Professional Documents

Culture Documents

Astm D999

Uploaded by

pradellesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm D999

Uploaded by

pradellesCopyright:

Available Formats

Designation: D 999 08

Standard Test Methods for

Vibration Testing of Shipping Containers1

This standard is issued under the fixed designation D 999; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon () indicates an editorial change since the last revision or reapproval.

--`,,```,,,,````-`-`,,`,,`,`,,`---

1. Scope priate safety and health practices and determine the applica-

1.1 These test methods cover vibration tests of filled ship- bility of regulatory limitations prior to use. Specific precau-

ping containers. Such tests may be used to assess the perfor- tionary statements are given in Section 6.

mance of a container, with its interior packing and means of 2. Referenced Documents

closure, both in terms of its strength and of the protection it

provides its contents when it is subjected to vibration such as 2.1 ASTM Standards: 4

it experiences in transportation. These procedures are suitable D 996 Terminology of Packaging and Distribution Environ-

for testing containers of any form, material, kind, design of ments

interior packing, means of closure, and any size and weight. D 3580 Test Methods for Vibration (Vertical Linear Motion)

They are not intended for determining the response of products Test of Products

to vibration for product design purposes, nor are they intended D 4169 Practice for Performance Testing of Shipping Con-

for tests of products in their operational configuration as other tainers and Systems

more suitable procedures are available for these purposes.2,3 D 4332 Practice for Conditioning Containers, Packages, or

1.2 The following methods appear: Packaging Components for Testing

Method A1Repetitive Shock Test (Vertical Motion). D 7387 Test Method for Vibration Testing of Intermediate

Method A2Repetitive Shock Test (Rotary Motion). Bulk Containers (IBCs) Used for Shipping Liquid Hazard-

Method BSingle Container Resonance Test. ous Materials (Dangerous Goods)

Method CPalletized Load, Unitized Load, or Vertical E 122 Practice for Calculating Sample Size to Estimate,

Stack Resonance Test. With Specified Precision, the Average for a Characteristic

1.3 For testing of intermediate bulk containers (IBCs) con- of a Lot or Process

taining liquid hazardous materials, refer to Test Method 2.2 ISO Standards:

D 7387. ISO 2247 PackagingComplete, Filled Transport

1.4 These test methods fulfill the requirements of Interna- PackagesVibration Test at Fixed Low Frequency5

tional Organization for Standardization standards ISO 8318 ISO 8318 PackagingComplete, Filled Transport

and ISO 2247. The ISO standards may not meet the require- PackagesVibration Tests Using a Variable Frequency5

ments for these methods. 3. Terminology

1.5 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical 3.1 DefinitionsFor definitions of terms used in these test

conversions to SI units that are provided for information only methods, see Terminology D 996.

and are not considered standard. 3.1.1 double amplitude, nthe maximum value of a sinu-

1.6 This standard does not purport to address all of the soidal quantity (peak-to-peak).

safety concerns, if any, associated with its use. It is the 3.1.2 octave, nthe interval between two frequencies hav-

responsibility of the user of this standard to establish appro- ing a ratio of two (2).

3.1.3 power spectral density (PSD), nused to quantify the

intensity of random vibration in terms of mean-square accel-

1

These test methods are under the jurisdiction of ASTM Committee D10 on eration per unit of frequency. The units are g2/Hz ((m/s2)2/Hz),

Packaging and are the direct responsibility of Subcommittee D10.22 on Physical where g is the acceleration of gravity, equal to 386 in./s2 (9.8

Test Methods.

Current edition approved Aug. 1, 2008. Published August 2008. Originally

approved in 1948. Last previous edition approved in 2007 as D 999 07.

2 4

Military Standard Environmental Test Methods, MIL-STD-810F, Method 514, For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Vibration, available from www.dodssp.daps.mil/dodssp.htm. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

International Electrotechnical Commission Recommendation, Publication 68- Standards volume information, refer to the standards Document Summary page on

2-6, Part 2, Test F: Vibration, Basic Environmental Testing Procedures for the ASTM website.

5

Electronic Components and Electrical Equipment, available from American Na- Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

tional Standards Institute, Inc., 25 W. 43rd St., 4th Floor, New York, NY 10036. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International 1

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

D 999 08

m/s2). Power spectral density is the limiting mean square value 4.8 Any or all of these test methods may be employed, as

in a given rectangular bandwidth divided by the bandwidth, as determined by the appropriate performance specification, with

the bandwidth approaches zero. test intensities, frequency ranges, and test durations as called

3.1.4 repetitive shock, nimpacts of a package on a test for in the specification. Although these tests do not simulate the

platform which occur cyclically from input oscillatory motion. shipping environment, they are intended to create the damage-

3.1.5 resonance, nfor a system undergoing forced vibra- producing potential of the shipping environment. Results of

tion, the frequency at which any change of the exciting any one of these methods may differ from the results of the

frequency, positive and negative, in the vicinity of the exciting others.

frequency causes a decrease in the response of the system.

