Professional Documents

Culture Documents

Comprehensive List of Causes

Uploaded by

socrates1958240550%(2)50% found this document useful (2 votes)

1K views1 pageComprehensive List of Causes

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentComprehensive List of Causes

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

50%(2)50% found this document useful (2 votes)

1K views1 pageComprehensive List of Causes

Uploaded by

socrates19582405Comprehensive List of Causes

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

GasLog LNG Services Ltd. Rev.

: 0

Comprehensive List of Causes CLC Effective Date: 01.Nov.2012

PRIOR STARTING COLLECTION OF EVIDENCE

INCIDENT/ Selection of Investigation Team: People taking part in the Position : take photos ,make sketches of the position of all participants from all angle

investigation team should be involved in the incident and have the

Parts : Evidence on the scene (equipment, tools, materials)

appropriate qualifications

ACCIDENT Secure evidence : Team should preserve the evidence prior starting People : Conduct Interviews no more than 24 hrs after the incident

the investigations Paper: Relevant documentation (permits, certificates, training records etc.)

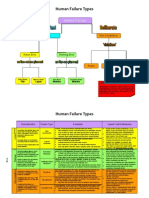

IMMEDIATE CAUSES

UNSAFE ACTS UNSAFE CONDITIONS

i. Failure to follow rules and iv. Incorrect use of equipment or viii. Failure to warn xiv. Under influence of i. Inadequate guards or v. Inadequate warning system xi. Fire and explosion hazards xvii. Bunkers and/or lub

regulations machinery ix. Failure to secure alcohol and/or other barriers vi. Adverse weather conditions xii. Noise or temperature oils

ii. Failure to use personal v. Using defective equipment or x. Making safety devices drugs ii. Inadequate or defective vii. Adverse sea conditions xviii. Port and berthing

xiii. Radiation exposure

facilities

protective equipment machinery inoperable xv. Sabotage, willful damage personal protective viii. Poor housekeeping xiv. Inadequate ventilation xix. Cargo

properly vi. Failure to follow xi. Improper position for task xvi. Suicide/Homicide equipment ix. Congestion or restricted action xv. Environmental conditions xx. Other substandard

iii. Operating equipment or repair/maintenance xii. Improper lifting, handling or xvii. Other substandard acts iii. Defective equipment, x. Inadequate or excessive xvi. Outdated charts, publications or conditions

machinery without authority instructions storage xviii. Failure to focus on the machinery or tools illumination xxi. Condition of Fire /

other documentations

vii. Incorrect navigation of ship conducted task iv. Hull and structural Emergency equipment

xiii. Inappropriate behavior

handling xix. Inappropriate pace

conditions

ROOT CAUSES

PERSONAL FACTORS JOB FACTORS

ROOT CAUSE ANALYSIS

Physical incapacity Injury or illness Inadequate leadership or/and supervision Inadequate research on materials / equipment Inadequate implementation of work

Hearing deficiency Oxygen deficiency Inadequate specification on requisitions standards/procedures

Consideration of HSSE in staffing not effective

Inadequate specifications to vendors Inadequate maintenance of standards

Inappropriate height, weight, size, strength, reach etc. Mental or psychological stress Giving inadequate policy, procedure, practices or

Limited ability to sustain body positions guidelines Inadequate maintenance o Monitoring use of standards/procedures/rules

Conflict demands o Updating

Other permanent physical disabilities Giving objectives, goals or standards that conflict Inadequate preventative

Confusing directions Inadequate management of change controls in place

Others sensory deficiency (tooth, taste, smell, balance) Improper or insufficient delegation o Adjustment / assembly

Emotional overload

Respiratory Incapacity Inadequate Hazard and/or Risk Assessment o Assessment of needs Excessive wear and tear

Extreme concentration/ perception demands

Restricted range of body movement Inadequate matching of individual qualifications and o Cleaning or resurfacing Improper extension of service life

Fatigue due to mental task load or speed

Sensitivities to sensory extremes (temperature, sound etc) job/task requirements o Lubrication and servicing Improper loading or rate of use

Frustration

Substance sensitivities or allergies Inadequate or incorrect performance feedback Inadequate repetitive Inadequate inspection and/or monitoring

