Professional Documents

Culture Documents

Chrysler Town and Country - Caravan - Voyager - 1998 Emission Control

Uploaded by

eephantomCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chrysler Town and Country - Caravan - Voyager - 1998 Emission Control

Uploaded by

eephantomCopyright:

Available Formats

NS/GS EMISSION CONTROL SYSTEM 25 - 1

EMISSION CONTROL SYSTEM

CONTENTS

page page

EMISSION CONTROL SYSTEM ON-BOARD DIAGNOSTICS

2.0L ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . 9 2.5L DIESEL ENGINE . . . . . . . . . . . . . . . . . . . 1

EXHAUST EMISSION CONTROLS

2.5L DIESEL ENGINE . . . . . . . . . . . . . . . . . . . 5

ON-BOARD DIAGNOSTICS2.5L DIESEL ENGINE

INDEX

page page

GENERAL INFORMATION DESCRIPTION AND OPERATION

SYSTEM DESCRIPTION DIAGNOSTIC TROUBLE CODES . . . . . . . . . . . . 2

2.5L DIESEL ENGINE . . . . . . . . . . . . . . . . . . . 1

GENERAL INFORMATION MONITORED CIRCUITS

The PCM can detect certain problems in the elec-

SYSTEM DESCRIPTION2.5L DIESEL ENGINE trical system.

The 2.5L diesel Powertrain Control Module (PCM) Open or Shorted Circuit The PCM can deter-

monitors and controls many different circuits in the mine if sensor output (which is the input to PCM) is

fuel injection pump and engine systems. If the PCM within proper range. It also determines if the circuit

senses a problem with a monitored circuit that indi- is open or shorted.

cates an actual problem, a Diagnostic Trouble Code Output Device Current Flow The PCM senses

(DTC) will be stored in the PCMs memory, and even- whether the output devices are electrically connected.

tually will illuminate the Diesel Glow Plug lamp con- If there is a problem with the circuit, the PCM

stantly while the key is on. If the problem is senses whether the circuit is open, shorted to ground

repaired, or is intermittent, the PCM will erase the (), or shorted to (+) voltage.

DTC after 40 warm-up cycles. A warm-up cycle con-

sists of starting the vehicle when the engine is cold, NONMONITORED CIRCUITS

then the engine to warms up to a certain tempera- The PCM does not monitor the following circuits,

ture, and finally, the engine temperature falls to a systems or conditions that could have malfunctions

normal operating temperature, then the key is that result in driveability problems. A DTC will not

turned off. be displayed for these conditions.

Certain criteria must be met for a DTC to be Fuel Pressure: Fuel pressure is controlled by the

entered into PCM memory. The criteria may be a fuel injection pump. The PCM cannot detect prob-

specific range of engine rpm, engine or fuel tempera- lems in this component.

ture and/or input voltage to the PCM. A DTC indi- Cylinder Compression: The PCM cannot detect

cates that the PCM has identified an abnormal uneven, low, or high engine cylinder compression.

signal in a circuit or the system. A DTC may indicate Exhaust System: The PCM cannot detect a

the result of a failure, but never identify the failed plugged, restricted or leaking exhaust system.

component directly. Fuel Injector Malfunctions: The PCM cannot

There are several operating conditions that the determine if the fuel injector is clogged, or the wrong

PCM does not monitor and set a DTC for. Refer to injector is installed. The fuel injectors on the diesel

the following Monitored Circuits and NonMonitored engine are not controlled by the PCM, although a

Circuits in this section.

25 - 2 EMISSION CONTROL SYSTEM NS/GS

GENERAL INFORMATION (Continued)

defective fuel injector sensor is monitored by the or the system. A DTC may indicate the result of a

PCM. failure, but most likely will not identify the failed

Vacuum Assist: Leaks or restrictions in the vac- component directly.

uum circuits of vacuum assisted engine control sys-

tem devices are not monitored by the PCM. ACCESSING DIAGNOSTIC TROUBLE CODES

PCM System Ground: The PCM cannot deter- A stored DTC can be displayed through the use of

mine a poor system ground. However, a DTC may be the DRB III scan tool. The DRB III connects to the

generated as a result of this condition. data link connector. The data link connector is

PCM Connector Engagement: The PCM cannot located under the instrument panel near bottom of

determine spread or damaged connector pins. How- the steering column (Fig. 1).

ever, a DTC may be generated as a result of this con-

dition.

HIGH AND LOW LIMITS

The PCM compares input signal voltages from each

input device. It will establish high and low limits

that are programmed into it for that device. If the

input voltage is not within specifications and other

DTC criteria are met, a DTC will be stored in mem-

ory. Other DTC criteria might include engine rpm

limits or input voltages from other sensors or

switches. The other inputs might have to be sensed

by the PCM when it senses a high or low input volt-

age from the control system device in question.