5. Apparatus

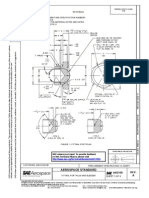

4. Significance and Use 5.1 Method A1Repetitive Shock Test (Vertical Motion):

4.1 Shipping containers are exposed to complex dynamic 5.1.1 Vibration Test Machine, with a platform having a

stresses when subjected to vibration present in all transporta- horizontal surface of sufficient strength and rigidity so that the

tion vehicles. Approximating the actual damage, or lack of applied vibrations are essentially uniform over the entire test

damage, experienced in shipping may require subjecting the surface when loaded with the test specimen. The platform shall

container(s) and contents to vibration inputs. be supported by a mechanism that vibrates it so the motion is

4.2 Resonant responses during shipment can be severe and approximately a vertical sinusoidal input. (A rotary motion of

may lead to package or product failure. Identification of critical the platform is not acceptable.) The double amplitude displace-

frequencies, and the nature of package stresses can aid in ment of the vibration shall be fixed at or controlled to 1 in. (25

minimizing the effect of these occurrences. mm), and the frequency shall be variable within the range from

4.3 Vibration tests should be based on representative field 2 to at least 5 Hz (cycles per second). The vibration test

data. When possible, the confidence level may be improved by machine shall be equipped with fences, barricades, or other

comparing laboratory test results with actual field shipment restraints to keep the test specimen from falling off the

data. It is highly recommended that one understand the most platform without restricting its vertical motion.

common failures to ones products and packaging in distribu- 5.2 Method A2Repetitive Shock Test (Rotary Motion):

tion, and then attempt to replicate those failures in the 5.2.1 Vibration Test Machine, with a platform having a

laboratory. Once such replication is established, then that test horizontal surface of sufficient strength and rigidity so that the

can become the minimum necessary test for future packaged applied vibrations are essentially uniform over the entire test

products to pass. surface when loaded with the test specimen. The platform shall

4.4 Exposure to vibration can affect the shipping container, be supported by a mechanism that vibrates it so that the motion

its interior packaging, means of closure, and contents. These is a rotational input with the vertical component approximately

tests allow analysis of the interaction of these components. sinusoidal. The double amplitude displacement of the vibration

Design modification to one or more of these components may shall be fixed at 1 in. (25 mm), and frequency shall be variable

--`,,```,,,,````-`-`,,`,,`,`,,`---

be utilized to achieve optimum performance in the shipping from 2 to at least 5 Hz (cycles per second). The vibration test

environment. machine shall be equipped with fences, barricades, or other

4.5 Methods A1 and A2, Repetitive Shock Tests, are suitable restraints to keep the test specimen from falling off the

for tests of individual containers that are transported unre- platform without restricting its vertical motion.

strained on the bed of a vehicle and may be suitable for tests of 5.3 Metal Shim:

containers that might be subjected to repetitive shocks due to 5.3.1 A metal shim is used in Methods A1 and A2 for

magnification of vibrations in unit loads or stacks. determining when the shipping container is leaving the testing

NOTE 1Methods A1 and A2 produce different vibration motions, and platform by a sufficient amount as described in Section 9.

therefore, will generate different forces which may result in different 5.3.2 Specifications for metal shim used in Methods A1 and

damage modes and intensities. Results from these two methods may not A2:

correlate with one another. Width: 50 mm (20. in.) minimum

Thickness: 1.6 mm (116 in.)

4.6 Method B, Single Container Resonance Test, tests or Length: 254 mm (10 in.) minimum

determines the ability of an individual container and its interior

packaging to protect the contents from transportation vibration, 5.4 Methods B and CResonance Tests:

particularly when the container and its contents might exhibit 5.4.1 Vibration Test Machine, with a platform having a

resonant responses. horizontal surface of sufficient strength and rigidity so that the

applied vibrations are essentially uniform over the entire test

NOTE 2Individual products that are palletized might be better tested surface when loaded with the test specimen. The platform shall

using Method C.

be supported by a mechanism capable of producing vibration in

4.7 Method C, Palletized Load, Unitized Load or Vertical the vertical linear plane at controlled accelerations or displace-

Stack Resonance Test, covers the determination of the presence ments, or both, over a controlled continuously variable range of

and the effects of resonance in palletized loads and multiple- frequencies. (A rotary motion of the platform is not accept-

unit stacked loads, and whether or not the strength of the able.) Suitable fixtures and attachment points shall be provided

containers is sufficient to withstand dynamic loads when to rigidly attach the test container to the platform for Method

stacked. B. Restraints shall be provided to restrain the horizontal motion

Copyright ASTM International 2

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

D 999 08

of the test specimens on the platform without restricting the 8. Conditioning

vertical motion of the specimen(s), for Method C. 8.1 Condition test specimens prior to the test or during the

5.5 InstrumentationAccelerometers, signal conditioners, test, or both, in accordance with the requirements of the

and data display or storage devices are required to measure and applicable specification. When no conditioning requirements

control the accelerations at the test surface in Methods B and are given, and the container materials are climatically sensitive,

C. Instrumentation may also be desirable for monitoring the a conditioning atmosphere is recommended (see Practice

response of the containers and packaged items. The instrumen- D 4332 for standard and special conditions).

tation system shall have a response accurate to within 65 %

over the range specified for the test. Accelerometers should be 9. Procedure

small and light weight enough as to not influence the response 9.1 Methods A1 and A2Repetitive Shock Tests:

of the item being measured nor influence the results of the test. 9.1.1 Place the shipping container on the test machine

