Professional Documents

Culture Documents

TIFM BP2013 Top 10 Cost - Improvement Plan in 2013: Implement CO2 Program, CF Savings RM113K by E12/2013

Uploaded by

khairolOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TIFM BP2013 Top 10 Cost - Improvement Plan in 2013: Implement CO2 Program, CF Savings RM113K by E12/2013

Uploaded by

khairolCopyright:

Available Formats

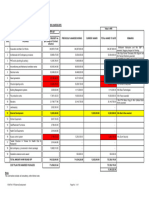

TIFM BP2013 Top 10 Cost - Improvement Plan

RM4,000,000

Implement CO2 Program, CF

savings RM113K by E12/2013

RM3,500,000

2,974,359.00Implemented Ramp Up Media

RM3,000,000 Consumption Process Flow

RM2,500,000 1. Perform System Technical Audits

2. FMEA Top 3 Systems

RM2,000,000 1. Compet

Spent OOAK Critical Spare Parts as 2. Closer M

RM1,500,000 1,405,128.00 part to improve OEE in 2014 via

1,040,747.00

Repair & Maintenance - Special Machine

Electric Power - External Procurement

RM1,000,000 734,432.00

Workshop Consumption - Gas Park

549,553.00 439,560.00

RM500,000 330,440.00

185,897

Rent & Leasing for Vehicle

RM-

Planned 3,454,669.00 1,735,601.00 850,339.00 992,803.00

Actual 2,974,359.00 1,405,128.00 1,040,747.00 734,432.00

- Improvement Plan in 2013

Water - External Procurement - Sewage Treatment Plant

1. Competency Training by Vendors

Critical Spare Parts as 2. Closer Mechanism to monitor misc. cost

ve OEE in 2014 via FM Budget Controller from E10/13

General Consulting Expenses (without IT)

Workshop Consumption - Consumables

Workshop Consumption - Spare Parts

9,553.00 439,560.00

330,440.00 Planned

185,897.00 164,835.00 153,846.00

Actual

Remuneration - Indirect

Costs for Catering

Focus Area

438,771.00 439,560.00 496,782.00 103,633.00 97,558.00 76,529.00

549,553.00 439,560.00 330,440.00 185,897.00 164,835.00 153,846.00

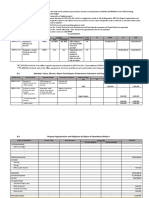

High Lights Low Lights

Zero Safety Incident during Sept 22nd Shut Down 30 minutes fire alarm evacuation caused by

Implemented succesfully Safety CiPs Contractor

Completed average 98.2% tasks for Sept 22nd SD C/M-Re-education of Contractor Team to in

Zero ITP (caused by FM) for 2 running months 1,2 in Safety Work Permit RA for related act

Completed Office roof leaking repair activities Level of noise of Transformers still high (at

Rectified the cracked beam in front of B1 damper installation, normally <65db)

Installed vibration damper for Transformers (as best > C/M-Discussion with OEM

practice) Non compliance of waste segregation

Achieved Agreement with MD on Power Supply > C/M-internal procedures improvement by

Back Up Strategies (based on cost profitability) Vibration of 4 Cooling Towers (under ext. w

Hardened Electrical & LSS system coverage by > C/M-OEM plans to be on site by M10/2013

implementing Assistant Engineers (2 headcounts)

FM 2013 is realistic within 2013 target Next Steps

Follow up FM Technical Audit findings (targ

Inter-dependence average 90% by E11/2013

Unclear Fire Engine room concept from HSE Follow up on Pull Ahead/ Spare Parts execu