DESCRIPTION AND OPERATION

Fig. 1 Data Link Connector LocationTypical

DIAGNOSTIC TROUBLE CODES ERASING TROUBLE CODES

On the following pages, a list of DTCs is provided After the problem has been repaired, use the DRB

for the 2.5L diesel engine. A DTC indicates that the III scan tool to erase a DTC.

PCM has recognized an abnormal signal in a circuit

Generic Scan DRB III Scan Tool Display

Tool Code

P1112 Boost Pressure Sensor Signal High

Boost Pressure Sensor Signal Low

Boost Pressure Sensor Supply High

Boost Pressure Sensor Supply Low

Boost Pressure Sensor Plausibility

P0110 Intake Air Temperature Sensor Signal High

Intake Air Temperature Sensor Signal Low

P1685 Immobilizer Signal Lost

Invalid SKIM Message

P0115 Temperature of Engine Coolant SRC High Exceeded

Temperature of Engine Coolant SRC Low Exceeded

P0180 Fuel Temperature Sensor SRC High Exceeded

Fuel Temperature Sensor SRC Low Exceeded

P0400 EGR Open Circuit

EGR Short Circuit

P0500 Vehicle Speed Sensor PEC Frequency Too High

Vehicle Speed Sensor Signal SRC High Exceeded

NS/GS EMISSION CONTROL SYSTEM 25 - 3

DESCRIPTION AND OPERATION (Continued)

Generic Scan DRB III Scan Tool Display

Tool Code

P0725 Engine Speed Sensor Dynamic Plausibility

Engine Speed Sensor Over Speed Recognition

Engine Speed Sensor Static Plausibilty

P1105 Atmospheric Pressure Sensor SRC High Exceeded

Atmospheric Pressure Sensor SRC Low Exceeded

P1201 Needle Movement Sensor SRC High Exceeded

Needle Movement Sensor SRC Low Exceeded

P1220 Fuel Quantity Actuator Neg. Gov. Deviation Cold

Fuel Quantity Actuator Neg. Gov. Deviation Warm

Fuel Quantity Actuator Pos. Gov. Deviation Cold

Fuel Quantity Actuator Pos. Gov. Deviation Warm

P1225 Control Sleeve Sensor Signal High Exceeded

Control Sleeve Sensor Start End Pos. Not Attained

Control Sleeve Sensor Stop End Pos. Not Attained

P1230 Timing Governing Negative Governor Deviation

Timing Governing Positive Governor Deviation

P1515 Accelerator Pedal Sensor Signal High Exceeded

Accelerator Pedal Sensor Signal Low Exceeded

Accelerator Pedal Sensor Signal PWG Plaus With Low Idle Switch

Accelerator Pedal Sensor Signal PWG Plaus With Potentiometer

P1600 Battery Voltage SRC High Exceeded

P1605 Terminal #15 Plausibility After Startup

P1610 Regulator Lower Regulator Limit

Regulator Upper Regulator Limit

P1615 Microcontroller Gate-Array Monitoring

Microcontroller Gate-Array Watchdog

Microcontroller Prepare Fuel Quantity Stop

Microcontroller Recovery Was Occurred

Microcontrller Redundant Overrun Monitoring

P1630 Timing Solenoid Valve Controller Open Circuit

Timing Solenoid Valve Controller Short Circuit

P1635 Glow Relay Controller Open Circuit

Glow Relay Controller Short Circuit

P1650 Diagnostic Lamp Open Circuit

Diagnostic Lamp Short Circuit

P1655 A/C Control Short Circuit

A/C Control Open Circuit

P1660 Redundant Emer. Stop Plausibility In After-Run

Redundant Emer Stop Powerstage Defective

P1665 Cruise Status Indicator Lamp Short Circuit

P1680 EEPROM Plausibility Checksum Error for Adj.

EEPROM Plausibility Checksum Error in CC212

EEPROM Plausibility Communication With EEPROM

EEPROM Plausibility Func. Switch Wrong or Missing

25 - 4 EMISSION CONTROL SYSTEM NS/GS

DESCRIPTION AND OPERATION (Continued)