Detailed information on suitable instrumentation may be found platform in its normal shipping orientation.

in the Shock and Vibration Handbook.6 9.1.1.1 For Method A1, place the shipping container in the

5.6 Conditioning ApparatusAdequate facilities shall be center of the platform. For Method A2, place the shipping

provided for conditioning test specimens at selected humidity container near the backstop or fence, equidistant from each

and temperature prior to or during the test, or both, in side of the platform.

accordance with the requirements of the applicable specifica- 9.1.1.2 Restraining devices may be needed to prevent the

tion. shipping container from moving horizontally or to prevent

excessive rocking. Restraining devices may effect the vertical

6. Safety Precautions movement of the shipping container and attention must be

6.1 These test methods may produce severe mechanical given to how and where restraints are used.

responses of the test specimens. Therefore, fences, barricades, 9.1.1.3 When restraining devices are used, orient and adjust

and other restraints must have sufficient strength and must be the restraining devices to allow free horizontal movement of

adequately secured. Operating personnel must remain alert to the shipping container without restricting the vertical move-

potential hazards and take necessary precautions for their ment. There should be no severe horizontal impacting of

safety. Stop the test immediately if a dangerous condition containers against restraints.

should develop. For example, causing the container to go into 9.1.2 Start the vibration of the platform at a frequency of

resonance during testing may result in uncontrollable respon- about 2 Hz, and steadily increase the frequency until the metal

sive bouncing. This may also lead to a dangerous situation, shim can be inserted under one long edge of the container and

over-testing, or premature failures and potential safety issues to moved intermittently along the entire length of the container.

testing personnel and equipment. When inserted, the shim must be flat, not at an angle.

9.1.2.1 The shim must be inserted a minimum of 100 mm (4

7. Test Specimens in.) under the shipping container when determining the proper

test frequency.

7.1 The test specimen shall consist of the container, as

9.1.2.2 The shim must be capable of being inserted between

intended for shipment, loaded with the interior packaging and

the shipping container and test platform throughout the dura-

the actual contents for which it was designed. Blemished or

tion of the test. Adjustments to the test frequency may be

rejected products may be used, if the defect is recorded prior to

required to maintain proper separation of container from

the test. Dummy test items should be used for developmental

platform because of container movement or physical changes

testing when necessary, but may not be used for final accep-

to the container. When adjustments are made, they should be

tance testing.

recorded.

NOTE 3Surrogate material may be used when actual product is 9.1.3 Continue the test at this frequency for a length of time

unacceptable for use (for example, package testing for hazardous materi- stated in the applicable specification, if any, or for a predeter-

als). For packaging intended to contain liquid dangerous goods (hazardous mined period, or until a predetermined amount of damage may

materials), water should be used as the standard test medium.

be detected. The test may be stopped momentarily to inspect

7.2 Sensors and transducers may be applied with the mini- for damage.

mum possible alteration of the test specimen, to obtain data on 9.1.4 If the container might possibly be transported in any

the container or packaged item. When it is necessary to observe other orientations, test at least one container in each possible

the contents during the test, holes may be cut in noncritical orientation for the full specified test duration.

areas of the container. NOTE 4When no test duration is specified, a test duration of 1 h is

7.3 Whenever sufficient containers and contents are avail- recommended. Practice D 4169 may also be referred to for test durations.

able, it is highly desirable that five or more replicate tests be

9.1.5 Inspect the container and its contents and record any

conducted to improve the statistical reliability of the data

damage or deterioration resulting from the test.

obtained (see Practice E 122).

9.2 Method BSingle Container Resonance Test:

9.2.1 Fasten the test specimen, in its normal shipping

orientation, securely to the platform of the vibration equipment

6

Harris, C. M., Shock and Vibration Handbook, McGraw-Hill, New York, NY, so that the specified vibration condition is transmitted to the

--`,,```,,,,````-`-`,,`,,`,`,,`---

1988, Chapter 16. outer part of the container. Mount the accelerometer to either

Copyright ASTM International 3

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

D 999 08

the top or bottom of the platform, as close to the test item as has limited frequency range capability and additional equipment may be

possible, (insuring the accelerometer is not damaged by the needed to cover the entire recommended frequency range.

product) or in a location that produces data representative of 9.2.3 Dwell for the specified length of time at each resonant

table motion. Monitor the amplitude and frequency data frequency determined in 9.2.2.1 (limited to a maximum of the

achieved on the platform to ensure that the desired test four most severe resonances), or until damage to the container

conditions are produced. is noted, whichever occurs first. Adjust the frequency of

9.2.2 Determine resonance frequency or frequencies in one vibration as necessary to maintain resonance.

of two ways: sine sweep or random input.

9.2.2.1 Resonance Search Using Sine SweepAdjust the NOTE 8If no dwell time is specified, a dwell of 15 min is recom-

mended. Practice D 4169 may also be referred to for test durations.

vibration test apparatus to produce the specified constant

acceleration amplitude (zero-to-peak) over the specified range 9.2.4 Repeat the procedures of 9.2.1, 9.2.2.1, and 9.2.3 with

of frequencies. Starting at the lowest frequency, sweep the the container oriented in those orientations that might be

frequency of the vibration at a continuous logarithmic rate of expected to occur in distribution.