HR hiring of 1 Technician, 1 Budget Controller to M12/2013

complete HC plan 2013 Start FM activities to Training Building by M

Execution of better efficient CxHy condenser design New TMS "Go Live" by Nov 1st, 2013

to resolve water carry over from MFG Installation of Meeting Room Cabins by E10

Installation of Static UPS to reduce power quality issues On time Construction Status for B2 and aux

by MFG Energy Audit by Vendor by E10/2013 (Legal

rm evacuation caused by

of Contractor Team to involve FM

Permit RA for related activities

ransformers still high (at 80db after

n, normally <65db)

f waste segregation

cedures improvement by E2/2014

ing Towers (under ext. warranty)

o be on site by M10/2013

hnical Audit findings (target>

Ahead/ Spare Parts execution by

to Training Building by M10/2013

" by Nov 1st, 2013

eting Room Cabins by E10/2013

ion Status for B2 and auxillaries

endor by E10/2013 (Legal requirement)

W

o

r

k

C

o

m

p

l

e

t

e

d

(

b

a

s

e

d

o

n

S

L

A

)

You might also like

- Tutorial 2 Traditional Overhead Q A STUDENT PDFDocument6 pagesTutorial 2 Traditional Overhead Q A STUDENT PDFN FrzanahNo ratings yet

- Assignment Day 2Document5 pagesAssignment Day 2Indahna SulfaNo ratings yet

- Abay Fana Dairy Farm & Milk Processing - FinalDocument42 pagesAbay Fana Dairy Farm & Milk Processing - Finalberhanu seyoumNo ratings yet

- Service Centre Cost Apportionment: Requirement: Apportion All Overheads To The Production Cost CentresDocument3 pagesService Centre Cost Apportionment: Requirement: Apportion All Overheads To The Production Cost CentresChi HoàngNo ratings yet

- Tutorial 5Document7 pagesTutorial 5YANG YUN RUINo ratings yet

- Local Disaster Risk Reduction and Management Fund Utilization LDRRMF February 2021Document2 pagesLocal Disaster Risk Reduction and Management Fund Utilization LDRRMF February 2021Balindoa JomNo ratings yet

- Faizan Bhai Overhead WorkingDocument3 pagesFaizan Bhai Overhead WorkingSalman SajidNo ratings yet

- Overhead Analysis8Document14 pagesOverhead Analysis8AberraNo ratings yet

- Local Disaster Risk Reduction and Management Fund Utilization 4th Quarter 2020Document6 pagesLocal Disaster Risk Reduction and Management Fund Utilization 4th Quarter 2020kQy267BdTKNo ratings yet

- Actual Cost AscendasDocument1 pageActual Cost Ascendasnagi.civil240No ratings yet

- Construction Cost MonitoringDocument13 pagesConstruction Cost MonitoringOng George Sammy100% (1)

- 3 Revision of Absorption Costing: Key TermDocument2 pages3 Revision of Absorption Costing: Key TermSyed Attique KazmiNo ratings yet

- 1 PDFDocument1 page1 PDFjeffrey josolNo ratings yet

- GAD Accomplishment (2018)Document6 pagesGAD Accomplishment (2018)JP JaypeeNo ratings yet

- Tutorial 6 Job Batch CostingDocument6 pagesTutorial 6 Job Batch CostingYANG YUN RUINo ratings yet

- Board DIRECTOR'S Fees - 2010-2011 FinalDocument1 pageBoard DIRECTOR'S Fees - 2010-2011 FinalJeromePalmerNo ratings yet

- Class Case 3 - Star Engineering CompanyDocument3 pagesClass Case 3 - Star Engineering Company9ry5gsghybNo ratings yet

- How To Prepare PPMPDocument4 pagesHow To Prepare PPMPᜁᜇᜒᜃ᜔ ᜊ᜔ ᜀᜄᜎᜒᜀᜋ᜔No ratings yet

- Chapter 7 ExplanationDocument24 pagesChapter 7 ExplanationCatherine OrdoNo ratings yet

- Tutorial 4 - Costing For OverheadDocument5 pagesTutorial 4 - Costing For OverheadMuhammad Alif100% (1)