Meaningless or disregarding activities

Temporary disabilities Inadequate performance measurement and evaluation o Communication of needs Inadequate maintenance

Mental illness

Vision deficiency Inadequate reinforcement of correct behaviors o Examination of units Inadequate planning of use

Preoccupation with problems

Mental/psychological incapacity Routine, monotony, demand of uneventful

Lack of supervisory/management job knowledge o Part substitution Use by unqualified or untrained people

Emotional disturbance vigilance

Monitoring/Auditing of HSSE not effective o Scheduling of work Abuse or misuse

Support of people not effective Inadequate Tools and Equipment Controlled by supervision

Fears & phobias Lack of knowledge/ skill / competence Unclear or conflict assignment of responsibilities

Inability to comprehend Inadequate adjustment / repair / maintenance o Intentional

Inadequate Competence Assessment Unclear or conflict reporting relationships

Intelligence level Inadequate assessment of needs and risks o Unintentional

Inadequate induction training

Low hearing aptitude Inadequate engineering Inadequate availability No condoned by supervision

Inadequate initial task specific training

Low mechanical aptitude Inadequate orientation

Inadequate assessment of operational readiness Inadequate human factors / ergonomics considerations Contractor selection and oversight

Memory failure Inadequate consideration of human factors/ergonomics Inadequate inspections of the tool, equipment or vehicle Contractor oversight not effective

Inadequate update training

Mental illness Inadequate evaluation of changes before use Contractor Pre-qualification process not effective

Infrequent performance / Practices

Poor co-ordination Inadequate hazard and risk assessment Inadequate removal and replacement of unsuitable item No contractor oversight process

Lack of Coaching / Toolbox talks

Poor judgment Inadequate monitoring of construction Inadequate salvage and reclamation No contractor pre-qualification

Lack of experience

Slow reaction time Inadequate monitoring of initial operation Inadequate standards and specifications Use of non-approved contractor

Misunderstood directions

Physical stress Inadequate standards, specification and /or design criteria Inadequate work standards Inadequate Training / Knowledge Transfer

Improper Behavior / motivation

Physical Stress Improper attempt to avoid discomfort

Incorrect technical design Inadequate communications of standards/ procedures Competency not assessed

Atmospheric pressure variations Inadequate Purchasing o Distribution Inadequate instructions, orientation and /or training

Improper attempt to gain attention

Improper handling of materials o Publication Lessons Learnt not applied

Blood sugar insufficiency Improper attempt to save time or effort

Improper salvage and/or waste disposal o Reinforcing with signs, color codes and job aids Training not effective

Constrained movement Improper performance rewarding

Improper storage of materials o Translation to appropriate languages

Drugs Improper production intensives

Improper transporting of material Inadequate development of standards / procedures

Exposure to health hazards Improper supervisory example

Inadequate communication of safety and health data o Coordination with process design

Exposure to temperature extremes Inadequate intervention for incorrect behavior

Inadequate identification of hazardous items o Employee involvement

Fatigue due to Circadian rhythm disturbance Inadequate reinforcement of correct behavior

Inadequate mode or route of shipment o Inconsistent standards/procedures/rules

Fatigue due to lack of rest Inappropriate aggression

Inadequate receiving inspection and acceptance o Inventory and evaluation of exposures and needs

Fatigue due to sensory overload Inappropriate peer pressure

Fatigue due to task load or duration Lack of incentives

CORRECTIVE & PREVENTIVE ACTIONS

You might also like

- Accident Incident InvestigationDocument3 pagesAccident Incident InvestigationrehanNo ratings yet

- Causes & DefinitionsDocument11 pagesCauses & DefinitionsSayed DarwishNo ratings yet

- Causation Analysis ModelDocument1 pageCausation Analysis ModelElla Agbettor100% (1)

- Cause AnalysisDocument1 pageCause Analysisfathul syaafNo ratings yet

- COSHH Risk AssessmentDocument6 pagesCOSHH Risk AssessmentKyle RobertsonNo ratings yet

- 14 RCAT - Root Cause Analysis TechniquesDocument3 pages14 RCAT - Root Cause Analysis TechniquesDanny Durham100% (1)

- App B SOP-10r0 PM10 Hi Vol Air SamplingDocument22 pagesApp B SOP-10r0 PM10 Hi Vol Air SamplingJorge Kovach AlvaradoNo ratings yet