0.5 to 1.0 octaves per minute to the upper frequency limit and 9.2.5 Inspect the container and its contents and record any

back to the lower limit. Repeat this complete cycle twice, damage or deterioration resulting from the test.

recording all the resonant responses of the test specimen. These 9.3 Method CPalletized Load, Unitized Load, or Vertical

resonance frequencies can be determined in a variety of ways, Stack Resonance Test:

including auditory (listening to the response), visual (a strobo- 9.3.1 Place the full-size unitized or palletized load(s) of test

scope or video system may be beneficial aids), or with an specimen(s) on the test machine platform to a height equal to

accelerometer. that used in the mode of shipment. It is best to test the load

NOTE 5Resonance frequency or frequencies may differ between

exactly the way it is prepared for normal shipment, that is,

sweep up and sweep down. The natural frequency of the test specimen is stretch wrap, banding, stacking configuration, etc. A single

approximately midway between the apparent resonance frequency (ies) vertical column of containers may be used if vertical stacking

found on the sweep up versus the sweep down. alignment is used in shipping. Attach restraining devices to the

NOTE 6If no test severity is specified, an acceleration amplitude of platform to prevent the specimen(s) from horizontal movement

0.25 gs 0.5 g (2.45 m/s2 4.9 m/s2) (zero to peak) over the frequency

--`,,```,,,,````-`-`,,`,,`,`,,`---

off the platform, and to prevent toppling and excessive rocking.

range from 3 to 100 Hz is often sufficient to excite resonance. Practice Adjust the restraining devices to permit free movement of the

D 4169 also may be referred to for test level and duration recommenda-

tions.

test specimen(s) of approximately 10 mm (0.4 in.) in any

horizontal direction. Attach the accelerometer to the platform

9.2.2.2 Resonance Search Using Random Vibration as close as possible to the test specimen(s), but protected so

InputAs an alternative to using sine sweep for identifying that it will not be contacted.

resonance frequency or frequencies of a packaged product, it 9.3.2 Determine resonance point(s) in one of two ways: sine

may be faster to use random vibration input, where a wide sweep or random input.

frequency input band excites all of the natural frequencies of a 9.3.2.1 Resonance Search Using Sine SweepAdjust the

packaged product simultaneously. Please see Test Method vibration test apparatus to produce the specified constant

D 3580 for further discussion of using random vibration input. acceleration amplitude (zero-to-peak) over the specified range

To utilize this methodology, it is necessary to attach an of frequencies. Starting at the lowest frequency, sweep the

accelerometer, or accelerometers, to the product to monitor frequency of vibration at a continuous logarithmic rate of 0.5 to

maximum response frequencies. It is also necessary to attach 1.0 octaves/min to the upper frequency limit, and then back to

an accelerometer to the platform to assure the platform motion the lower limit. Repeat this complete cycle twice, and record

is representative of the desired PSD input spectrum. Mount a all the resonance responses of the test load. These resonance

transducer in such a way as to identify the resonant frequency frequencies can be determined in a variety of ways, including

or frequencies of the package in the direction of the table auditory (listening to the response), visual (a stroboscope or

motion. video system may be beneficial aids), or with an accelerometer

9.2.2.3 The minimum frequency range should be from 3 to located on an upper package in the stack.

100 Hz at a minimum power spectral density (PSD) level of

0.005 g2/Hz (0.049 (m/s2)2/Hz), or a spectrum known to be NOTE 9Multiple-unit loads likely are to exhibit several resonant

appropriate. Note that this spectra does not represent any responses.

particular real world environment but simply allows one to NOTE 10Resonance frequencies may differ between sweep up and

sweep down. The natural frequency of the test specimen is approximately

identify package natural frequencies within the area of forcing midway between the apparent resonance frequency found on the sweep up

frequencies found most often in transportation. Start the versus the sweep down.

vibration system such that the PSD levels do not overshoot the NOTE 11If no test severity is specified, an acceleration amplitude of

desired spectrum during startup. Initiate the test at least 6dB 0.25 g (2.5 m/s2) (zero to peak) over the frequency range from 2 to 100 Hz

below full level and increment in one or more subsequent steps is recommended. Practice D 4169 also may be referred to for test level

to full test level. Allow the control system to stabilize suffi- recommendations.

ciently to represent a stable spectrum shape and level. Compare 9.3.2.2 Resonance Search Using Random Vibration

the input with the response. Record the resonance responses of InputAs an alternative to using sine sweep for identifying

the test item. resonance frequency or frequencies of a unitized, palletized, or

NOTE 7It should be noted that some existing vibration test equipment stacked load, it may be faster to use random vibration input,

Copyright ASTM International 4

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

D 999 08

where a wide frequency input band excites all of the natural 10.1.4 Sequence of test methods and the test intensities,

frequencies of the test specimen simultaneously. Please see frequencies, and durations used. State whether radom or swept

Test Method D 3580 for further discussion of using random sine input was used to determine resonance frequencies. If

vibration input. To utilize this methodology, it is necessary to random, report the spectrum used.

attach an accelerometer or accelerometers to an upper package 10.1.5 Verification of compliance with the test method or

in the stack to monitor the maximum response frequency or describe any deviations.

frequencies. This tansducer should be mounted on the outside 10.1.6 Number of replications of each test.