Generic Scan DRB III Scan Tool Display

Tool Code

EEPROM Plausibility Ver Number Not Corresponding

P1685 Vehicle Theft Alarm Code Line Breakdown

P1690 Fan Control Open Circuit Fan #1

Fan Control Open Circuit Fan #2

Fan Control Short Circuit Fan #1

Fan Control Short Circuit Fan #2

P1695 A/C System Pressure Sensor Signal High Exceeded

A/C System Pressure Sensor Signal Low Exceeded

A/C System Pressure Supply Signal High Exceeded

A/C System Pressure Supply Signal Low Exceeded

P1703 Brake Signal Plaus With Redundant Contact

P1740 Clutch Signal Plausibilty

P1725 Inductive Aux. Speed Sensor Dynamic Plausibilty

Inductive Aux. Speed Sensor Overspeed Recognition

Inductive Aux Speed Sensor Plausibilty

Inductive Aux. Speed Sensor Static Plausibilty

NS/GS EMISSION CONTROL SYSTEM 25 - 5

EXHAUST EMISSION CONTROLS2.5L DIESEL ENGINE

INDEX

page page

DESCRIPTION AND OPERATION REMOVAL AND INSTALLATION

EXHAUST GAS RECIRCULATION (EGR) EGR TUBE . . . . . . . . . . . . . . . . . . . . . . . . ..... 7

SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . ..... 5 EGR VALVE . . . . . . . . . . . . . . . . . . . . . . . ..... 7

VACUUM HOSE ROUTING SCHEMATIC . ..... 5 ELECTRIC VACUUM MODULATOR (EVM) ..... 7

DIAGNOSIS AND TESTING SPECIFICATIONS

EGR GAS FLOW TEST . . . . . . . . . . . . . . ..... 6 TORQUE CHART2.5L DIESEL . . . . . . . ..... 8

ELECTRIC VACUUM MODULATOR (EVM)

TEST . . . . . . . . . . . . . . . . . . . . . . . . . . ..... 7

DESCRIPTION AND OPERATION EXHAUST GAS RECIRCULATION (EGR) SYSTEM

VACUUM HOSE ROUTING SCHEMATIC GENERAL INFORMATION

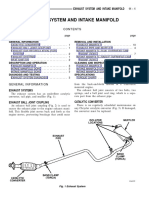

Vacuum for the EGR system is supplied by the The EGR system reduces oxides of nitrogen (NOx)

internal engine mounted vacuum pump. Refer to in the engine exhaust. This is accomplished by allow-

EGR System Operation for vacuum pump informa- ing a predetermined amount of hot exhaust gas to

tion. Vacuum harness routing for emission related recirculate and dilute the incoming fuel/air mixture.

components is displayed in (Fig. 1). A malfunctioning EGR system can cause engine

stumble, sags or hesitation, rough idle, engine stall-

ing and poor driveability.

EGR SYSTEM OPERATION

The system consists of:

An EGR valve assembly. The valve is located

behind the intake manifold (Fig. 2).

Fig. 1 Typical Hose Routing

Fig. 2 EGR Valve and Tube Location

25 - 6 EMISSION CONTROL SYSTEM NS/GS

DESCRIPTION AND OPERATION (Continued)

An EGR Solenoid. The EGR solenoid is located

in the engine compartment next to the PDC (Fig. 3).

The EGR solenoid opens and closes the vaccum sup-

ply that opens and closes the EGR valve. The

amount of time the EGR solenoid is held open is con-

trolled by the PCM. This is referred to as the on

time of the EGR valve.

Fig. 4 Internal Vacuum Pump

The engine is running to operate the vacuum

pump.

A ground signal is supplied to the EVM.

Vacuum passes to the EGR valve.

The inlet seat (poppet valve) at the bottom of

the EGR valve opens to dilute and recirculate

Fig. 3 EGR Solenoid exhaust gas back into the intake manifold.

An EGR tube (Fig. 2) connecting a passage in The EGR system will be shut down by the PCM

the EGR valve to the rear of the exhaust manifold. after 60 seconds of continuous engine idling to

The vacuum pump, which supplies vacuum for improve idle quality.

the EGR Solenoid valve. This pump also supplies

vacuum for operation of the power brake booster. The DIAGNOSIS AND TESTING

pump is located internally in the front of the engine

block (Fig. 4) and is driven by the crankshaft gear. EGR GAS FLOW TEST

Vacuum lines and hoses to connect the various Use the following test procedure to determine if

components. exhaust gas is flowing through the EGR valve. It can

When the PCM supplies a on or off signal to the also be used to determine if the EGR tube is plugged,

EGR Solenoid by grounding the circuit, EGR system or the system passages in the intake or exhaust man-

operation starts to occur. The PCM will monitor var- ifolds are plugged.

ious engine conditions and determine when to supply This is not to be used as a complete test of the

and remove this ground signal. Some of the engine EGR system.

conditions that are monitored are the engine coolant The engine must be started, running and warmed

temperature, throttle position and engine speed sen- to operating temperature for this test.

sors. (1) All EGR valves are equipped with a vacuum

When the ground signal is supplied to the EGR supply fitting located on the EGR valve vacuum

Solenoid, vacuum from the vacuum pump will be motor (Fig. 2).

allowed to pass to the EGR valve via a connecting (2) Disconnect the rubber hose from the vacuum

hose. supply fitting (Fig. 2).