- Generic Risk Assessment - General Lathe Use v.1Document7 pagesGeneric Risk Assessment - General Lathe Use v.1Darus YasunNo ratings yet

- System Cause Analyzed Technique Accident Investigation Root Analysis Cause ChecklistDocument5 pagesSystem Cause Analyzed Technique Accident Investigation Root Analysis Cause ChecklistponggoooNo ratings yet

- UNC Fire Protection System Impairment Procedures 6 17Document7 pagesUNC Fire Protection System Impairment Procedures 6 17Sigit MahardikaNo ratings yet

- Types of Human ErrorDocument2 pagesTypes of Human ErrorPankaj PaulNo ratings yet

- General Industrial Safety Inspection Checklist Document No: Date Modified: Revision: 0Document9 pagesGeneral Industrial Safety Inspection Checklist Document No: Date Modified: Revision: 0ابو محمدNo ratings yet

- Comprehensive List of Causes: A Tool For Root Cause AnalysisDocument1 pageComprehensive List of Causes: A Tool For Root Cause AnalysisChandru75% (4)

- Comprehensive List of Causes PDFDocument1 pageComprehensive List of Causes PDFReda MashalNo ratings yet

- CLC Poster AWDocument1 pageCLC Poster AWmharja100% (2)

- Pt. Tirtamas Anugrah Iq-Oq Dryer Unit and Filter SeriesDocument8 pagesPt. Tirtamas Anugrah Iq-Oq Dryer Unit and Filter SeriesArwin PradanaNo ratings yet

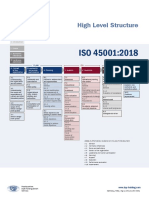

- ISO 45001 Process MapDocument1 pageISO 45001 Process MapAnkurNo ratings yet

- Riskman Template-FinalDocument3 pagesRiskman Template-Finalapi-238786020No ratings yet

- Procedure For Incident Investigation, Non-Conformity and Corrective ActionDocument8 pagesProcedure For Incident Investigation, Non-Conformity and Corrective ActionDaniel Cheng MahsaNo ratings yet

- Cause and Effect Diagram: CA/PA-RCA: Basic ToolDocument21 pagesCause and Effect Diagram: CA/PA-RCA: Basic Toolsiddiquiee74100% (1)

- Equipment Risk AssessmentDocument7 pagesEquipment Risk Assessmentgullipalli srinivasa raoNo ratings yet

- SCAT Chart - Systematic Cause Analysis Technique - SCAT ChartDocument6 pagesSCAT Chart - Systematic Cause Analysis Technique - SCAT ChartSalman Alfarisi100% (1)

- Using A Fume Hood: RiskwareDocument7 pagesUsing A Fume Hood: RiskwaretafouzeltNo ratings yet

- Contingency Plan FormatDocument2 pagesContingency Plan FormatNagarajanNo ratings yet

- HSE-P-08 Corrective and Preventive Action Issue 2.1Document5 pagesHSE-P-08 Corrective and Preventive Action Issue 2.1eng20072007No ratings yet

- Root Cause Analysis Report FormDocument7 pagesRoot Cause Analysis Report Formbenaoumeur benounaNo ratings yet

- Personal & Process Safety For PO-1Document44 pagesPersonal & Process Safety For PO-1Aftab Ahmed MemonNo ratings yet

- SOP Compressed GasDocument4 pagesSOP Compressed GasSandeep ShettyNo ratings yet

- Procedure For Monitoring and MeasurementDocument2 pagesProcedure For Monitoring and MeasurementSAKTHIVEL ANo ratings yet

- 8.19 Poster Unusual SituationsDocument1 page8.19 Poster Unusual Situationsedumm001No ratings yet

- ABH Environmental Impact and Aspect RegisterDocument8 pagesABH Environmental Impact and Aspect RegisterOnaFajardoNo ratings yet

- Class 10000 Iso 7 Cleanroom CleaningDocument5 pagesClass 10000 Iso 7 Cleanroom CleaningRafael De JesusNo ratings yet

- DQSHolding - 760E2 - High Level Structure ISO 45001Document1 pageDQSHolding - 760E2 - High Level Structure ISO 45001MTOLLERNo ratings yet