of the specimen to capture the resonance frequency of the load 10.1.7 Atmospheric conditions the test specimens were

versus the resonance information of the interior of the indi- subjected to, both prior and during the test.

vidual package. It is necessary to attach an accelerometer to the 10.1.8 Any other test the specimens were subjected to prior

platform to assure the platform motion is representative of the to this test.

desired PSD input spectrum. 10.1.9 Description of the apparatus and the instrumentation

9.3.2.3 The minimum frequency range should be from 3 to used, including the date of last calibration.

100 Hz at a minimum power spectral density (PSD) level of 10.1.10 Detailed descriptions and photographs of the fixtur-

0.005 g2/Hz (0.049 (m/s2)2/Hz), or a spectrum known to be ing used in the test.

appropriate. Note that this spectra does not represent any 10.1.11 Results of the test.

particular real world environment but simply allows one to 10.1.12 Descriptions and photographs of any damage or

identify stack natural frequencies within the area of forcing deterioration to the containers or their contents as a result of the

frequencies found most often in transportation. Start the test(s).

vibration system such that the PSD levels do not overshoot the 10.1.13 State whether the damage created in the laboratory

desired spectrum during startup. Initiate the test at least 6dB testing replicates actual field damage to the container and

below full level and increment in one or more subsequent steps contents.

to full test level. Allow the control system to stabilize suffi- 10.1.14 All resonant responses and any observations that

ciently to represent a stable spectrum shape and level. Com- may assist in correct interpretation of results or lead to

paring the input with the response, record the resonance improvements in the design of the container, interior packag-

responses of the test load. ing, or product.

9.3.3 Dwell for the specified length of time at each resonant 10.1.15 Statement of whether or not the specimen(s) com-

frequency determined in 9.3.2 (limited to a maximum of the plied with the requirements of the applicable specification.

four most severe resonances), or until damage is noted in the 10.1.16 For Methods A1 and A2, describe any adjustments

load, whichever occurs first. Adjust the frequency of the made to the test frequency during the test.

vibration as necessary to maintain resonance.

11. Precision and Bias

NOTE 12If no dwell time is specified, a dwell time of 15 min is

recommended. Practice D 4169 may be referred to for test durations.

11.1 Precision:

11.1.1 No information is presented about the damage-

9.3.4 Inspect the container(s) and contents and record any producing ability of these test methods, since the results are

damage or deterioration resulting from the test. usually nonquantitative.

11.1.2 Based on limited data from one laboratory, the

10. Report within-laboratory repeatability standard deviation for the pri-

10.1 The report shall include the following: mary resonance may be below 1 Hz, depending on the item

10.1.1 Identification and description of the test specimens, tested. Higher order resonances may have more variability.

including the container, the interior packaging, and the product 11.2 BiasThe procedures in these test methods have no

(give size, weight, and any other pertinent details). bias because there is no accepted reference material or proce-

10.1.2 If Method C is used for unitized loads, describe the dure.

unitized load and the height of the stack, and the unitizing

method employed. 12. Keywords

10.1.3 Purpose of the test and the applicable performance 12.1 repetitive shock; resonance; shipping container; stack

specification, if any. resonance; vibration

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright ASTM International 5

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

You might also like

- Sonatherapy, Cymatics, and Phonon Chains PDFDocument11 pagesSonatherapy, Cymatics, and Phonon Chains PDFGary Robert Buchanan100% (2)

- Schumann Resonance Tuning: 430.65 HZDocument4 pagesSchumann Resonance Tuning: 430.65 HZVince Migliore100% (2)

- Fastener Grades A1, A2, A3 & A4, A5 To BS en ISO 3506Document3 pagesFastener Grades A1, A2, A3 & A4, A5 To BS en ISO 3506Paul OnionsNo ratings yet

- Astm D 3767Document8 pagesAstm D 3767jackie wang100% (1)

- Measuring Building Vibrations with the VM40Document40 pagesMeasuring Building Vibrations with the VM40MeetNo ratings yet

- Astm D4169-16 PDFDocument17 pagesAstm D4169-16 PDFAnhKiet67% (3)

- Randall L. Waechter and Lauren Sergio - Manipulation of The Electromagnetic Spectrum Via Fields Projected From Human Hands: A Qi Energy Connection?Document27 pagesRandall L. Waechter and Lauren Sergio - Manipulation of The Electromagnetic Spectrum Via Fields Projected From Human Hands: A Qi Energy Connection?SonyRed100% (2)

- Vibration Testing of Shipping Containers: Standard Test Methods ForDocument6 pagesVibration Testing of Shipping Containers: Standard Test Methods ForShaker Qaidi100% (1)

- Astm A513 PDFDocument20 pagesAstm A513 PDFpradelles89% (9)

- Astm A572Document4 pagesAstm A572charles4667% (3)

- As 5169Document5 pagesAs 5169Wuod JipangaNo ratings yet

- As 5169Document5 pagesAs 5169Wuod JipangaNo ratings yet

- ASTM Vs ISTA For Package TestingDocument27 pagesASTM Vs ISTA For Package TestingKR123No ratings yet

- En Iso 2578Document19 pagesEn Iso 2578Uriel Peña100% (2)