- 30 7 2020 REVISED SR-mis Rates For Bhubaneswar Power PVT LTD RevisedDocument14 pages30 7 2020 REVISED SR-mis Rates For Bhubaneswar Power PVT LTD RevisedPradeep PanigrahiNo ratings yet

- Assignment - OHD ACC116Document3 pagesAssignment - OHD ACC116Nurul NajihaNo ratings yet

- Mas 03 - Activity Based CostingDocument6 pagesMas 03 - Activity Based CostingCarl Angelo LopezNo ratings yet

- Internal Memo Calloff Orders Sultan Eng KaggaDocument1 pageInternal Memo Calloff Orders Sultan Eng KaggaGerald ObalimNo ratings yet

- Cy 2022 Annual Investment Program Program/Project/Activity by SectorDocument6 pagesCy 2022 Annual Investment Program Program/Project/Activity by SectorBudget OfficeNo ratings yet

- The Required Initial Disbursement That The Business Needs To Facilitate The Proposed Project Will Be P 11,830,562.58. The Itemization Is As Shown in Table 22Document16 pagesThe Required Initial Disbursement That The Business Needs To Facilitate The Proposed Project Will Be P 11,830,562.58. The Itemization Is As Shown in Table 22Lhara Mae ReyesNo ratings yet

- RAB Driver Harbun 2020 5 Personnel ApprovedDocument1 pageRAB Driver Harbun 2020 5 Personnel Approvedbimo anggoroNo ratings yet

- Foh DistributionDocument91 pagesFoh Distributionkhalid1173No ratings yet

- Annual BudgetDocument6 pagesAnnual BudgetLan So NessNo ratings yet

- LDRRMF 4th Quarter 2016Document2 pagesLDRRMF 4th Quarter 2016remarNo ratings yet

- LDRRMF 4th Quarter 2016Document2 pagesLDRRMF 4th Quarter 2016remarNo ratings yet

- APB FORMAT For CY2023Document16 pagesAPB FORMAT For CY2023Jayr NelbNo ratings yet

- LEVEL 2 Online Quiz - Answers SET ADocument10 pagesLEVEL 2 Online Quiz - Answers SET AVincent Larrie MoldezNo ratings yet

- Request For Realignment of FundsDocument1 pageRequest For Realignment of Fundsjohn pardo75% (4)

- I. Financial Projections 1. Summary of Pre-Operating, CAPEX, OPEX and Organizational Structure by Type of Office/ LocationDocument15 pagesI. Financial Projections 1. Summary of Pre-Operating, CAPEX, OPEX and Organizational Structure by Type of Office/ Locationᜆ᜔ᜀᜄ᜔ᜀ ᜉ᜔ᜀᜄ᜔ᜉ᜔ᜀᜎ᜔ᜀᜌ᜔ᜀNo ratings yet

- V-Ride, Inc.: Case 4-1Document11 pagesV-Ride, Inc.: Case 4-1Dave Castillo Bangisan100% (1)

- Chapter 3 Overheads: Joudat Ali Malik ACMA, APFA, MA (Economics), CFC (Canada)Document8 pagesChapter 3 Overheads: Joudat Ali Malik ACMA, APFA, MA (Economics), CFC (Canada)sarahNo ratings yet

- REVISED 27 7 2020 SR-mis Rates For Bhubaneswar Power PVT LTD RevisedDocument15 pagesREVISED 27 7 2020 SR-mis Rates For Bhubaneswar Power PVT LTD RevisedPradeep PanigrahiNo ratings yet

- Chapter 7 - Manufacturing Overhead - DepartmentalizationDocument77 pagesChapter 7 - Manufacturing Overhead - DepartmentalizationJiko GuintoNo ratings yet

- Part 3 SpaDocument17 pagesPart 3 SpaClaide Vencent Arendain-Cantila DesiertoNo ratings yet