- RMR HSMS P 002 Aspect Impact AssessmentDocument5 pagesRMR HSMS P 002 Aspect Impact AssessmentkamranNo ratings yet

- Evacuation Drill Report FormatDocument6 pagesEvacuation Drill Report FormatMohammed Ali Qazi100% (1)

- WI of Environment MonitoringDocument5 pagesWI of Environment MonitoringdonnyloNo ratings yet

- Loss Causation ModelDocument6 pagesLoss Causation ModelTerry Penney63% (8)

- JHADocument8 pagesJHARayyan ramosNo ratings yet

- Risk Assessment For Demolition Work 10 Hampstead Road, Dorking, Surrey, RH43AFDocument26 pagesRisk Assessment For Demolition Work 10 Hampstead Road, Dorking, Surrey, RH43AFmohammad Qutubuddin100% (1)

- Checklist Walk Down InspectionDocument1 pageChecklist Walk Down InspectionaspambudiNo ratings yet

- Spill Response Procedures OCLDocument14 pagesSpill Response Procedures OCLThusithaNo ratings yet

- Synergic Safety Engineers: Environmental Aspect & It'S ImpactDocument22 pagesSynergic Safety Engineers: Environmental Aspect & It'S ImpactsgrsthNo ratings yet

- The Root Cause Analysis Process Should Follow These 7 StepsDocument5 pagesThe Root Cause Analysis Process Should Follow These 7 StepsFaisal AbbasNo ratings yet

- List of Documents ISO 45001 Transition Toolkit EN PDFDocument3 pagesList of Documents ISO 45001 Transition Toolkit EN PDFAquino SianiparNo ratings yet

- HSE Program 2024Document2 pagesHSE Program 2024Herdiyansyah AhmadNo ratings yet

- Root Cause Analysis FormDocument2 pagesRoot Cause Analysis Formgunnery02No ratings yet

- Hazards Analysis and Risk Control Record HSE-RACDocument2 pagesHazards Analysis and Risk Control Record HSE-RACHSE S4No ratings yet

- F7-006 Near Miss Report FormDocument5 pagesF7-006 Near Miss Report FormAuthur Konde100% (1)

- F 05 KDI QHSE 17a Environmental Inspection ChecklistDocument4 pagesF 05 KDI QHSE 17a Environmental Inspection ChecklistArsh AlamNo ratings yet

- Calibration Procedure - Pressure Test Transducers For API Specification 6A ApplicationsDocument5 pagesCalibration Procedure - Pressure Test Transducers For API Specification 6A Applicationsvinsensius rasaNo ratings yet

- Hse Program: NO Hse Program Frequency PIC Schedule M-1 M-2 M-3 M-4 M-5 M-6 M-7 M-8 M-9 M-10 M-11 M-12Document1 pageHse Program: NO Hse Program Frequency PIC Schedule M-1 M-2 M-3 M-4 M-5 M-6 M-7 M-8 M-9 M-10 M-11 M-12Hamzan LutfiNo ratings yet

- ISO 17025 Risk Management Example: December 2019Document6 pagesISO 17025 Risk Management Example: December 2019paeg6512No ratings yet

- Environmental MonitoringDocument28 pagesEnvironmental MonitoringAmr Rifai100% (1)

- Risk Assesment Sample ProtocolDocument20 pagesRisk Assesment Sample ProtocolPraveenNo ratings yet

- Incident Investigation (2020)Document77 pagesIncident Investigation (2020)Elchin100% (1)

- Maraba Al Iraq Al Khadraa: Emergency Drill ReportDocument3 pagesMaraba Al Iraq Al Khadraa: Emergency Drill Reportfdfddf dfsdfNo ratings yet

- HiraDocument8 pagesHirarajmohapatraNo ratings yet

- 06a AccreportDocument1 page06a AccreportMohammed MinhajNo ratings yet

- JSA #32 Manual HandlingDocument1 pageJSA #32 Manual HandlingSubham Sohal100% (2)

- 05a AccreportDocument1 page05a AccreportMohammed MinhajNo ratings yet

- Merchant Marine Academy - Pumps PDFDocument251 pagesMerchant Marine Academy - Pumps PDFsocrates19582405100% (2)