- Astm A681 PDFDocument14 pagesAstm A681 PDFraulNo ratings yet

- ASTM D642 Determining Compressive Resistance of ShippingDocument5 pagesASTM D642 Determining Compressive Resistance of ShippingMohd RazaNo ratings yet

- Spark Gap TransmitterDocument34 pagesSpark Gap TransmitterpepeNo ratings yet

- Astm D4727Document9 pagesAstm D4727Matt ShultzNo ratings yet

- Astm G85-11Document14 pagesAstm G85-11Rafa Lopez PuigdollersNo ratings yet

- Astm d4169Document12 pagesAstm d4169wdavid81100% (2)

- Astm D 1388-18 2019Document6 pagesAstm D 1388-18 2019KM100% (4)

- ASTM B 213-13pdf PDFDocument4 pagesASTM B 213-13pdf PDFPacifier NothingfaceNo ratings yet

- Chassis, Aerodynamics and FeaDocument25 pagesChassis, Aerodynamics and FeaSivaPrasad Chekri100% (1)

- Legally Binding US Standard for Cold-Formed Steel TubingDocument8 pagesLegally Binding US Standard for Cold-Formed Steel TubingpradellesNo ratings yet

- Astm D4169-14Document15 pagesAstm D4169-14robNo ratings yet

- Astm D-4212Document6 pagesAstm D-4212Dan Mat100% (2)

- ASTM D-374 ThicknessDocument11 pagesASTM D-374 ThicknessHaryantiNo ratings yet

- Astm A689 PDFDocument4 pagesAstm A689 PDFpradellesNo ratings yet

- Mil-Std-1251a - Listing Screw and Bolts - An-Nas-MsDocument182 pagesMil-Std-1251a - Listing Screw and Bolts - An-Nas-Mspradelles100% (2)

- Iso 14243 1 2002 FR PDFDocument8 pagesIso 14243 1 2002 FR PDFRobe01No ratings yet

- Mechanical Handling of Unitized Loads and Large Shipping Cases and CratesDocument5 pagesMechanical Handling of Unitized Loads and Large Shipping Cases and CratesGabriel Herrera Gonzalez100% (1)

- D785 08Document6 pagesD785 08Adam Chin100% (2)

- Iso Astm 52904 2019 PDFDocument9 pagesIso Astm 52904 2019 PDFFantasticNo ratings yet

- Peel or Stripping Strength of Adhesive Bonds: Standard Test Method ForDocument3 pagesPeel or Stripping Strength of Adhesive Bonds: Standard Test Method ForCris BandaNo ratings yet

- D 3045Document5 pagesD 3045practice rosNo ratings yet

- ASTM D 4332 - 2014 Standard Practice For Conditioning Containers, Packages, or Packaging Components For TestingDocument3 pagesASTM D 4332 - 2014 Standard Practice For Conditioning Containers, Packages, or Packaging Components For TestingAndrew Horowitz100% (2)

- ASTM D572 04 - Standard Test Method For Rubber-Deterioration by Heat and OxygenDocument4 pagesASTM D572 04 - Standard Test Method For Rubber-Deterioration by Heat and OxygenAndre SpirimNo ratings yet

- Performance Testing of Packages For Single Parcel Delivery SystemsDocument10 pagesPerformance Testing of Packages For Single Parcel Delivery SystemsAlevj Db100% (1)

- Guidelines For Selecting and Using ISTA Test Procedures and ProjectsDocument16 pagesGuidelines For Selecting and Using ISTA Test Procedures and ProjectsScott KramerNo ratings yet

- SR en 10025-04Document8 pagesSR en 10025-04pukla100% (2)

- SR en 10025-04Document8 pagesSR en 10025-04pukla100% (2)

- Astm D880Document4 pagesAstm D880keberso1602100% (1)

- Burst Testing of Flexible Package Seals Using Internal Air Pressurization Within Restraining PlatesDocument8 pagesBurst Testing of Flexible Package Seals Using Internal Air Pressurization Within Restraining PlatesraulNo ratings yet

- Characteristics and Applications of Different Types of Dampers As Seismic Energy DissipaterDocument4 pagesCharacteristics and Applications of Different Types of Dampers As Seismic Energy DissipaterKiran N S GowdaNo ratings yet

- Determining The Effects of High Altitude On Packaging Systems by Vacuum MethodDocument4 pagesDetermining The Effects of High Altitude On Packaging Systems by Vacuum Methodmohammed karasnehNo ratings yet

- MSRR 6522Document7 pagesMSRR 6522pradellesNo ratings yet

- Def Stan 01-8Document33 pagesDef Stan 01-8pradellesNo ratings yet

- ASTM D4169-22 - Standard Practice For Performance Testing of Shipping Containers and Systems REDLINESDocument28 pagesASTM D4169-22 - Standard Practice For Performance Testing of Shipping Containers and Systems REDLINESRotem SokolovskyNo ratings yet

- Undercut TableDIN 509Document6 pagesUndercut TableDIN 509Dwi DarsonoNo ratings yet

- Diffraction Gratings PDFDocument580 pagesDiffraction Gratings PDFJuan BarradasNo ratings yet

- The Self-Resonance and Self-Capacitance of Solenoid CoilsDocument35 pagesThe Self-Resonance and Self-Capacitance of Solenoid CoilsharishkumarsinghNo ratings yet