Exhaust gas recirculation will begin in this order (3) Connect a handheld vacuum pump to this fit-

when: ting.

The PCM determines that EGR system opera- (4) Start the engine.

tion is necessary.

NS/GS EMISSION CONTROL SYSTEM 25 - 7

DIAGNOSIS AND TESTING (Continued)

(5) Slowly apply 10 inches of vacuum to the fitting (5) Remove the two EGR valve mounting bolts

on the EGR valve motor. Vacuum should hold steady (Fig. 2) and remove EGR valve.

at 10 inches. If not, replace the EGR valve. If vac- (6) Discard both of the old EGR mounting gaskets.

uum holds steady at 10 inches, proceed to next step.

(6) While applying vacuum, and with the engine INSTALLATION

running at idle speed, the idle speed should drop, a (1) Clean the intake manifold of any old gasket

rough idle may occur, or the engine may even stall. material.

This is indicating that exhaust gas is flowing through (2) Clean the end of EGR tube of any old gasket

the EGR tube between the intake and exhaust man- material.

ifolds. (3) Position the EGR valve and new gasket to the

(7) If the engine speed did not change, the EGR intake manifold.

valve may be defective, the EGR tube may be (4) Install two EGR valve mounting bolts. Do not

plugged with carbon, or the passages in the intake tighten bolts at this time.

and exhaust manifolds may be plugged with carbon. (5) Position new gasket between EGR valve and

(a) Remove EGR valve from engine. Refer to EGR tube.

EGR Valve Removal in this group. (6) Install two EGR tube bolts. Tighten all four

(b) Apply vacuum to the vacuum motor fitting mounting bolts to 23 Nm (204 in. lbs.).

and observe the stem on the EGR valve. If the (7) Tighten EGR tube fitting at exhaust manifold.

stem is moving, it can be assumed that the EGR (8) Connect vacuum line to EGR valve.

valve is functioning correctly. The problem is in (9) Install the rubber hose from turbocharger to

either a plugged EGR tube or plugged passages at metal tube.

the intake or exhaust manifolds. Refer to step (c).

If the stem will not move, replace the EGR valve. EGR TUBE

(c) Remove the EGR tube between the intake The EGR tube connects the EGR valve to the rear

and exhaust manifolds. Check and clean the EGR of the exhaust manifold (Fig. 2).

tube and its related openings on the manifolds.

Refer to EGR Tube in this group for procedures. REMOVAL

Do not attempt to clean the EGR valve. If the (1) Remove rubber hose from turbocharger to

valve shows evidence of heavy carbon buildup near metal tube.

the base, replace it. (2) Remove two EGR tube mounting bolts at EGR

valve end of tube (Fig. 2).

ELECTRIC VACUUM MODULATOR (EVM) TEST (3) Loosen fitting at exhaust manifold end of tube

(Fig. 2).

VACUUM TEST (4) Remove EGR tube and discard old gasket.

With the engine running, disconnect the vacuum (5) Clean gasket mating surfaces and EGR tube

supply line at the fitting on the EVM. Minimum vac- flange gasket surfaces.

uum should be no less than 20 inches. If vacuum is (6) Check for signs of leakage or cracked surfaces

lower, check for leaks in vacuum supply line. If leaks at both ends of tube, exhaust manifold and EGR

cannot be found, check for low vacuum at vacuum valve.

pump. Refer to Group 5, Brake System for proce-

dures. INSTALLATION

(1) Install a new gasket to EGR valve end of EGR

tube.

REMOVAL AND INSTALLATION (2) Position EGR tube to engine.

(3) Loosely tighten fitting at exhaust manifold end

EGR VALVE of tube.

(4) Install 2 mounting bolts at EGR valve end of

REMOVAL tube. Tighten bolts to 23 Nm (204 in. lbs.) torque.

(1) Remove the rubber hose from turbocharger to (5) Tighten fitting at exhaust manifold end of tube.

metal tube. (6) Install hose from turbocharger to metal tube.

(2) Disconnect vacuum line at EGR valve vacuum

supply fitting (Fig. 2). ELECTRIC VACUUM MODULATOR (EVM)

(3) Loosen the tube fitting at exhaust manifold end The EVM (EGR Duty Cycle Purge Solenoid) is

of EGR tube (Fig. 2). mounted to the side of the PDC (Fig. 6).

(4) Remove the two bolts retaining the EGR tube

to the side of EGR valve (Fig. 2).

25 - 8 EMISSION CONTROL SYSTEM NS/GS

REMOVAL AND INSTALLATION (Continued)

REMOVAL INSTALLATION

(1) Disconnect both cables from battery, negative (1) Install electrical connector to EVM.

cable first. (2) Install EVM and tighten mounting screws.

