratings yet

- Codeseller InstallationDocument10 pagesCodeseller InstallationamitkrayNo ratings yet

- Run No Ip When Debian BootedDocument3 pagesRun No Ip When Debian BootedamitkrayNo ratings yet

- Process Data Sheet: Calculation of Pressure Drop in Fixed Catalyst BedsDocument1 pageProcess Data Sheet: Calculation of Pressure Drop in Fixed Catalyst BedsamitkrayNo ratings yet

- Growing Up A LotusDocument6 pagesGrowing Up A LotusamitkrayNo ratings yet

- How To Control FearDocument23 pagesHow To Control Fear4titudeNo ratings yet

- Input R0Document22 pagesInput R0amitkrayNo ratings yet

- Honesty Is The Best Policy EssayDocument5 pagesHonesty Is The Best Policy Essayamitkray100% (3)

- Items RequiredDocument2 pagesItems RequiredamitkrayNo ratings yet

- List of Yoga SchoolsDocument1 pageList of Yoga SchoolsamitkrayNo ratings yet

- When You Finally Realise That Nothing Is Permanent in This LifeDocument1 pageWhen You Finally Realise That Nothing Is Permanent in This LifeamitkrayNo ratings yet

- Pump TemplateDocument2 pagesPump TemplateamitkrayNo ratings yet

- PRDS Station Operation PrincipleDocument1 pagePRDS Station Operation PrincipleamitkrayNo ratings yet

- Chola Claim FormDocument4 pagesChola Claim Formamitkray100% (1)

- Length)Document4 pagesLength)George Godswill AguNo ratings yet

- DomainsDocument1 pageDomainsamitkrayNo ratings yet

- A Walk Through On The Present Format of Lokpal Declaration Meant For Central Government Employees: 1. Appendix-1Document2 pagesA Walk Through On The Present Format of Lokpal Declaration Meant For Central Government Employees: 1. Appendix-1amitkrayNo ratings yet

- OC-CC FeeDocument1 pageOC-CC FeeamitkrayNo ratings yet

- AMB4520R0v06: Antenna SpecificationsDocument2 pagesAMB4520R0v06: Antenna SpecificationsЕвгений ГрязевNo ratings yet

- Handout CalmAlphaDocument2 pagesHandout CalmAlphaDave SnowdenNo ratings yet

- Frequently Asked Questions: Wiring RulesDocument21 pagesFrequently Asked Questions: Wiring RulesRashdan HarunNo ratings yet

- New Japa Retreat NotebookDocument48 pagesNew Japa Retreat NotebookRob ElingsNo ratings yet

- Elements of Ayurveda Daily Routine GuideDocument1 pageElements of Ayurveda Daily Routine GuideShivani GargNo ratings yet

- Chapter 7 - The Political SelfDocument6 pagesChapter 7 - The Political SelfJohn Rey A. TubieronNo ratings yet

- Sexual & Reproductive Health of AdolocentsDocument8 pagesSexual & Reproductive Health of AdolocentsSourav HossenNo ratings yet

- China Sichuan Province Se'Ergu Hydro Power Project PDD 20080821Document50 pagesChina Sichuan Province Se'Ergu Hydro Power Project PDD 20080821akhilkuwarNo ratings yet

- Horizontal Vertical MarketDocument4 pagesHorizontal Vertical MarketVikasNo ratings yet

- GBM Auction Versus English Auction A Large-Scale Empirical Study - E. Bessire, K. Elhadji Tchiambou (October 2021)Document18 pagesGBM Auction Versus English Auction A Large-Scale Empirical Study - E. Bessire, K. Elhadji Tchiambou (October 2021)Guillaume GonnaudNo ratings yet

- SSRN Id26238Document21 pagesSSRN Id26238Ayame KusuragiNo ratings yet

- OTGNNDocument13 pagesOTGNNAnh Vuong TuanNo ratings yet

- Tutorial Backpropagation Neural NetworkDocument10 pagesTutorial Backpropagation Neural NetworkHeru PraNo ratings yet

- Graphic Organizers for Organizing IdeasDocument11 pagesGraphic Organizers for Organizing IdeasMargie Tirado JavierNo ratings yet

- 04 LimeDocument32 pages04 LimeGoogle user100% (1)

- EDIBLE VACCINES: A COST-EFFECTIVE SOLUTIONDocument21 pagesEDIBLE VACCINES: A COST-EFFECTIVE SOLUTIONPritish SareenNo ratings yet

- F&B Data Analyst Portfolio ProjectDocument12 pagesF&B Data Analyst Portfolio ProjectTom HollandNo ratings yet

- Dryers in Word FileDocument5 pagesDryers in Word FileHaroon RahimNo ratings yet

- 740 (Q50, V40, Awa 4Document10 pages740 (Q50, V40, Awa 4rawat2583No ratings yet

- OsmanabadDocument5 pagesOsmanabadKirankumar MutnaliNo ratings yet

- TelanganaDocument16 pagesTelanganaRamu Palvai0% (1)

- XYZ Company Asset Inventory ReportDocument1 pageXYZ Company Asset Inventory ReportNini KitsNo ratings yet

- Gregory University Library Assignment on Qualities of a Reader Service LibrarianDocument7 pagesGregory University Library Assignment on Qualities of a Reader Service LibrarianEnyiogu AbrahamNo ratings yet

- Re: Laparoscopic Myomectomy: A Review of Alternatives, Techniques and ControversiesDocument1 pageRe: Laparoscopic Myomectomy: A Review of Alternatives, Techniques and ControversiesMayada OsmanNo ratings yet

- Reading in Philippine History (Chapter 3)Document14 pagesReading in Philippine History (Chapter 3)AKIO HIROKINo ratings yet

- J-Garlic in CheeseDocument12 pagesJ-Garlic in CheeseMary GinetaNo ratings yet

- SIM7020 Series - HTTP (S) - Application Note - V1.04Document15 pagesSIM7020 Series - HTTP (S) - Application Note - V1.04Vinicius BarozziNo ratings yet