- Determining Residual Solvents in Packaging Materials: Standard Test Method ForDocument4 pagesDetermining Residual Solvents in Packaging Materials: Standard Test Method ForHernan MartNo ratings yet

- Astm A36 PDFDocument5 pagesAstm A36 PDFAnindya Aulia Pratiwi67% (3)

- Quality Assurance of Pressure-Sensitive Tapes: Standard Practice ForDocument6 pagesQuality Assurance of Pressure-Sensitive Tapes: Standard Practice ForYoga PradanaNo ratings yet

- Bridge Impact Testing: Standard Test Method ForDocument5 pagesBridge Impact Testing: Standard Test Method ForAlevj DbNo ratings yet

- Astm D 543-06Document7 pagesAstm D 543-06varniktpNo ratings yet

- ASTM D 792 2013 6pDocument6 pagesASTM D 792 2013 6psandrasilvabr2124100% (1)

- Prevent pulsation problemsDocument10 pagesPrevent pulsation problemsfathim1356No ratings yet

- Iso 7380Document8 pagesIso 7380pradelles100% (1)

- MSRR 6011Document14 pagesMSRR 6011pradellesNo ratings yet

- Astm d4332Document3 pagesAstm d4332許喬甯No ratings yet

- MSRR 6523Document5 pagesMSRR 6523pradelles100% (1)

- ASTM D 999 01 Vibration Testing of Shipping Containers PDFDocument5 pagesASTM D 999 01 Vibration Testing of Shipping Containers PDFManuel Castillo FernandezNo ratings yet

- D642-15 Standard Test Method For Determining Compressive Resistance of Shipping Containers, Components, and Unit LoadsDocument5 pagesD642-15 Standard Test Method For Determining Compressive Resistance of Shipping Containers, Components, and Unit LoadsAlbertus EinsteiniusNo ratings yet

- 3 A Overview ISTADocument8 pages3 A Overview ISTApbipkgNo ratings yet

- Microwave Lab Manual-1Document108 pagesMicrowave Lab Manual-1waleed nazar0% (1)

- ASTM D4459.6249 Standard Practice For Xenon-Arc Exposure of Plastics Intended For Indoor Applications PDFDocument4 pagesASTM D4459.6249 Standard Practice For Xenon-Arc Exposure of Plastics Intended For Indoor Applications PDFkkakosimNo ratings yet

- ASTM D4169-22 - Standard Practice For Performance Testing of Shipping Containers and SystemsDocument17 pagesASTM D4169-22 - Standard Practice For Performance Testing of Shipping Containers and SystemsRotem Sokolovsky100% (7)

- Astm D6344-98 PDFDocument4 pagesAstm D6344-98 PDFRajeshNo ratings yet

- Overview of Procedure 3E: Similar Packaged-Products in Unitized Loads For Truckload ShipmentDocument12 pagesOverview of Procedure 3E: Similar Packaged-Products in Unitized Loads For Truckload ShipmentAnonymous KTQZaINo ratings yet

- Tearing Strength of Fabrics by Trapezoid Procedure: Standard Test Method ForDocument7 pagesTearing Strength of Fabrics by Trapezoid Procedure: Standard Test Method ForMaqsoodUlHassanChaudharyNo ratings yet

- ASTM D470. Crosslinked Insulations and Jackets For Wire and Cable1Document25 pagesASTM D470. Crosslinked Insulations and Jackets For Wire and Cable1sanrris4503090% (1)

- Astm d412 Testing FixtureDocument6 pagesAstm d412 Testing FixturePallab Jyoti DasNo ratings yet

- ASTM D 638 - 14 Standard Test Method For Tensile Properties of PlasticsDocument1 pageASTM D 638 - 14 Standard Test Method For Tensile Properties of PlasticsGustavoNo ratings yet

- F648 1889433-1Document8 pagesF648 1889433-1Kandido AcaNo ratings yet

- As 60068.3.6-2003 Environmental Testing - Supporting Documentation and Guidance - Confirmation of The PerformDocument8 pagesAs 60068.3.6-2003 Environmental Testing - Supporting Documentation and Guidance - Confirmation of The PerformSAI Global - APAC0% (1)

- BS en 60068-3-5-2002Document16 pagesBS en 60068-3-5-2002Benny KuehNo ratings yet

- Q Lab CRHDocument165 pagesQ Lab CRHFernando CarmonaNo ratings yet

- D 333 - 96Document6 pagesD 333 - 96PoyoeberNo ratings yet

- Packaging Test RequirementDocument54 pagesPackaging Test Requirementjinmao100% (1)

- Transformation Temperature of Nickel-Titanium Alloys by Thermal AnalysisDocument5 pagesTransformation Temperature of Nickel-Titanium Alloys by Thermal AnalysisSullivam PrestesNo ratings yet

- F1855 1479757-1Document2 pagesF1855 1479757-1Thaweekarn ChangthongNo ratings yet

- D3638-12 Standard Test Method For Comparative Tracking Index of Electrical Insulating MaterialsDocument5 pagesD3638-12 Standard Test Method For Comparative Tracking Index of Electrical Insulating Materialsjose flores100% (1)

- Rust Protection by Metal Preservatives in The Humidity CabinetDocument9 pagesRust Protection by Metal Preservatives in The Humidity CabinettoanvmpetrologxNo ratings yet