(2) Remove 2 screws holding PDC to bracket, (3) Connect vacuum hoses.

swing out of way. (4) Install PDC to bracket and tighten mounting

(3) Remove nut and clamp holding battery to bat- screws.

tery tray (Fig. 5). (5) Install battery.

(6) Connect battery cables positive first.

Fig. 5 Battery Clamp

Fig. 6 EVM Location

(4) Remove battery from vehicle.

(5) Disconnect two vacuum hoses at EVM (Fig. 6). SPECIFICATIONS

(6) Remove mounting screws of EVM.

(7) Remove the EVM to gain access to the EVM TORQUE CHART2.5L DIESEL

electrical connector.

(8) Remove electrical connector at EVM. Description Torque

EGR Valve Mounting Bolts . . . . . . . . . . . . . . 23 Nm

(204 in. lbs.)

EGR Tube Mounting Bolts . . . . . . . . . . . . . . 23 Nm

(204 in. lbs.)

EVM (Electric Vacuum

Modulator) Mounting Bolt . . . . 2 Nm (20 in. lbs.)

NS/GS EMISSION CONTROL SYSTEM 25 - 9

EMISSION CONTROL SYSTEM2.0L ENGINE

INDEX

page page

GENERAL INFORMATION REMOVAL AND INSTALLATION

GENERAL INFORMATION . . . . . . . . . . . . . . . . . 9 EGR TUBE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

POSITIVE CRANKCASE VENTILATION SYSTEM EGR VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

(PCV) SYSTEM2.0L ENGINE . . . . . . . . . . . . 9 TORQUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

GENERAL INFORMATION The PCV System for 2.0L engines function the

same as PCV systems for 2.4/3.0/3.3/3.8L engines.

GENERAL INFORMATION Refer to group 25 for more information.

The emission control system for the 2.0L engine

functions the same as the systems for the 2.4/3.0/3.3/

REMOVAL AND INSTALLATION

3.8L engines. Refer to group 25 for more information

about Diagnostic Trouble Codes and other system

EGR VALVE

features.

If the EGR system operates incorrectly, replace the

entire EGR valve and transducer together. The EGR

POSITIVE CRANKCASE VENTILATION SYSTEM

valve and electrical transducer (EET) are calibrated

(PCV) SYSTEM2.0L ENGINE together.

REMOVAL

The EGR valve attaches to the rear of the cylinder

head (Fig. 2). EGR transducer is attached to the air

inlet duct.

(1) Remove EGR transducer from air inlet duct.

(2) Disconnect vacuum supply tube from EGR

transducer solenoid.

(3) Disconnect electrical connector from solenoid.

(4) Remove air inlet duct.

(5) Remove EGR tube to EGR valve screws.

(6) Remove EGR valve mounting screws. Remove

EGR valve and transducer.

(7) Clean gasket surfaces. Discard old gaskets. If

necessary, clean EGR passages.

Fig. 1 PCV System2.0L

25 - 10 EMISSION CONTROL SYSTEM NS/GS

REMOVAL AND INSTALLATION (Continued)

INSTALLATION (3) Remove EGR tube. Clean gasket surface on the

(1) Loosely install EGR valve with new gaskets. EGR valve. Wipe clean the grommet on the intake

(2) Finger tighten EGR tube fasteners. manifold.

(3) Tighten EGR tube fasteners to 11 Nm (95 in.

lbs.) torque.

(4) Tightening EGR valve mounting screws to 22

Nm (200 in. lbs.) torque.

(5) Install air inlet duct.

(6) Connect vacuum supply tube to solenoid.

(7) Attach electrical connector to solenoid.

(8) Install EGR transducer onto air inlet duct.

Fig. 3 EGR Tube Stud Bolts

INSTALLATION

The rubber grommet that seals the EGR tube to

intake manifold connection is reusable.

(1) Loosely install the EGR tube and fasteners.

(2) Tighten the EGR tube to intake manifold ple-

num screws to 11 Nm (95 in. lbs) torque.

Fig. 2 EGR System (3) Tighten the EGR tube to EGR valve screws to

11 Nm (95 in. lbs.) torque.

EGR TUBE

The EGR tube attaches to the intake manifold ple- TORQUE

num below the throttle body and EGR valve.

Description Torque

REMOVAL EGR valve to cyl. head . . . . . . . 22 Nm (200 in. lbs.)

(1) Remove screws attaching EGR tube to intake EGR tube to EGR valve . . . . . . . . . . . 11 (95 in. lbs.)

manifold (Fig. 3). EGR tube to intake manifold . . . 11 Nm (95 in. lbs.)

(2) Remove EGR tube to EGR valve screws.