- Seafarer Training Record Book MEC6Document85 pagesSeafarer Training Record Book MEC6socrates19582405No ratings yet

- Merchant Marine Academy - Pumps PDFDocument251 pagesMerchant Marine Academy - Pumps PDFsocrates19582405100% (2)

- Electrical Safety Guidance PDFDocument111 pagesElectrical Safety Guidance PDFsocrates19582405No ratings yet

- Electrical Safety Guidance PDFDocument111 pagesElectrical Safety Guidance PDFsocrates19582405No ratings yet

- Propulsion Control OverviewDocument6 pagesPropulsion Control Overviewsocrates19582405No ratings yet

- HV Manual MCADocument262 pagesHV Manual MCAsocrates19582405100% (1)

- HSG 85 - Electricity at WorkDocument33 pagesHSG 85 - Electricity at WorkLandryNo ratings yet

- Comprehensive List of CausesDocument1 pageComprehensive List of Causessocrates1958240550% (2)

- Ex - 04 - Operate Main and Auxiliary Machinery and Associated ControlDocument1 pageEx - 04 - Operate Main and Auxiliary Machinery and Associated Controlsocrates19582405No ratings yet

- How To Select A Pump-By Majid HamedyniaDocument72 pagesHow To Select A Pump-By Majid Hamedyniamajid100% (2)

- Air Compressor Capacity CalculationDocument2 pagesAir Compressor Capacity Calculationsocrates19582405No ratings yet

- Superheat The "Compressor Killer"!: Points To NoteDocument3 pagesSuperheat The "Compressor Killer"!: Points To Notesocrates19582405No ratings yet

- Engine Room Simulator - Based TrainingDocument94 pagesEngine Room Simulator - Based Trainingsocrates19582405100% (1)

- Marine Electrical KnowledgeDocument53 pagesMarine Electrical KnowledgeRhn RhnNo ratings yet

- Hsg253 The Safe Isolation of Plant and EquipmentDocument81 pagesHsg253 The Safe Isolation of Plant and EquipmentRichard HollidayNo ratings yet

- 00 h23 EngineRoomResourceManagement English PDFDocument36 pages00 h23 EngineRoomResourceManagement English PDFsocrates19582405100% (1)

- Gig2 Dec2003 v4 8 PDFDocument36 pagesGig2 Dec2003 v4 8 PDFsocrates19582405No ratings yet

- E.U. Decision On LNG Carriers Equivalency Method and CriteriaDocument3 pagesE.U. Decision On LNG Carriers Equivalency Method and Criteriasocrates19582405No ratings yet

- Bearing SKF Engineering Handbook April2010Document377 pagesBearing SKF Engineering Handbook April2010DanielAvellaneda100% (4)

- IGU World LNG Report 2016 PDFDocument92 pagesIGU World LNG Report 2016 PDFAnonymous 7CxwuBUJz3No ratings yet

- At Berth FAQ Final - V1Document18 pagesAt Berth FAQ Final - V1socrates19582405100% (1)

- Imo Fategue Part 1Document85 pagesImo Fategue Part 1Ali AzouaouNo ratings yet

- Black Out Recovery AnafiDocument1 pageBlack Out Recovery Anafisocrates19582405No ratings yet

- Harmonic Method of Tidal PredictionDocument1 pageHarmonic Method of Tidal Predictionsocrates19582405100% (2)

- Joint Press Release CIC STCW Hours of Rest (Final) PDFDocument4 pagesJoint Press Release CIC STCW Hours of Rest (Final) PDFsocrates19582405No ratings yet

- What Is PID - TutorialDocument5 pagesWhat Is PID - Tutorialsocrates19582405No ratings yet

- Methane ColDocument1 pageMethane ColRodrigo UnzuetaNo ratings yet

- Psychrometric ChartDocument1 pagePsychrometric Chartsocrates19582405No ratings yet

- CHCECE017 Student Assessment Task 3 - ScenariosDocument7 pagesCHCECE017 Student Assessment Task 3 - ScenariosDanica RodriguezNo ratings yet

- ISE III - Task 4 - Extended Writing - CA1 (Role Models in The Media)Document8 pagesISE III - Task 4 - Extended Writing - CA1 (Role Models in The Media)Monika PerezNo ratings yet