- Official Gazette V - 118, N - 1 26: Iv. Department of Agrarian Reform A. Office of The SecretaryDocument49 pagesOfficial Gazette V - 118, N - 1 26: Iv. Department of Agrarian Reform A. Office of The SecretaryNel SabornidoNo ratings yet

- Variety Ply - 2014 - FInalDocument19 pagesVariety Ply - 2014 - FInalSridhar GandikotaNo ratings yet

- Management Advisory Services: BudgetedDocument26 pagesManagement Advisory Services: Budgetedi hate youtubersNo ratings yet

- Cost Accounting: Rs. Rs. Rs. Rs. Rs. RsDocument8 pagesCost Accounting: Rs. Rs. Rs. Rs. Rs. RsShehrozSTNo ratings yet

- Official Gazette 1000 9 1 : General Appropriations Act, Fy 2023Document3 pagesOfficial Gazette 1000 9 1 : General Appropriations Act, Fy 2023mypuppy411No ratings yet

- Costing & Profitability: Magiclite Building SolutionsDocument16 pagesCosting & Profitability: Magiclite Building SolutionsPrince AroraNo ratings yet

- LB Kingston Upon ThamesDocument3 pagesLB Kingston Upon ThamesparkingeconomicsNo ratings yet

- Lecture-7 Overhead (Part 3)Document9 pagesLecture-7 Overhead (Part 3)Nazmul-Hassan SumonNo ratings yet

- Acctg201 ServiceCostAllocationLectureNotesDocument4 pagesAcctg201 ServiceCostAllocationLectureNotesSophia Marie Eredia FerolinoNo ratings yet

- Tutorial 2 Traditional OverheadsDocument3 pagesTutorial 2 Traditional OverheadsSyafiqNo ratings yet

- FM Parts (Final)Document13 pagesFM Parts (Final)Muhamad Harith DanialNo ratings yet

- KRONOLOGI ASIA BERHAD (Company No. 1067697-K)Document7 pagesKRONOLOGI ASIA BERHAD (Company No. 1067697-K)TestNo ratings yet

- Financial Slide For ReportDocument6 pagesFinancial Slide For ReportTuan Noridham Tuan LahNo ratings yet

- Status of Appropriations, Allotments, Obligations and Balances (Pre-Closing, As of December 2010)Document94 pagesStatus of Appropriations, Allotments, Obligations and Balances (Pre-Closing, As of December 2010)Alexis Cañizar ChuaNo ratings yet

- I. Financial AssumptionsDocument14 pagesI. Financial AssumptionsJaera shopaholicNo ratings yet

- Management Control and Strategic Performance Measurement Strategic Investment Units and Transfer PricingDocument68 pagesManagement Control and Strategic Performance Measurement Strategic Investment Units and Transfer PricingPhia Teo100% (1)

- PROBLEM 4 (Evaluation of Performance) : TotalDocument3 pagesPROBLEM 4 (Evaluation of Performance) : TotalArt IslandNo ratings yet

- Agile Procurement: Volume II: Designing and Implementing a Digital TransformationFrom EverandAgile Procurement: Volume II: Designing and Implementing a Digital TransformationNo ratings yet

- European Contract Electronics Assembly Industry - 1993-97: A Strategic Study of the European CEM IndustryFrom EverandEuropean Contract Electronics Assembly Industry - 1993-97: A Strategic Study of the European CEM IndustryNo ratings yet

- Instruction Manual 115cx ENGLISHDocument72 pagesInstruction Manual 115cx ENGLISHRomanPiscraftMosqueteerNo ratings yet

- 03-F10 Planned Job ObservationDocument1 page03-F10 Planned Job ObservationSn Ahsan100% (1)

- Assessing The Marks and Spencers Retail ChainDocument10 pagesAssessing The Marks and Spencers Retail ChainHND Assignment Help100% (1)