You might also like

- Eja 25Document32 pagesEja 25Myasaga AdrianNo ratings yet

- Emission Control Systems: On-Board DiagnosticsDocument22 pagesEmission Control Systems: On-Board DiagnosticsPelis CloneNo ratings yet

- Emissions ControlDocument33 pagesEmissions ControlgeekmasterNo ratings yet

- Emission Control Systems: On-Board DiagnosticsDocument28 pagesEmission Control Systems: On-Board Diagnosticsensmartis100% (1)

- 15 - Engine Control System: Workshop Manual - Diablo 6.0Document83 pages15 - Engine Control System: Workshop Manual - Diablo 6.0jahzooneNo ratings yet

- Acura MDX Obd-II CodesDocument55 pagesAcura MDX Obd-II CodesRonald Ogden100% (2)

- Ls1 ManualDocument113 pagesLs1 ManualMTNo ratings yet

- Emission Control SystemsDocument30 pagesEmission Control SystemsRoberto VazquezNo ratings yet

- Emisipn Control SystemsDocument4 pagesEmisipn Control SystemsArt Doe100% (1)

- 2013fusion Steering 5Document58 pages2013fusion Steering 5Andre VPNo ratings yet

- Erori MasinaDocument9 pagesErori MasinaPapa Grigore DanielNo ratings yet

- On-Board Diagnostics Ii SystemDocument266 pagesOn-Board Diagnostics Ii Systemvadim vadimNo ratings yet

- Powertrain DTC SummaryDocument71 pagesPowertrain DTC SummaryplanelNo ratings yet

- C5-DTC P0463 Fuel Level Sensor Circuit High VoltageDocument7 pagesC5-DTC P0463 Fuel Level Sensor Circuit High Voltage100a100aNo ratings yet

- Codigos Error ComputadoraDocument17 pagesCodigos Error ComputadoraMiguel RondónNo ratings yet

- Schematic Wiring Diagrams: Accessories & Equipment Cruise ControlDocument51 pagesSchematic Wiring Diagrams: Accessories & Equipment Cruise ControlMuhammed Douma100% (1)

- Emissions Control: EMISSIONS 3.7L/4.7L/5.7LDocument36 pagesEmissions Control: EMISSIONS 3.7L/4.7L/5.7LProducto DigitalNo ratings yet

- P0562-Battery Voltage LowDocument7 pagesP0562-Battery Voltage Lowguillermoal539100% (1)

- System Component Tests Chevrolet S10Document19 pagesSystem Component Tests Chevrolet S10Maxi Sardi100% (1)

- Obd 1Document14 pagesObd 1jevelezsoft100% (4)

- OEM Ford 7.3 Litre Diesel OBD II DiagnosticsDocument26 pagesOEM Ford 7.3 Litre Diesel OBD II DiagnosticsTigxMig75% (8)

- Dodge Neon CodesDocument3 pagesDodge Neon Codesmecano_54No ratings yet

- Group 9 Self-Diagnostic System: Outline 1Document3 pagesGroup 9 Self-Diagnostic System: Outline 1giapy0000No ratings yet

- P 2229Document3 pagesP 2229Doug SmileyNo ratings yet

- DTC 2021-05-18 10.52.04Document6 pagesDTC 2021-05-18 10.52.04SC SEPROEN IASI-ROMANIANo ratings yet

- 1-Nguyen Ly Cua OBD (English)Document9 pages1-Nguyen Ly Cua OBD (English)Thanh Tùng HuỳnhNo ratings yet

- Mass or Volume Air Flow Range ProblemDocument2 pagesMass or Volume Air Flow Range ProblemDaniel Mamani ParedezNo ratings yet

- Cummins Fault Code 222 or SPN 108 Fmi 4Document2 pagesCummins Fault Code 222 or SPN 108 Fmi 4Juan GonzalezNo ratings yet

- Alarmes SmartcraftDocument52 pagesAlarmes SmartcraftEdgar PinheiroNo ratings yet

- 2008 Chevrolet HHR DTCDocument6 pages2008 Chevrolet HHR DTCTal Benyamin100% (1)

- Instrument Cluster: SECTION 413-01A: Instrument Cluster - Conventional 2001 F-150 Workshop Manual Diagnosis and TestingDocument45 pagesInstrument Cluster: SECTION 413-01A: Instrument Cluster - Conventional 2001 F-150 Workshop Manual Diagnosis and Testingsqhu100% (1)

- 086 - ImmobilizerDocument62 pages086 - ImmobilizerGedas GvildysNo ratings yet

- Xtype Power Train DTC SummariesDocument53 pagesXtype Power Train DTC Summariescardude45750No ratings yet