- Infinitive and The GerundDocument8 pagesInfinitive and The GerundSergoSanikidze100% (2)

- Malingin - Ronibe B. UTS - BTLED-ICT 1-1AADocument3 pagesMalingin - Ronibe B. UTS - BTLED-ICT 1-1AARonibeMalinginNo ratings yet

- The Marzano Teacher Evaluation Model PowerpointDocument42 pagesThe Marzano Teacher Evaluation Model PowerpointUkulele PrincessNo ratings yet

- 5 Research Methods Used in PsychologyDocument2 pages5 Research Methods Used in PsychologyElysium MindsNo ratings yet

- After Defense Thesis 3Document93 pagesAfter Defense Thesis 3Shenna Mae LibradaNo ratings yet

- Grade-11 EAPP Q1W7Document24 pagesGrade-11 EAPP Q1W7Ain lorraine BacaniNo ratings yet

- Speech CraftDocument3 pagesSpeech CraftJeane DagatanNo ratings yet

- Problem Solving: Lecture Notes: Part I. Types of ProblemsDocument6 pagesProblem Solving: Lecture Notes: Part I. Types of ProblemsVenice izza VenancioNo ratings yet

- Greek To Me Practice Sheet 002Document2 pagesGreek To Me Practice Sheet 002Seth SmithNo ratings yet

- Noam Chomsky (Ch-4)Document26 pagesNoam Chomsky (Ch-4)Rahul KumarNo ratings yet

- GrashaDocument9 pagesGrashaLisha LiuNo ratings yet

- Aditya Sharma - Muktak SirDocument2 pagesAditya Sharma - Muktak SirAditya SharmaNo ratings yet

- The Physics Principle That Inspired Modern AI Art - Quanta MagazineDocument10 pagesThe Physics Principle That Inspired Modern AI Art - Quanta MagazineAleksandar SpasojevicNo ratings yet

- The Impact of Social Media On Consumer Behavior - Case Study KosovoDocument21 pagesThe Impact of Social Media On Consumer Behavior - Case Study KosovoIshandeep SinghNo ratings yet

- Study BDocument2 pagesStudy BMai ChutyaNo ratings yet

- Traducere EnglezaDocument6 pagesTraducere EnglezaVlad VargauNo ratings yet

- Management by Objectives - Wikipedia, The Free EncyclopediaDocument4 pagesManagement by Objectives - Wikipedia, The Free EncyclopediaDebanjan DebNo ratings yet

- Second Term Revision Extra PracticeDocument2 pagesSecond Term Revision Extra PracticeSara ColoresNo ratings yet

- LAC-MINUTES-nlc 1Document2 pagesLAC-MINUTES-nlc 1Florence FernandezNo ratings yet

- Collective Nouns Printable Worksheets For Grade 2Document6 pagesCollective Nouns Printable Worksheets For Grade 2jay singhNo ratings yet

- 40AIQuestion Bank 8SEMDocument6 pages40AIQuestion Bank 8SEMG PrabhakarNo ratings yet

- ATC Module 1Document59 pagesATC Module 1Indranil MandalNo ratings yet

- Reading Writing & Grammar Math Science Social Studies SEL: Ideas For LearningDocument26 pagesReading Writing & Grammar Math Science Social Studies SEL: Ideas For LearningImeyNo ratings yet

- Sven Ove Hansson, Gertrude Hirsch Hadorn Eds. The Argumentative Turn in Policy Analysis Reasoning About Uncertainty PDFDocument354 pagesSven Ove Hansson, Gertrude Hirsch Hadorn Eds. The Argumentative Turn in Policy Analysis Reasoning About Uncertainty PDFakerrp100% (2)

- Rubric Pembentangan SADN 1033Document6 pagesRubric Pembentangan SADN 1033Atif NaqiuddinNo ratings yet

- Lam Q4 Week 6 8Document19 pagesLam Q4 Week 6 8Chrisjon Gabriel EspinasNo ratings yet

- Analysis 7 Types of Meaning in AdvertisementDocument7 pagesAnalysis 7 Types of Meaning in AdvertisementWinda WelanNo ratings yet

- Syllabus of The Course Integral Pedagogical PracticeDocument10 pagesSyllabus of The Course Integral Pedagogical PracticeLorz CatalinaNo ratings yet