- Designation: E1994 09 (Reapproved 2013)Document23 pagesDesignation: E1994 09 (Reapproved 2013)Lupita RamirezNo ratings yet

- E384 31110Document40 pagesE384 31110GonzaloNo ratings yet

- ASTM D3163 For Determining Strength of Adhesively Bonded Rigid Plastic Lap-Shear Joints in Shear by Tension LoadingDocument3 pagesASTM D3163 For Determining Strength of Adhesively Bonded Rigid Plastic Lap-Shear Joints in Shear by Tension LoadingSaavedra Aurel MarcNo ratings yet

- Ista 2a 08-09Document16 pagesIsta 2a 08-09heobukonNo ratings yet

- Astm D 999Document5 pagesAstm D 999sales1spreadNo ratings yet

- TKG® HGW 2083 / 2082: Density Colour DesignationDocument1 pageTKG® HGW 2083 / 2082: Density Colour DesignationpradellesNo ratings yet

- BS-970-part3-Specification-for-Wrought-steels (Bright Bars) - For-Mechanical-And-Allied-Engineering-Purposes PDFDocument39 pagesBS-970-part3-Specification-for-Wrought-steels (Bright Bars) - For-Mechanical-And-Allied-Engineering-Purposes PDFvahab_shaikNo ratings yet

- 605m36 SteelDocument2 pages605m36 Steelhimanshudhol25No ratings yet

- Iso 4014-Din 931Document2 pagesIso 4014-Din 931serzo75No ratings yet

- ARMOR SPECDocument22 pagesARMOR SPECpradellesNo ratings yet

- MS51967DDocument3 pagesMS51967DpradellesNo ratings yet

- An3 Thru An20 Rev-12 PDFDocument4 pagesAn3 Thru An20 Rev-12 PDFpradellesNo ratings yet

- Everyspec Document Download DateDocument4 pagesEveryspec Document Download DatepradellesNo ratings yet

- Mil W 12133 3Document6 pagesMil W 12133 3pradellesNo ratings yet

- Iso 261Document4 pagesIso 261pradellesNo ratings yet

- BS8888Document13 pagesBS8888pradelles0% (1)

- Exp01 ME Meldes ExperimentDocument4 pagesExp01 ME Meldes ExperimentUtkarsh AgarwalNo ratings yet

- Framed Foundation Design for Turbo GeneratorDocument31 pagesFramed Foundation Design for Turbo GeneratorVisa Meena2351No ratings yet

- In-Lab Work: Department of Electrical and Computer Engineering ECE 2262 - Electric CircuitsDocument4 pagesIn-Lab Work: Department of Electrical and Computer Engineering ECE 2262 - Electric CircuitsThiago Araújo de AssisNo ratings yet

- Dynamic Characteristics of A Semi-Rigid Hanging Roof Structure Composed of Glulams and Steel PlateDocument16 pagesDynamic Characteristics of A Semi-Rigid Hanging Roof Structure Composed of Glulams and Steel PlateLong Hin WongNo ratings yet

- 03 Forced OscillatorDocument17 pages03 Forced OscillatorZal FaarizNo ratings yet

- MDOF Transfer FunctionDocument9 pagesMDOF Transfer FunctionSatya Prakash SahooNo ratings yet

- Mechanical VibrationsDocument57 pagesMechanical VibrationsHari Tej AvvaruNo ratings yet

- Basic Concepts in The Design of Electric Bus Ror Short-Circuit Conditions by Bates 1958Document8 pagesBasic Concepts in The Design of Electric Bus Ror Short-Circuit Conditions by Bates 1958customerxNo ratings yet

- Astm C597 09Document2 pagesAstm C597 09Saber AlsidNo ratings yet

- 6731-Article Text-28555-1-10-20121214Document9 pages6731-Article Text-28555-1-10-20121214yasameen NaeemNo ratings yet

- Dom Question BankDocument24 pagesDom Question BankM.Saravana Kumar..M.ENo ratings yet

- Generation of High Voltages & CurrentsDocument79 pagesGeneration of High Voltages & CurrentshamzaNo ratings yet

- Control Systems Engineering MCQDocument74 pagesControl Systems Engineering MCQformyphdNo ratings yet

- D4015 - Resonant ColumnDocument3 pagesD4015 - Resonant ColumnDaniel RodriguezNo ratings yet

- 1988zhang - JAP - An NMR Study of Tetragonal Nd2Fe1 4B and Nd2Fe14 xCoxBDocument4 pages1988zhang - JAP - An NMR Study of Tetragonal Nd2Fe1 4B and Nd2Fe14 xCoxBPatrícia CanazartNo ratings yet

- Api 617 Q-Factor Rotor DynamicsDocument2 pagesApi 617 Q-Factor Rotor Dynamicsmuhfuggin mikeNo ratings yet

- S2 ECE SyllabusDocument58 pagesS2 ECE Syllabuslakshmivs23No ratings yet

- Problems and Solutions Section 2.5 (2.61 Through 2.68)Document6 pagesProblems and Solutions Section 2.5 (2.61 Through 2.68)Kintania Sisca Rivana Part IINo ratings yet

- Air Core ToroidDocument10 pagesAir Core ToroidChandra ShettyNo ratings yet