- Cummis Code 2000 To 2009Document25 pagesCummis Code 2000 To 2009fer28nando100% (1)

- Generator & RegulatorDocument132 pagesGenerator & Regulatordima65No ratings yet

- 4Hk1 6HK1 Engine Diagnostic and Drivability Student PDF (035 040) PDFDocument6 pages4Hk1 6HK1 Engine Diagnostic and Drivability Student PDF (035 040) PDFluigi100% (1)

- INstrument Cluster Test PDFDocument122 pagesINstrument Cluster Test PDFryanhartery100% (1)

- 02 Engine PDFDocument1,000 pages02 Engine PDFFranco Franco TovarNo ratings yet

- Bi-Fuel CNG-01-01Document28 pagesBi-Fuel CNG-01-01Sudeep k UdayNo ratings yet

- 039 - Displays and GaugesDocument81 pages039 - Displays and GaugesGedas Gvildys100% (1)

- 1999-2004 Discovery2 RR 38A Bosch GS8.87 TCMDocument13 pages1999-2004 Discovery2 RR 38A Bosch GS8.87 TCMBernard TrippNo ratings yet

- 1997 OBD 7.3 Diesel SYStem OperationDocument25 pages1997 OBD 7.3 Diesel SYStem Operationroachmech100% (6)

- Dobdsm971 PDFDocument25 pagesDobdsm971 PDFTecknobites VallenarNo ratings yet

- EcDocument11 pagesEcFrancesca Ackumbur0% (1)

- Daewoo Lift Truck Fault Codes de FalhasDocument4 pagesDaewoo Lift Truck Fault Codes de FalhasM L D R100% (1)

- Manual Injeção Mercedes Bens DetroitDocument160 pagesManual Injeção Mercedes Bens DetroitDmitry100% (9)

- 2009-12-27 171410 XtypeDocument98 pages2009-12-27 171410 XtypeDeni WardiniNo ratings yet

- P1637Document3 pagesP1637ALEMAN GARAGE AUTOMOTRIZNo ratings yet

- Tundra CheckDocument5 pagesTundra CheckChristopher ClaretNo ratings yet

- Coduri Eroare OpelDocument27 pagesCoduri Eroare OpelAdi Berari AdrianNo ratings yet

- Xneon Connectores 334Document324 pagesXneon Connectores 334Roger Mirabet RuizNo ratings yet

- Lumina 95 3.1 PDFDocument96 pagesLumina 95 3.1 PDFLuis Alberto Gutierrez Leyva100% (2)

- Body DTC Summaries: Quick Reference Diagnostic GuideDocument34 pagesBody DTC Summaries: Quick Reference Diagnostic GuideMiguel CarrilloNo ratings yet

- Coolant Sensor G3516 WPTDocument11 pagesCoolant Sensor G3516 WPTDjebali MouradNo ratings yet

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Chrysler Neon 99 - Vehicle Speed Control SystemDocument2 pagesChrysler Neon 99 - Vehicle Speed Control SystemeephantomNo ratings yet

- Chrysler Neon 99 - Instrument Panel and SystemsDocument4 pagesChrysler Neon 99 - Instrument Panel and SystemseephantomNo ratings yet

- Chrysler Neon 99 - Instrument Panel and SystemsDocument4 pagesChrysler Neon 99 - Instrument Panel and SystemseephantomNo ratings yet

- Chrysler Neon 99 - Immobiliser SystemDocument4 pagesChrysler Neon 99 - Immobiliser SystemeephantomNo ratings yet

- Chrysler Neon 99 - Power WindowsDocument4 pagesChrysler Neon 99 - Power WindowseephantomNo ratings yet

- Chrysler Neon 1997 - Intake Manifold and Exhaust SystemDocument12 pagesChrysler Neon 1997 - Intake Manifold and Exhaust SystemeephantomNo ratings yet

- Chrysler Neon - Turn Signal - Hazzard Warning SystemsDocument6 pagesChrysler Neon - Turn Signal - Hazzard Warning SystemseephantomNo ratings yet

- Chrysler Town and Country - Caravan - Voyager - 1998 - Steering ContentsDocument2 pagesChrysler Town and Country - Caravan - Voyager - 1998 - Steering ContentseephantomNo ratings yet

- Chrysler Neon - Audio SystemDocument10 pagesChrysler Neon - Audio SystemeephantomNo ratings yet

- Chrysler Neon - Turn Signal - Hazzard Warning SystemsDocument6 pagesChrysler Neon - Turn Signal - Hazzard Warning SystemseephantomNo ratings yet

- Chrysler Town and Country - Caravan - Voyager - 1998 - IntroductionDocument10 pagesChrysler Town and Country - Caravan - Voyager - 1998 - IntroductioneephantomNo ratings yet