- SAP HR - Legacy System Migration Workbench (LSMW)Document5 pagesSAP HR - Legacy System Migration Workbench (LSMW)Bharathk KldNo ratings yet

- Taxation Law 1Document7 pagesTaxation Law 1jalefaye abapoNo ratings yet

- 2.1 DRH Literary Translation-An IntroductionDocument21 pages2.1 DRH Literary Translation-An IntroductionHassane DarirNo ratings yet

- 6 Uec ProgramDocument21 pages6 Uec Programsubramanyam62No ratings yet

- What Is Product Management?Document37 pagesWhat Is Product Management?Jeffrey De VeraNo ratings yet

- Integrator Windup and How To Avoid ItDocument6 pagesIntegrator Windup and How To Avoid ItHermogensNo ratings yet

- MiddleWare Technology - Lab Manual JWFILESDocument171 pagesMiddleWare Technology - Lab Manual JWFILESSangeetha BajanthriNo ratings yet

- Maharashtra State Board 9th STD History and Political Science Textbook EngDocument106 pagesMaharashtra State Board 9th STD History and Political Science Textbook EngSomesh Kamad100% (2)

- Anviz T5 RFID ManualDocument52 pagesAnviz T5 RFID ManualLuis Felipe Olaya SandovalNo ratings yet

- AAR Shell ProgrammingDocument13 pagesAAR Shell ProgrammingMarimuthu MuthaiyanNo ratings yet

- Uts Cmo Module 5Document31 pagesUts Cmo Module 5Ceelinah EsparazNo ratings yet

- HPCL CSR Social Audit ReportDocument56 pagesHPCL CSR Social Audit Reportllr_ka_happaNo ratings yet

- Abc Uae Oil and GasDocument41 pagesAbc Uae Oil and GasajayNo ratings yet

- CUET 2022 General Test 6th October Shift 1Document23 pagesCUET 2022 General Test 6th October Shift 1Dhruv BhardwajNo ratings yet

- 2 - Sample Kids Can Read and Write 2 and 3 Letter Words - Step 2 Final Downloadable Version For Website PDFDocument18 pages2 - Sample Kids Can Read and Write 2 and 3 Letter Words - Step 2 Final Downloadable Version For Website PDFsantoshiNo ratings yet

- Anthony Robbins - Time of Your Life - Summary CardsDocument23 pagesAnthony Robbins - Time of Your Life - Summary CardsWineZen97% (58)

- Effect of Plant Growth RegulatorsDocument17 pagesEffect of Plant Growth RegulatorsSharmilla AshokhanNo ratings yet

- Em FlexicokingDocument8 pagesEm FlexicokingHenry Saenz0% (1)

- Risk Analysis and Assessment Methodologies in Work SitesDocument49 pagesRisk Analysis and Assessment Methodologies in Work SitesNhut NguyenNo ratings yet

- Controlled DemolitionDocument3 pagesControlled DemolitionJim FrancoNo ratings yet

- ATAL Selected FDPs AY 2023 24Document15 pagesATAL Selected FDPs AY 2023 24parthiban palanisamy100% (2)

- Case Study To Find Tank Bulging, Radial Growth and Tank Settlement Using API 650Document15 pagesCase Study To Find Tank Bulging, Radial Growth and Tank Settlement Using API 650Jafer SayedNo ratings yet

- ANS145 - Beef Cattle ProductionDocument52 pagesANS145 - Beef Cattle ProductionEgie BulawinNo ratings yet

- Plant Report Template Class 81Document2 pagesPlant Report Template Class 81Kamran KhanNo ratings yet

- Malling DemallingDocument25 pagesMalling DemallingVijay KumarNo ratings yet

- Lifting PermanentmagnetDocument6 pagesLifting PermanentmagnetShekh Muhsen Uddin Ahmed100% (1)

- Current Surgical Therapy 13th EditionDocument61 pagesCurrent Surgical Therapy 13th Editiongreg.vasquez490100% (41)