- Hemostatic AgentsDocument18 pagesHemostatic AgentshariNo ratings yet

- Ecological Imbalance in IndiaDocument4 pagesEcological Imbalance in IndiaabhywaNo ratings yet

- Industries Visited in Pune & LonavalaDocument13 pagesIndustries Visited in Pune & LonavalaRohan R Tamhane100% (1)

- Article 1, The Role of Science and TechnologyDocument3 pagesArticle 1, The Role of Science and TechnologyNSBMRNo ratings yet

- ContinueDocument2 pagesContinueNeal ReppNo ratings yet

- Week5 6 2Document2 pagesWeek5 6 2SAMANIEGO BERMEO DAVID SEBASTIANNo ratings yet

- Jurnal SOL MeningiomaDocument6 pagesJurnal SOL MeningiomaConnie SianiparNo ratings yet

- Operational Safety and Health Procedures, Practices and RegulationsDocument20 pagesOperational Safety and Health Procedures, Practices and RegulationsDionisa ErnacioNo ratings yet

- Fundamental Molecular Biology: GenomesDocument45 pagesFundamental Molecular Biology: GenomesMoonHoLeeNo ratings yet

- Formulation and Evaluation of Mefenamic Acid Ointment Using Penetration EnhancersDocument5 pagesFormulation and Evaluation of Mefenamic Acid Ointment Using Penetration EnhancersIndradewiNo ratings yet

- Campus Sexual Violence - Statistics - RAINNDocument6 pagesCampus Sexual Violence - Statistics - RAINNJulisa FernandezNo ratings yet

- Menu Siklus RSDocument3 pagesMenu Siklus RSChika VionitaNo ratings yet

- 9801 Low-Shrinkage Camera Module Epoxy With LED and Heat-Cure CapabilityDocument3 pages9801 Low-Shrinkage Camera Module Epoxy With LED and Heat-Cure CapabilityAchraf BouraNo ratings yet

- Microsoft Security Intelligence Report Volume 21 EnglishDocument180 pagesMicrosoft Security Intelligence Report Volume 21 EnglishAlejandro CadarsoNo ratings yet

- Dabur Vs PatanjaliDocument4 pagesDabur Vs PatanjalirangarajanNo ratings yet

- Section 80CCD (1B) Deduction - About NPS Scheme & Tax BenefitsDocument7 pagesSection 80CCD (1B) Deduction - About NPS Scheme & Tax BenefitsP B ChaudharyNo ratings yet

- Figure 1: Basic Design of Fluidized-Bed ReactorDocument3 pagesFigure 1: Basic Design of Fluidized-Bed ReactorElany Whishaw0% (1)

- A.8. Dweck (2007) - The Secret To Raising Smart KidsDocument8 pagesA.8. Dweck (2007) - The Secret To Raising Smart KidsPina AgustinNo ratings yet

- Cis MSCMDocument15 pagesCis MSCMOliver DimailigNo ratings yet

- Biology - Cell City AnswersDocument5 pagesBiology - Cell City AnswersDaisy be100% (1)

- Intentions and Results ASFA and Incarcerated ParentsDocument10 pagesIntentions and Results ASFA and Incarcerated Parentsaflee123No ratings yet

- Roto Fix 32 Service ManualDocument31 pagesRoto Fix 32 Service Manualperla_canto_150% (2)

- Issue of HomosexualityDocument4 pagesIssue of HomosexualityT-2000No ratings yet

- Test On QuantifiersDocument1 pageTest On Quantifiersvassoula35No ratings yet

- BUERGER's Inavasc IV Bandung 8 Nov 2013Document37 pagesBUERGER's Inavasc IV Bandung 8 Nov 2013Deviruchi GamingNo ratings yet

- NURTURE Module-V 11 1 en PDFDocument4 pagesNURTURE Module-V 11 1 en PDFJorge SingNo ratings yet

- Tackling Food Inflation: Ashwinkumar Kokku - 67 Malcolm Pinto - 89 Samir Vele - Nitin JadhavDocument9 pagesTackling Food Inflation: Ashwinkumar Kokku - 67 Malcolm Pinto - 89 Samir Vele - Nitin JadhavMalcolm PintoNo ratings yet

- Unit-7 (EVS)Document32 pagesUnit-7 (EVS)g6614134No ratings yet

- 2015 12 17 - Parenting in America - FINALDocument105 pages2015 12 17 - Parenting in America - FINALKeaneNo ratings yet

- Hubungan Body Image Dengan Pola Konsumsi Dan Status Gizi Remaja Putri Di SMPN 12 SemarangDocument7 pagesHubungan Body Image Dengan Pola Konsumsi Dan Status Gizi Remaja Putri Di SMPN 12 SemarangNanda MaisyuriNo ratings yet